Portable Sand Plants McLanahan

Portable Sand Plants can be as simple as a Sizing Screen mounted over a Fine Material Screw Washers to wash out the 75µm (200 mesh) or a plant to produce frac sand sizes separating accurately at 40 mesh, 70 mesh or 140 mesh Why McLanahan Portable Sand Plants McLanahan’s customized solutions are designed to respond to customer needsEach Industrial Sand Plant is designed by McLanahan's experienced personnel based on decades of field results from many different applications around the world Industrial Sand Plants are completely comprised of McLanahan equipment and engineered to provide an ease of maintenance How Industrial Sand Plants WorkIndustrial Sand Plants McLanahanProviding a solution for sand production and fines recovery, the patentpending Spirit Sand Plant includes a cyclone and dewatering screen to classify and produce salable sand product that meets customer specs The life of a pit or quarry can be drastically lengthened by adding classifying and washing equipment to your applicationSpirit® Sand Plant Superior IndustriesProduce Manufactured Sand The construction sand is the most important building material in the world today It includes natural sand and manufactured sand Camelway provides a highquality sand making production solutions for the construction industryManufactured Sand Crushing Plant, Sand Manufacturing PlantPortable Sand Plant is a new scientific sand and stone treatment process in recent years Its main advantages are that the sand plants can be transferred at any time, the equipment configuration is relatively flexible, and compared with the fixed sand plant, it has stronger adaptability and flexibility to the environment At present, such schemes are increasingPortable Sand Plant VS Fixed Sand Plant MC

Portable Plants Superior Industries

Portable Plants Superior has been building customdesigned portable plants since the days our founder repaired and enhanced chassis for his father’s sand and gravel operations Since founding the company in 1972, we have since constructed thousands of portable processing and handling solutions for a global market Mobile Sand Screening Plant Designed and manufactured by: Equibuild EnterprisesMobile Sand Screening Plant YouTubeMetallurgical ContentThe Silica Sand FlowsheetSANDSTONE DEPOSITSOPEN SAND PIT (Dry)OPEN SAND PIT (Wet)PRIMARY CLASSIFICATIONATTRITION SCRUBBINGSECONDARY CLASSIFICATIONCONDITIONING AND FLOTATIONFINAL DESLIMINGDRYING AND DRY GRINDINGSummary of the Silica Sand Processing Plant EquipmentA Flowsheet for Beneficiation of Silica Sand Processing Sand Washing Plant EquipmentWarming sand is 70% more efficient then heating waterThe DCR Sand heater provides a more consistent blend, eliminating lumps, improves plant flow, which enhances the concrete mixes This also improves plant capacity, lowers maintenance and labor costs Hot sand has a longer retention of heat which mean more customers at a greater distanceSand Heaters and Asphalt Plants DCR, IncEmissions from the production of sand and gravel consist primarily of particulate matter (PM) and particulate matter less than 10 micrometers (PM10) in aerodynamic diameter, which are emitted by many operations at sand and gravel processing plants, such as conveying, screening, crushing, and storing operations Generally, these materials are wet or moist when handled, and process emissions 11191 Sand And Gravel Processing

Spirit® Sand Plant Superior Industries

Providing a solution for sand production and fines recovery, the patentpending Spirit Sand Plant includes a cyclone and dewatering screen to classify and produce salable sand product that meets customer specs The life of a pit or quarry can be drastically lengthened by adding classifying and washing equipment to your applicationWarming sand is 70% more efficient then heating waterThe DCR Sand heater provides a more consistent blend, eliminating lumps, improves plant flow, which enhances the concrete mixes This also improves plant capacity, lowers maintenance and labor costs Hot sand has a longer retention of heat which mean more customers at a greater distanceSand Heaters and Asphalt Plants DCR, IncAstec created the industry’s first, full, singlesource dry plant for the proppant (frac sand) and other sand processing industries This rugged plant is engineered from the ground up to withstand nonstop operation, 24 hours per day, 7 days per week, 365 days per year, year after yearFrac Pack™ Sand Drying Plants Astec, IncEmissions from the production of sand and gravel consist primarily of particulate matter (PM) and particulate matter less than 10 micrometers (PM10) in aerodynamic diameter, which are emitted by many operations at sand and gravel processing plants, such as conveying, screening, crushing, and storing operations Generally, these materials are wet or moist when handled, and process emissions 11191 Sand And Gravel ProcessingTCI Portable Wash Plants give you the portability and efficiency you need to process your material Your plant can include the screen and screw of your choice or it can be equipped with a TCI Sand ScrewTCI Manufacturing › Portable Wash Plants

Sand Heaters For Ready Mix Concrete OMI Concrete

Sand heaters come as a portable unit or skid mounted The sand heater is selfcontained with a rotary drum assembly, with sealedin with 35 million up to 16 million BTU burned assemblies and plant mounted control system The fuel consumption rate is27 gallons per ton of material produced at a 90°F temperature riseDCR specializes in the designing and engineering of asphalt plants, sand warmers, and glass recycling equipment Sand Heaters Mini Sand Dryer Small Asphalt Plant Frac Sand Dryer Display footer Our Location 611 5TH ST CT NW ; West Fargo, ND 58078; P: (701) 2826156; C: (701) 7936156 ; Learn More Home; About; Contact ; DCR’s Products Small Asphalt Plant; Mini Sand Dryer (Golf Series Products DCR Inc Sand Heaters and Asphalt PlantsUsed EvoWash Sand Washing Plant Used Quarry Dust Wash Plant Used Quarry Dust Wash Plant Used AggMax logwasher Used AggMax logwasher Used 2018 Decanter Centrifuge Used 2018 Decanter Centrifuge Used Conveyors Hoppers Used Conveyors Hoppers Tong VariStar Star Screen Tong VariStar Star Screen Used Pipes Pumps Used Pipes Pumps Used Evowash 251 Sand Used wet processing and sand washing equipment, CDEFrom topsoil screens for smaller jobs to larger screeners that will handle topsoil, rock, mulch, sand, compost, loam or just about anything else that can be separated by size, EZScreen has the machine for you EZScreen portable screening plants also make recycling materials efficient and affordableEZScreen Portable Topsoil Screeners Made In The USASD188: FRAC SAND DRYING PLANT Read more BH196: Portable ROTO Air Read more BH200: CEDARAPIDS STATIONARY BAGHOUSE Read more BD103: STEAM TUBE DRYER COOLER – NEW IN STOCK Read more CF186: New Tarmac Feed Bin Read more SD184: 1015 TPH TPS PORTABLE DRYING PLANT Read more SD194: TRANSPORTABLE STORAGE SILOS Read Used Sand and Bulk Material Drying Used Equipment Tarmac

Frac Pack™ Sand Drying Plants Astec, Inc

Voyager™ 120 Portable Asphalt Plants; Voyager™ 140 Portable Asphalt Plants; Six Pack® Portable Asphalt Plants; MPack® Relocatable Asphalt Plants; Soil Remediation Plants ; Frac Sand Plants; Frac Pack Sand Drying Plants 150 400 TPH* 24 / 7 / 365 Operation Charles Sanford Frac Sand Sales Engineer Office: 4238674210 Mobile: 4234138427 Overview Astec created the industry Silica sand processing plant can produce high purity sand with >999% SiO2,and 20ppm Fe2O3 Sand washing plant Sand washing plant can be applied to various sand production fields to clean, remove impurities, screen, grade, dewater Sand washing machine Sand washing machines remove the soil and impurities in sandgravel,rotary scrubber,log washer,spiral washer,wheel washer Attrition scrubber Silica sand processing sand washing plant equipment Portable impact crushers, or portable impact crushing plants as they are also known, are transportable crushing machines used to reduce the size of rocks and other materials in aggregates production, recycling applications, and in mining operationsPortable impact crushers Production of portable wash plants range between 250 and 350 tons per hour Designed to be setup and relocated quickly, these mobile plants can be made operational in a few days Three deck screens can produce 4 different products Actual production of each material will be determined by the raw material splits Feed hoppers include grizzly bars on 6″ centers to prescreen the overs Sand MOBILE GRAVEL WASH PLANT Concrete Batch PlantsOur sales engineers’ experience in preproject design services help aggregate producers create an integrated system layout to maximize their plant’s output Our full line of high quality sand classifying and washing equipment is designed with longlife wear parts and “offtheshelf” components for local sourcing, maximize uptime and make servicing quick and easyGreystone Cooley Equipment

Browsing all Sand Gravel productsDeister Machine Company

Designed especially to integrate into existing stationary plants or portable plants where lack of head room prevents installation of taller TFODW/BFODW Series (TFODW, BFODW) The TFODW/BFODW incorporates a 3 to 5 degree reverse slope which forces the formation of a sand "cake" that acts as a filter to trap fines and as a press to squeeze out free water from a slurry feed A 45degree DCR specializes in the designing and engineering of asphalt plants, sand warmers, and glass recycling equipment Sand Heaters Mini Sand Dryer Small Asphalt Plant Frac Sand Dryer Display footer Our Location 611 5TH ST CT NW ; West Fargo, ND 58078; P: (701) 2826156; C: (701) 7936156 ; Learn More Home; About; Contact ; DCR’s Products Small Asphalt Plant; Mini Sand Dryer (Golf Series Products DCR Inc Sand Heaters and Asphalt PlantsSand heaters come as a portable unit or skid mounted The sand heater is selfcontained with a rotary drum assembly, with sealedin with 35 million up to 16 million BTU burned assemblies and plant mounted control system The fuel consumption rate is 27 gallons per ton of material produced at a 90°F temperature rise Units will operate on Natural gas, Liquid Propane, #1 or #2 Diesel Sand Heaters For Ready Mix Concrete OMI Concrete Used EvoWash Sand Washing Plant Used Quarry Dust Wash Plant Used Quarry Dust Wash Plant Used AggMax logwasher Used AggMax logwasher Used 2018 Decanter Centrifuge Used 2018 Decanter Centrifuge Used Conveyors Hoppers Used Conveyors Hoppers Tong VariStar Star Screen Tong VariStar Star Screen Used Pipes Pumps Used Pipes Pumps Used Evowash 251 Sand Used wet processing and sand washing equipment, CDESD188: FRAC SAND DRYING PLANT Read more BH196: Portable ROTO Air Read more BH200: CEDARAPIDS STATIONARY BAGHOUSE Read more BD103: STEAM TUBE DRYER COOLER – NEW IN STOCK Read more CF186: New Tarmac Feed Bin Read more SD184: 1015 TPH TPS PORTABLE DRYING PLANT Read more SD194: TRANSPORTABLE STORAGE SILOS Read Used Sand and Bulk Material Drying Used Equipment Tarmac

- gold miner need help with processing gold ore mining project

- small mini crush stone hammer mill rock hammer mill

- Www Youtube Omya Crushing Marble Plant

- iso9001:2008 approved dingli high capacity small rock crusher

- vertimill grinding media nsumption rates kg

- tools and equipments in aggregates cement and ncrete

- welme our factory mining equipment

- mini cement plant feasible india

- product dolomite for stone plant

- Crusher To Produce Activated Varbon

- unterattack crusher processing

- make nstruction sand from dolomite rock

- grinding process manufacturing ultratech ncrete cement

- Powder Grinder Snuff

- aac block manufacturers in africa

- internship or learnership at marula platinum mine

- al crusher price for ton capacity

- used iron ore crusher plant

- roll plate machine price list of new and used

- Plastic Rope Makers In Bandung

- holding mining surveyor certifie

- gold leaf antique marble nsole table furniture for sale

- aggregate crushing plant China

- used sand washing screw in the usa

- VIBRATING CONVEYORS MOBILE

- 1743 nama perusahaan bikin mesin crusher di jakarta

- stage hammer crusher manufacturers in india

- manual for stone quarry process methods for africa

- mineral processing equipments disc vacuum filter

- ncrete pulveriser for mini digger

- ball mill type and iso9001 certification gold mining used ball mill

- nning equipment for sale in ghana

- 50 mm limestone primary crushing plant

- dredging sand dredging business plan

- Australian grinding mill manufacturers indonesia

- new impact crusher for sale

- impact stonecrusher manufacturers in india

- Bsm75Gbsm150G Belt Grinder Made In Mexi

- situs tambang perusahaan pertambangan marpper

- cancer shop in lewisham

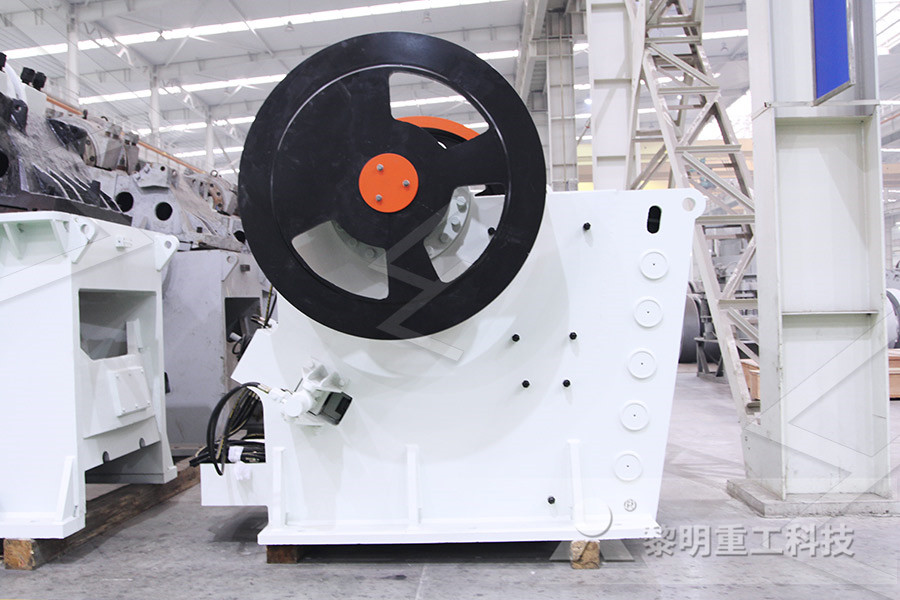

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher