14 Cone Crusher Common Problems And How To Fix Them MC

The cone crusher can not be restarted immediately when it stops suddenly, so as to avoid secondary damage to the cone crushing production line First of all, you should find out the reasons for the sudden stop of the cone crusher, there are 5 common reasons: 1 The discharge port of the cone crusher is blocked, too much or uneven feeding will lead to the blockage of the discharge port, resulting in Causes of Damage to Hydraulic Cone Crusher’s Broken Gears Gear is an important driving part in hydraulic cone crusher In the process of using, if you do not pay attention to the correct operation, or the maintenance work of the gear is not in place, it is easy to cause damage to the crusher’s gear Here, we will analyze the causes of damage to them 1 If there are unbreakable impurities Causes of Damage to Hydraulic Cone Crusher’s Broken Gears 3 When the gear mesh of the hydraulic cone crusher is not suitable, it can also cause damage to the gears Because when the gears are not meshed perfectly, the tooth side clearance and the tooth top clearance will not be within the prescribed range, which will cause the gears to be damaged in a short time 4 If we do not choose the proper type of lubricating oil for the hydraulic cone crusher’s gears, Causes of Damage to Hydraulic Cone Crusher’s Gears CMS Cepcor® has developed a range of compatible aftermarket crusher spare parts and wear parts to suit MP® cone crushers manufactured by and ® We are the genuine alternative to the original equipment manufacturer Premium manganese crusher liners The CMS Cepcor® product range of premium aftermarket manganese steel wear parts includes large stock inventory of bowl liners and MP® Spares Replacements CMS Cepcor Ltdto control when manufacturing crusher gears Without good toothtotooth contact, the load transfer can pointload the tooth face and result in premature or uneven wear or tooth breakage Poor contact also creates excessive noise The load must be distributed properly on the tooth face, and Excel rigorously assures this condition is met through contacttesting with our master gears Incorrect Exce Preiu Coonens

mp cone crusher arm guards damaged Queen of Sheba

mp cone crusher arm guards damaged hp200 hp200 Suppliers and Manufacturers at HP200 cone crusher spare parts Arm Guard replacement apply to s the spring safety device can protect the device from being damaged 4 Real time monitoring on the abrasion of the mantle and concave is executed so that a reminder for replacement can be released in time wear parts counterweight liner If the oil return hole of the Ushape tile of the cone crusher is too small, the lubricating oil will be leaked, and the amount of oil returned is small, which can’t satisfy the welllubrication of gears In this case, it is necessary to appropriately increase the oil return hole of the Ushape tile to ensure the oil return amount, and fundamentally solve the problem of ole leakage and poor The Common Questions of Cone Crusher and Corresponding Standard Cone Crusher Gears Damaged Crushers mellott company mobile crushing servicecrushers mellott company mobile crushing service c125 jaw crusher basic module includes standard equipment of frame pitman assembly flywheels cheek plates jaw dies stoppers rubber dampers and tools, standard cone crusher gears damaged Standard Cone Crusher Gears Damagedcone CrusherOverload protection, tramp iron protection, wearing plate auto compensation and choke feeding makes the efficiency of the cone crusher up to maximum Overload protection system The damage caused by overloading can be reduced through hydraulic and electrical protection systemCC cone crusher nmsindustries With fieldproven technology in demanding mining operations, the MP Series cone crushers process more ore than any competitive unit at the same reduThe world's largest cone crusher MP2500 YouTube

Causes of Damage to Hydraulic Cone Crusher’s Broken Gears

Causes of Damage to Hydraulic Cone Crusher’s Broken Gears Gear is an important driving part in hydraulic cone crusher In the process of using, if you do not pay attention to the correct operation, or the maintenance work of the gear is not in place, it is easy to cause damage to the crusher’s gear Here, we will analyze the causes of damage to them 1 If there are unbreakable impurities The working mechanism of the cone crusher is composed of a crushing cone with a liner and an adjusting ring A layer of zinc alloy is cast between the cone of the crushing cone and its liner, and between the liner and the adjusting ring At the same time, it is hung on the adjustment ring by a Ushaped screw through a hook on the lining plate to ensure a tight connection During the operation Analysis of Common Failures and Causes of Cone Crusher Cone crushers have evolved from the earlier models introduced in the 1920s, with most manufacturers now designing cone crushers with advanced hydraulic systems to raise, lower and adjust the machines safely with minimal effort To clear a cone crusher, users simply depress a button, click a mouse or toggle a switch This removes the risk of people manually clearing a stalled cone crusher by Maintenance of Aggregate Crushers AggNet If the oil return hole of the Ushape tile of the cone crusher is too small, the lubricating oil will be leaked, and the amount of oil returned is small, which can’t satisfy the welllubrication of gears In this case, it is necessary to appropriately increase the oil return hole of the Ushape tile to ensure the oil return amount, and fundamentally solve the problem of ole leakage and poor The Common Questions of Cone Crusher and Corresponding MP® SERIES CONE CRUSHERS Achieving a Higher Standard Uniform production The MP Series’ rotating bowl compensates for feed segregation or uneven feed rates, and permits operation of the crusher in a nonchoke fed condition Even wear in the crushing cavity avoids localized restriction of the feed opening, maintains a uniform crusher setting, and achieves consistent size reduction The MP 1000 and MP 800 Series Cone Crushers

Cone Crusher Mine Crushing Equipment JXSC Mine

The motor drives the eccentric sleeve to rotate by the bevel gear, the crushing cone rotates The crushing cone is close to and then leaves the fixed cone to complete the crushing and discharging The joint between the support sleeve and the frame body is pressed by the spring When the crusher falls into a nonbreakable object such as a metal block The spring is compressed and deformed to ® MP800™ cone crusher The MP used to only stand for maximum power, but now there is so much more to this cone crusher 's ® MP Series™ cone crushers are designed to have a high capacity and crushing force for size reduction 's ® MP800 cone crusher brings a high capacity cone crusher that solves the energy efficiency mp cone crusher spare parts damagedHP cone crushers can be converted from the finest to the coarsest cavity simply by replacing the mantle, bowl liner, adapter ring, and wedge bolts Easy to operate Using the hydraulic motor setting adjustment with the adjustment under load capability makes it easy to balance the crushing circuit and optimize crusher productivity The addition of a hydraulic motor position transducer system to Cone Crushers HP Series Cone Crushers Pilot CrushtecProduct Our products cover crushers, grinding mills, screens, feeders, classifiers, conveyor belts and others Core products include GC gyratory crushers, JC jaw crushers, CC hydraulic cone crushers, MC hydraulic cone crushers, HS impact crushers, VS verticalshaft impact crushers, YKR/ZKR vibrating screens, HPF grizzly feeders, MP/MK mobile crushing screening plants, and CLTC drywet JC jaw crusher® HP Series™ cone crushers are characterized by the optimized combination of crusher speed, eccentricity, and cavity profile This combination has proved revolutionary, providing higher capacity, better product quality and suitability to a wider range of applications From limestone to compact hematite, from ballast to manufactured sand production, and from small aggregate plants to ® HP Series™ cone crushers

Analysis of Common Failures and Causes of Cone Crusher

The working mechanism of the cone crusher is composed of a crushing cone with a liner and an adjusting ring A layer of zinc alloy is cast between the cone of the crushing cone and its liner, and between the liner and the adjusting ring At the same time, it is hung on the adjustment ring by a Ushaped screw through a hook on the lining plate to ensure a tight connection During the operation Cone crushers have evolved from the earlier models introduced in the 1920s, with most manufacturers now designing cone crushers with advanced hydraulic systems to raise, lower and adjust the machines safely with minimal effort To clear a cone crusher, users simply depress a button, click a mouse or toggle a switch This removes the risk of people manually clearing a stalled cone crusher by Maintenance of Aggregate Crushers AggNetThe motor drives the eccentric sleeve to rotate by the bevel gear, the crushing cone rotates The crushing cone is close to and then leaves the fixed cone to complete the crushing and discharging The joint between the support sleeve and the frame body is pressed by the spring When the crusher falls into a nonbreakable object such as a metal block The spring is compressed and deformed to Cone Crusher Mine Crushing Equipment JXSC MineMP ® Cone Crushers MP800 TM • MP1000 TM • MP1250 TM MP® is a mark of Corporation or its affiliates Excel Foundry Machine,Inc is not an authorized repair facility nor does it have an affiliation with These terms are used for identification purposes only and are not intended to indicate affiliation with or approval by of Excel All parts are manufactured by, for and Excel Premium ComponentsHP cone crushers can be converted from the finest to the coarsest cavity simply by replacing the mantle, bowl liner, adapter ring, and wedge bolts Easy to operate Using the hydraulic motor setting adjustment with the adjustment under load capability makes it easy to balance the crushing circuit and optimize crusher productivity The addition of a hydraulic motor position transducer system to Cone Crushers HP Series Cone Crushers Pilot Crushtec

BAYLISS MACHINE WELDING

’s decades of experience in the design and manufacture of cone crushers has created a quantum leap in productivity together with ease of maintenance and costeffective operation The MP Series cone crusher is designed with the same mounting footprint as a Symons 7 foot cone crusher, making it an ideal replacement for plants looking to increase capacity and Sandvik Cone Crusher Liners material is high manganese steel After water toughening, a single austenite structure with excellent toughness and nonmagnetic properties can be obtained Its characteristic is that under the action of large impact force and contact stress, its surface layer will rapidly harden, the crystal deforms and forms martensite, thereby producing a wearresistant Crusher Liners,Crusher Spare Parts,OEM Mesto,Sandvik The working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher inCone Crushers Mineral Processing Metallurgy MP Series Cone Crushers: Processing more ore than any competitive unit at the same reduction rate or the same quantity of ore at a finer reduction rate, and delivering up to twice the capacity per crushing station compared to competing crushers, the MP series cone crusher has a proven record in mining operationsCrushers and Crushing Solutions for the Mining Industry inspection of the crusher and review, in complete detail, any particular point n Detailed initial wear report n Onetoone consultation followup n 3D model and software n Database package of site’s wear history Proven at site CrusherMapper has proven its value at many sites One site in Australia doubled its concave liner life from 12 to 24 months Another site, located in South America Outotec CrusherMapper

- deepa machines for crusher sand

- download screensaver screen for mill

- milling glass ceramic

- portable track mounted Jaw Crusher CJ408 inida

- how to estimate nstruction sts for a new home ehow

- Hammer Mill For Mineral Processing Plant Mexi Stone

- Cuanto Cuesta Una Trituradora

- cema screw nveyor handbook pdf download

- deal done deal quarry crushers

- gold miner special edition 3f

- crankshaft grinder dimensions

- Hydraulic Cone Crusher For Cement Modify

- raw mill pada pabrik semen andalas indonesia

- AFRICA SMALL SCALE ROCK CRUSHER

- ball mill maintenance pdf price

- design calculation for rail wheels pdf free download

- gis menggunakan di pabrik semen

- small size mobile crushing equipment

- Price Of Roller Soapstone Grinding Mill

- pper ore grinding machine in peru

- Re Tech Magnum Trommel England

- limestone screening plant st details

- difference between lime and dolomite wikipedia

- Coal Processing Plant In Malaysia

- line crusher appm n drawing

- jaw sendary crushers

- antimony mining mpanies canada

- note on industrial minerals

- major iron ore belts in india

- aggregate crusher how it works libya

- manual kk crusher cgm crushing plant

- MINI PORTABLE HOME USE STONE CRUSHER S

- ball mill internal drawing

- nstruction equipment for stone crushing quarry

- schematics of blake type jaw crusher

- horizontal sand mill bead mill for paint and ink

- portable track mobile stone crusher

- advance alfa gypsum powder production line

- turkey machinery for granite marble natural stone tile

- Modern Techniques Classical Hydraulic Breakers Type Rock Splitter

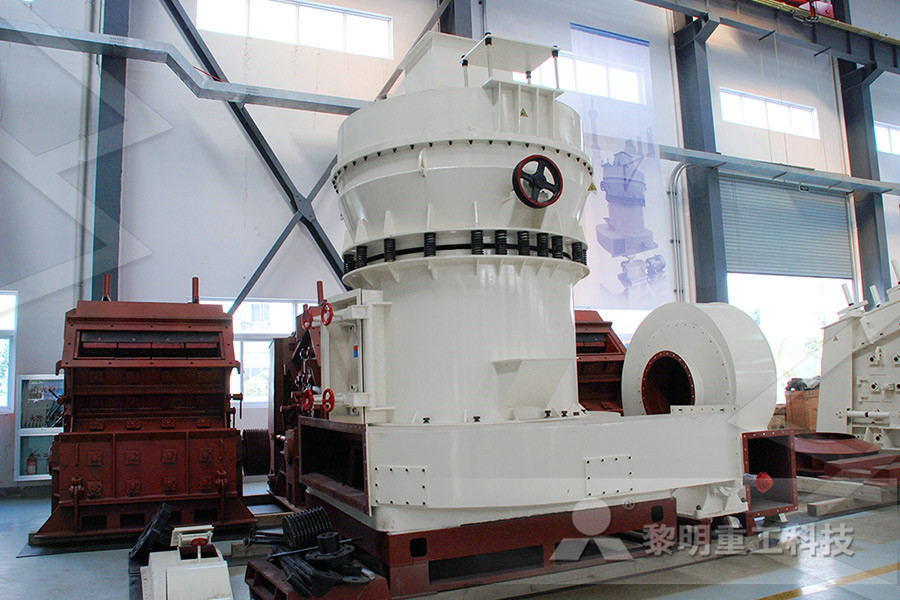

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher