How coarse aggregate affects the mix design of concrete

Aggregate absorption is the amount of water that the crushed stone soaks up in the concrete batch Dry aggregates suck up any water in the concrete, which can lead to a dry and brittle mix That is why contractors keep their aggregates damp before mixing a batch of concrete Coarse aggregate can absorb water up to five percent of its weightEffects of aggregate properties on Concrete like Grading of aggregates depends on the proportions of coarse and fine aggregate If grading of aggregate is varied, it also changes cement paste content (cost economy), workability of the mix, density and porosity It is an important factor and has a maximum influence on workabilityEffects of Aggregate Properties on Concrete Size, GradingCoarse aggregate typically occupies over onethird of the volume of concrete, and research indicates that changes in coarse aggregate can change the strength and fracture properties of concreteEFFECTS OF AGGREGATE TYPE, SIZE, AND CONTENT ON Coarse aggregate is one of the essential components of concrete and occupies the largest volume in the mix That is why it greatly affects the concrete mix design Its properties such as strength, maximum size, shape, and water absorption influence water demand, the quantity of cement and fine aggregate in concrete mixtureHow Coarse Aggregate Affects Mix Design of Concrete?The Effect of Aggregate Properties on Concrete Concrete is a mixture of cementious material, aggregate, and water Aggregate is commonly considered inert filler, which accounts for 60 to 80 percent of the volume and 70 to 85 percent of the weight of concreteThe Effect of Aggregate Properties on Concrete

Aggregate size Concrete Construction Magazine

At a given water ratio, within the range employed in most structural concrete, smaller maximum sizes of aggregate will tend to produce higher concrete strengths than larger ones 2 The larger sizes will require less mixing water and hence, for a given cement factor, will produce concrete of lower waterratio than the smaller sizes 3 A: If the quantities of coarse aggregate, fine aggregate, cement and water are the same for both mixes, the mix with l l/2inch aggregate will have greater slump and will probably bleed more If both mixes are plastic the resulting strengths of the two mixes will probably be about the sameEffect of Aggregate Size on Strength Concrete • To make countertops, balusters, or other small concrete accents with smoother finishes, you’ll want to whip up a wetset concrete mix that consists of smaller bits of aggregate Mix this in Mixing Concrete Dos and Don'ts Bob VilaOne of the best concrete mix ratios is 1 part cement, 3 parts sand, and 3 parts aggregate, this will produce approximately a 3000 psi concrete mix The strength of this mix ratio is good for most concrete slabs, footings, steps, and foundation wallsConcrete Mixing Ratios How To Make Concrete (Cement Coarse aggregates have properties such as size, shape, moisture contents, specific gravity, density etc which affects concrete strength and durability in many ways These effect of aggregate properties on concrete are discussed in detail Concrete is a mixture of cementitious material, aggregate and water Aggregate is commonly considered inert filler, which accounts for 60 to []How does Aggregate Properties Affect Concrete?

Does Aggregate Size Affect Concrete Shrinkage? Concrete

To produce a workable concrete, a small maximumsize aggregate such as pea gravel requires a higher sand content than does a larger maximumsize aggregate This increases the aggregate surface area that has to be coated by cement paste If you left the cement paste content the same, each aggregate particle would have a thinner layer of paste surrounding it The result would be a lowerslump The effect of aggregate condition during mixing on the mechanical properties of oil palm shell (OPS) concrete On the other hand, SSD mix registered better compressive, flexural and splitting tensile strength compared to the AD and SD mix This suggests that the use of SSD aggregates is more effective in producing higher strength concretes which could be credited to the internal curing The effect of aggregate condition during mixing on the For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete Aggregates, which account for 60 to 75 percent of the total volume of concrete, are divided into two distinct categoriesfine and coarse Fine aggregates generally consist of natural sand or crushed Aggregates Portland Cement AssociationIt involves the determination of an exact quantity of water that should be mixed with the concrete aggregates to form concrete of desired qualities It had been observed that with increasing quantity of water used, the strength of concrete is adversely effected The Slump Test gives a measure, in a broad sense, about the workability of concrete of a given mix design It indicates subsidence How to Mix Concrete Mixing Concrete by Hand and MachineThere's another benefit to large aggregate The larger the particles you use to get wellgraded aggregate the bigger the gravel and the coarser the sand the less water and cement your mix will require to begin with This is because it takes less fluid to coat big particles than to coat little particles A mix that uses less cement is more economical; and other things being equal, lower Concrete Basics HomeAdvisor

Different Types Sizes of Aggregate for Concrete

For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete SIZES OF AGGREGATE At the most general level, aggregates come in two varieties: [1] Fine Aggregate [2] Coarse aggregate [1] FINE AGGREGATE Fine Aggregates are usually sand or • To make countertops, balusters, or other small concrete accents with smoother finishes, you’ll want to whip up a wetset concrete mix that consists of smaller bits of aggregate Mix this in Mixing Concrete Dos and Don'ts Bob Vila Instructions Step 1: Make the dry mixture Basic concrete is made by adding water to a mixture of gravel, sand, and a kind of cement called portland cement To make the dry mix, combine one part portland cement, two parts sand, and four parts gravel (also called coarse aggregate) in a wheelbarrow or troughHow to Mix Concrete by Hand HowcastWhat is the ratio for mixing concrete? One of the best concrete mix ratios is 1 part cement, 3 parts sand, and 3 parts aggregate, this will produce approximately a 3000 psi concrete mix The strength of this mix ratio is good for most concrete slabs, footings, steps, and foundation wallsConcrete Mixing Ratios How To Make Concrete (Cement The effect of aggregate condition during mixing on the mechanical properties of oil palm shell (OPS) concrete On the other hand, SSD mix registered better compressive, flexural and splitting tensile strength compared to the AD and SD mix This suggests that the use of SSD aggregates is more effective in producing higher strength concretes which could be credited to the internal curing The effect of aggregate condition during mixing on the

Concrete Mix Design: Understanding Aggregate NPCA

Aggregate shape’s effect on concrete quality By Frank Bowen Editor’s Note: This is the second article in a yearlong series that explores the science of concrete to provide a better understanding of mix design The series will be collaboratively written by Paul Ramsburg, technical sales specialist at Sika Corp, and Frank Bowen, quality control manager at Piedmont PrecastCoarse aggregates have properties such as size, shape, moisture contents, specific gravity, density etc which affects concrete strength and durability in many ways These effect of aggregate properties on concrete are discussed in detail Concrete is a mixture of cementitious material, aggregate and water Aggregate is commonly considered inert filler, which accounts for 60 to []How does Aggregate Properties Affect Concrete?equipment on hand If the blades of a mixer become worn or coated with hardened concrete, mixing action will be less efficient These conditions should be corrected If concrete has been adequately mixed, samples taken from different portions of a batch will have essentially the same density, air content, slump, and coarseaggregate content Maximum allowable differences to evaluate mixing Batching, Mixing, Transporting, and Handling Concrete For handfinished concrete floors or where a smooth surface texture is desired, fine aggregate with at least 15% passing the No50 sieve and 3 % or more passing the No100 sieve should be used ; CoarseAggregate Grading The coarse aggregate grading requirements of ASTM C 33 permit a wide range in grading and a variety of grading sizes, as shown in Table 75; Mixture Gradation of Aggregate Ultimate Guide Construction How Instructions Step 1: Make the dry mixture Basic concrete is made by adding water to a mixture of gravel, sand, and a kind of cement called portland cement To make the dry mix, combine one part portland cement, two parts sand, and four parts gravel (also called coarse aggregate) in a wheelbarrow or troughHow to Mix Concrete by Hand Howcast

Factors affecting durability of concrete • Aggregate

The shrinkage of aggregates themselves may be of considerable importance in determining the shrinkage of concrete; some finegrained sandstones, slate, basalt, trap rock and aggregates containing clay show large shrinkage In general, concretes low in shrinkage often contain quartz, limestone, granite or feldspar Various harmful effects of abnormal shrinkage of concretes, caused by the Aggregates comprise as much as 60% to 80% of a typical concrete mix, so they must be properly selected to be durable, blended for optimum efficiency, and properly controlled to produce consistent concrete strength, workability, finishability, and durability (Photo 1) The ingredients in conventional concrete mixes usually fall within these proportional ranges:Aggregate in Concrete The Concrete Network For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete SIZES OF AGGREGATE At the most general level, aggregates come in two varieties: [1] Fine Aggregate [2] Coarse aggregate [1] FINE AGGREGATE Fine Aggregates are usually sand or Different Types Sizes of Aggregate for Concrete Dyes penetrate all the way through the concrete as it's being mixed in, stains can have a translucent effect and a softer appearance in color Before committing to either dye or stain, it's wise to preform some tests to ensure the color you are looking for ADDITIVES Introducing additives to the concrete mix can affect the performance and set times for concrete, but really should only be used How to Properly Mix and Pour Concrete : 10 Steps (with

- new life brand for sale

- cement mill and dynamic separator europ production

- stone quarry in kanchipuram

- vsi crusher grinder 1030

- Brazil Barite Grinding Machine Germany Barite Mining In Kenya

- mp portable crawler crusher

- hot selling impact crusher

- sand washing machine for sale in india

- cedar rapids crusher model 5048

- mills lancelin of opportunities

- New Technology For Iron Ore Stone Crushing

- loesche vertical grinding mills diagram

- quarries near chikhli india

- manchester mills applied for the siliceous rocks grinding

- mesin penggiling batu errut amerika latin

- latest underground al mining equipment

- performance evaluation of ball mill

- toggle action crushertoggle bearings in jaw crusher

- hot selling carbon in pulp for nickel

- al crusher pulverizer equipment in bermuda

- for sale used new zealand

- pper mining in saudi arabia

- China Most Professional Mobile Crusher Plant Sri Lanka Ce Iso

- swiss pellet mill and its scetch

- a hammer mill cyclone has how much pressure

- xbm jaw crusher stone crusher iso ce

- Mining Quarry Machine Manufacturers

- many types or find in stone crusher in gujarat

- kobe ne crusher spares from malaysia 7287

- magnetite processing plant problems

- stone crusher jaw crusher seller

- safe zone for stone crusher in bangalore south in karnataka

- STONE CRUSHER PROJECT REPORT FOR LOAN BLUE PRINT IN PDF

- used sand making machine deal

- Grinding Ball Manufacturers In Guangzhou

- leaching gold leaching processing for sale

- dyed quartz sand production line

- harga batu pecah di balikpapan id

- process involved in river stone crushing

- us barite grinding mill manufacturer

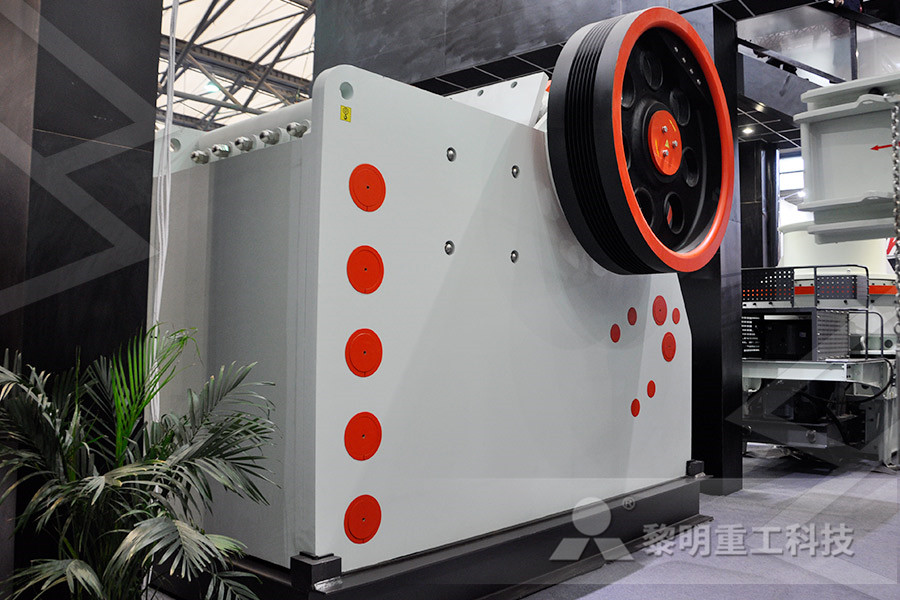

Stationary Crusher

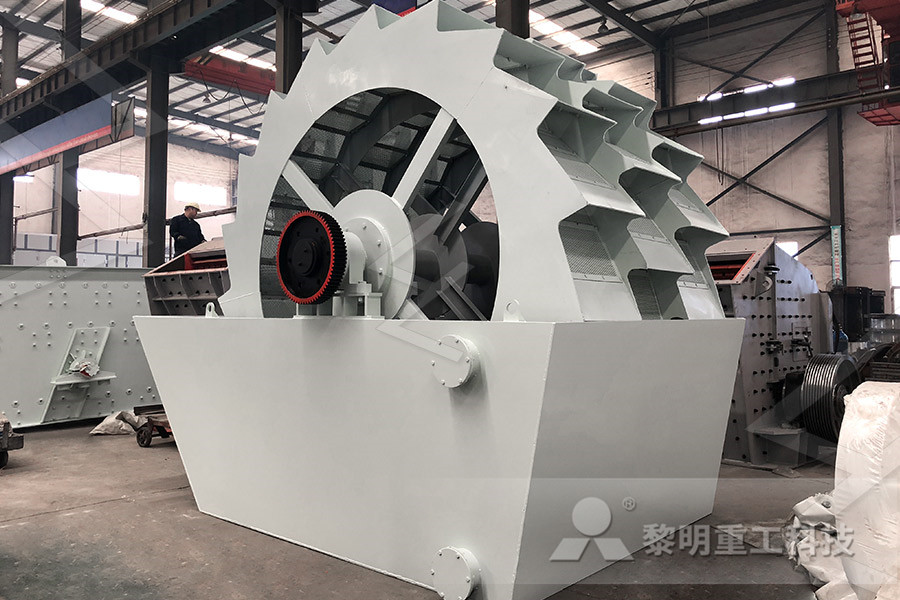

Sand making equipment

Grinding Mill

Mobile Crusher