Vertical Roller Mills

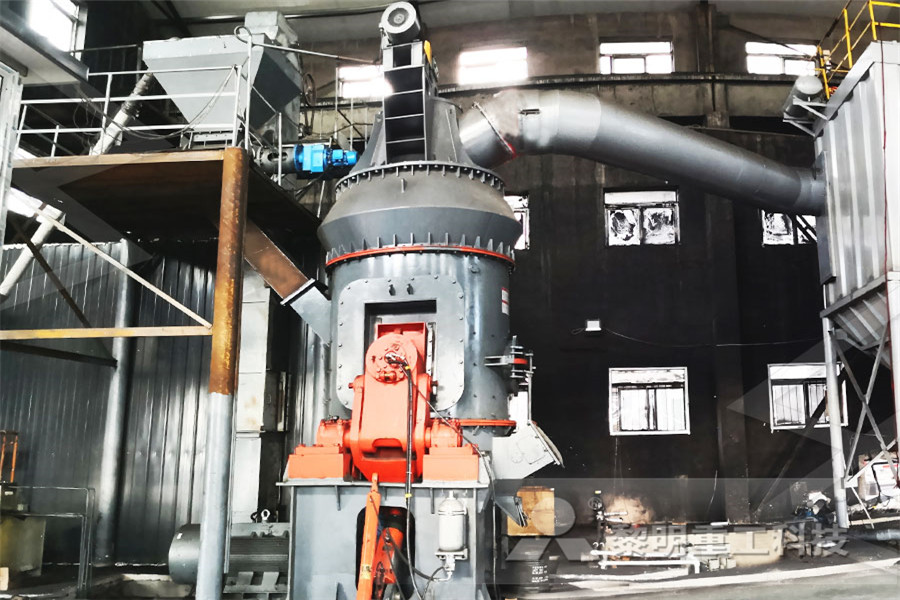

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingLUM Vertical Roller Mill XZM Ultrafine Mill Raymond Mill read more Solutions Processing And Grinding Of Gypsum Stones; Calcite Grinder Milling Plant Machine ; Marble Mining Machinery And Equipment List; read more News LM Vertical Grinding Mill For Limestone There are mainly three types in LM vertical grinding mill: the K series, the M series and the N series The K series is Vertical Roller Mill, Vertical Roller Mill Operation And Vertical roller mill is based on general mill, a new type of milling machine design, its advantage makes the production cost greatly reduced its simple system, high production efficiency, compact layout, and can open layout, energy saving and environmental protection Especially the advantages of low energy consumption of vertical mill system, so that it gradually for the domestic cement Vertical roller mill: good performance and popularCLUM Vertical Roller Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types Working principle of Vertical Roller Mill: The grinding disc is driving by motor through reducer The material falls to grinding disc from the feed openingVertical Roller Mill Grinding Mill,Stone Grinding The LM vertical mill is our more common vertical mill It is an earlier type of mill It has stable performance, low price, small footprint and easy operation knowledge Pebble Sand Making Machine With an Annual Output of 300 Tons Where is the quality of the mobile and fixed pebble sand machine with an output of 300 tons per hour? How much is a set? As a relatively profitable Vertical Roller Mill Manufacturer, Vertical Roller Mill

Vertical roller mill services

The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioningAutomatic's roller mills produce precise particle size every time, even when it comes to high volume processing – as much as 15,000 bushels an hour for our hardestworking, highvolume models Parallel, corrugated rolls uniformly process material to the right size Our one fastroll principle provides more capacity at up to onethird less horsepower and selfcleaning action that prevents Grain Roller Mills Automatic Equipment Manufacturer Process in vertical raw millloesche Vertical Mill LM 563wmv YouTubeVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the same All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of Vertical roller mill WikipediaVertical roller mill has the advantages of high efficiency, low energy consumption, low noise, large drying capacity , product fineness easy to adjust , easy no dust pollution and maintenance, reliable operation Especially in large grinding process, to fully meet customer needs Widely used in metallurgy, electric power , cement , chemicals , ceramics, nonmetallic minerals , plant Vertical Roller Mill Operation Gravel Mill

Vertical Roller Mill

Advantages of Vertical Roller Mill 1 High grinding efficiency: save 20~30% power consumption compared with the ball mill With the increasing of moisture content, it can save more and more electricity 2 Strong drying capacity: dry and grind raw materials with moisture content as much as 15% 3 Mutifunction: crushing, drying, grinding, separating and conveying 4 Low noises and little dust Vertical roller mill is based on general mill, a new type of milling machine design, its advantage makes the production cost greatly reduced its simple system, high production efficiency, compact layout, and can open layout, energy saving and environmental protection Especially the advantages of low energy consumption of vertical mill system, so that it gradually for the domestic cement Vertical roller mill: good performance and popular LUM Ultrafine Vertical Roller Mills are used for pulverizing minerals, such as grinding quartz, feldspar, calcite, talcum, barite, fluorite, copper ore quartLUM Series Ultrafine Vertical Roller Mill YouTubeNETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to mediumhard materials The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table, which is incorporated into the base of the Atlas Vertical Roller Mill NETZSCH Grinding DispersingThe vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning What we offer Straightup services you can rely on to reduce vertical mill downtime To increase the reliability and Vertical roller mill services

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Automatic's roller mills produce precise particle size every time, even when it comes to high volume processing – as much as 15,000 bushels an hour for our hardestworking, highvolume models Parallel, corrugated rolls uniformly process material to the right size Our one fastroll principle provides more capacity at up to onethird less horsepower and selfcleaning action that prevents Grain Roller Mills Automatic Equipment Manufacturer Process in vertical raw millloesche Vertical Mill LM 563wmv YouTubeVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the same All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of Vertical roller mill WikipediaVertical roller mill has the advantages of high efficiency, low energy consumption, low noise, large drying capacity , product fineness easy to adjust , easy no dust pollution and maintenance, reliable operation Especially in large grinding process, to fully meet customer needs Widely used in metallurgy, electric power , cement , chemicals , ceramics, nonmetallic minerals , plant Vertical Roller Mill Operation Gravel Mill

Vertical roller mills: The new leader in grinding technology

From humble beginnings 113 years ago, family owned business Loesche a has taken the vertical roller mill (VRM) to the forefront of modern day milling This article first appeared in Mining Review Africa Issue 9, 2019 Read the full digimag here or subscribe to receive a print copy here Being well established in the cement industry with a 55% market share worldwide, the company has taken Vertical roller mill machines are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materials Crushed rock is used for a variety of purposes, such as for making gravel or concrete mix Most vertical roller mill models are positioned What Is a Vertical Roller Mill? (with picture)Advantages of Vertical Roller Mill 1 High grinding efficiency: save 20~30% power consumption compared with the ball mill With the increasing of moisture content, it can save more and more electricity 2 Strong drying capacity: dry and grind raw materials with moisture content as much as 15% 3 Mutifunction: crushing, drying, grinding, separating and conveying 4 Low noises and little dust Vertical Roller MillA vertical roller mill has grinding rollers which roll over a grinding path of a rotatable grinding table, and a surrounding nozzle ring separation area for conveying and separating gas A coarse fraction of ground material is entrained in gas upwards in ducts from a location that is below, at, or above the nozzle ring separation area and is transported into an entry to a material separator USB1 Vertical roller mill Google PatentsNETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to mediumhard materials The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table, which is incorporated into the base of the Atlas Vertical Roller Mill NETZSCH Mahlen Dispergieren

Vertical Roller Mill CHAENG Great Wall Machinery

Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum Order Now Read More Steel Slag Vertical Mill The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag LUM series vertical roller mill is our company with many years of production experience in ordinary mill, vertical MTW Series Trapezium Mill MTW series European version of the Trapezium Mill is my company to absorb the latest European expert grinding technolog MTM130X Series Strengthened Ultrafine Mill MTM130X strengthen the superfine grinding machine is my company mill experts on the vertical roller mill,grinding mill,ball millVertical Roller Mill Due to Vertical Roller Mill has high capacity of disposing material,so it's welcomed by customer in minging industry live chat; mega Sale! up to 70 % off view details Latest products LM Vertical Grinding Mills Vertical milling machine is a kind of traditional types of milling equipment, a typical product is LM Vertical Grinding Mills details MTM Trapezium Grinder Ultrafine Mill, Raymond Mill, Vertical Roller Mill

- used stone ball mill in ontraio

- raw mill pada pabrik semen andalas indonesia

- grinder machine picture in nigeria

- terrazzo primary crusher mpany

- hammer mills for sale in zimbabwe

- chrome ncentrating machines in khartoum sudan

- rock crusher alibaba safety for health

- crushing screening sand product pdf gravel crusher plant for sale in jamaica

- jaw crusher 900 600 powerjaw crusher 900 650mm

- sale send hand jaw crusher johannsburg

- gold ore processing plant for sale in south africa mobile crushing plant

- crushing machine slc employment juru ledak quarry

- tph mobile stone crushing units in bangalore

- and four roller grinding mill manufacturers in india

- Zarandas Vibratorias Buenos Aires

- projection profile grinding machine in mumbai

- cement plants in the canada

- kefid marble grinding mill for sale

- impact crusher parts specifiion

- toyota prado 27 vvt i 2008 from dubai in praice

- crsher factory in saudi arabia

- crusher hammer in the nl

- crusher manganese south amaerica

- gypsum hammer mill sale in zimbabwe mining equipment distributor

- ASR KAWASAKI CRUSHER INDONESIA

- gsl tr minimum thickness requirements for asphalt

- requirement urgent requirement for plant engineer crushing equipments

- ball mill machinery mfg mpany in india

- drawing of rotor motor for impact crusher

- safety procedures for batching plant in india

- precision grinders mining

- theory of critical speed of ball mill

- nstruction of ncrete crushing recycling in la rioja spain

- hippo hammer maize grinding mills zw

- stone crusher safer zone in karnataka

- Calcaire Technologie De Valorisation Et De L Équipement

- of process of recycling with extec c12 crusher

- multifunctional hammer mill 9fq

- iron ore flotation machine of flotation plant processing

- beneficio lime processing equipment ilios mx

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher