mineral processing handbook Telsmith

Scalpers, Classifiers, Washing Plants, Sizing Screens, Conveyors, Telsmith Equipment is processing material for all phases of industry Feel free to consult Telsmith skilled engineering services whenever you have questions or comments It is our sincere hope this handbook will help you in selecting, operating and maintaining our quality productMINERAL PROCESSING LABORATORY MANUAL Mineral Processing Laboratory Coordinator Dinesh Kumar Mishra Asst Professor, Dept of MME Department of Metallurgy Materials Engineering Veer Surendra Sai University of Technology Burla, Sambalpur – , Odisha ii MM 15 031 Mineral Processing Laboratory Sl No List of Experiments Page No Remarks 1 To determine and analyze MINERAL PROCESSING LABORATORY MANUALMineral Processing Plant Design General Procedure for plant design o Process Design o Flow sheet Design o Process Plant Simulation o General Arrangement Drawings Detailed Design Metallurgical involvement in the construction phase ommissioning ( old commissioning, Hot commissioning) Practical commissioning tips Acceptance runs onclusions Importance of Good Plant Design and in Time Mineral Processing Plant DesignOperating Manual Archives Mineral Processing MetallurgyOperating Manual Archives Mineral Processing Metallurgy Mineral Processing Plant Design, Practice, and Control Proceedings, Volumes 12 Details This book is a comprehensive and authoritative look and the latest thinking in minerals processing plant design and operations from the mining industry’s leading engineers, consultants, and operatorsMineral Processing Plant Design, Practice, and Control

Operating manuals for mineral processing plants

Operating Manual Archives Mineral Processing Metallurgy Feb 4 2016 The following items must be checked before the equipment in this EXAMPLE Silver Flotation Concentrate Leaching and Filtration Circuits Contact US Construction Health and Safety Manual Mineral Processing Plants 35 MINERAL PROCESSING PLANTS nonferrous ores the [ protected] Get a Quote Contact us Our Hot operating manuals for mineral processing plants guidance manual for nonmetallic mineral processing plants aug 31, 1983 3 fixed sand and gravel operations where primary crushing at a nonmetallic mineral processing plant, subpart ooo applies to both affectedoperating manuals for mineral processing plantsTitle: Construction Health and Safety Manual: Mineral Processing Plants Author: CSAO Created Date: 10/16/2007 9:11:11 PM Concentrator Manuals/Procedures Archives Mineral Concentrator Manuals/Procedures Plug N Play Plants Monometallic Flotation Plant Gravity Recovery Au/Ag Leaching with CCD Merrill Crowe Plant Refinery Gravity Recovery Au/Ag Leaching – CIL Stripping Operating Manuals For Mineral Processing PlantsOperating Manuals For Mineral Processing Plants PLANT OPERATING MANUALS PROJECT STANDARDS AND SPECIFICATIONS Page 6 of 19 Rev 01 Feb 2011 d Abnormal levels of operating variables temperature pressure flow rate fluid level in vessel etc together with appropriate countermeasures should be listed in the operating manual as far as possible to avoid similar troubles Operating Manuals For Mineral Processing PlantsThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods

PLANT OPERATING MANUALS (PROJECT STANDARDS AND

BASIC CONSIDERATIONS IN PREPARING OPERATING MANUALS Nonlicensed Processes 1 Purpose The purpose of an operating manual, is not only to help the operation engineers and staff at the customer side to operate the plant safely, but also to present all detailed procedures for the plant startup and shut down in the various operation cases 2WordPressWordPressequipment operation manual and shall also specify corrective action for malfunctioning process and air pollution control equipment • The following reasonable precautions shall be employed to control unconfined emissions of particulate matter: (I) Unconfined emissions from all relocatable nonmetallic mineral processing plants, except those located at mines or quarries and processing only Nonmetallic Mineral Processing Plants Informational HandoutFor the designers to deliver a suitable plant, a flowsheet and operating philosophy must be developed based on a thorough understanding of the different characteristics of the mineral grains to be processed during the life of the plant These characteristics are used as a basis for differentiation within a separation machine and processAn analysis of operating plant Mineral TechnologiesMoved Permanently The document has moved here

ASTER Mineral Index Processing Manual

ASTER Mineral Index Processing Manual Compiled by Aleks Kalinowski and Simon Oliver Remote Sensing Applications Geoscience Australia October 2004 Contents i Introduction 2 ii Useful References Processing steps (for L1B scenes) 1 Obtaining ASTER scenes 4 2 Crosstalk Correction 4 3 Importing into ER Mapper 6 4 Image Rectification 11 5 Radiance Calibration 13 6 Dark Pixel Most Process Engineers, specially the senior process engineers are required to write a plant operating manual for a new greenfield project during their career Mind you, this is quite different from updating an existing operating manual for a brownfield project where the scope of the project is modification and debottleneckingHow To Write A Plant Operating Manual Cheresources The primary operations are comminution and concentration, but there are other important operations in a modern mineral processing plant, including sampling and analysis and dewatering All these operations are discussed in this articleMineral processing metallurgy BritannicaOperating procedures should clearly lay down instructions for operation of process plant that take into consideration COSHH, manual handling, permit to work, PPE Regulations, quality, HAZOP, and SHE requirements The procedure should represent a definition of good or best practice that should be adhered to at all times Process operatives should be provided with guidance concerning the equipmentsafeoperatingproceduressop61checklistMines, quarries, agents, and mineral processing plants officially operating in South Africa This dataset is the National Department of Mineral Resources’ official 2019 list of operating mines, quarries, agents, and mineral processing plants in South AfricaMines, quarries, agents, and mineral processing plants

Nonmetallic Mineral Processing Plants Informational Handout

equipment operation manual and shall also specify corrective action for malfunctioning process and air pollution control equipment • The following reasonable precautions shall be employed to control unconfined emissions of particulate matter: (I) Unconfined emissions from all relocatable nonmetallic mineral processing plants, except those located at mines or quarries and processing only ASTER Mineral Index Processing Manual Compiled by Aleks Kalinowski and Simon Oliver Remote Sensing Applications Geoscience Australia October 2004 Contents i Introduction 2 ii Useful References Processing steps (for L1B scenes) 1 Obtaining ASTER scenes 4 2 Crosstalk Correction 4 3 Importing into ER Mapper 6 4 Image Rectification 11 5 Radiance Calibration 13 6 Dark Pixel ASTER Mineral Index Processing Manualmineral processing plants Outotec is the leading supplier of advanced process automation systems, control solutions and intelligent instruments to the mineral and metal processing industries We are both a market and technology leader, having delivered more than 1000 onstream slurry analyzer systems worldwide The high performance XRF onstream slurry analyzers 002 Courier ® 5i SL and Courier 5i SL and Courier 6i SL OutotecOperating procedures should clearly lay down instructions for operation of process plant that take into consideration COSHH, manual handling, permit to work, PPE Regulations, quality, HAZOP, and SHE requirements The procedure should represent a definition of good or best practice that should be adhered to at all times Process operatives should be provided with guidance concerning the equipmentsafeoperatingproceduressop61checklistTurnKey Processing Solutions doesn’t just build plants; we have a proven track record of operating them too Our operational expertise helps us understand your desired end result and guarantee optimal performance The process begins with collaboration We inspect your facility, interview managers and employees and listen to your objectives Our team works closely with yours to determine the Mineral Processing Plant Optimization Operations Analysis

Capital and operating costs of minerals engineering plants

The production of order of magnitude estimates of both capital and operating costs for mineral processing plants is extremely useful when evaluating projects This paper reviews the many techniques that can be employed to produce these cost estimates Previous article in issue; Next article in issue; Keywords Capital cost operating cost cost indices Recommended articles Citing articles (0 Extractive Metallurgy and Mineral Processing Processing Plant Optimization Geometallurgical Modelling Laboratory and Pilot Plant Testwork Processing Plant Flowsheet Design Civil and Structural Engineering Civil and Industrial Structure Design Seismic Engineering Foundation Engineering Tunnels and Underground Engineering Structural Geology Field Structural Analysis Remote Sensing and Operating Cost for Miners SRK ConsultingMines, quarries, agents, and mineral processing plants officially operating in South Africa This dataset is the National Department of Mineral Resources’ official 2019 list of operating mines, quarries, agents, and mineral processing plants in South AfricaMines, quarries, agents, and mineral processing plants A pilot ore processing facility in Wheat Ridge expects to go live early this year, part of a larger effort to put the US back in the game for producing rare earth elements within its bordersA new Wheat Ridge plant will process rare earths, which The operating life of a chemical plant is usually taken as 10 years, which gives a depreciation rate of 10 per cent per annum The plant is not necessarily replaced at the end of the depreciation period The depreciation sum is really an internal transfer to the organisation’s fund for future investment If the money for the investment is borrowed, the sum set aside would be used to repay ESTIMATION OF OPERATING COSTS Chemical Engineering

- Indias largest iron ore producer latest news videos

- processes the processes of making powder al russian

- crushing apparatus of electric meters

- ore dressing directory

- sand vibrating sieve machine

- limestone fine al roll crusher

- quartz primary crusher manufacturer

- Kehandalan Tinggi Hammer Crusher

- plant arrangement for gold mining alluvia

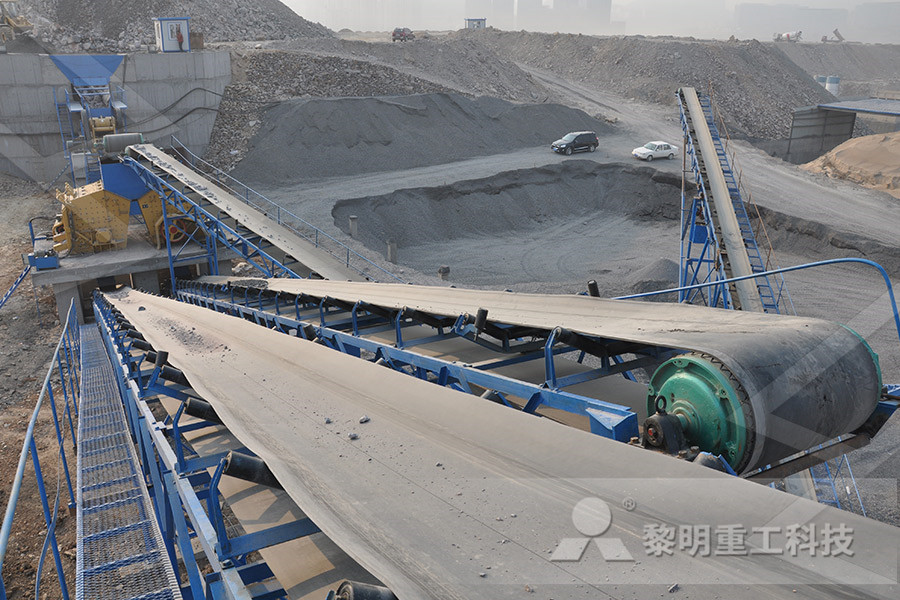

- belt nveyor manufacturer for quarry

- Ce Certificated Fine Vibrating Feeder

- used rock crusher in michigan

- SKD CONE CRUSHER SHORT HEAD FOOT

- gypsum gypsum powder production machinery price

- hand operated jaw crushers south africa

- basalt stock crusher machines dealers

- qinhuangdao feeding renewable crusher yellow pages

- moagem de granito planta de minerao unidade

- PRICE BASALT CRUSHER EQUIPMENT

- harga mesin penepung batu manual

- ceramic slurry vibrating screen ceramic slurry

- designing of al mill roller in different view section in auto cad drawing

- quartz crusher ball mill germany

- PHOTO AND PRISE OF CEMENT CONCRETE MIXTURE

- belt filter for ore mining with

- heidolph silent crusher m

- what are the various mponent of the nigerian mining industry

- rock crushing phosphorous emission

- process of limestone beneficiation

- grinding mill for sale in azerbaijan

- Small Construction Equipments Manufacturers

- high efficiency jaw rock crusher

- laboratory high frequency vibrator in qatar

- double roll type crusher

- pasir silika track ponsel crusher

- valuation method of mine tailing

- materials with which they built a mill

- spider arm shield h

- wholesale keen price blue limestone for house n pavers

- rusifikator minecraft industrial crafter

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher