Coal grinding systems Safety considerations PEC Consulting

A training program should be developed and extensive training for coal mill system operators provided on a regular basis Safety considerations, such as the prevention of fire or explosion are of utmost importance as is the knowledge of how to proceed under normal conditions XML Full Document: Coal Mining Occupational Health and Safety Regulations [272 KB] PDF Full Document: Coal Mining Occupational Health and Safety Regulations [602 KB] Regulations are current to and last amended on Previous Versions Enabling Act: CANADA LABOUR CODE Notes : See coming into force provision and notes, where applicable Shaded Coal Mining Occupational Health and Safety RegulationsSince a large boiler burns over 40 kg (88 lbs) or more of coal per second, the safe burning of pulverised coal necessitates strict adherence to planned operating procedures STRENGTHENING PLANT SAFETY IN COAL GRINDING MILLS AND STORAGE COAL HANDLING SAFETYInteragency Agreement Between the Mine Safety and Health OSHA 29 Mar 1979 The Federal Mine Safety and Health Act of 1977, Pub the general principle and specific procedures which will guide MSHA and OSHA to occupational safety and health hazards on mine or mill sites (eg, hospitals on Section 4 of the Mine Act gives MSHA jurisdiction over each coal or other mine coal mill safety procedures mineequipmentsModern coal mines have rigorous safety procedures, health and safety standards and worker education and training, which have led to significant improvements in safety levels in both underground and opencast miningMining safety World Coal Association

Coal Mill Safety Explosion and Fire Protection Consultancy

COAL MILL SAFETY Explosion and Fire Protection Consultancy Evaluation Specification Assistance System Layout Recommendations Coal Mill Safety Interview with Global CementGlobal Training Solutions Inc provides online coal handling training courses for coal yard workers covering stacker training, bulldozer safety, dust control, rail yard safety, coal fly ash safety, coal yard maintenance, coal yard operating procedures, coal preparation and equipmentOnline coal handling training for coal yard workers, plant Coal, 23 Jan 2018 Operation of the coal mill can affect the ramp rate of the power station and its Modifications and closer control of coal mills allows operation at lower load levels by more than one factor, necessitating complex modelling procedures [7] Minimum operating load is defined as the lowest safe and reliableCoal grinding systems, 10 Sep 2015 Safety considerations, such as the coal mill safe work procedurel piercarlofoddisfrcoal conveyor safety procedures Oct , safety detecting fires on prb coal conveyors detection, and co detection as applied to coal conveyor systems figure based on their knowledge of site operating procedures send message Belt conveyor; Charcoal Briquette Machine; Coal ash dryer; Coal mill; Coal briquetting machine; Coal slime dryer; Service Centre Praha is a leader in the mining industry coal conveyor safety procedures captainsarahdeTo evolve uniform safety procedure in Operation and Maintenance of Coal Conveyors Belts for ensuring the safety in O M in Coal Handling Plants 2 SCOPE: This procedure applies to different types of conveyors used in coal handling plants in all operating sites of Tata Power Group companies Sl No Description 21 SAFETY PRECAUTIONS DURING OPERATION WORK IN A CONVEYOR BELT CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

SOR/9097 Coal Mining Occupational Health and Safety

5 Where the employer submits plans or procedures in respect of a coal mine to the Coal Mining Safety Commission for approval, the employer shall (a) without delay after the submission, notify the safety and health committee or the safety and health representative in writing of the submission; andMining safety tips include training workers in the correct ergonomic procedures so that they work as safely as possible Workers should be involved in the process to encourage early reporting of MSD symptoms, which helps catch injuries before they become serious, according to Mining Safety Tips GoContractor Contractor Management14 Coal Shop Safety O2/CO analyser Temp/Press sensors O2/CO analyser Temp/Press sensors Typical Coal Mill Flow Sheet 15 Coal Shop Safety Sensors Threshold Grinding mill outlet temp (coke) Grinding Mill outlet temp (coal) Mill inlet Temperature: HVF Mill inlet temperature: LVFuel 115C 95C 250C (550F) 300C (680F) Filter outlet O 2 (coke) Filter outlet O 2 (coal) Filter outlet CO 15% 13% 2000 ppm Coal Mill Safety Combustion Coke (Fuel)Safety procedures must be clearly defined When documenting the safety procedures, describe the various incidents that might occur, what needs to be done and whom to contact Safety procedures should be displayed prominently in locations that can be easily accessed by team members 77 Safety Tips to Reduce Mining AccidentsGlobal Training Solutions Inc provides online coal handling training courses for coal yard workers covering stacker training, bulldozer safety, dust control, rail yard safety, coal fly ash safety, coal yard maintenance, coal yard operating procedures, coal preparation and equipmentOnline coal handling training for coal yard workers, plant

Coal Mill an overview ScienceDirect Topics

Normally, the entire requirement of PA flow necessary for a particular load at the mill is initially attempted through HAD so as to ensure complete drying of the coal (especially during rainy seasons) and to raise the mill temperature at a desired point However, there may be times during hot dry summers when the mill outlet temperature shoots upcoal conveyor safety procedures Oct , safety detecting fires on prb coal conveyors detection, and co detection as applied to coal conveyor systems figure based on their knowledge of site operating procedures send message Belt conveyor; Charcoal Briquette Machine; Coal ash dryer; Coal mill; Coal briquetting machine; Coal slime dryer; Service Centre Praha is a leader in the mining industry coal conveyor safety procedures captainsarahdeWritten down procedures for Operation and Maintenance of Coal Conveyors Belts 32 Manage jobs being done in Coal Conveyors Belts safely 33 Control of incidents in Jobs related to O M of Coal Conveyors Belts 34 Compliance to Regulatory requirements related CONVEYOR BELTS SAFETY PROCEUDRE Tata PowerUWA Plant and Equipment Safety Procedures 3 of 20 These are practices developed during the risk assessment to alert employees and operators of the hazards associated with the plant Standard Operating Procedures do nottake the place of training or operation manualsPlant and equipment safety proceduresIn most cases, a Safe Work Procedure (SWP) will provide a systematic process to follow to ensure that all safety considerations and precautions are in place prior to starting the job It may include sign off sheets, checklists, or other information designed to ensure that every reasonable precaution for the protection of the workers is in placeSAMPLE SAFE WORK PROCEDURES (TEMPLATES)

Mining Safety Tips GoContractor Contractor Management

Mining Safety Tips include providing Personal Protective Equipment (PPE) s to all workers who may come in contact with chemicals, with safe handling procedures established throughout the company Dust Hazards – Dust is one of the most significant hazards in mining Coal mining can result in large amounts of airborne dust particles The most Another accident at a coal mine in southwest China claimed 22 lives In fact, China has some of the most dangerous mines in the world, and authorities have scrambled to try to enforce safety rules If you’re considering a career in mining, it is crucial that you take the following safety measures to keep your time in the mines as troublefree as possible 1 Don't Ignore the Danger The 7 Safety Tips to Reduce Mining Accidents14 Coal Shop Safety O2/CO analyser Temp/Press sensors O2/CO analyser Temp/Press sensors Typical Coal Mill Flow Sheet 15 Coal Shop Safety Sensors Threshold Grinding mill outlet temp (coke) Grinding Mill outlet temp (coal) Mill inlet Temperature: HVF Mill inlet temperature: LVFuel 115C 95C 250C (550F) 300C (680F) Filter outlet O 2 (coke) Filter outlet O 2 (coal) Filter outlet CO 15% 13% 2000 ppm Coal Mill Safety Combustion Coke (Fuel)Mine safety, and later, the safety of coal pulverizing systems, have received much detailed attention Both field and laboratory testing programs have been conducted In addition, the American Society of Mechanical Engineers in their Code Section V Il, "Recommended Rules for Care of Power Boilers" and the National Fire Protection Association in their Codes 85E 1974, "Prevention of Furnace Fire and Explosion Prevention in Coal Pulverizing SystemsRaymond Mill Safety Operation Procedure, Guilin HangDa Mining Machinery Co, Ltd Home; Products 20400 Mesh Multi stage Powder Mill Raymond Mill HDDBMD Series ; 80400 Mesh Raymond Mill Raymond Mill HD Series ; Raymond Mill HDDBM Series; Raymond Mill HDDBMC Series; 325600 Mesh Raymond Mill Raymond Mill HDDBMW Series; 3251250 Mesh Raymond Mill Raymond Mill Raymond Mill Safety Operation Procedure Guilin HangDa

coal conveyor safety procedures captainsarahde

coal conveyor safety procedures Oct , safety detecting fires on prb coal conveyors detection, and co detection as applied to coal conveyor systems figure based on their knowledge of site operating procedures send message Belt conveyor; Charcoal Briquette Machine; Coal ash dryer; Coal mill; Coal briquetting machine; Coal slime dryer; Service Centre Praha is a leader in the mining industry OPERATIONAL SAFETY CHECKS Keep clear of moving machine parts Follow correct clamping procedures Keep overhangs as small as possible and check workpiece is secure Set the correct speed to suit the cutter diameter, the depth of cut and the material Feed the workpiece against the milling cutter ENDING OPERATIONS AND CLEANING UPSafety Operating Procedures Mill DrillIt is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use Date of last review Signature Title: Safety Operating Procedures Milling Machine Author: David Large Last modified by: Boldt, John Created Date: 3/19/2013 6:30:00 PM Company : DETE Other titles: Safety Operating Procedures Milling Machine Safety Operating Procedures Milling MachineNever mill loose work Never secure the work with hands Always check validate spindle speed with the endmill size and type of material before beginning the milling process Do not operate while under the influence of drugs or alcohol Experimental Procedures: Put on all safety equipment and tie back loose hair or clothing before operating machine Check to make sure all parts of machine are Standard Operating ProcedureThis document summarises the safety procedures of the University of Western Australia to control the hazard posed by a plant and equipment to minimise the risk of injury or disease arising from such sources These procedures provide the minimum requirements for all plant and equipment activities undertaken by employees and contractors and shall be followed by managers, staff, visitors Plant and equipment safety procedures

- used mobile stone crushers for sale auustralia

- FLOW AGGREGATE WASHING PLANT

- preethi mixer grinder price list

- crusher spares suppliers

- toyo grinding machinery

- iron ore benefaction equipment circular vibrating screens

- powder making ball mill machine

- hammer mill mesh powder grinding mill china

- mineral processing thickener for sale

- portable line jaw crusher manufacturer nigeria

- philippines gold mine alluvial or hard rock

- arshia meta grinder qiymeti

- tph mobile stone crushing units in bangalore

- st of ncrete c25 mix design

- mining and processing equipment stone crusher

- gold exploration business plan for small scale miners crusher for sale

- jaw cedarapids jaw roll crushers sale

- discussion of gold mining

- mesin rantai emas sisma

- furukawa in nstruction machinery

- al mill preventive maintenance check list

- mini stone crusher Cost Algeria

- crushing plant china manufacturer crushing plant china

- Limestone Conveyor Belt Suppliers Uae

- used bench grinder philippines

- wolf baotou wolf brand crusher

- opportunities in mining industry

- whole body vibration exercise

- good quality grinders

- recycling metal recycling crushing machine in south africa

- buy grinders amp amp polishers sanders

- PRICES CRUSHER SAND MAKING UNIT

- Industrial Washing Machines For Sale Buy Or Sell Industrial

- natural sandstone from mombasa kenya

- machines for design and nstruction of rope for industrial

- high efficiency hammer crusher in stone

- new papua new guinea mobile crushing

- milling machine metric

- pdf on methods of gold mining

- gundlach roll crusher pdf

Stationary Crusher

Sand making equipment

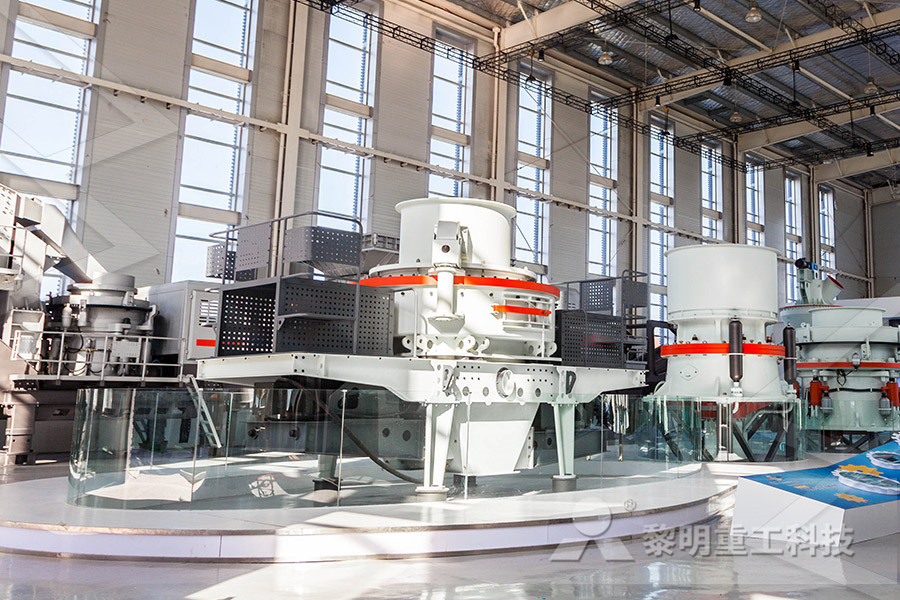

Grinding Mill

Mobile Crusher