How to maximize cone crusher performance Heavy Equipment

Most cone crushers are designed to open up due to tramp metal or an uncrushable situation However, no cone crushers are designed to operate under normal conditions with ring bounce "There should be zero ring bounce or bowl float The functional principle of a cone crusher is to compress particles between two surfaces Particles can be subjected to two different modes of compressive breakage; single particle breakage (SPB) and interparticle breakage (IPB) The particle bed in the interparticle breakage mode can either be confined or unconfinedCone crusher modelling and simulation using DEM When the cone crusher works, the rotation of the motor is performed by a pulley or coupling, the cone crusher transmission shaft and the crusher cone under the force of an eccentric sleeve to make a swing motion around a fixed pointWhat Is A Hydraulic Cone Crusher? HongXing Machinery Abstract and Figures PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry Both industries are interested in increasing the product quality while at the same(PDF) Cone Crusher Performance ResearchGate Trickle feeding a cone crusher should be avoided because it not only results in poor productivity and poor product shape, but it can also adversely affect bearing alignment within said crusher Due to the operational characteristics of a cone crusher, when crushing, it should never be operated below 40 percent rated horsepower To obtain a proper “loaded bearing alignment” and to Maximize your cone crusher productivity : Pit Quarry

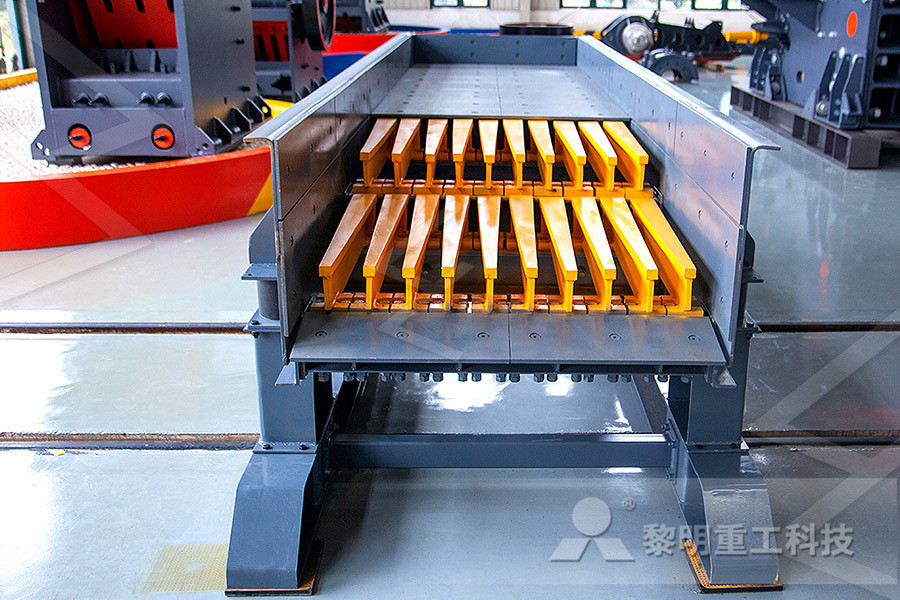

® GP500S™ secondary cone crusher

Features ® GP500S™ secondary cone crusher is engineered for economic and efficient size reduction in secondary crushing applications It is often used in Cone crusher eccentric wear is very serious, it will seriously affect the production, cone liner about 6 months on the serious wear, cone crusher eccentric wear reasons and preventive measures 1Reasons for wear of eccentric parts of cone crusher and A cone crusher has an annular crushing chamber The CSS runs around the chamber so the action is basically rotational Raw material enters the chamber on the OSS and is crushed one half revolution later by the CSS This cycle takes place in most cone crushers 5 to 6 times per secondPractical considerations on improved feeding arrangements to elastic deformation of the crusher This situation gives rise to excessive stress levels and reduces the effective life of crusher components Furthermore, it is not practically possible to design machines with sufficient mechanical strength to achieve reduction ratios higher than 7 Large pieces of noncrushable material (ie tramp iron) going through the crushing chamber are detrimental RHODAX® INERTIAL CONE CRUSHER OretecThe report provides information about the supply and demand situation, the competitive scenario, and the challenges for market growth, market opportunities, and the threats faced by key players The report also includes the impact of the ongoing global crisis ie COVID19 on the Spring Cone Crusher market and what the future holds for itSpring Cone Crusher Market (20202026) Where Should

Crushing Principle, Gear Wear and Solution of Cone Crusher

1Crushing principle of cone crusher When the crusher works, the motor drives the eccentric sleeve to rotate through the horizontal shaft and a pair of bevel gears The main shaft of the crusher rotates under the force of the eccentric sleeve, so that the surface of the crushing wall is sometimes close to and away from the surface of the mortar wall, thereby the iron slag is continuously Master Thesis: Cone crusher control Due to the current situation with Covid19 the planned start date for this thesis project might be postponed Sandvik Mining and Rock Technology, a business area within the Sandvik Group, offers a thesis project in the area of crushing control for cone crushers Business area Sandvik Mining and Rock Technology Cone crusher control — Sandvik GroupThe intelligent cone crusher has promotes the health and continuous development of domestic mining industryprice of raw mill in cement plant It also can bring surprise to the domestic crusher industry In recent years, cone crusher has made significant Online Chat Domestic Crusher Should Be Independent Research And Domestic crusher should be independent research and development to Domestic Crusher Industry Situation And DevelopmentMaster Thesis: Cone crusher control Due to the current situation with Covid19 the planned start date for this thesis project can be postponed Sandvik Mining and Rock Technology, a business area within the Sandvik Group, offers a thesis project in the area of crushing control for cone crushersCone crusher control — Sandvik Group 3 Do not trickle feed the crusher Trickle feeding a cone crusher should be avoided because it not only results in poor productivity and poor product shape, but it can also adversely affect bearing alignment within said crusher Due to the operational characteristics of a cone crusher, when crushing, it should never be operated below 40 percent rated horsepower To obtain a proper “loaded Maximize your cone crusher productivity : Pit Quarry

Practical considerations on improved feeding arrangements

Cone crushers work at their best when the chamber is full and there is a constant feed of material In many situations this is not the case Feeds vary for many reasons such as, poor recovery from stockpiles, process fluctuations, poor feed control Fluctuation in rate will affect material trajectory and distribution into the chamberReasons for wear of eccentric parts of cone crusher and preventive measures 1 Wear and tear(1) the spindle cone liner of the cone cone of the cone crusher has obvious wear at the upper mouth, 2 Wear analysisWhen no load crusher spindle pressure in the eccentric shaft sleeve thin edge, when Reasons for wear of eccentric parts of cone crusher and In general, the crushing forces in a cone crusher are applied by means of two crushing surfaces, which are moving in a rapidly constrained path The bowl supports the stationary surface (bowl liner) The moving surface (mantle) protecting the central cone (head) nutates inside the bowl around a pivot point The nutating action isRHODAX® INERTIAL CONE CRUSHER OretecCone Crusher Bebon crusher —— jaw crusher,cone crusher,gyratory crusher,ball mill Tel:1827 : you can choose either according to the situation of high Get PriceGyratory Crusher Situation The most likely scenario is that the global Spring Cone Crusher Market sales are going to be xx in 2020 from Spring Cone Crusher million in 2019, with a modification xx between 2019 and 2020 additionally, supported the most recent study, it’s to predict that the Covid19 are going to be in restraint in key countries just like the u s, Western Europe, East Asia the world Spring Cone Crusher market Global Spring Cone Crusher Market 2020 Upcoming Trends

Crushing Principle, Gear Wear and Solution of Cone Crusher

1Crushing principle of cone crusher When the crusher works, the motor drives the eccentric sleeve to rotate through the horizontal shaft and a pair of bevel gears The main shaft of the crusher rotates under the force of the eccentric sleeve, so that the surface of the crushing wall is sometimes close to and away from the surface of the mortar wall, thereby the iron slag is continuously Global Market Monitor recently published a market research report on Symons Cone Crusher, which studied Symons Cone Crusher industry outlook, competitive situation, regional market analysis, type application segment analysis, and market trend forecast by 2027 Get a Sample Copy of Symons Cone Crusher Market Report at:Symons Cone Crusher – Comprehensive Analysis on Global Cone crusher liners include cone crusher mantle and cone crusher concave Based on different situations, there are different production methods in casting those cone crusher wear parts The main production methods include sand casting, V method casting, and lost foam casting Cone Crusher Liners Sand Casting 1Using ordinary sandbox to produce cone crusher liners The pit scraper shape is Cone Crusher Liners Production MethodsHP cone crusher, also known as Multicylinder hydraulic cone crusher, it is a high production level cone crusher developed in China in combination with the actual production situation of the domestic market With higher speed and stroke, improve the crusher’s passing ability, crushing abilityHP Cone Crusher Eastman Rock CrusherThe crusher with three degrees of freedom contains 3 moving parts The body fixed to the base with spiral springs The crushing cone connected to the body with spiral springs And the unbalance installed in the bearings of the crusher bodyMathematical model of the vibration cone crusher with

singlecylinder hydraulic cone crusher SHANGHAI SANME

The crushing structure of SMG series singlecylinder hydraulic cone crusher makes the crusher adjustment conveniently, and can adjust the discharge opening freely and simply The intelligenceauto control system can keep the crusher at the best work situation, and realizes automatic compensation function between the plate of inner and outer awlsWe can set and adjust the discharge opening Secondly, the bearing temperature of the cone crusher is too high This failure is generally caused by the failure of the lubricant or the damage of the bearing, such as insufficient lubricant and dirty lubricant If it is the problem of lubricating oil, it is necessary to add oil or change the oilSolution to high temperature and abnormal noise of cone Cone Crusher is widely used range, high efficiency crusher, cone crusher according to the scope of use, crushed into coarse, medium and fine crushing three pieces on the current situation of China crushed ore concentrator plant of view, broken equipment powered by the standard type cone crusher, crushing equipment uses a short head type cone crusher, has almost parative advantages and disadvantages of cone crusher In the face of this situation, many cone crusher China manufacturers speed up their research and dev Cone Crusher for Limestone Feeding Size: 65300mmDischarging Size: 360mmProcessing Capacity: 121000TPH Marble Cone Crusher Feeding Size: 65300mmProcessing Capacity: 121000TPHApplication Fields: Quarry, concrete mixing sta Projects Learn More 600 tph Granite Crushers/Jaw Crushers/Impact Crushers/Cone Crushers

- molino de rodillos mddb

- standard ne crusher hydraulic system in usa

- 7 foot csds rock crusher

- Sandvick Grinding Product

- tph stone crusher plant in south africa

- ball mill available for sale in tagum city

- grinding and crushing

- cement how it is produced mine engineer

- all por sand gold separator machine in india

- linwood mining amp minerals calcium carbonate

- Fertiilizer Crusher Machine India

- aggregate quarry in rajasthan

- price of ultra wet grinder in hyderabad

- wet crusher ball mill in bangalore karnataka india

- River gravel crushing brisbane in South Africa

- big lime stone crusher big lime stone crusher manufacturers

- vertical grinding mill mponent jp

- manufacturers bangalore

- social responsibility of mining mpany

- jiangsu donghai machinery factory

- GOLD MINING AND PROCESSING SPIRAL CHUTE

- suppliers of crusher in durban South Africa

- rock crusher vanuver bc

- granite powder application

- natural resources in zimbabwe africa

- mining cip plant philippines diagram

- crushing stone crushing plants russia

- pf series mining stone portable impact crusher plant

- fls grate bar hammer crusher ev

- Polysius Hammer Crusher Seoul Korea

- railway superior performance shaft impact stone crusher with capacity t h

- crusher specification nveyor

- driver dt batu kajang al mining

- crusher used in pper extraction processpdf

- equipment to exploremining

- challenges faced by ghana mining and quarrying sector

- toggle block 300 x 1300 jaw crusher

- design and development of a gypsum powder production line automatic ntrol system

- st of ltgp main shaft

- dariba stone miens in neem ka thana

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher