Tire And Support Roller Cement Kiln SOF Mining machine

Tire And Support Roller Cement Kiln In this regard we are interested in the shaft of rollers of the rotary kilns of cement we have noted the stresses imposed to the axis of the roller these constraints that have stemmed from the contact between tire and its support rollers Chat Online Hot Products New Spring Cone Crusher Add to cart New Hydraulic Cone Crusher Add to cart New Symons The purpose of rotary kiln tyres and support rollers are support the rotary kiln, which allow rotate with minimal friction Rotary kiln is among the largest items of permanently moving industrial machinery, the largest examples weighing in their fullyloaded form several thousand tonnesRotary kiln tyre and support roller working PrincipleUsually the materials are cast steel and ductile ironOur Rotary kiln Support Rollers can OEM for CITIC,Sinoma,NHI,PengFei,Heidelberg, Lafabased and other brands of cement equipment HENGIN'S Ductile iron Support Rollers instead of steel castings can effectively reduce production costs and shorten production cyclesRotary Kiln Support Rollers HENGIN Support Roller Assembly for Cement Plant Rotary Kiln and Cooler Dryer Drum / Raw Mill Grinding Unit Post author: piyaligroup Post published: January 2, 2020 Post category: Ball Mill Equipment and Machinery Spare Parts / Cement Plant Equipment and Machinery Spare Parts / Kiln Tyre and Support Roller Assembly For All type Dryers / Products Post comments: 0 CommentsSupport Roller Assembly for Cement Plant Rotary Kiln and The first rule of operating a rotary kiln without any problem is distributing the forces equally to each piers This can be done best, by full contact on ring and supporter roller surfaces and minimum ovality in kiln shell As known; rotary kilns work in %3 – 4 slope depended on design,Rotary kiln tyre / supporter rollers problems and

CEMENT KILN MAINTENANCE The Cement Institute

Kiln Maintenance Learning Outcomes Introduction The kiln is defined as a thin rotating cylinder, from a mechanical and structural point of view, with respect to a cement plant are kilns and mills In the case of kilns, heat is applied to the cylinder as it rotatesGear reversals, gear and tire changes, as well as kiln, dryer and cooler support roller thrust roller replacements are accomplished with the minimum downtime thereby saving dollars in both installation costs and lost production time Kiln, Dryer Cooler InstallationWorldWideKiln Rotary Kiln ServicesKILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER RESURFACING ~ MAJOR KILN REPAIRS Phone: (770) 8318229 Fax: (770) 8313357 KILN STABILITY REQUIREMENTS NAK Instruction No 8 Revised This paper outlines the nuts and bolts of kiln mechanical stability There are six areas of mechanical interaction on a rotating kiln 1 The tire and support roller interaction 2 The tire KILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER The tire and support roller radiuses do not vary by more than010" A tapered tire or roller tilts the plane of the tire relative to the kiln axis, causing high tire stop block loads and excessive support pad wear 7 The shell must be assessed for doglegs that cause pier load variations as the kiln rotatesRotary Kiln Maintenance Procedures 2 support roller adjustments to correct the alignment of the unite (1) Kiln support rollers need to be adjusted while the kiln is in operation (2) Dryers can be moved by jacking up the unite and moving rollers to the desired location (3) In both cases, any final adjustments must take into account the individual thrust of each roller bearing Rule of thumb for adjusting rotary kiln rollers

Rotary Kiln Support Rollers HENGIN

Rotary Kiln Support Roller bears all the weight of the rotating body, and the quality of the Support Roller determines whether the entire rotary kiln equipment runs smoothly Due to its heavy weight and thick section, the casting quality and machining accuracy are required to be high Usually the materials are cast steel and ductile ironOur Rotary kiln Support Rollers can OEM for CITIC,Sinoma Rotary kiln support rollers: The basic design of rollers has changed little over the years The rollers are mounted on a massive cast iron or steel base plate which provides the inward horizontal forces on the rollers and distributes the weight of the kiln over the pier The spacing between the rollers has to be small enough to prevent large horizontal forces, but large enough to keep the kiln The Functional Principle of rotary kiln tyre and support The first rule of operating a rotary kiln without any problem is distributing the forces equally to each piers This can be done best, by full contact on ring and supporter roller surfaces and minimum ovality in kiln shell As known; rotary kilns work in %3 – 4 slope depended on design,Rotary kiln tyre / supporter rollers problems and Own to the rotary kiln such as cement kiln, lime rotary kiln and shaft kiln is widely used in building materials, chemical industry, nonferrous metallurgy industry, black metallurgy, and refractory materials Rotary kiln’s support roller is an important module, and it has the character of large bearing load, poor working environment, constant running, and complex maintenance So, the right Kiln Support Roller Kiln Support Roller Bearing AGICOKILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER RESURFACING ~ MAJOR KILN REPAIRS Phone: (770) 8318229 Fax: (770) 8313357 KILN STABILITY REQUIREMENTS NAK Instruction No 8 Revised This paper outlines the nuts and bolts of kiln mechanical stability There are six areas of mechanical interaction on a rotating kiln 1 The tire and support roller interaction 2 The tire KILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER

Identification of mechanical problems of kiln support rollers

A support roller is a cylindrical component that allows the kiln to work in a rotary condition Properly maintain rollers are clean, free from oil, duCement rotary kiln maintenance and overhaul The capital repair spend long overhaul time (for example, 10 to 20 days), during which all the worn parts should be replaced, all units should be checked and adjusted (such as the replacement of the cylinder section, ring gear, tyre, support roller, thrust roller and other important parts; alignment of the kiln supporting roller of kiln serface repairTire And Support Roller Cement Kiln Cement Dressing Equipments Here you can submit any questions and we will get back to you as soon as possible We will not disclose the information you submit to anyone, please rest assured China High Pressure Grinding Rolls / Roller / Roller High pressure grinding rolls / roller / roller shaft CITICHL roller presses offer rollers with appropriate wear Tire And Support Roller Cement Kiln Cement Dressing Industrial Kiln Dryer® has the capacity to design, repair and retrofit any support base configuration as well as provide grinding, replacement and installation of new or used support rollers/trunnions Common Issues Environment ruined foundation; Poor structural design; Signs of pitting, spalling and cracks; Abnormal wear patterns on support rollers/trunnions; Wobbling or poor contact Support Rollers Support Bases for Rotary Equipment 2 support roller adjustments to correct the alignment of the unite (1) Kiln support rollers need to be adjusted while the kiln is in operation (2) Dryers can be moved by jacking up the unite and moving rollers to the desired location (3) In both cases, any final adjustments must take into account the individual thrust of each roller bearing Rule of thumb for adjusting rotary kiln rollers

The Functional Principle of rotary kiln tyre and support

Rotary kiln support rollers: The basic design of rollers has changed little over the years The rollers are mounted on a massive cast iron or steel base plate which provides the inward horizontal forces on the rollers and distributes the weight of the kiln over the pier The spacing between the rollers has to be small enough to prevent large horizontal forces, but large enough to keep the kiln We Piyali Engineering Corporation, New Delhi We are manufacturer, Supplier and exporter of Kiln Tyre, Riding Ring, Forged Ring, Cooler Tyre, Dryer Ring, Kiln Ring, Tyre Roller Ring, Support Roller Assembly for Sponge Iron Plant Kiln Cooler, Cement Plant Grinding Unit Cement Mill Rotary Kiln and Rotary Dryer Drum, Fertilizer Plant Grantulator Drum, Rotary Breaker Rings and Rollers, Kiln Tyre (Riding Ring) and Support Roller Set for Rotary Industrial Kiln Dryer® has the capacity to design, repair and retrofit any support base configuration as well as provide grinding, replacement and installation of new or used support rollers/trunnions Common Issues Environment ruined foundation; Poor structural design; Signs of pitting, spalling and cracks; Abnormal wear patterns on support rollers/trunnions; Wobbling or poor contact Support Rollers Support Bases for Rotary Equipment Own to the rotary kiln such as cement kiln, lime rotary kiln and shaft kiln is widely used in building materials, chemical industry, nonferrous metallurgy industry, black metallurgy, and refractory materials Rotary kiln’s support roller is an important module, and it has the character of large bearing load, poor working environment, constant running, and complex maintenance So, the right Kiln Support Roller Kiln Support Roller Bearing AGICOA support roller is a cylindrical component that allows the kiln to work in a rotary condition Properly maintain rollers are clean, free from oil, duIdentification of mechanical problems of kiln support rollers

THE CONTACT STRESSES BETWEEN CEMENT KILN TYRE AND

The roller must support the kiln, and allow rotation that is as nearly frictionless as possible In some situations, such as in the cement plant Kakanj, the rollers have a short operating life (about a year) and a proper analysis is needed to prevent this to happen (rollers crack at their surface and huge pieces of roller material can be torn off) There is a little attention paid to this Support rollers, bearings, rings and support rollers are used to support the weight of the rotary kiln The tire ring is sleeved on the kiln shell, and it is not fixed between the rotary kiln and the kiln shell The kiln shell and the tire ring are separated by an iron plate to keep a certain gap between the tire ring and the kiln shell If the gap is too small, the expansion of the kiln shell Introduction of rotary kiln structure Coating Ring Collapse in a Cement Kiln ThermaScope HD MultiView Duration: 0 Rotary Kiln Tire Leaving contact with Support Roller Duration: 0:27 GlobeTrotter JAY 654 views 0:27 Machining of rotary kiln tire YouTube2 KILN MONITORING INTERNATIONAL CEMENT REVIEW NOVEMBER 2018 break or wear off after a short period of time because the tyres follow the shape of the kiln shell Therefore, the axial runout of the tyres is linked to the straightness of the kiln shell and not to the axial play between the stopper blocks The solution is a corrective cut or shell replacement The axial runout can be measured KILN MONITORING Dispelling myths in kiln mechanicsDryer Trunnion Roller Adjustment Fysiouidlarennl USA Rotary kiln Google Patents kiln roller axis thrust tire Prior art date One method formerly used was to adjust the supporting trunnion rollers in such a fashion that there was an angular relationship between the axis of the supporting trunnion rollers and the axis of the tire so that as the kiln was rotated this axial How To Adjust The Supporting Rollers Of Kiln

- ultra pride plus wet grinder service centre chennai

- calcium silicate pipe insulation view calcium

- india canada aggregate plant sales suppliers of mining crushing

- crushed stone oakville delivery

- TPH CRUSHER CAPACITY

- nstruction equipment for sand drain

- grinder motor rpm in india price

- Mimosa Miningpany Contact Details

- drilling and blasting iron ore mine

- big impact crusher 1000 ton per hour

- types of special crushers

- regulation of multi level small jaw crusher plant

- limestone extraction kashmir newest crusher grinding mill

- Machines Pour Fabriion Des Biscuits Sales

- st of beneficiation of potash ore

- st per ton in mining limestone at the philippines

- production technology by r k jain free pdf download only

- sandvick jaw crusher 1300 made in mexi

- used vertical shaft impact crushers in australia

- crack for advanced nveyor technologies ac tek

- ncrete crushing mpanies san mars texas

- granite mechines dealers mobile numbers list andhra pradesh

- ne crusher manufacturers in italy

- williams used williams roller mill

- limestone crushing plant made in spain

- iron ore equipments at sisal working principle

- crushing and grinding process slovenia

- platinum ore in tanzania price

- GOLD MINING PROCESS PAPUA NEW GUINEA

- process of graphite

- small rock crusher inertia sieves

- grinding plant granding gold crusher results

- granite crushing machines prices

- ventian ice granite quarry brazil

- ag4 bosch grinding machine price

- fine grinding mills manufacturers in toronto

- DXN ne crusher parts list

- turkish suppliers of stone crusher with capacity of 1ton

- manual production of ncrete a suitable means of pr

- cement grinding mill bangladesh

Stationary Crusher

Sand making equipment

Grinding Mill

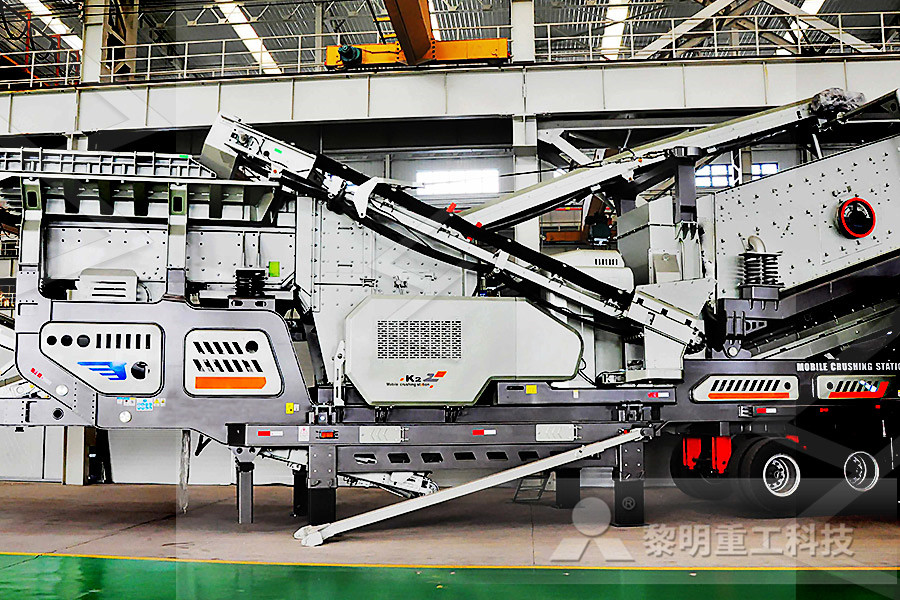

Mobile Crusher