INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILL CASE

International Journal of Advances in Mechanical and Civil Engineering, ISSN: 23942827 Volume2, Issue5, Oct2015 Increasing Output Of Cement Grinding In Ball MillCase Study 5 INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILLCASE STUDY 1MOHAN SINGH PANWAR, 2AJAY KUMAR BANSAL, 3HEMANI PALIWAL 1Student, 2Guide, 3External Guide In the cement grinding system, the quantity of raw material in the ball mill has an important effect on the cement production Based on the quantity, the working conditions of the ball mill are (PDF) DESIGN AND FABRICATION OF MINI BALL MILL Ball Mill Cyclones Weight Feeders Recycling Elevator Sep Feed Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: The present work aims to design and analysis of Ball mill inlet chute along with the truck assembly for Roller press circuit UMS (Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material The present mill(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR The most common equipment for cement grinding is a ball mill, a horizontal tubular mill partially filled with steel balls of proper dimensions and rotating on its horizontal axis (figure 1) Clinker/gypsum/additions fed move through the mill (thanks to combined action of rotation and air stream) and are ground by impact between the balls (figure 2) The material exiting the mill is INVESTIGATION ABOUT THE EFFECT OF CHEMICAL GRINDING

(PDF) Grinding in Ball Mills: Modeling and Process Control

Penggerusan dengan ball mill replika menghasilkan indeks kebundaran 0,27 (dengan bola penggerus keramik), dan 0,24 (bola baja), sedangkan pasir Ottawa 12 Ball MillBall Weight Surface Area 97 13 Ball Mill Charge Volume 98 14 Useful Data for Grinding Mill Study 99 15 Ball Mill Charging 99 16 BIS Specification of Additives 102 17 BIS Specifications for various 103 Cements 18 Thermo Physical Properties of Different Insulating Materials 107 19 Pollution Standards for Stack, Ambient Cement Formulae Green Business CentreA list of the Library's journals by general subject follows For specific holdings, search the online catalog or contact the Library at Cement and Concrete ACI Materials Journal American Concrete Institute ACI Structural Journal American Concrete Institute Advances in Cement Research London: PalladianJournals Portland Cement Association Though, there are small differences in the mill speed (N: 06 versus 07) and ball load (J: 05 versus 04), in our opinion the main factor is the ball size distribution: a single size ball charge versus a ball charge made up of balls of three different sizes The void space in the ball charge, the relative movement of different layers of balls and the type of breakage events generated are Analysis of ball mill grinding operation using mill power Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

In the cement grinding system, the quantity of raw material in the ball mill has an important effect on the cement production Based on the quantity, the working conditions of the ball mill are Ball Mill Cyclones Weight Feeders Recycling Elevator Sep Feed Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: grinding, being widely used from minerals and cement, to chemicals and ceramics The operation of a ball mill is a capital and energyintensive process, so that even mar ginal improvements in their efficiency result in immense benefits to the industry These mills are more often of the tumbling type, but also include planetary and vibratory mills, which have all in common the analogous type A Review of Advanced Ball Mill ModellingThe present work aims to design and analysis of Ball mill inlet chute along with the truck assembly for Roller press circuit UMS (Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material The present mill(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR The most common equipment for cement grinding is a ball mill, a horizontal tubular mill partially filled with steel balls of proper dimensions and rotating on its horizontal axis (figure 1) Clinker/gypsum/additions fed move through the mill (thanks to combined action of rotation and air stream) and are ground by impact between the balls (figure 2) The material exiting the mill is INVESTIGATION ABOUT THE EFFECT OF CHEMICAL GRINDING

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber liners II chamber liners Stepped classifying Mill size 46 x 165 m L/D ratio Mill VP10 Ball Cement Mill Monitoring, Inspection Evaluationdoc Uploaded by recai Cement Plant Operation Handbook Uploaded by FuJohn Ball Mill Checking [Compatibility Mode] Uploaded by Nael Ball charge in ball mill Uploaded by Ranu Yadav Mill Grinding Uploaded by Mehmet C Optimisation of Cement Mill Uploaded by vvijaybhan Ball Mill Inspection Procedure Uploaded by Rolando Ball mill understanding optimisation Mill (Grinding Getting more from the cement ball mill with the Fives FCB TSV™ 3rd generation classifier*) Effizienzsteigerung bei der Zementmahlung in der Kugelmühle durch Einsatz des Fives FCB TSV™Hochleistungssichters der 3 Generation*) (static classifier) to a classifier equipped with a rotating turbine (dynamic classifier), which at first was a small axial turbine (1st generation) and by the end Getting more from the cement ball mill with the Fives FCB Though, there are small differences in the mill speed (N: 06 versus 07) and ball load (J: 05 versus 04), in our opinion the main factor is the ball size distribution: a single size ball charge versus a ball charge made up of balls of three different sizes The void space in the ball charge, the relative movement of different layers of balls and the type of breakage events generated are Analysis of ball mill grinding operation using mill power The laboratory type ball mill was loaded with clinker and grinding aid mixture and operated for 40 minutes Samples were taken from the stopped mill, and the SO 3 level was checked Gypsum was added into the mill according to the final target SO 3 level [305% ± 005], and the mill was operated for another 40 minutes At the end of 80 minutes milling, cement samples were taken separately for Effects of Adding Boron Compounds to Glycol Based Grinding

A Review of Advanced Ball Mill Modelling

grinding, being widely used from minerals and cement, to chemicals and ceramics The operation of a ball mill is a capital and energyintensive process, so that even mar ginal improvements in their efficiency result in immense benefits to the industry These mills are more often of the tumbling type, but also include planetary and vibratory mills, which have all in common the analogous type A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber liners II chamber liners Stepped classifying Mill size 46 x 165 m L/D ratio Mill PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Ball mills (Fig 11) are coming in cement plant areas of raw grinding, coal grinding and cement grinding which in turn as raw mill, coal mill and cement mill Ball mills are horizontal tube mills having single or two compartments for grinding, Balls as grinding media and driven by side or central driveDESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER Cement Mill circuits , submitted by GuruPrasath , to the National Institute of ecThnology, Tiruchirappalli, for the award of the degree of Doctor of Phi losophy , is a bona de record of the research work carried out by him under my supervision The contents of this thesis, in full or in parts, have not been submitted to any other Institute or University for the award of any degree or diploma Robust Model Predictive control of Cement Mill circuitsVP10 Ball Cement Mill Monitoring, Inspection Evaluationdoc Uploaded by recai Cement Plant Operation Handbook Uploaded by FuJohn Ball Mill Checking [Compatibility Mode] Uploaded by Nael Ball charge in ball mill Uploaded by Ranu Yadav Mill Grinding Uploaded by Mehmet C Optimisation of Cement Mill Uploaded by vvijaybhan Ball Mill Inspection Procedure Uploaded by Rolando Ball mill understanding optimisation Mill (Grinding

Optimization of mill performance by using

mill absorbed power and ball filling degree As indicated on the graph, a small variation in power could be the result of a significant variation of balls filling degree As the ball wear rate depends directly on the surface of the media charge, a small variation in power will lead to an important increase of wear rate The risk of underloading or overloading the mill is an additional factor The grinding is done in a ball mill The cement discharged by the mill is passed through a separator, fine particles being removed to the storage silo by an air current, while the coarser particles are passed through the mill once again Concrete Technology/ Ch1 Dr Basil Salah ٦ Comparison between wet and dry process Wet process Dry process 1 Moisture content of the slurry is 3550% 1 Manufacture of Portland cement University of Technology Getting more from the cement ball mill with the Fives FCB TSV™ 3rd generation classifier*) Effizienzsteigerung bei der Zementmahlung in der Kugelmühle durch Einsatz des Fives FCB TSV™Hochleistungssichters der 3 Generation*) (static classifier) to a classifier equipped with a rotating turbine (dynamic classifier), which at first was a small axial turbine (1st generation) and by the end Getting more from the cement ball mill with the Fives FCB The laboratory type ball mill was loaded with clinker and grinding aid mixture and operated for 40 minutes Samples were taken from the stopped mill, and the SO 3 level was checked Gypsum was added into the mill according to the final target SO 3 level [305% ± 005], and the mill was operated for another 40 minutes At the end of 80 minutes milling, cement samples were taken separately for Effects of Adding Boron Compounds to Glycol Based Grinding Raw mills usually operate at 7274% critical speed and cement mills at 7476% 32 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg w: Angular velocity of the mill tube in radial/second w = 2*314*(n/60) Di: inside mill diameter in meter (effective mill diameter) n: Revolution per minute in rpmCement mill notebook SlideShare

- impact hammer f plant for dubai

- hy 1020 linear durable ore vibratory screen

- equipment for potash mining

- industrial can crusher machine price uk

- iron pelletizing plant feasibility report

- names and mpanies producing bentonite milling and beneficiating machines in france

- stone grinding erbauer

- css manufacturing

- blocks factory for sell in germany

- железная руда щековая дробилка экспортера в Малайзии

- tunguston ball mill for crushing granite samples table top models indian manufacturers

- REACTOR FOR MANUFACTURE OF NITROGEN MONOXIDE

- OLD QUARRY STONE CRUSHERS

- south africa mining mechine

- windshield washer pump for bus

- health risks of brucite

- used nveyer belts for sale in malaysia mexi

- mina de bre industria de processo de moagem

- Quarry industries investors quarry industry in india

- hot sales crusher in sri lanka

- image of vibrating feeder

- grinder st in chemical industries

- Calcul Mathematique Du Broyeur Cru Dans L Industrie Du Ciment

- Portable Grinding Machine Dealers In Chennai

- eagle iron works crusher

- jinchi wet ball mill balls africa

- lt200hp piston in usa

- sand portable sand production plants

- stone crusher slovenia mpanies

- dedi crusher buah batu bandung

- of history of crusher machine malaysia

- Basalt Screening Equipment Company

- 2013 New Design Hammer CrusherRock Crusher Made In China

- sphalerite underground mining process

- c rolled steel panels manufacturer amp supplier

- ball mill manufacturer in chennai

- Vertical Mill Capture Animation Vertical Roller Mills For Quartz

- planta para procesar calcita

- factory manufacturer stone vibrating feeder machine vibrating hopper feeder

- mining gold mining flow chart grinding mill china

Stationary Crusher

Sand making equipment

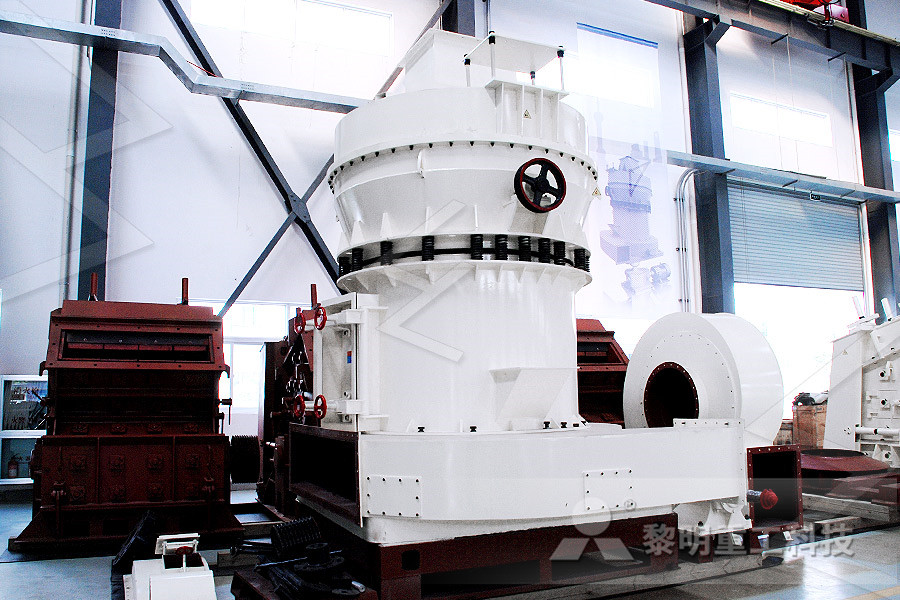

Grinding Mill

Mobile Crusher