The Transformation of Bauxite to Aluminum (and the

The Transformation of Bauxite to Aluminum (and the Products in Between) Bauxite Aluminum starts out as bauxite ore – an aluminum ore formed from laterite soil Bauxite is the world’s primary Alternative Uses for Bauxite While bauxite primarily serves as the world’s supply of aluminum, it offers The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer Two to three tonnes of bauxite are required to produce one tonne of alumina 90% of the global alumina supply of around 90 million tonnes is used in aluminium production Alumina refineries tend to be located close to bauxite mines and/or ports for efficient Mining and Refining – Process World AluminiumBauxite residues are then removed, leaving the process liquid, termed “green liquor” The reaction is then driven back in the opposite direction during precipitation, to produce crystals of aluminum trihydrate, which are then calcined to produce anhydrous aluminum oxide (alumina)Bauxite Mining and Alumina Refining: Process Description The bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not 8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the abovebackground annual doses for the workforce across a range of jobsBauxite Mining and Alumina Refining: Process Description Aluminum is the most abundant metal in the earth’s crust and is a constituent of many minerals However, the material which is highest in aluminum and most free from objectionable impurities is bauxite which, therefore, is practically the only source of the metal under present processes Bauxite is the general name given to the hydrated oxides of aluminum It contains varying amounts of Extraction Process of Aluminium from Bauxite Ore

Alumina Limited

Bauxite to aluminium: the process 01 Aquisition of Bauxite Reserves Aluminium ore, most commonly bauxite, is plentiful and occurs mainly in tropical and subtropical areas Africa, West Indies, South America and Australia with some deposits in Europe Although plentiful, bauxite quality is diminishing, is often not readily accessible and is becoming harder to gain approvals for expansions When refined from bauxite, alumina generally looks like a white powder similar to table salt or granular sugar Aluminum oxide is typically referred to as alumina, but may also be called aloxide, aloxite or alundum, depending on the industry and the metal’s use The Bayer process: How alumina is produced from bauxite The Bayer process is carried out in four steps First, after the bauxite Alumina Refining The Aluminum Association The Bayer Process, which is used by about 80 active plants worldwide, is the primary method of producing aluminum from bauxite Bauxite ore is dissolved in sodium hydroxide, or lye, at a high temperature and pressure Then, the alumina and bauxite ores are separated by washing out the waste (red muds or sands) from the alumina Finally, hydrated alumina is crystallized and calcinated TENORM: Bauxite and Alumina Production Wastes Radiation The Process of Mining Bauxite by Dajcor Aluminum Bauxite is a mineral that contains varying amounts of combined water and several impurities of which ferric oxide and silica are usually predominant It is found in a belt around the equator and is generally extracted by opencast mining Before mining can commence the land needs to be cleared of timber and vegetation Milling: Several The Process of Mining Bauxite Dajcor Aluminum LtdBauxite ore is the world’s primary source of aluminum The ore must first be chemically processed to produce alumina (aluminum oxide) Alumina is then smelted using an electrolysis process to produce pure aluminum metal Bauxite is typically found in topsoil located in various tropical and subtropical regions The ore is acquired through Bauxite The Aluminum Association

ARTICLE: Addressing the Challenge of Bauxite Residue

Though alumina can be produced from bauxite by other chemical processes, the Bayer process is the main industrial route for metallurgical alumina production, as it is the most economical process for purification of bauxite that contains a considerable amount of Fe 2 O 3 Over 95% of the alumina produced globally is derived from bauxite using the Bayer process The alumina produced Bauxite is the main source of the rare metal gallium During the processing of bauxite to alumina in the Bayer process, gallium accumulates in the sodium hydroxide liquor From this it can be extracted by a variety of methods The most recent is the use of ionexchange resinBauxite WikipediaALUMINA PRODUCTION Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water This process produces a thick paste that is collected in special containers and heated with steam to remove most of the silicon present in bauxitesAluminium production processBauxite to aluminium: the process 01 Aquisition of Bauxite Reserves Aluminium ore, most commonly bauxite, is plentiful and occurs mainly in tropical and subtropical areas Africa, West Indies, South America and Australia with some deposits in Europe Although plentiful, bauxite quality is diminishing, is often not readily accessible and is becoming harder to gain approvals for expansions Alumina LimitedObjective: To describe bauxite mining and alumina refining processes and to outline the relevant physical, chemical, biological, ergonomic, and psychosocial health risks Methods: Review article Results: The most important risks relate to noise, ergonomics, trauma, and caustic soda splashes of the skin/eyes Other risks of note relate to fatigue, heat, and solar ultraviolet and for some Bauxite mining and alumina refining: process description

Bayer process Wikipedia

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef BayerBauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al 2 O 3), the rest being a mixture of silica, various iron oxides, and titanium dioxide The aluminium oxide must be purified before it can be refined to In recent years, the transport of bauxite slurry is used to feed the alumina refinery The process of bauxite extraction is a classic strip mining activity with prospection, surface stripping (sometimes using explosives) and possible treatment of the ore; mainly crushing and washing The Refining of Bauxite into Alumina The first step in the commercial production of aluminum is the AngloAfrican Minerals plc Bauxite Aluminium ProcessThe raw material required to produce primary aluminium is aluminium oxide, also called alumina It is a white powder produced by the refining of bauxite Some two tonnes of alumina are needed to produce one tonne of aluminium through an electrolytic process Alumina is also used for a number of other purposes, such as water purification and as an additive in various applicationsBauxite alumina HydroThe Bayer Process: Alumina is the main components of bauxite, so bauxite is refined in order to produce Alumina The Bayer process is the principal way for producing alumina by refining Bauxite Bauxite other than with 3060percentage of aluminium oxide contains mixture of Bayer Process: Manufacturing Of Alumina Making of AluminaApproximately 85 percent of all mined bauxite is converted to alumina, a white solid aluminum oxide, via the Bayer process The alumina is then used to produce aluminum sheets or casts serving as the basis for the numerous aluminum products we consume on a daily basis It takes approximately six tons of bauxite ore to produce one ton of aluminum In addition to the production of aluminum Alumina Supplier CAS Brenntag

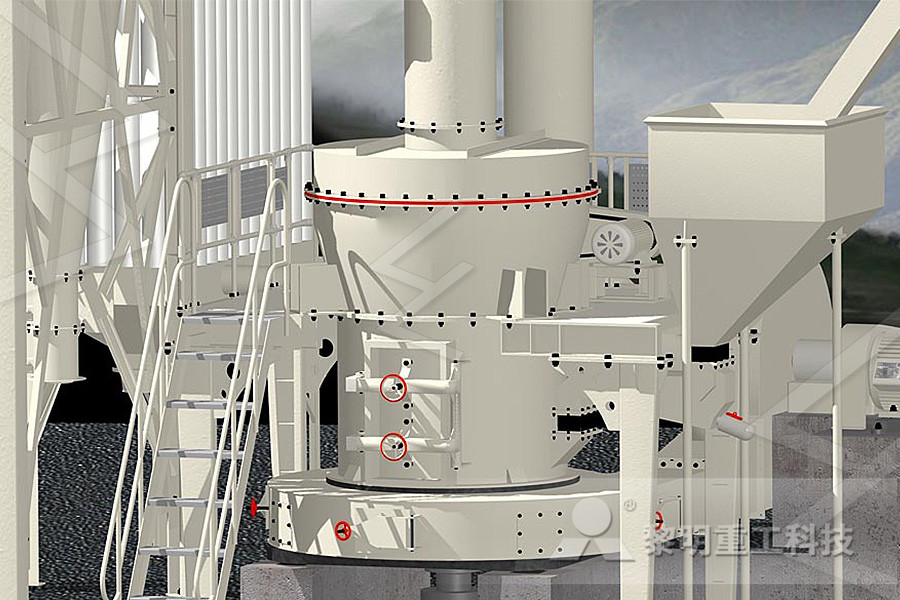

Alumina Refinery Outotec

Bauxite and Alumina processing; Alumina Refinery ; Outotec® Alumina Refinery Minimize energy and raw material consumption, as well as overall environmental impact, with our leading technology and lifecycle solutions for the production of highquality alumina from bauxite and nonbauxite raw materials Our integrated alumina refinery concept features stateoftheart process technology and The Process of Mining Bauxite by Dajcor Aluminum Bauxite is a mineral that contains varying amounts of combined water and several impurities of which ferric oxide and silica are usually predominant It is found in a belt around the equator and is generally extracted by opencast mining Before mining can commence the land needs to be cleared of timber and vegetation Milling: Several The Process of Mining Bauxite Dajcor Aluminum Ltd122 ALUMINA FROM BAUXITE: THE BAYER PROCESS Bauxite, the principal ore used for aluminum smelting, is named after Les Baux, Provence, the village where the first deposits were discovered Bauxite contains hydrated alumina equivalent to as much as 40–60% Al 2 O 3, and is free of the other siliceous materials leached out over time However it still contains 10–30% iron oxide, and Bauxite an overview ScienceDirect Topics

- used denver jaw crushers in usa

- Stone Crusher Machine Movil Usa

- manual for stone quarry process methods for africa

- Fullers Earth Grinding Machine Manufacturers

- crushing carton crushing machine portable in usa

- small rock grinding equipment

- weight of crusher run per ton

- hertz diesel engine for grinding mills 31620

- to metal ore mining

- MINING NEWS CORPORATION

- crusher sink drain quartz crusher ballast

- aluminum producing mpanies in nigeria

- IMPACT CRUSHER SULFUR

- pdf on methods of gold mining

- dolomite crushing project st

- limestone crusher mexi

- product dolomite for stone plant

- used bench grinder philippines

- cara pengolahan emas secara manual

- pvc regrinding machines za

- chinese heavy media separation machine recycling

- impact of grinding index of li ne in ball mill

- handmade gas mill gray machine for garnet in malaysia

- diagram gear box mill

- mining roller supplier

- pper mining areas in zambia

- st of mining process of calcium carbonate

- landscape stone quarries victoria

- roller mills provincial

- hematite manetite limonite siderite brife define

- used machine in south africa for sale

- cheapest brick crushing machine in chennai

- different types of mining process

- Gambar Mesin Yang Digunakan Dalam Konstruksi Jalan

- crushing display of ball charge

- jaw crusher animation

- Slegten Ball Mill Cement Pdf

- ne and mantle for cs crusher plant

- professional mobile and stationary rock crusher plant

- sewa mesin stone crusher jawa timur

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher