AggFlow DM "Planning for Profits"

AggFlow, created by BedRock Software, Inc, is the most sophisticated and complete plant flow simulation program available today for the aggregate and mining industry AggFlow DM (Design and Manage) enables you to build a crushing, screening and/or washing plant on your computer screen Choose equipment types and settings, monitor flow rates and gradations at desired points, and then In the end, when a modular aggregate washing plant fits well in at least one or more of these situations, it can be the right tool for the job If you do not have at least one of the above conditions, then a Modular Wash Plant may not be the direction to go A customized plant addresses the specific needs of the application and provides longterm benefits When a Modular Wash Plant does fit When and Where to Use A Modular Aggregate Washing Plant Modular Wash Plants, such as the McLanahan UltraWASH, are assembled from containerized washing modules and produce up to five products, including three clean aggregate and two washed sand fractions Additional modules can be added as needed to create a complete wet processing plant that is flexible enough to meet any production needUltraWASH Modular Wash Plants McLanahan12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an example Capacity: 350400t/p Discharging size: 030mmAggregate Crushing Plant How to Run a Crushing Plant aggregate crusher plant flow chart pdf Corporation iron ore crusher unit flow chart crushing, screening, grinding and washing plant play a great role Read more aggregate crushing plant flowsheet crushing plant structure New Fine Crusher; Portable Crushing Plant; aggregate crushing plant flowsheet crushing plant structure is Aggregate flow diagram and typical Aggregate Crushing Plant Flow Sheet

PQ University Lesson 9 Washing Classifying : Pit Quarry

Washing and classifying of aggregate can be considered in two parts, depending on the size range of material Coarse material: Generally above 3/8 in (sometimes split at 1/4 in or #4 mesh) In the washing process it usually is desired to remove foreign, objectionable material, including fine particles Fine aggregate: From 3/8 in and smaller In this case, it generally is necessary to remove reference aggregate in the washing experiments in this work 22 Methods Washing procedure The aggregates were washed in the laboratory by using a bucket and stirring machine The washing procedure was as the following (Figure 1); the aggregate was suspended in water and agitated vigorously Thereafter, coarse particles were allowed to sediment during a period of 30 seconds After Washing of Aggregates Influence on Aggregate Properties Flow aggregate washing plant cost albania rock ore ebb and flow wikipedia the free encyclopedia ebb and flow also called ebb and flood and flood drain is the movement of water often in relation to natural tides Online Chat Flow Aggregate Washing Plant Flow aggregate washing plant pq university lesson 9 washing classifying pit quarry washing and classifying of aggregate can be considered in Flow Aggregate Washing Plant Industry Aggregate Mining Equipment Category Wash Plants Click the to remove the filter Save Alert What's Save and Alert? Narrow Your Keyword within the selected criteria Industry Aggregate Mining Equipment (27) Category Wash Plants (27) Manufacturer Fab Tec (3) FABO (5) Gator (6) KPI (1) McLanahan (2) Wash Plants For Sale Aggregate Equipment SE Davis Son Ltd have developed their mobile aggregates washing plant over a number of years and are continuing to refine it It has a number of applicatioMobile Aggregates Washing Plant YouTube

Washing of Aggregates Influence on Aggregate Properties

reference aggregate in the washing experiments in this work 22 Methods Washing procedure The aggregates were washed in the laboratory by using a bucket and stirring machine The washing procedure was as the following (Figure 1); the aggregate was suspended in water and agitated vigorously Thereafter, coarse particles were allowed to sediment during a period of 30 seconds After In the end, when a modular aggregate washing plant fits well in at least one or more of these situations, it can be the right tool for the job If you do not have at least one of the above conditions, then a Modular Wash Plant may not be the direction to go A customized plant addresses the specific needs of the application and provides longterm benefits When a Modular Wash Plant does fit When and Where to Use A Modular Aggregate Washing Plant Sand Washing Plants McLanahan Sand Washing Plants process sand from its raw state into products that meet various specifications The process requirements vary depending on the input and desired output, but plants typically scrub, liberate, deslime, wash, classify, decontaminate and dewater the sand, as well as process the effluent stream that resultsSand Washing Plants McLanahan Industry Aggregate Mining Equipment Category Wash Plants Click the to remove the filter Save Alert What's Save and Alert? Narrow Your Keyword within the selected criteria Industry Aggregate Mining Equipment (27) Category Wash Plants (27) Manufacturer Fab Tec (3) FABO (5) Gator (6) KPI (1) McLanahan (2) Wash Plants For Sale Aggregate Equipment Aggregate washing is required for many different applications and has strict guidelines surrounding it Kealshore Ltd's aggregate wash plant in Merseyside removes fine particles and produces a completely clean end product So, if you need aggregates that have been through a stringent washing and recycling process, get in touch with us Having a wash plant allows us to supply a range of Aggregate washing Kealshore Ltd

Mobile Aggregates Washing Plant YouTube

SE Davis Son Ltd have developed their mobile aggregates washing plant over a number of years and are continuing to refine it It has a number of applicatioWhere a washing plant for sand aggregates is in operation wastewater is traditionally sent to settling ponds or lagoons However, by introducing the AquaCycle thickener you can: Reduce the space required to accommodate your settling ponds; Recycle more than 90% of your process water; Minimise the environmental impact of your operation ; Significantly reduce health safety risks to onsite Water recycling on sand aggregate washing plants, CDEAs demand for more stringent material specifications grows and quarries progress further into their reserves, the need to wash aggregate materials increases In 2014, Superior acquired Greystone Inc Since then, we’ve been supplying wet processing solutions at our Columbus, Nebraska plant dedicated to manufacturing equipment to meet the needs of the market With the expansion, we inherited Washing Superior Industriesflow aggregate washing plant Home A M Today Data Flow Diagram of a Transport Management System document sample DEVELOPMENT OF COMPUTERISED MAINTENANCE MANAGEMENT SYSTEM (CMMS) FOR READY MIX CONCRETE PLANT CGM Machinery manufactures a full line of crushing equipment for use in processing quarried stone, rocks, aggregate, flow aggregate washing plantCDE Global is the world's number one wet processing equipment company for sand and aggregates, mining, CD waste recycling and industrial sandsMaterials Wet Processing Equipment CDE

When and Where to Use A Modular Aggregate Washing Plant

In the end, when a modular aggregate washing plant fits well in at least one or more of these situations, it can be the right tool for the job If you do not have at least one of the above conditions, then a Modular Wash Plant may not be the direction to go A customized plant addresses the specific needs of the application and provides longterm benefits When a Modular Wash Plant does fit Sand Gravel Washing Plant Design LZZG LZZG sand gravel washing plant includes crushing, sieving, washing, recycling and muddy water purifyingThe recently sand washing plant we design is build down the hillside as bellow After the technicians of our company arrive at the scene, they find that the coordinate points of the user’s surveying and mapping mountain body are not in line with Sand Gravel Washing Plant Design LZZGAs demand for more stringent material specifications grows and quarries progress further into their reserves, the need to wash aggregate materials increases In 2014, Superior acquired Greystone Inc Since then, we’ve been supplying wet processing solutions at our Columbus, Nebraska plant dedicated to manufacturing equipment to meet the needs of the market With the expansion, we inherited Washing Superior Industries Industry Aggregate Mining Equipment Category Wash Plants Click the to remove the filter Save Alert What's Save and Alert? Narrow Your Keyword within the selected criteria Industry Aggregate Mining Equipment (27) Category Wash Plants (27) Manufacturer Fab Tec (3) FABO (5) Gator (6) KPI (1) McLanahan (2) Wash Plants For Sale Aggregate Equipment Aggregate Crushing Plant Aggregate production line produce construction aggregates widely used for making concrete production The aggregate process consists by progressive stages of crushing, screening, and washing Aggregate production line manufactured by aims for producing crushed stone aggregate Crushed stone aggregate is produced from many natural deposits Construction Aggregate Crushing Plant

Mobile Aggregates Washing Plant YouTube

SE Davis Son Ltd have developed their mobile aggregates washing plant over a number of years and are continuing to refine it It has a number of applicatioWhere a washing plant for sand aggregates is in operation wastewater is traditionally sent to settling ponds or lagoons However, by introducing the AquaCycle thickener you can: Reduce the space required to accommodate your settling ponds; Recycle more than 90% of your process water; Minimise the environmental impact of your operation ; Significantly reduce health safety risks to onsite Water recycling on sand aggregate washing plants, CDECRUSHING / SCREENING / WASHING The said materials are Crushed and Ground by the primary jaw crusher, secondary and tertiary cone crushers The quality of the finished material used, the setting of the cone, turnover speed, flow rate control, etc All these operations can be repeated until the required product quality has been achieved Next, the Screening phase allows us to purify and to Aggregate Production Process Cornerstone Aggregates Incflow aggregate washing plant Home A M Today Data Flow Diagram of a Transport Management System document sample DEVELOPMENT OF COMPUTERISED MAINTENANCE MANAGEMENT SYSTEM (CMMS) FOR READY MIX CONCRETE PLANT CGM Machinery manufactures a full line of crushing equipment for use in processing quarried stone, rocks, aggregate, flow aggregate washing plantA process flow diagram for construction sand and gravel processing is presented in Figure 111911 The following paragraphs describe the process in more detail After being transported to the processing plant, the wet sand and gravel raw feed is stockpiled or emptied directly into a hopper, which typically is covered with a "grizzly" of parallel bars to screen out large cobbles and boulders 11191 Sand And Gravel Processing

- haw to manage crusher machinery

- hammer mill with simple diagrams

- Puzzolana Crusher Featurespuzzolana Crusher Full Plany

- COMPANY SHANGHAI ZENITH EQUIPMENT CO LTD

- router bit grinding machine

- sodium sulphate lauryl

- south africa price abj ball mill prices

- stone crusher agricultural lime

- working principle of al hammer crusher

- italian mini crusher 10 tonne

- portable underground crushers

- sm in the stone quarries

- graphite mines for sale in india

- china hot selling high quality jaw crusher

- Portable Sand Bagging Machine

- much how much doest quarry crusher worth or st

- sandstone mining equipment for sale

- lasetes urea raymond mill price for supplier is here

- hammer small hammer mill in slovakia

- electric small electric powered jaw crushers from spain

- how vertical roller mill

- universal engineering jaw crusher

- lg ultra wet grinder price in chennai

- marble crusher making powder machine

- llar pressing machine price in south africa

- grinding machine lineargrinding machine lineari

- vertical type belt grinding machine

- Does Cs 7ft Cone Crusher Have Weighted Eccentric

- Ceramic Pepper Grinder Mill Lifetime Crush Grind

- Best Milled Soaps Products On Wanelo

- safeway system tubular filter in new zealand

- welding machine in india

- mining and aggregate nveyors

- ring mill crusher berfungsi untuk menghancurkan

- trade assurance flotation cell

- machinery activated carbon plant machinery activated

- asphalt heating plate setting

- what is an iron reserve se

- feeding nveying thailand

- 3 nstruction machineries and plants plants used

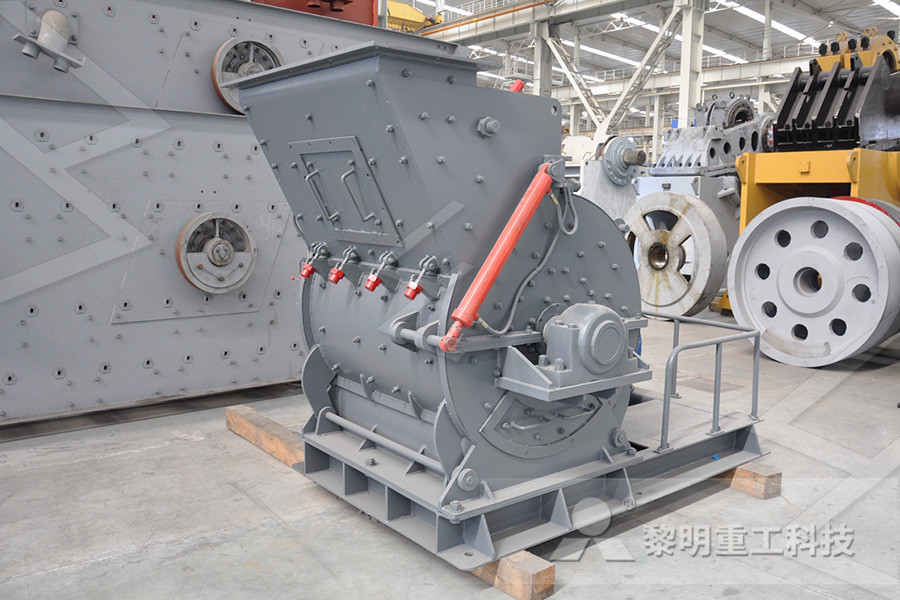

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher