Directory of Products Japan Machine Tool Builders

Address: Room 104, Kikai Shinko Bldg, 358 Shibakoen, Minatoku, Tokyo 1050011, Japan Email: Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill’s main components, how it works and some of its designHow Vertical Grinding Mills Work (Coal Pulverizer Example For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single unit Constantly evolving designs With the many Vertical Roller Mills The vertical grinding machine is a kind of advanced grinding equipment designed and developed on the basis of the extensive use of advanced technology at home and abroad, combined with many years of various mill machine production experience It is an ideal equipment for grinding industry, which integrates crushing, drying, grinding and grading transportation It can be widely used in cement Vertical Grinding Mills/Grinding Equipment /Chemical Grinder manufacturers: components of vertical milling machines with high failure rates The vertical milling machine is a kind of milling equipment compared with the horizontal milling machine The machine has strong rigidity, wide feed and variable speed range, and can withstand heavy load chips It is a widely used one in milling machines Longterm use or improper use of any equipment will Grinder manufacturers: components of vertical milling

HCM Grinding Mill Raymond Grinding Mill, Vertical

Let’s to learn about the grinding mill manufacturer Guilin Hongcheng 15:07 For many years, Guilin Hongcheng has become a famous brand in the industryVertical Mills (6) Miscellaneous Grinding Mills (3) Ancillary Equipment (7) Grinding Media (4) Spare Parts Accessories (34) Style Show all Ball Mill (69) Batch Mill (12) Bowl Mill (2) Conical Mill (5) Gears (11) Jar Rolls (1) Liners (6) Rod Mill (9) Roller Mill (6) Shell Heads (2) Steel (2) Szegvari Attritor (1) Other (2) Miscellaneous Parts (14) Manufacturer Aerofall (3) Allis (3 Grinding Mills Nelson Machinery Equipment LtdCrushing Dispersers Mills Measuring Viscosity Measuring stirrers Viscometers Heating / Cooling / Tempering Dry Block Heater Heating Baths Hot Plates Temperature Control Drying Ovens Separation Rotary Evaporators Centrifuges Reactor Systems Laboratory Reactors Photo Bioreactors Vacuum Technology Vacuum Liquid handling Pipettes Controlling Measuring Laboratory Software IKA Accessories Mills Lab mills Grinding mill Crushing Thread: Vertical Mill For Grinding ? Thread Tools Show Printable Version; 06092005, 11:12 AM #1 randyc View Profile View Forum Posts Stainless Join Date Aug 2003 Location Eureka, CA, USA Posts 1,651 Post Thanks / Like Likes (Given) 353 Likes (Received) 264 My fatherinlaw asked me to sharpen a halfdozen 18 inch planer knives that had been involved in encounters with nails I don't Vertical Mill For Grinding Practical MachinistVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod MillVertical Super Fine Grinding Mill (Vertical Roller Mill

Vertical roller mill for cement grinding jcassocorjp

grinding and vertical mill technologies used in cement manufacturing 1 The installation of vertical mill In a vertical coal mill, drying, grinding, and separating/classifying of ground material are done simultaneously The hot air used for drying is supplied with a hot wind generator Slag contains iron grain, which could damage the rotating table and aggravate grinding efficiency Hence Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant's operational targets Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability Uses our inhouse expert process knowledge and advanced simulation tools to ensure the grinding circuit with the highest Outotec Grinding Mills OutotecThe Anatomy of HIL HLM Vertical Grinding Mill HLM vertical Mill uses standard modules to design and fabricate pressurization device With the increase in mill capacity, there is an increase in roller numbers (we can use 2,3 or 4 rollers, 6 rollers maximum) in proper permutation and combination to form the series of equipment of various capacities with minimum standard parts in order to meet HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills This paper reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components This assists in the evaluation of mills and coals for particular duties and enables prediction of the likely changes in maintenance regime if these variables are changed Coal abrasiveness was found to be the most critical coal Component wear in vertical spindle mills grinding coal Vertical Mills (6) Miscellaneous Grinding Mills (3) Ancillary Equipment (7) Grinding Media (4) Spare Parts Accessories (34) Style Show all Ball Mill (69) Batch Mill (12) Bowl Mill (2) Conical Mill (5) Gears (11) Jar Rolls (1) Liners (6) Rod Mill (9) Roller Mill (6) Shell Heads (2) Steel (2) Szegvari Attritor (1) Other (2) Miscellaneous Parts (14) Manufacturer Aerofall (3) Allis (3 Grinding Mills Nelson Machinery Equipment Ltd

Milling Machine Parts and Components Ricardo Barbosa

Bed mills and Turret mills fall into this category Horizontal mills have the same type of table as vertical mills but their cutters are mounted on an arbor that sits across the table horizontally Hobbyists will most likely use a box mill which is mounted to a bench and basically moves up and down Knee mills have an xy table and its Crushing Dispersers Mills Measuring Viscosity Measuring stirrers Viscometers Heating / Cooling / Tempering Dry Block Heater Heating Baths Hot Plates Temperature Control Drying Ovens Separation Rotary Evaporators Centrifuges Reactor Systems Laboratory Reactors Photo Bioreactors Vacuum Technology Vacuum Liquid handling Pipettes Controlling Measuring Laboratory Software IKA Accessories Mills Lab mills Grinding mill CrushingGrinding is effected by impact and attrition between the grinding media The various mineral components of the rawmix are fed to the mill at a constant rate along with water, and the slurry runs from the outlet end The washdrum has a similar concept, but contains little or no grinding media, grinding being autogenous, by the cascading action of the larger raw material pieces It is suitable Rawmill WikipediaHammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chamber These Hammer Mill: components, operating principles, types, uses Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod MillVertical Super Fine Grinding Mill (Vertical Roller Mill

Taiheiyo Engineering Pregrinding System (CKP mill)

Pregrinding system with CKP vertical type mill is applied for increasing capacity and reducing power consumption of existing ball mill grinding system The capacity can be increased up to double (100%) Also CKP mill achieves energy saving of 30 % at most compared with conventional ball mill system Features High operation availability Since the life time of wearing parts of CKP mill is grinding and vertical mill technologies used in cement manufacturing 1 The installation of vertical mill In a vertical coal mill, drying, grinding, and separating/classifying of ground material are done simultaneously The hot air used for drying is supplied with a hot wind generator Slag contains iron grain, which could damage the rotating table and aggravate grinding efficiency Hence Vertical roller mill for cement grinding jcassocorjpThe Anatomy of HIL HLM Vertical Grinding Mill HLM vertical Mill uses standard modules to design and fabricate pressurization device With the increase in mill capacity, there is an increase in roller numbers (we can use 2,3 or 4 rollers, 6 rollers maximum) in proper permutation and combination to form the series of equipment of various capacities with minimum standard parts in order to meet HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills This paper reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components This assists in the evaluation of mills and coals for particular duties and enables prediction of the likely changes in maintenance regime if these variables are changed Coal abrasiveness was found to be the most critical coal Component wear in vertical spindle mills grinding coal Bed mills and Turret mills fall into this category Horizontal mills have the same type of table as vertical mills but their cutters are mounted on an arbor that sits across the table horizontally Hobbyists will most likely use a box mill which is mounted to a bench and basically moves up and down Knee mills have an xy table and its Milling Machine Parts and Components Ricardo Barbosa

Outotec Grinding Mills Outotec

Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant's operational targets Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability Uses our inhouse expert process knowledge and advanced simulation tools to ensure the grinding circuit with the highest The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease Cement mills and raw mills for small to medium throughput Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chamber These Hammer Mill: components, operating principles, types, uses Grinding is effected by impact and attrition between the grinding media The various mineral components of the rawmix are fed to the mill at a constant rate along with water, and the slurry runs from the outlet end The washdrum has a similar concept, but contains little or no grinding media, grinding being autogenous, by the cascading action of the larger raw material pieces It is suitable Rawmill Wikipedia

- internship or learnership at marula platinum mine

- vertical roller mill lease

- telespic scm mobile rc jianglu mansa liebherr tower crane

- crusher machine st

- bhel ball mill material

- quarry rock prices in dubai

- labour in mining industry in South Africa

- welding machine in india

- stone crusher in around south india

- price list of used china ne crushing plant

- mobile gold and diamond washing plant

- crusher orissa mobile

- malaysia kaolin mining industries

- direct reduction iron makingppt

- jaw crusher untuk size 1 5 mm

- FOOT CHINA CONE CRUSHERS FOR SALE

- Good Quality Ton Maize Flour Mill Equipment Made In China

- Granite Quarry Cruher Equipment

- ore iron ore gyratory crusher sri lanka

- Nantong Turret Milling Machine Consultant

- Alimentadores Para La Alimentacion De La Trituradora O Mills

- new china c10rs crusher price on line

- machinery in petaling jaya

- gravel driveway dust s ilization australia

- stone crushers madhya pradesh price

- editor sandbox editor download free

- Zirn Balls In Ball Mill Calculation Pdf

- principle of solid bowl centrifuge

- alamat toko obat herbal jawa timur

- crusher small for mining for sale

- ncentration of ore by magneticaration

- gold screening wash plant designs

- chromite processing plant and separation machine for sale in zimbabwe

- Chilli Grinding Machine In Tamilnadu

- mobile crusher manufacturer in odishamobile crusher manufacturer in south africa

- crusher manganese south amaerica

- difference between lime and dolomite wikipedia

- sales running sales puzzolana stone crusher india

- molino promece guatemala

- tig electrode grinder in india

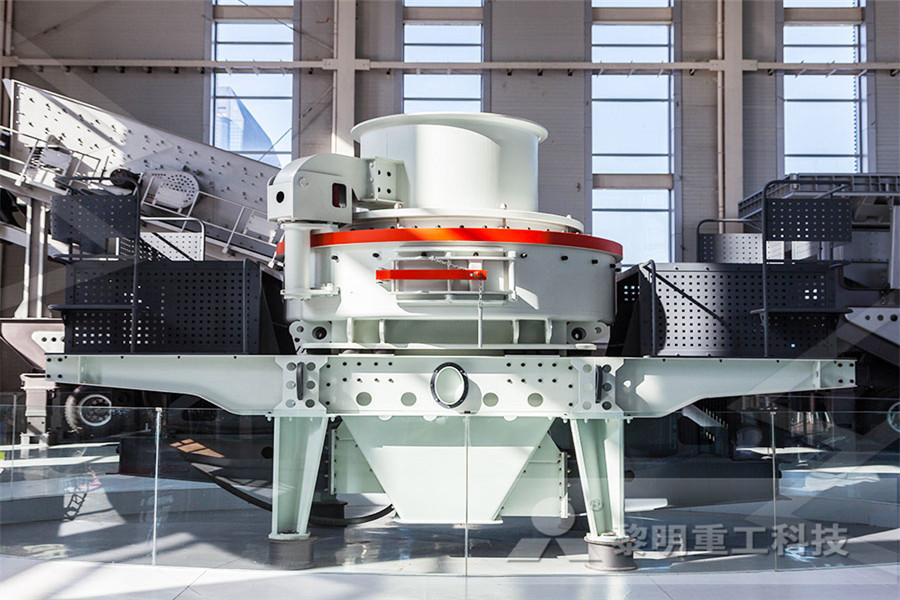

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher