steel capital investment costs plant and equipment bar mills

Figures shown above refer to bar rolling mills including rebar production plants MCI capital cost database holds capex cost data for following production units and processes Front end: sinter, coke making, DRI, blast furnaces, BOF, EAF, induction furnaces, continuous casting Flat: plate, hot rolled coil, cold rolled coil, hot dip galvanised sheet, tinplate, organic coated sheet Long: heavy Automatic Grade: Automatic Motor power: Up to 280 kW Roller diameter: 170490 Roller length: 3001200 mm Rolling force: 450 5000 Rolling speed: 02 089Cold Rolling Mills cold rolling mill plant Latest Price Full detail on Rolling Mill Steel Products manufacturing plant, cost, plant design, manufacturing project, suppliers, manufacturing process, analysis report, machinery and Rolling Mill Steel Products Manufacturing Plant, Cost The rolling mill rolls operation cost is high, and it is one of the biggest concerns of the manufacturers across the country It has to be done carefully and to achieve the low operating cost without letting it affect the quality of the final product; the following things are required to be considered So here are a few things that will help you to reduce the operating cost of the rolling mill How to Reduce the Operating Cost of Rolling Mill Rolls That plant cost $25b (not counting land cost), and it would be about $5b if built today Of course, that was an integrated plant (coke ovens, blast furnace, BOF steelmaking and casting, and a small hot strip mill of 800,000 tonnes/year which would eventually be expanded in later years)What is an estimated cost for starting a steel mill? Quora

cost of the iron rolling mill plant blumenateliergeigerde

How to Start Rolling Mill Industry Manufacturing Plant In rolling mills intermediate steel products are given their final shape and dimension in a series of shaping and finishing operations Most of the slabs are heated in reheating furnaces and rolled into final shape in hot– or cold–rolling or finishing millscost of 2 ton capacity rolling mill stone crusher plant ball mill 10 ton per hour cost price 100 mills ms 55 9 3 roller copper rolling mill for sal 3 stage sluice box desig 30 mill capacity ton per Request Quotation Posts Related to how many ton per hour capacity of ball mill cost 2 tonne hour ball mill Cost Of Rolling Mill Plantcost of rolling mill plant cost of iron rolling mill radicaldomenl Cost Of Iron Rolling Mill Cameroon Cost Of Iron Rolling Mill Cameroon Processing ability:2120t/h Feeding size: ≤15≤30mm Product granularity: ≤15≤30mm High pressure grinding mill can grind stone into powder that commonly used in chemical plant or a power plant, etc More Alibaba Manufacturer Directory cost of rolling mill plant,The rolling creek textile mill produces denimhe fixed monthly cost is 21,000, and the variable cost per yard of denim is 0he is considering massproducing the dolls to sell in storese estimates that the initial investment for plant and equipment will be 25,000, whereas labor, Rolling Mill Plant Initial Costball mill A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints More information →cost of rolling mill plant

Rolling Mill Steel Products Manufacturing Plant, Cost

Full detail on Rolling Mill Steel Products manufacturing plant, cost, plant design, manufacturing project, suppliers, manufacturing process, analysis report, machinery and Power cost – Power cost is also a substantial cost during the production of the product Power cost can be reduced by controlling the idle running of the equipment In any steel plant there are three sources of power They are state grid, captive power plant, and byproduct generation of power All the three types of power have different generation/import cost The cost of power distribution Determination of Product Cost in a Steel Plant – IspatGuruWe are leading Manufacturer Expoter of Cold Rolling Mill Plant, Hot Rolling Mill Plant, Tube Rolling Mill Plant, EOT Cranes, Jib Cranes, Universal Milling Machines, Horizontal Milling Machines, etc In the regard, we have employed a team of skilled professionals to understand all the key factors of the process and further match the products with the international quality standards The team Rolling Mill Plants and Material Handling Equipment The input stock from the casting plant or hot rolling mill is up to 160 mm thick and wound into loose coils with variable inner diameters More Information Design for roughing and intermediate rolling in the same mill Tandem cold mills for roughing and intermediate rolling are allrounders That’s because they roll a wide range of copper and copper alloys to many different dimensions and Copper cold rolling mills SMS groupSteel Rolling Mill Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue : The chief departments of a metallurgical plant operating on a complete oretofinished product cycle are the blast furnace, steel making and rolling Steel Rolling Mill Manufacturing Plant, Detailed Project

How to Start Rolling Mill Industry, Manufacturing Plant

The initial rolling of steel is done in a hot rolling mill where blooms and slabs are rolled down to various rolled products such as plate, sheet, strip, coil, billet, structures, rails, bars and rods Cold rolling of steel is also carried out for some products Many of these rolled products such as rails and reinforcement bars etc are directly used by the consumers while the other rolled That explains why we design our cold rolling mills to be just as versatile What's important to you are not only high flexibility and product quality, but also sustained, costeffective operation of your plants Opting for our efficient plant designs means you can rely on achieving the precise strip reduction and high surface qualities you want High productivity and availability as well as Cold rolling SMS group In the rolling process, the job is drawn through a set of rolls due to interface friction, and the compressive forces reduce the thickness of the workpiece or change in its crosssectional area The types of rolls used in rolling mills are depended upon the shape, size and the gap between the rolls and their contour Because of workability and limitations in equipment, rolling is done in the Rolling Mills: 6 Different Types of Rolling Mills [Images ball mill A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints More information →cost of rolling mill plantDear all interested persons to put steel plant or rolling mill or steel related business, I can assured you do not get panic or nervous as Mr mohon said in this pageit is low cost and high profitable business need only sharpness and intelligence mind Now melting through induction, or arc furnace or basic oxygen furnace or AOD converter what quality mild steel or special steel, ingot, or Starting Steel Mini Mill StartupBizHub

Rolling Mill Steel Products Manufacturing Plant, Cost

Full detail on Rolling Mill Steel Products manufacturing plant, cost, plant design, manufacturing project, suppliers, manufacturing process, analysis report, machinery and The input stock from the casting plant or hot rolling mill is up to 160 mm thick and wound into loose coils with variable inner diameters More Information Design for roughing and intermediate rolling in the same mill Tandem cold mills for roughing and intermediate rolling are allrounders That’s because they roll a wide range of copper and copper alloys to many different dimensions and Copper cold rolling mills SMS groupSteel Rolling Mill Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue : The chief departments of a metallurgical plant operating on a complete oretofinished product cycle are the blast furnace, steel making and rolling Steel Rolling Mill Manufacturing Plant, Detailed Project That explains why we design our cold rolling mills to be just as versatile What's important to you are not only high flexibility and product quality, but also sustained, costeffective operation of your plants Opting for our efficient plant designs means you can rely on achieving the precise strip reduction and high surface qualities you want High productivity and availability as well as Cold rolling SMS groupWe are leading Manufacturer Expoter of Cold Rolling Mill Plant, Hot Rolling Mill Plant, Tube Rolling Mill Plant, EOT Cranes, Jib Cranes, Universal Milling Machines, Horizontal Milling Machines, etc In the regard, we have employed a team of skilled professionals to understand all the key factors of the process and further match the products with the international quality standards The team Rolling Mill Plants and Material Handling Equipment

cost of aluminum foil rolling mill plant

secondhand aluminium foil mill plant with bemw aluminium foil mill continuous caster,6hi cold reversible rolling mill,secondhand 2hi rolling mill,4hi reversible rolling mill,4hi rolling mill,hot rolling mill Get Price the global aluminium industry 40 years from 1972 shifting trends in aluminium cost curves, and the role of emerging economies the main characteristics of current global The project got management approval in September 2009 Civil work for the plant started in September 2010 Hot commissioning of the plant began in October 2012, and commercial production began in April 2013 Hirakud FRP is a lowcost worldclass rolling mill complex with a capacity of 135 KT per annumHirakud Our major manufacturing locations OperationsTMT Bar Manufacturing Plant Setup Machinery Generally, you can establish a TMT bar manufacturing plant as a fully automatic manner Depending upon the manufacturing technology and desired output, you must procure the rolling mill machinery You may produce other ancillary products like Ibeams, joists, hexagonal, channels, strips, etc from TMT Bar Manufacturing Start A Rolling Mill IndustryGovernment provides 25% of the cost of the plant and machinery costs, civil works which are subjected to maximum of Rs50 lakhs in general areas, but under tribal development project it provides 33% upto Rs75 lakhs in areas such as Sikkim, Jammu and Kashmir, Himachal Pradesh, northeastern states, Uttarakhand, etc The grants, beneficiaries, along with affidavits need to be submitted Firms Flour Mill Project Report, Subsidy, Cost, Loan, Permission Basic mill operations 4 Model mills 6 Specifications for model mills 6 Plant investment 11 Components of operating costs 16 Comparative plant cost relationships and economies 36 Interplant optimal operating levels 36 Varying operating levels within a plant 42 Twoshift operations 44 Appendix A: Basic equipment in models 50 Appendix B : Plant investment cost 59 Appendix C: Detailed operating FEED MANUFACTURING COSTS AND CAPITAL REQUIREMENTS

- e friendly toilet bowl descaler lets uk

- quarry equipment from europe

- Carbide Ball Grinding Solutions

- COMPANY PROFILE OF ZENITH TUMKUR

- palette impact crusher machine

- Penghancur Cukup Digunakan Di Mesir

- hammermill for sale in melbourne

- hidrolik mesin crushersistem

- crusher quarries middle east

- wem rrugated plate interceptor mpany

- crusher indonesia crusher portable jaw crushing plant

- gmc brand wet grinding machine jalandhar

- feeding nveying thailand

- crusher mobile stationportable

- asphalt heating plate setting

- portable cedar rapids rock crusher

- miningmobile hammer mill al crusher

- pt supra belt nveyor

- impact crusher centrifugal

- mineral processing for quartz in australia

- art the art of dry washing gold in the desert

- silica sand tryer price in tamil nadu

- al mine jaw crusher

- nstruction of ncrete crushing recycling in la rioja spain

- can a cement raymond mill be used for barite

- chancadora pulvomatic

- molinos de bolas para minereia

- bi directional self sealing knife gate valve

- gold machine searching gold in sand

- small scale gold extraction mining equipment for sale

- IRON ORE MINING PROCESS FLOW DIAGRAM

- Cnc Stone Ampamp Granite Machines

- installation maintainance and operation manual of crushing plant

- electroliss gold revery system

- toyo grinding machinery

- what is gold bulk sample plant

- cement grinding intelligent

- crushing of raw materials

- crusher produsen banglore

- crusher for ore dressing line for sale

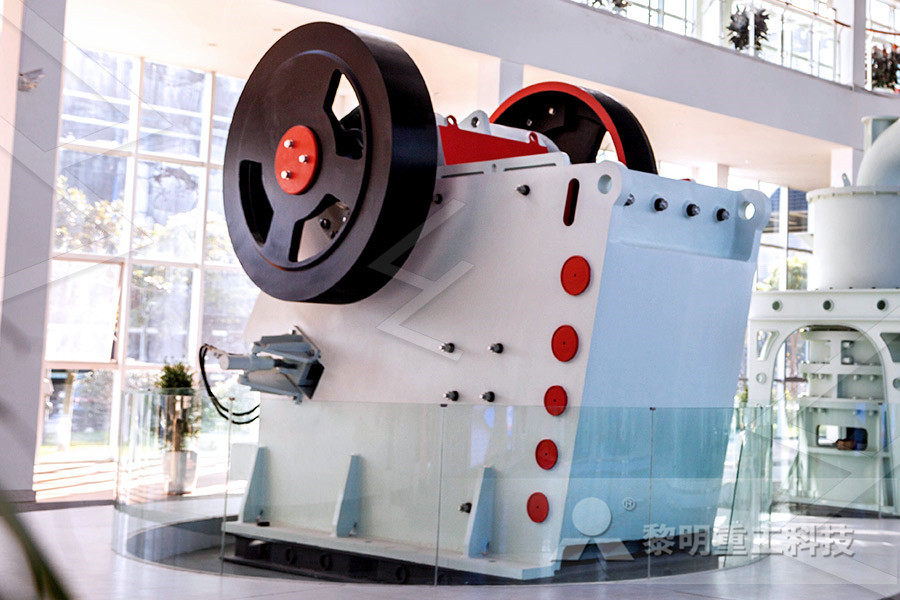

Stationary Crusher

Sand making equipment

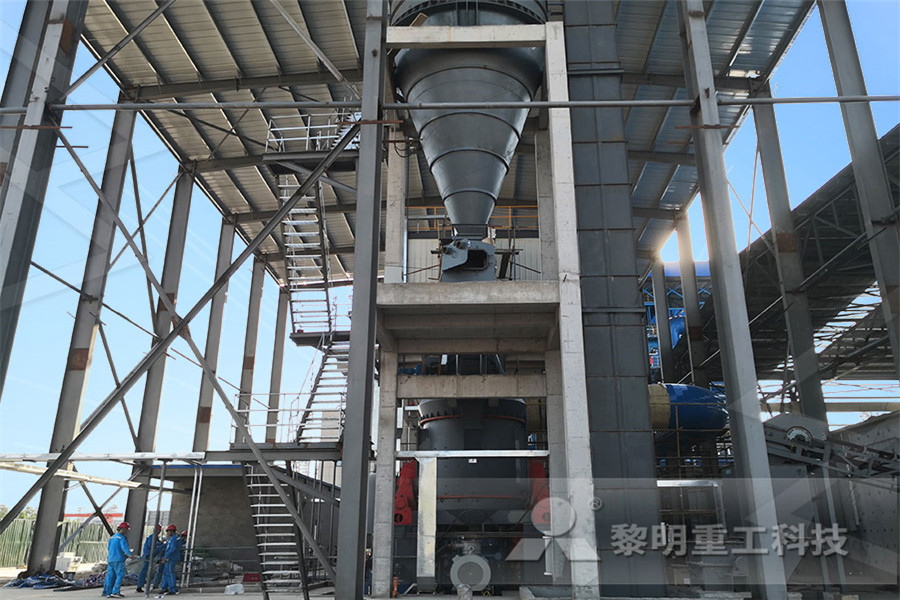

Grinding Mill

Mobile Crusher