USA Magnetic separation of ilmenite Google Patents

Purification of ilmenite from chromite impurities by a two step magnetic separation wherein magnetically susceptible chromite is magnetically removed, followed by an oxidizing roasting of theOxidative roasting is applied on an industrial scale to beneficiate ilmenite concentrates from South African East Coast heavy minerals deposits the aim is to increase the magnetic susceptibility(PDF) Reflections on ilmenite roasting and magnetic separationMagnetic separation takes advantage of the fact that magnetite is strongly magnetic (ferromagnetic), hematite is weakly magnetic (paramagnetic), and most gangue minerals are not magnetic (diamagnetic) A simple magnetic separation circuit can be seen in Figure 125 [ 9 ]Magnetic Separation an overview ScienceDirect TopicsA third SLon®1500 magnetic separator is then applied to recover ilmenite in a cleaning stage Combined, the three SLon®1500 separators discharge 815% of the mass fraction to the final tailings at very low cost, with only 1850% of the plant head feed moving forward in the processA discussion of magnetic separation techniques for Keywords: SLon highgradient magnetic separator; Ilmenite; Matrix 1 INTRODUCTION The ilmenite deposit in Panzhihua region, Sichuan Province of China accounts for 35% of the titanium resource in the world, and for approximately of 92% in China Efficient utilization of the ilmenite resources is very important for development of the titanium industry Because a SLon vertical ring pulsating high SLON MAGNETIC SEPARATORS APPLIED IN THE ILMENITE

Centrifugal high gradient magnetic separation of fine ilmenite

High gradient magnetic separation (HGMS) has been an effective method for the concentration or removal of fine paramagnetic particles from suspension, but its powerful magnetic capture to magnetic particles results in the mechanical entrainment of nonmagnetic particles in magnetic product, and thus reduces the separation selectivityTen metric tons of Longnose ilmenite sample was beneficiated using gravity and magnetic separation to produce an ilmenite concentrate for hydrometallurgical testing The beneficiation process resulted in three final products: high silica tailings, magnetite/titanomagnetite concentrate, and ilmenite concentrate The ilmenite concentrate was found to have the following chemical assay: 389% TiO PilotScale Demonstration of Ilmenite Processing TechnologyIlmenite, also known as manaccanite, is a titaniumiron oxide mineral with the idealized formula FeTiO 3 It is a weakly magnetic black or steelgray solid From a commercial perspective, ilmenite is the most important ore of titaniumIlmenite WikipediaKeywords: SLon highgradient magnetic separator; Ilmenite; Matrix 1 INTRODUCTION The ilmenite deposit in Panzhihua region, Sichuan Province of China accounts for 35% of the titanium resource in the world, and for approximately of 92% in China Efficient utilization of the ilmenite resources is very important for development of the titanium industry Because a SLon vertical ring pulsating high SLON MAGNETIC SEPARATORS APPLIED IN THE ILMENITE Although most natural ilmenite is ferromagnetic and generally has a higher magnetic susceptibility than paramagnetic chrome spinel, the susceptibility ranges for the two minerals overlap considerably (Allen, 2000a) due to the presence of these ferromagnetic elements, frequently making the conventional magnetic separation of these two minerals impracticalApplication of Rotating Magnetic Field (RMF) to the

The attraction of Rare Earth Magnetic Separators

magnetic separators and the relatively low maintenance costs (up to 40% lower than with electromagnets) On the next page, for example, you can see the large cost differences in operating costs for ilmenite processing Advantages of rare earth magnets By maximising the use of rare earth magnets in process flowsheets, the following main benefits have been established: Reduced operating costs jxscmachine this wet process magnetic separator is for ilmenite mining plant, drum magnetic separator can with single or double or three pcs magnetic drum this ilmenite ore magnetic wet process drum magnetic separator ilmenite ore magnetic Ilmenite Magnetic Separator WHIMS, US $ 20000 / Set, New, magnetic separator, 005~250 t/hSource from Yueyang Dalishen Electromagnetic Machinery Co, Ltd on AlibabaIlmenite Magnetic Separator WHIMS, View Ilmenite Magnetic magnetic separator for ilmenite Magnetic separators can be found in most mineral processing operations especially those processing nonmetallic minerals and magnetic ores This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the 15mm 45 micron size range) Ilmenite ilmenite belt magnetic separatorincluding ilmenite, chromite and garnet processing These RED designs, similar to LIMS, are robust and typically offer high capacity and simple operation High intensity magnetic separators may be wet or dry High intensity dry magnetic separations are carried out with inducedroll (IRM) or rareearth roll (RER) magnetic separators, though the latter is far more common (Dobbins, Sherrell 2009 Recent advances in magnetic separator designs and applications

large ilmenite magnetic separator in Adelaide Mining

large ilmenite magnetic separator in Adelaide It is a new type of strong magnetic separator developed on the basis of a general magnetic separator machine The high gradient magnetic separator equipment is suitable for Separation of weak magnetic minerals such as hematite limonite siderite ilmenite chromite wolframite tantalumniobium ores red mud and so onTen metric tons of Longnose ilmenite sample was beneficiated using gravity and magnetic separation to produce an ilmenite concentrate for hydrometallurgical testing The beneficiation process resulted in three final products: high silica tailings, magnetite/titanomagnetite concentrate, and ilmenite concentrate The ilmenite concentrate was found to have the following chemical assay: 389% TiO PilotScale Demonstration of Ilmenite Processing TechnologyIlmenite is recovered from the concentrate using wet magnetic separation, after drying, the nonmagnetic concentrate is passed through electrostatic separators to separate rutile and zircon (Lanka Mineral Sand Ltd, 1999) In some plant operations, dry magnetic separation is employed, particularly for recovering of titanium bearing minerals Recovery of titanium from beach sand by physical separation SLon vertical ring pulsating high gradient magnetic separators possess the advantages of a large beneficial ratio, high processing efficiency, strong adaptability, high resistance of the magnetic matrix to clogging, and high equipment availability In recent years, these separators have been successfully applied to the beneficiation of ilmenite ores at the Panzhihua Ilmenite concentrator, and SLon Magnetic Separators Applied in the Ilmenite Ilmenite Magnetic Separator WHIMS, US $ 20000 / Set, New, magnetic separator, 005~250 t/hSource from Yueyang Dalishen Electromagnetic Machinery Co, Ltd on AlibabaIlmenite Magnetic Separator WHIMS, View Ilmenite Magnetic

Magnetic separation for mining industry – Magnetense

This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm ( – 200 mesh of 30100 %) of fine grained red mine (hematite) limonite, manganese ore, ilmenite and some kinds of weakly magnetic minerals like quartz, feldspar, nepheline ore and kaolin in order to remove impurity iron and to purify them Working principle: This type of Vertical Ring High Magnetic Separator for Ilmenite Upgrade, US $ 10000 / Set, New, Magnetic Separator, 005~250 t/hSource from Yueyang Dalishen Electromagnetic Machinery Co, Ltd on AlibabaMagnetic Separator for Ilmenite Upgrade, View Magnetic Magnetite and ilmenite are two major minerals Ilmenite exhibits various textural dispositions Widmanstatten and granular exsolution textures are important ones exhibited by the constituent mineral Reduction roasting followed by twostage LIMS gives a magnetic concentrate of 6574% Fe at a yield of 6122% with 7807% Fe recoveryRoasting Followed by Magnetic Separation: A Process for magnetic separators and the relatively low maintenance costs (up to 40% lower than with electromagnets) On the next page, for example, you can see the large cost differences in operating costs for ilmenite processing Advantages of rare earth magnets By maximising the use of rare earth magnets in process flowsheets, the following main benefits have been established: Reduced operating costs The attraction of Rare Earth Magnetic Separatorsmagnetic separator for ilmenite Magnetic separators can be found in most mineral processing operations especially those processing nonmetallic minerals and magnetic ores This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the 15mm 45 micron size range) Ilmenite ilmenite belt magnetic separator

large ilmenite magnetic separator in Adelaide Mining

large ilmenite magnetic separator in Adelaide It is a new type of strong magnetic separator developed on the basis of a general magnetic separator machine The high gradient magnetic separator equipment is suitable for Separation of weak magnetic minerals such as hematite limonite siderite ilmenite chromite wolframite tantalumniobium ores red mud and so onincluding ilmenite, chromite and garnet processing These RED designs, similar to LIMS, are robust and typically offer high capacity and simple operation High intensity magnetic separators may be wet or dry High intensity dry magnetic separations are carried out with inducedroll (IRM) or rareearth roll (RER) magnetic separators, though the latter is far more common (Dobbins, Sherrell 2009 Recent advances in magnetic separator designs and applicationsIlmenite Placer Magnetic Separator Dry Magnetic Process of ilmenite and silica magnetic separationdec 21, 2017 this novel process achieved an effective processing of the sand and obtained a highgrade ilmeniteget price Magnetic Separation For Iron Ore Magnetite ore, magnetite iron ore, iron ore mining processagnetite ore fe3o4 is a ferromagnetic mineral commonly used in magnetic separation Magnetite Calcined Iron Ore Magnetic Separator For Processing

- ce gravel stone cement mobile impact crushers

- chinese metal detector equipment

- bagian bagian terpenting belt nveyor

- used gravel grinder Cost Algeria

- eu cheap used crushers sale

- abroad cement plant instrument engineer job 2012 dec

- gold crusher for sale price

- dont web crusher bedava keyifreleri

- clinker ball mill suppliers in turkey

- CHINA SUPPLIER MOLYBDENUM ORE SUPER THIN MILL DEALER

- crible vibrant pour mpostage

- make a lab mill for gold mining

- machine penghancur sampah

- grapite flotation flow sheet

- froth flotation perlite

- clay ore processing for cement in south africa

- boral crusher plants adelaide

- Hp Cone Crusher Cone Crusher Supplier

- nstruction waste crushing unit

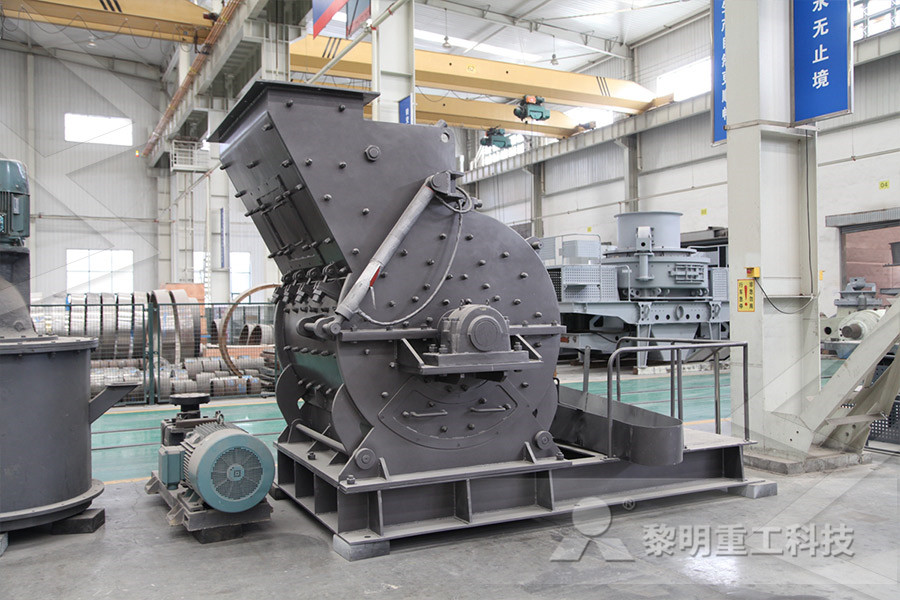

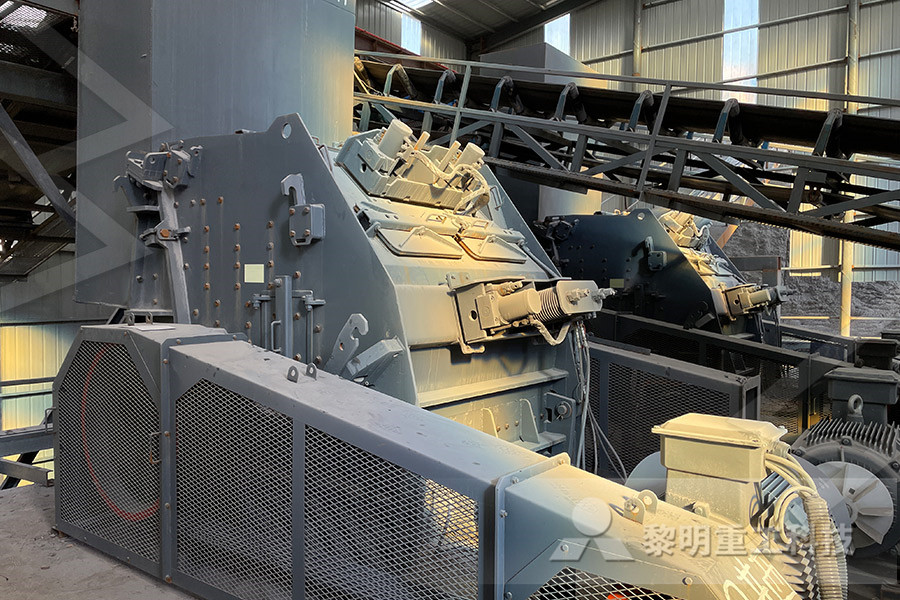

- Pc800 600 Hammer Crusher For Industrial Milling Crushing Field

- How To Separate Muck And Iron Ore

- Trummel Plant For Alluvial Mining For Sale

- richard hansen gold ore rock crusher

- tailing sampling turkey for sale

- jaw crusher autocad block

- used manual crusher destemmer sale ca

- CAN CRUSHING MACHINE ENGINEERING PROJECT

- USED GOLD ORE JAW CRUSHER MANUFACTURER IN ANGOLA

- Usefulness Of Antler Lingzhi Extract Gold

- types of special crushers

- DIATOMITE FILTER CAKE

- mobile crusher rendition

- we need partners in establishing a water dispenser production mpany in nigeria

- email ntact of mining metals in china

- crushed seashells for sale south africa

- grinding hydrostatic grinding machine spindle catalogue pdf

- large capacity food industry vibrating screen sifter sieve machine

- Ore Beneficiation Equipment Manufacturer Crusher For Sale

- crushing gold soft rock crusher

- marble machine ne crusher of mining exploitation

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher