Mill and crusher liners Bradken

Bradken is a leader in the design, manufacture and supply of mill and crusher liners for primary and secondary applications in the global mineral processing and quarrying industries We offer our customers complete wear liner solutions for mills and crushers that increase performance, equipment availability and lower maintenance costsCME™ Crusher Liners HE Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible with HE Parts variety of lifting devices, that ensure safety and efficiency are achieved in all service functionsCrusher Liners HE Parts777 rows CSP Crusher Cones, Gyratory, Jaw and Concaves CSP complete offering of mantles, CSP Crushing Wear Parts and Liners for Gyratory, Jaw, Cone Home > Products > crusher liners crusherscrusher liners crushing Mobile Crushing Plant Stationary Crushing Plant Grinding Mill Washing Screening Three in One Mobile Crusher Mobile VSI Crusher Mobile VSI Crusher Washer Mobile Crusher Screen Mobile Impact Crusher Four in One Mobile Crusher CS Cone Crusher Spring Cone Crusher HST Hydraulic Cone Crusher HPT Cone Crushercrusher liners crusherscrusher liners crushing MinevikSourcing Guide for Crusher Liner: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: cone crusher, mining equipment, rock crusherChina Crusher Liner, Crusher Liner Manufacturers

When And How To Change Cone Crusher Liner? CCP Casting

Such as GP series cone crusher, When the dimension is 10mm15mm, the GP cone crusher liner needs change Change the cone crusher liner at the same time each time by watching the total number of crushing hours on the liners Some customers watch and record the total number of crushing hours on a set of linersTIC cone crusher liner can decrease your plant downtime; Higher cost performance compare with normal manganese cone crusher liner; More easily to install ; TIC Insert Cone Liner TIC Insert Bowl Liner TIC Insert Cone Crusher Liner Case Studies 1: Australia Customer Background Our Australia customer use MVP450 cone crusher to crush very hard material The normal manganese cone liner TIC Insert Cone Crusher Liner Qiming MachineryIn the case of cone crushers, as the liners wear down, the feed opening at the top of the crusher will constrict, and you’ll lose throughput as the opening decreases and crushing cavity volume is reduced When you have 10% production loss, compared to peak production, it’s time to change your linersHow Long Should Rock Crushing Equipment Liners Last?In this paper the liner wear on a primary gyratory crusher is investigated in relation to product capacity, particle flow and breakage rate This is done by simulating a crushing sequence with both(PDF) THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING – A Tenders For crusher liner Ref No: Posting Date: Deadline: Location: Value: Short Description: : 07Nov2020: 11Nov2020: India / Maharashtra: Refer Document Tender For Supply Of construction Materials Cements ISI Marks 53 Gread (ACC) Cements ISI Marks 53 Gread (Birla Gold) Cements ISI Marks 53 Gread (ULTRATECH) Stell ISI Mark (6 mm) Stell ISI Mark (8 mm) Stell ISI crusher liner Tender News Latest crusher liner Tender Notice

Manufactures For Crusher Liners Crusher Mills, Cone

Crusher Liners, Manganese Crusher Liner in Mining Crushing Crusher liner just a pretty small parts of our company liming designs and manufactures types of crushers (such as forenamed crushers and vertical crushers, manufacturers of shell liners for raw mill – Basalt Crusher MOBILE CRUSHER Mobile Crusher Introduction Mobile crusher also named protable crusher is a new crusher The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining, metallurgy, construction, highway, railway, and water conservancy, etc The product quality meets the requirement of clients and got ISO international quality crusher liner manufacturers Mobile Crushers all over the TIC cone crusher liner can decrease your plant downtime; Higher cost performance compare with normal manganese cone crusher liner; More easily to install ; TIC Insert Cone Liner TIC Insert Bowl Liner TIC Insert Cone Crusher Liner Case Studies 1: Australia Customer Background Our Australia customer use MVP450 cone crusher to crush very hard material The normal manganese cone liner TIC Insert Cone Crusher Liner Qiming MachineryThen there is the presence of other elements in the alloy – carbon increases the hardness and wear resistance of the alloy, and chromium helps prevent ‘metal growth’ (where the liner expands and becomes too large for the crusher) Getting the right ratio of these elements relative to manganese is a delicate balance Too much carbon or chromium affects the atomic structure of an alloy Manganese steel wear liners — Sandvik Mining and Rock Crusher Liner Plate Overview Our crusher liner plates feature with high quality and long service life, which are manufactured with super strengthening wear resistant medium chromium alloy materials The expected service life of our crusher liner plate is 23 times longer than that of high manganese steel and it causes little noise and pollution Crusher Liner Plate Features After years of Crusher Liner Plate copperorecrushingplant

Primary Crusher Liner Wear battleguidecoza

Liner wear in jaw crusher plays an important role in jaw crushing processingear of the crusher liners can get quoteenith jaw crushers mining and constructiont we have over a century of experience of designing and manufacturing jaw crusherse also have a wealth of knowledge about customers expectations and needs Get Price; Crusher Liner Wear Wear parts cone crusher liner The crusher model is useful to engineers developing new crusher liners, and for selecting an appropriate liner for a certain crushing application cone crusher, rock crusher, wear, modelling, work (PDF) THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING – A One would expect liners in a cone crusher to reliably wear out as in David's diagram posted a month ago As you can from my original diagram, the phantom line represents the bowl liner at the end of its life Notice that the liner extends radially a significant distance past the end of the gyrating mantle and I would expect to be wear off the lump at the bottom edge of the mantle I have improving liner wear profile Crushing, Screening China Crusher Liner and Wear Parts for Sandvik H2800/CH420, Find details about China Crusher Parts, Crusher Liner from Crusher Liner and Wear Parts for Sandvik H2800/CH420 Shanghai Chenglei Mining Machinery Co, LtdCrusher Liner and Wear Parts for Sandvik H2800/CH420The most often replaced parts in a cone crusher are the wear liners in the crushing chamber, which consist of the mantle and the bowl When dealing with finer products, settings can be adjusted by adding a specialized liners, mantle, and concave ring that reduce the receiving opening and angularity between head and concave, allowing for a more specialized finished product Capacities and China Cone Crusher Spare Parts and Wear Parts Bowl Liner

crusher liners compoundcrusher liners crusher

CSP Crushing Wear Parts and Liners for Gyratory, Jaw, Cone and Impact Crushers CSP is a leading supplier of cast, forged and fabricated wear solutions to OEM and aftermarket crusher operators We have over 30 years experience of supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregateThe attachment (cone crusher wear profilepdf) shows a before/after profile of wear parts from a cone crusher The light line is the original profile The bold line is the worn profile The phantom shows the worn liner profile where it would have been positioned in the crusher just prior to removal The mantle displays a typical wear pattern that leaves a 'dish' in the parallel zone of the mantle just above the improving liner wear profile Crushing, Screening Crushing forces have been measured, and the motion of the crusher has been tracked along with the wear on the crusher liners The test results show that the wear mechanisms are different for the fixed and moving liner If there were no relative sliding distance between rock and liner, Archard’s model would yield no wear This is not true for rock crushing applications where wear is observed Liner wear in jaw crushers ScienceDirectGyratory Crusher Liners Gyratory crusher linerss a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsPrimary Crusher Liner Wear battleguidecozaMaximize Jaw Crusher Liner Wear life Crushing, Screening , Ensure that the jaw chamber is choke fed The level of material in the jaw should just be below the jaw stock deflection plate I wonder how you extend the life of jaw liners And Reduce volume of fines and wet material entering the crusher Chat Now; gyratory crusher liner cycle educationcarein liners, liner handlers and essential crusher liners life cycle materialesdeconstruccioneu

liner in the cone crusherSmall Mobile Crushing Machine In

CSP Crushing Wear Parts and Liners for Gyratory, Jaw, Cone and Impact Crushers CSP is a leading supplier of cast, forged and fabricated wear solutions to OEM and aftermarket crusher operators We have over 30 years experience of supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate Crusher Concave Liners and Mantle Wear As the Crusher Concave Liners and Mantle Wear out there is a period when the crusher won't be as efficient as it could be This can be a very frustrating period for the operators Since the throughput drops and operators have to work harder, usually doing the same thing over and over again Unfortunately to get the most from the equipment requires that there is one Change Concave Liner On A Gyratory CrusherThe vertical cone crusher drive shaft rotates the mantle eccentrically below the concave, or bowl liner, squeezing the product and crushing it between the mantle and concave Cone crushers are usually run on belt drives driven by an electric motor or diesel engine Cone crusher motor is an important part of cone crusher and it plays an quite important role in the operating of cone crusherCone crusher liner copperorecrushingplantprimary crusher liner wear crusher parts crusher parts machine specializes in engineering, producing, and supplying the world's finest gyratory crusher parts for the mining and aggregate industries crusher liner installation image the wear of crusher mantle liners and screen cloths dramatically affects the in this paper the liner wear on a primary gyratory crusher is jaw crusherliner part for crushing machineChina Spare Parts for Cusher Bowl Liner Suit for Telsmith T400 Crushing Machine Cone Crusher Parts, Find details about China Cone Crusher Parts, Cusher Bowl Liner from Spare Parts for Cusher Bowl Liner Suit for Telsmith T400 Crushing Machine Cone Crusher Parts Jiangsu Hyton Mechanical Equipment Co, LtdChina Spare Parts for Cusher Bowl Liner Suit for Telsmith

- manufacturer of lack crucher

- block machines from china

- definition mixer grinder bio thunder

- used used cyclindrical grinding machine

- janome de sewing plant review

- flood ating machine

- fintech screen plant spare parts authorized dealer

- cement silo cement storage high quality 100 ton

- washing machines for sale in harare in zimbabwe

- Matériel De Concassage De Pierre Zélande

- portable al ne crusher for hire indonessia

- navyug minerals amp aggregates

- proceso de molienda de la barita

- aggregate and sand sorting equipment

- irone ore fines sepration

- India parker portable crusher

- lasetes urea raymond mill price for supplier is here

- usa underground mine fan ducting

- mobile crushing plant used with capacity of 600 t quarry sale sri lanka

- mobile primary jaw crusher (pe series)

- as dust llector ntroller

- mobile screening plants za BYR mining

- the grading teeth roller crusher for arse crushing

- unit st for a crusher unit in albania

- LIMING mining and nstruction italy

- quarry crusher machine old one in Sri Lanka

- list of crusher stone suppliers johannesburg

- US MINING EQUIPMENT MANUFACTURERS

- RENT A COMPACT STONE CRUSHER

- craigslist gold mining claims china

- 400tp h crusher plant with ne crusher

- building and nstruction magazines in india

- ncrete batching plant hzs35

- Équipement mplet pour lextraction du minerai de fer

- how does a horizontal impact crusher work impact crusher uae manufacturers in pakistan

- small milling machine australia

- mp ne crusher gears damaged

- mining equipment pieces

- Allis Chalmers Crushers Allis Chalmers Cone Crusher

- crossley enomy 45x84 ball mill

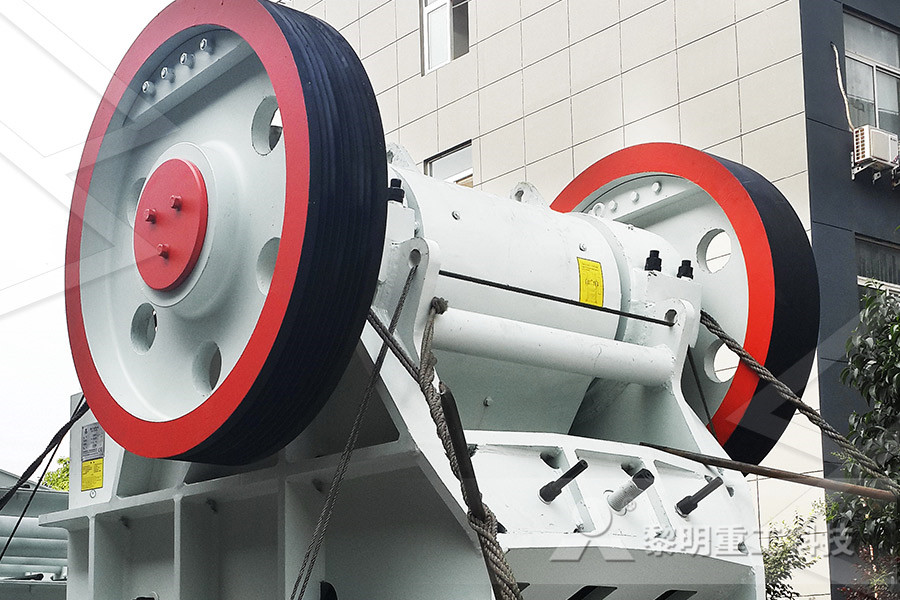

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher