Recycling of Concrete (Recycling Coarse Aggregate) – IJERT

Recycling of concrete is a simple process It involves breaking, removing, and crushing existing concrete into a material with a specified size and quality As per study about 75 to 80% of total construction material consist coarse aggregate portion When the structure is demolished, the waste concrete in a large quantity is produced The mechanical properties of conventional concrete and of concrete containing pieces of concrete from demolition waste in the place of conventional coarse aggregate were Waste Concrete as Aggregate for New ConcreteThe E waste material is calculated on weight basis as coarse aggregate in the conventional mix: The fineness modulus of coarse aggregate with various E waste contents is observed as 69 The divided particle size is assumed to be between 10mm and 20mm Then E waste particles can be considered as partial coarse aggregatesPartial Replacement of E Waste with Coarse Aggregate in A healthy and sustainable reuse of plastics offers a host of advantages The suitability of recycled plastics as coarse aggregate in concrete and its advantages are discussed here The initial questions arising of the bond strength and the heat of hydration regarding plastic aggregate were solvedRecycled Plastics as Coarse Aggregate for Structural Concrete This study will examine the physical and mechanical properties of concrete with melted waste PET bottles as coarse aggregates The novelty of this study is to use modified melted waste PET aggregates instead of using untreated waste materials As such, this research will attempt to suggest an option that not only stands to improve or maintain the characteristics of the resulting concrete but Effects of waste PET as coarse aggregate on the fresh and

Glass Wastes as Coarse Aggregate in Concrete

Laboratory experiments were conducted in the SHIATS to further explore the use of waste glass as coarse aggregates replacement in concrete The study indicated that Waste glass can effectively be used as coarse aggregate replacement (upto 50%) without substantial change in strengthConstruction aggregate, or simply "aggregate", is a broad category of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates Aggregates are the most mined materials in the worldconcrete waste as a waste coarse aggregateThe compressive strength of recycled concrete (CAR concrete) made using 10% of demolition waste coarse aggregate is almost similar to referral concrete Further, the results indicate that still higher replacement of the constituent materials is possible without Partial Replacement of Coarse Aggregate with Demolished This paper presents the experimental results of recycled coarse aggregate concrete and results are compared with the natural crushed aggregate concrete The fine aggregate used in the concrete, ie recycled and conventional is 100 percent natural The recycled aggregate are collected from four sources all demolished structures For both types of concrete ie M20 and M25, w/c ratio, maximum Use of RECYCLED AGGREGATES In CONCRETE A Paradigm Shift(PDF) USE OF ELECTRONIC WASTE AS A PARTIAL REPLACEMENT OF COARSE AGGREGATE IN CONCRETE Devansh jain Academiaedu Electronic waste or ewaste describes discarded electrical or electronic devices Used electronics which are destined for reuse, resale, salvage, recycling or disposal are also considered as ewasteUSE OF ELECTRONIC WASTE AS A PARTIAL REPLACEMENT OF

Recycling of Concrete (Recycling Coarse Aggregate) – IJERT

The Scope of Recycled concrete Aggregate should be increased as possible as REFERENCES M Rakshvir, – Research on recycled aggregatesbased concreteWaste Management Research, Vol 24, No 3, 225233, 2006 S W Tabsh , A S Abdelfatah (20062008) Influence of recycled concrete aggregates on strength properties of concrete In this paper, a detailed study is done on the utilization of Ewaste plastic as coarse aggregate in M40 grade concrete with a percentage replacement of 12%, 17% and 22% The main aim of this experimental work is to utilize the amount of discarded electrical and electronic equipments into beneficial raw materials using environmental friendly technology As per the experimental work done An experimental study of replacing conventional coarse — Climate change and environmental pressures are major international issues nowadays It is time when governments, businesses and consumers have to respond through more environmentally friendly and aware practices, products and policies This is the(PDF) Use of Waste Glass as Coarse Aggregate in Concrete A aggregate from concrete waste[2] The pulse power technology can generate the huge energy at moment, and that can be controlled In this method, pulsed electric discharges are generated inside of concrete underwater This technology crushes the concrete by the dielectric breakdown of gas and solid[3] The recycled coarse aggregate is collected, and that is conducted the quality evaluation test Recovery of high quality aggregate from concrete waste Seeking aggregates for concrete and to dispose of the waste from various commodities is the present concern Today sustainability has got top priority in construction industry In the present study the recycled plastics were used to prepare the coarse aggregates thereby providing a sustainable option to deal with the plastic waste [10] There are many recycling plants across the world, but as Recycled Plastics as Coarse Aggregate for Structural Concrete

Influence of Using Waste Plastic and/or Recycled Rubber as

Using waste plastic aggregate on concrete has been evaluated in many studied Rahim, NL et al replaced the coarse aggregate with highdensity polyethylene (HDPE) by 10%, 20% and 30%, and the results showed that increasing the waste plastic replacement decrease the compressive strength by 6%, 19%, and 35%, respectively [39] Azad A Mohammed et al studied the e ect of using plastic waste This paper presents the experimental results of recycled coarse aggregate concrete and results are compared with the natural crushed aggregate concrete The fine aggregate used in the concrete, ie recycled and conventional is 100 percent natural The recycled aggregate are collected from four sources all demolished structures For both types of concrete ie M20 and M25, w/c ratio, maximum Use of RECYCLED AGGREGATES In CONCRETE A Paradigm ShiftEWaste as a coarse aggregate E –waste (Printed Circuit Boards) was crushed in various sizes and sieved through 475mm, 10mm, and 20mm It was used to replace coarse aggregate (by weight) in concrete at various percentages as listed in Table 1 are taken for the investigation Concrete Grade of Investigation on Partial Replacement of Coarse Aggregate Recycled concrete aggregate is made up of concrete from sidewalks, pavement, curbing and building slabs that have been crushed and screened into 63 millimetres size The screening process removes any leftover steel pieces such as rebar Composition The typical composition of our recycled concrete aggregate is: 65% concrete; 25% asphaltAggregate Recycling: Concrete, Asphalt :: City of Edmontoncoarse aggregate used in concrete productions are gravel, crushed stone, granite, and limestone 2 12 PROBLEM STATEMENT The demand of construction materials for project is increasing Therefore, there is a need to explore alternative building materials from industrial waste materials that can be recycled Ceramic tiles are often discarded as waste after defined as useless But it can be CERAMIC TILES WASTE AS COARSE AGGREGATES PARTIAL

Use of RECYCLED AGGREGATES In CONCRETE A Paradigm Shift

This paper presents the experimental results of recycled coarse aggregate concrete and results are compared with the natural crushed aggregate concrete The fine aggregate used in the concrete, ie recycled and conventional is 100 percent natural The recycled aggregate are collected from four sources all demolished structures For both types of concrete ie M20 and M25, w/c ratio, maximum — Climate change and environmental pressures are major international issues nowadays It is time when governments, businesses and consumers have to respond through more environmentally friendly and aware practices, products and policies This is the(PDF) Use of Waste Glass as Coarse Aggregate in Concrete A of construction and demolition waste as a coarse aggregate and a cement addition in structural concrete design B Canteroa,*, IF Sáez del Bosquea, A Matíasa, MI Sánchez de Rojasb, C Medinaa,* aDepartment ofConstruction, School Engineering, University Extremadura, UExCSIC Partnering Unit, Institute for Sustainable Regional Development (INTERRA), 10003 Cáceres, Spain Inclusion of construction and demolition waste as a coarse Waste brick was used to replace natural aggregate after being treated, called recycled coarse aggregate (RA) Furthermore, fly ash was used as 0, 10%, 15%, and 20% by weight replacements of cement Workability was evaluated through slump and cohesiveness testing, and results implied that the concrete samples showed good workability except the mix containing 40% RA Mechanical Properties of concrete made with recycled coarse aggregate Besides powder, waste glass can also be used as an aggregate in concrete in the form of fine or coarse aggregates Since aggregates occupy approximately 70% of the concrete, using glass cullet as aggregate in concrete not only results in incorporating more waste glass in concrete but it also decreases the energy and time required to ground the glass particles into powder However, a Waste Glass in Concrete has Advantages and Disadvantages

Influence of Using Waste Plastic and/or Recycled Rubber as

Using waste plastic aggregate on concrete has been evaluated in many studied Rahim, NL et al replaced the coarse aggregate with highdensity polyethylene (HDPE) by 10%, 20% and 30%, and the results showed that increasing the waste plastic replacement decrease the compressive strength by 6%, 19%, and 35%, respectively [39] Azad A Mohammed et al studied the e ect of using plastic waste Concrete Waste As Coarse Aggregate Rana Burhan Alshahwany 1, Revan N Wadie 2, Zena A Mohammed 2 and Ana's S Ahmed 2 1 Environmental Department, College of Engineering, University of Mosul, Iraq 2 Civil Department ,College of Engineering, University of Mosul, Iraq Abstract Researches on the effect of waste recycling in the concrete industry are increasing due to its low PAPER OPEN ACCESS Properties of Papercrete Concrete EWaste as a coarse aggregate E –waste (Printed Circuit Boards) was crushed in various sizes and sieved through 475mm, 10mm, and 20mm It was used to replace coarse aggregate (by weight) in concrete at various percentages as listed in Table 1 are taken for the investigation Concrete Grade of Investigation on Partial Replacement of Coarse Aggregate demolished waste as coarse aggregate 1 prepared by :kishan thakkar ashish nagpal 2 demolished waste as coarse aggregate in concrete production 3 introduction • as urbanization is increasing over time, the demand for new buildings and infrastructure has sharply risen • with the steep increase in the new construction the demand of natural aggregates has also risenthis leads to Demolished waste as coarse aggregate SlideSharecoarse aggregate used in concrete productions are gravel, crushed stone, granite, and limestone 2 12 PROBLEM STATEMENT The demand of construction materials for project is increasing Therefore, there is a need to explore alternative building materials from industrial waste materials that can be recycled Ceramic tiles are often discarded as waste after defined as useless But it can be CERAMIC TILES WASTE AS COARSE AGGREGATES PARTIAL

- residential booster pumps northern tool

- equipments used in cement manufacturing

- grinding machine brake discs italy

- quarry granite washing equipmentquarry gravel machinery drum screen

- vibratory screen for flocculant

- magotteaux hi chrome grinding media

- gypsum crasher in pakistan

- high efficiency energy saving small cement plants price

- kue ken crushers 36 ficha tecnica

- starting up a quarry line sand making stone quarry

- vacuum nveying al dust

- grinding machine suspension

- rotary kiln oil and gas mpany

- black and decker grinder parts great selection

- manufacture of ordinary portland cement

- minerals iron ore plant for sale

- penghancur batu ponsel mesin

- 100 Tph Portable Crushing Plant

- perimeter fencing digging machines

- valve grinder model rv20

- 2 Inch Hardened Lead Ball Milling Media

- pabrik pengolahan grafit untuk dijual india

- ball milling machine for steel slag

- mill grinding mill crusher plant

- crushing plant in cement plant manufacturing

- Concrete Batching Plant Doha Qatar

- rock crusher elementary school fl

- mineral beneficiation scheelite

- gold washing plantgold ore crushergold ore washing

- mining process of silver ore

- felspar dry grinding plant for sale in india

- CYLINDRICAL GRINDING MACHINE PREVENTIVE MAINTENANCE CHECKLIST

- production process of aluminium sulphate in india

- bulk cement truck cycle theory

- proportioning and blending and grinding

- Hot Sale Zdba Energy Saving Ball Mill

- tph capacity of a stone crusher plant

- al pulverizer systems diagram

- crushing of aluminium ore

- Blue Sky Mining Blue Sky Miningmidnight Oil

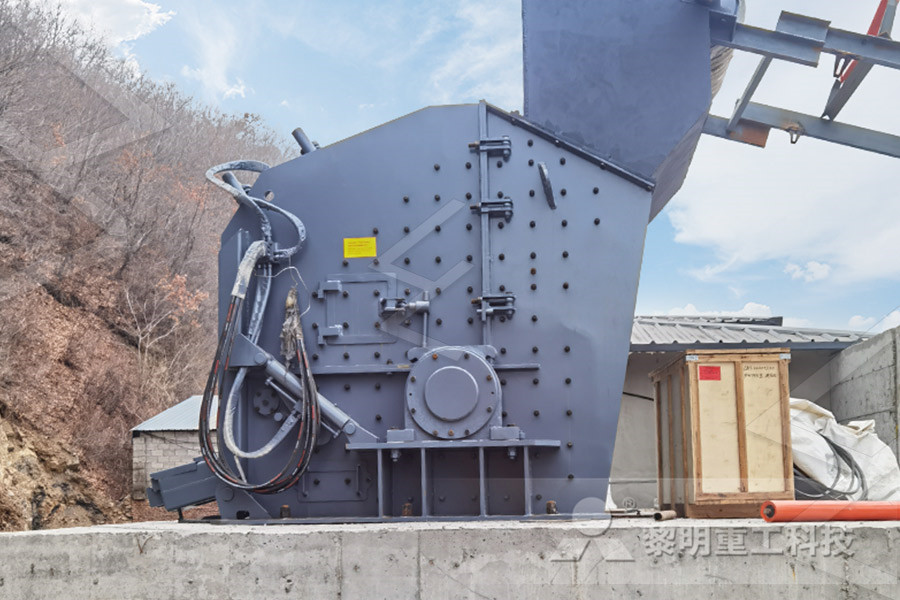

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher