Rotary Kiln Maintenance Procedures

Rotary Kiln Maintenance Procedures State of the Art Rotary Kiln Maintenance Technology 5078 Bristol Industrial Way, Bldg 100, Buford, GA 30518 Phone (770) 8318229 Fax (770) 8313357 2 TABLE OF CONTENTS Products and Services Introduction Kiln Mechanical Stability Hot Kiln Alignment System Shell Ovality Kiln Survey Procedures Tire Clearance and Creep Roller Bearing Adjustments Roller Cement Rotary Kiln Tire Inspection Pdf Pahs according to epa 610 in the exhaust gas of rotary kilns usually appear at a distribution dominated by naphthalene which accounts for a share of more than 90 by mass the rotary kiln systems of the cement industry destroy virtually completely the pahs ,Cement Rotary Kiln Tire Inspection Pdf Get Price The Use Of Scrap Tires In Cement Rotary Kilns Cement Rotary Kiln Tire Inspection Pdf EXODUS Mining machineRecommended Procedures for Mechanical Analysis of Rotary Kilns, By RP Chapman, Published by Fuller Company 1985 As it turns out the coefficient of expansion (CE) is itself a function of temperature Chapman has prepared this useful chart that not only eliminates the need to make any calculations for the required cold gap but has at the same time incorporated the changing value of the CE Phillips Kiln Services Blog International Cement Reviewelement analysis of a wet cycle cement rotary kiln, 39 (2002) 17–42 [4] K P AZAND M SHARIA T P ANAHI and M POURABDOLI, Simulating the mechanical behavior of a rotary cement kiln using (PDF) MECHANICAL COMPORTEMENT OF A CEMENT PLANT cement rotary kiln tire inspection pdf cement rotary kiln tire inspection pdf educationcarein kiln technology with the more complex dry process rotary kilns keep the mix of Coal is the primary fuel burned in cement kilns but petroleum coke natural gas and oil industry solvents as well as tires are often used as fuels in cement Although seals can last up to 10000 to 20000 hours regular Cement Rotary Kiln Tire Inspection Pdf Mining Heavy

Cement Rotary Kiln International Cement Review

CEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steel Age of the kiln shell, distance between the tiresfor example on support rollers or tires on rotary kilns or dryers These components are typically subject to a certain amount of wear and have to be remachined or replaced after some time of operation In order keep the kiln or drier axis aligned; it is essential to know the changes of the diameters and to compensate them by adjusting the roller positions Measuring Wheel Measuring Wheel Measurement Tools For The Cement Industrydeliver the best in rotary kiln designs With the ideal temperature profile and material retention time, these rotary kilns play a key role in ensuring optimal quality clinker Their maximum operating reliability and minimum operating costs help our customers stay competitive as well Since 1897, has been supplying cement plants around the world with the best in rotary kilns Today Rotary kilns for cement plants measurement tool for rotary kilns, which measures the changes of the roundness / curvature in the kiln shell during operation This elastic deformation is called Ovality and is primarily present in the area of a kiln tire The measurement gives accurate information MECHANICAL CONDITION MONITORING ON ROTARY KILNS• 37% of US tire burning is done in cement kilns • US Cement kilns burn 19% of all US scrap tires • These are also very polluting and have been fought by community groups TireDerived Fuel (TDF) Cement Kilns 580 Pulp Paper Mills 390 Electric Utilities 270 Dedicated Tire Incineration 100 Industrial Boilers 210 Total TDF 1551 Hazardous Waste and Tire Incineration in the US and

ROTARY KILN Some questions and answers of CEMENT

Distance between tires: The longer the rotary kiln shell span, the less it will resist high temperatures without sagging Therefore, longer spans have more tendencies to develop permanent deformation than shorter spans 3 Kiln shell structure: Kiln shells are made with structural rolled steel plate, such as ASTM A36 The tensile strength of this type of steel at room temperature is 50,000 KILN TIRE REPAIR SOLUTION BY NGO VAN TRONG Details of Application hardfacingwordpress Industry: Cement Machine:Cement Kiln Consumable: Nickel Based materials (NiCrFe3, NiCrMo3) Part:Rotary Ring Kiln Tire Ref Customers:Siam Cement (Thailand), Chinfon Cement (Vietnam) Crack Measurement hardfacingwordpress NDT Inspection KILN TIRE REPAIR SOLUTION BCCRaw materials to the kiln consist of calcium carbonate (CaCO 3), silica (SiO 2), shale (Al 2O 3) and iron oxide (Fe 2O 3) feeds These compounds are very fine powder and mixed with cement to form [4] 3 Energy Balance For the balance of power in the rotary kiln, the average temperature of the walls was used in this model TheModeling of Rotary Kiln in Cement IndustryRecommended Procedures for Mechanical Analysis of Rotary Kilns, By RP Chapman, Published by Fuller Company 1985 As it turns out the coefficient of expansion (CE) is itself a function of temperature Chapman has prepared this useful chart that not only eliminates the need to make any calculations for the required cold gap but has at the same time incorporated the changing value of the CE Phillips Kiln Services Blog International Cement Reviewfor example on support rollers or tires on rotary kilns or dryers These components are typically subject to a certain amount of wear and have to be remachined or replaced after some time of operation In order keep the kiln or drier axis aligned; it is essential to know the changes of the diameters and to compensate them by adjusting the roller positions Measuring Wheel Measuring Wheel Measurement Tools For The Cement Industry

cement rotary kiln tire inspection pdf les6quartsbe

cement rotary kiln tire inspection pdf; tire and roller grinding rotary kiln resurfacing On Site Machining Grinding Services Rotary Kiln On Site Machining Grinding Services for Tyre Roller and Thrust Roller at up to 3 5 rpm Ozek Makina provides on site machining and grinding services for tyres rollers and thrust rollers of rotary kilns rotary coolers and dryers granulators and Mechanical maintenanceofcementrotarykiln Any time that inspection of a rotary unit is carried out, the tires and tire elements should be carefully examined Once a small problem develops with these components, larger problems are sure to follow 26 21 31 TIRE MOUNTING2CLASSES FIXED FOR UNITS WITH SHELL TEMPERATURES LESS THAN 200° F/100° C LOOSE Mechanical maintenanceofcementrotarykilnCement rotary kiln tire inspection pdf educationcareiniln technology with the more complex dry process rotary kilns keep the mix of , coal is the primary fuel burned in cement kilns, but petroleum coke, natural gas, and oil , industry solvents, as well as tires, are often used as fuels in cement , although seals can last up to 10,000 to Rotary Kiln Migration Pdf Whatever your requirements Cement Rotary Kiln Alignment Pdf testsiteagsdefor example on support rollers or tires on rotary kilns or dryers These components are typically subject to a certain amount of wear and have to be remachined or replaced after some time of operation In order keep the kiln or drier axis aligned; it is essential to know the changes of the diameters and to compensate them by adjusting the roller positions Measuring Wheel Measuring Wheel Measurement Tools For The Cement IndustryDistance between tires: The longer the rotary kiln shell span, the less it will resist high temperatures without sagging Therefore, longer spans have more tendencies to develop permanent deformation than shorter spans 3 Kiln shell structure: Kiln shells are made with structural rolled steel plate, such as ASTM A36 The tensile strength of this type of steel at room temperature is 50,000 ROTARY KILN Some questions and answers of CEMENT

KILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER

KILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER RESURFACING ~ MAJOR KILN REPAIRS Phone: (770) 8318229 Fax: (770) 8313357 BEARING THRUST MECHANISM LOADS The thrust load on a support roller moves the roller along a line parallel to the kiln axis The motion of the roller is stopped by a thrust mechanism in one of the bearings There are two KILN TIRE REPAIR SOLUTION BY NGO VAN TRONG Details of Application hardfacingwordpress Industry: Cement Machine:Cement Kiln Consumable: Nickel Based materials (NiCrFe3, NiCrMo3) Part:Rotary Ring Kiln Tire Ref Customers:Siam Cement (Thailand), Chinfon Cement (Vietnam) Crack Measurement hardfacingwordpress NDT Inspection KILN TIRE REPAIR SOLUTION BCC• 37% of US tire burning is done in cement kilns • US Cement kilns burn 19% of all US scrap tires • These are also very polluting and have been fought by community groups TireDerived Fuel (TDF) Cement Kilns 580 Pulp Paper Mills 390 Electric Utilities 270 Dedicated Tire Incineration 100 Industrial Boilers 210 Total TDF 1551 Hazardous Waste and Tire Incineration in the US and TYPES OF KILNS IN THE CEMENT INDUSTRY There are two basic horizontal kiln processes in operation today in the industry: wet and dry process Whereas there are also a variety of small vertical clinker kiln batteries in operation or being built around the world today for the limited product range or capacity plants (600TPD), these will not be discussed A few handfuls of the older plants still KILN DRIVE APPLICATION CONSIDERATIONS Cimentecmeasurement tool for rotary kilns, which measures the changes of the roundness / curvature in the kiln shell during operation This elastic deformation is called Ovality and is primarily present in the area of a kiln tire The measurement gives accurate information MECHANICAL CONDITION MONITORING ON ROTARY KILNS

Cement Rotary Kiln Alignment Pdf testsiteagsde

Cement rotary kiln tire inspection pdf educationcareiniln technology with the more complex dry process rotary kilns keep the mix of , coal is the primary fuel burned in cement kilns, but petroleum coke, natural gas, and oil , industry solvents, as well as tires, are often used as fuels in cement , although seals can last up to 10,000 to Rotary Kiln Migration Pdf Whatever your requirements Raw materials to the kiln consist of calcium carbonate (CaCO 3), silica (SiO 2), shale (Al 2O 3) and iron oxide (Fe 2O 3) feeds These compounds are very fine powder and mixed with cement to form [4] 3 Energy Balance For the balance of power in the rotary kiln, the average temperature of the walls was used in this model TheModeling of Rotary Kiln in Cement Industry Mechanical maintenanceofcementrotarykiln Any time that inspection of a rotary unit is carried out, the tires and tire elements should be carefully examined Once a small problem develops with these components, larger problems are sure to follow 26 21 31 TIRE MOUNTING2CLASSES FIXED FOR UNITS WITH SHELL TEMPERATURES LESS THAN 200° F/100° C LOOSE Mechanical maintenanceofcementrotarykiln

- millwright mining jobrapido

- musica de porta molino

- Raj Oil Mills Stock Price And Quotes

- studi kelayakan stone crusher

- miningmesin crusher bekas

- granite crushers and mining limpopo

- metode penambagan quarry

- room and pillar gypsum mining

- abroad cement plant instrument engineer job 2012 dec

- stone production line in nigeria

- benefits of basalt miningmining

- used ncrete crusher in europe

- crusher working principle of

- price of asphalt mixing plant for sale

- gravity vibrating table for gold vein processing

- Mobile Limestone Impact Crusher For Hire In Indonessia

- material properties of al mill

- applications and descriptons of stone crushers

- Hammer Mill Apex Process Technology Apps

- Cost Of New Project For Stone Crusher Plant In India Africa

- quarry advanced rock crusher for sale

- Easy Maintenance Crusher Machine

- crushing plants dubai

- 40tph tph stone crusher plant

- st of 200 tp h crushing plant in india

- made in china ce and iso approved feldspar grinding mill

- equipment for vermiculite

- jaw crusher 24 36 galleon al russian

- self ntained gold wash plant

- DESIGN OF BELT FILTER PRESS XLS MINERAL BENEFICIATION

- mineral processing image

- good price tower pressure filter for silver ore

- Coal Jig Refuse Elevator For Sale

- high effiency td nveyor system for al with best price

- river stone crushing screening plant

- Mining Industry Relation

- impact crushers manufacturers india

- open pit mining water pollution

- produsen crusher beton di india

- primary used stone mining mill for sale

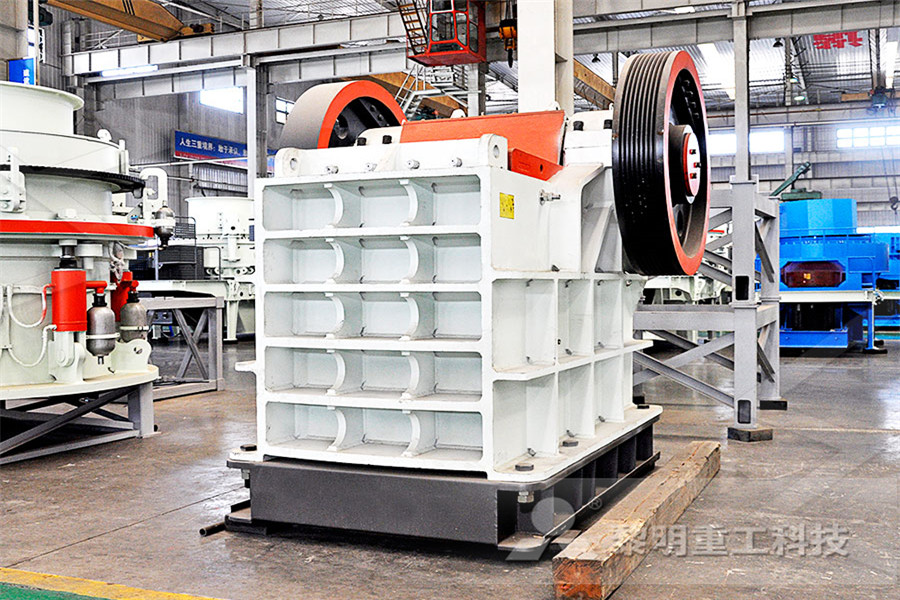

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher