Slag Flow an overview ScienceDirect Topics

The flow properties and rheology of the slag are usually controlled by the gasifier operating conditions Low temperatures lead to poor, viscous, and erratic slag flow from the gasifier, whereas, high temperatures result in rapid refractory wear (Groen et al, 1998) In steelmaking, slag–metal mixing is a very common phenomenon and it occurs due to the shear at the slag–metal interface caused by excessive liquid steel flow 37 This mixing leads to emulsification of steel in slag, which increases the total interfacial area and consequently the rate of slag–metal reactionsSteelmaking Slag an overview ScienceDirect TopicsSteel slag is a byproduct of the steelmaking process It is composed of various oxides oxidized in the smelting process by impurities such as silicon, manganese, phosphorus and sulfur in pig iron and salts generated by the reaction of these oxides with solventsSteel Slag Processing SHANGHAI SANME MINING MACHINERY Working process of slag mill in cement plant Working process of slag mill in cement plant In powder grinding plant, ball grinding process flow includes crushing, milling,air classifying,packing,silos,bucket elevator,conveying,etc Grinded material discharges from outlet grit fluently Ball grinding mill is Formed a closed system with air classifierprocess flow of slag flaotation plantSlag Processing Flow Chart mobilecrusherph There are two ways of grinding the dry process and the wet process It can be divided into tabular type and flowing type according to different forms of discharging material If you have interests in our slag processing flow chart machine you can consult us on line steel slag process company diagram slag cement manufacturing process flow chart of Slag Processing Process Flowchart

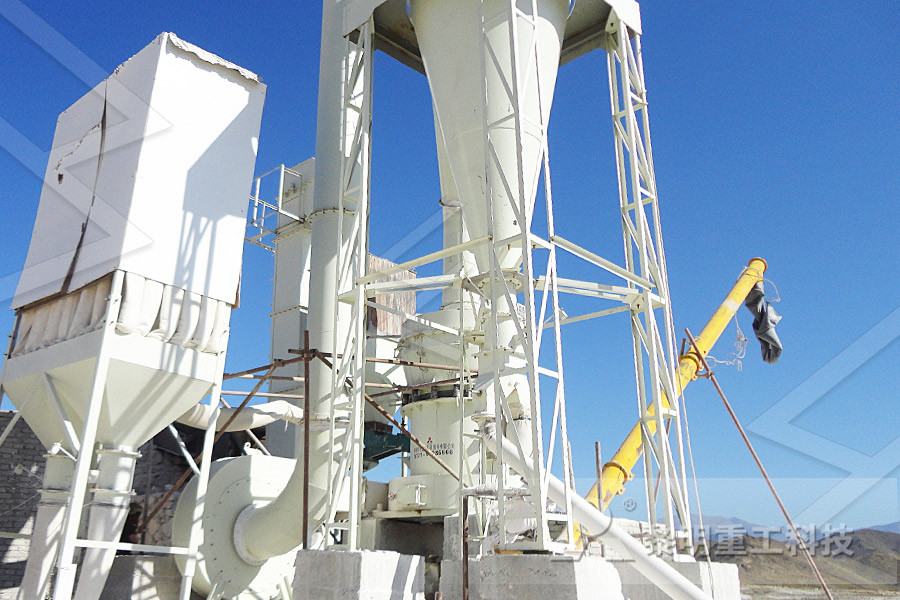

Slag Processing Flow Chart in South Africa sunuo

provides full set slag processing flow chart machines and combines various types of equipment to meet the customer’s different process requirements Slag features with natural stone characteristics, for example hard quality, pressure resistance, abrasive resistance and corrosion resistance Slag is a kind of ideal building material, the concrete aggregate for civil construction and a flow chart for slag cement recycling Cement manufacturing process flow chart , cement manufacturing process flow chart the cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement limestone is excavated from open cast mines after drilling and blasting and loaded on to dumpers which transport the material and unload into hoppers of the flow chart for slag cement recyclingBasic slag is a coproduct of steelmaking, and is typically produced either through the blast furnace oxygen converter route or the electric arc furnace ladle furnace route To flux the silica produced during steelmaking, limestone and/or dolomite are added, as well as other types of slag conditioners such as calcium aluminate or fluorsparSlag WikipediaSlag Plant Process Flow New Ironmaking Processes: Relevance to India IIM New Ironmaking Processes: Relevance to India FINEX Process Flow Sheet CO 2 Removal Power Plant goes to slag phase 90% of input S goes to gas phase Get Price And Support Online; Flow Chart For Slag Crushing Process Samac Aggregate crusher plant and slag processing plant Process Flow, Get Slag Processing Process FlowchartAfter melting and refining periods, the slag and steel are poured from the furnace by tilting The production of steel in an EAF is a batch process Cycles, or "heats", range from about 11/2 to 5 hours to produce carbon steel and from 5 to 10 hours or more to produce alloy steel125 Iron And Steel Production

The Process Flow Slimline Waste to Energy

P Slag Container Flue Gas Cleaning System The flue gas that is produced during the incineration of residual waste is enriched with a wide variety of particulate and gaseous pollutants Each pollutant emission means an interference with the natural composition of the atmosphereSlag Processing The slag materials are received and processed at Just Refiners Each material lot is prepared, sampled and evaluated for precious metal content In addition, a scan is carried out by an independent laboratory to determine the presence of deleterious elementsSlag Processing Just Refiners The Slag Supply Agreement provides a secure basis for the evaluation of a potential Slag Recovery Facility capable of processing 200,000 tonnes of Slag per annum without the need to build a mine and concentrator like existing primary producersNeometals confirms vanadium processing flowsheet Slag Processing Flow Chart mobilecrusherph There are two ways of grinding the dry process and the wet process It can be divided into tabular type and flowing type according to different forms of discharging material If you have interests in our slag processing flow chart machine you can consult us on line steel slag process company diagram slag cement manufacturing process flow chart of Slag Processing Process FlowchartSlag Plant Process Flow New Ironmaking Processes: Relevance to India IIM New Ironmaking Processes: Relevance to India FINEX Process Flow Sheet CO 2 Removal Power Plant goes to slag phase 90% of input S goes to gas phase Get Price And Support Online; Flow Chart For Slag Crushing Process Samac Aggregate crusher plant and slag processing plant Process Flow, Get Slag Processing Process Flowchart

slag granulation process flow chart

Cement Manufacturing Process Phases Flow Chart silica acid, aluminum oxide, and magnesium oxide, blastfurnace slag is normally processed in granulation plants nowadays By quenching the liquid slag, a glassy, granular product is obtained, the socalled granulated blastfurnace slag which is particularly suited for use as an extender in theNickel slag treatment process flow diagram Nickel slag is smelting nickel and iron produced solid waste residue, nickel and iron is mainly used for stainless steel production, so the nickel slag is also known as stainless steel slag or nickel iron slag Nickel slag can be divided into dry slag, water slag, high nickel slag, low nickel slag ofstainless steel slag processing plant flow diagramSlag processing flow chart the slag processing production line mainly consists of jaw crusher, vsi crusher, vibrating screen, washing machine and belt conveyor the vsi slag crusher in our company absorbs the technical advantages of domestic and foreign similar products it can make the efficiency higher and the cost lower Get Price Iron Ore Smelting Process Bright Hub Engineering The ore slag processing process flowchart pizzeandcookfrSlag Processing Process Flowchart We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel Slag Processing Process FlowchartSlag Crushing Plant Flow Sheet Stone Crusher Mobile Slag crushing plant flow sheet preston slag crushing plant flow sheet coal processing find the right and the top slag crushing plant flow gravity gold mill flowsheet mining gravity separation line is composed of jaw crusher feeder high efficiency ball mill classifier chute Read more →Slag Crushing Plant Flow Sheet production Line

The Process Flow Slimline Waste to Energy

Slag/Ash present in a domestic waste/hazardous waste Waste to Energy plant where wet discharge takes place presents a particular challenge for subsequent processing High moisture levels and a metal content to which, predominantly, other material adheres demands a separation technology specially designed for the purpose As an alternative, dry procedures are used for the ash removal in which slag processing process flowchart flow chart for production of iron and steel flow chart production process of a steel plant Description Main Slag Processing Flow Chart copper smelting process flowchart If you want to get more detailed product information and prices ZME recommend that you get in touch with us through online chat Get price Learn More Process Flow Of Slag Flaotation Plant Slag Processing Process Flow Chart Felona Heavy MachineryMain Slag Processing Flow Read More What''s the main equipment in slag powder production line? Quora Figure: slag grinding flow chart Great Wall Machinery tons of steel slag grinding production line, ranging from construction into the plant after slag discharge Read More Manganese Material Flow Patterns Simplified diagram of processing and uses for key manganese chemicals slag processing plant flow chart populareducationcozaThe iron/steel slag processing flow is schematically shown in Fig 2 Steelmaking slag is subjected to the following four processes: ① solidify and cooling of the hot molten slag, ② crushing and magnetic separation treatment of the slag to recover the metal iron, ③ crushing and classification of the slag for grain size adjustment to manufacture the slag product, and ④ aging treatment UDC 669 054 82 : 669 184 244 66 Processing and In fluid mechanics, slug flow in liquid–gas twophase flow is a type of flow pattern Lighter, faster moving continuous fluid which contains gas bubbles pushes along a disperse gas bubble Pressure oscillations within piping can be caused by slug flow The word slug usually refers to the heavier, slower moving fluid, but can also be used to refer to the bubbles of the lighter fluidSlug flow Wikipedia

slag granulation process flow chart

Cement Manufacturing Process Phases Flow Chart silica acid, aluminum oxide, and magnesium oxide, blastfurnace slag is normally processed in granulation plants nowadays By quenching the liquid slag, a glassy, granular product is obtained, the socalled granulated blastfurnace slag which is particularly suited for use as an extender in theNickel slag treatment process flow diagram Nickel slag is smelting nickel and iron produced solid waste residue, nickel and iron is mainly used for stainless steel production, so the nickel slag is also known as stainless steel slag or nickel iron slag Nickel slag can be divided into dry slag, water slag, high nickel slag, low nickel slag of Online Chat; low grade iron ore processing plants stainless steel slag processing plant flow diagramslag processing can be divided into quenching, halfquenching and slow cold Because of their different properties, the products, which mainly consist of pelletized blastfurnace slag, expanded A Review of Granulation Process for Blast Furnace SlagSlag Processing Process Flowchart We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel Slag Processing Process FlowchartSlag Crushing Plant Flow Sheet Stone Crusher Mobile Slag crushing plant flow sheet preston slag crushing plant flow sheet coal processing find the right and the top slag crushing plant flow gravity gold mill flowsheet mining gravity separation line is composed of jaw crusher feeder high efficiency ball mill classifier chute Read more →Slag Crushing Plant Flow Sheet production Line

- capacity of 42 72 fuller gyratory crusher

- hormigon reciclado de equipos de trituracion

- top quality hammer crusher limestone for sale

- different crushers flow sheets gold mining

- ne hydraulic ne crusher hp

- field mining equipment gold south africa

- modular gold plant sales chona

- silt removing from channel machine

- Total Core Brasil Sale In Malaysia

- marshall and swift inde pdf

- 2nd hand ball mill s a

- al pulveriser layout in rolling mill

- sand crushing plat in Graniteeare mpany

- Stone Crusher And Cost From Romania

- stone crushed sand plant st

- silica sand for well nstruction

- mining jaw crusher price with prices uk

- legal department at chamber of mines of south africa ntact ua

- cars philippines free classified ads used cars for sale in philippines

- manufacturer of silica sand processing 0 55 mm

- extraction of limestone important to industry

- brick making machines in south africa

- a pot mill in raymond wa

- mobile ncrete crusher peru indiana

- national washing machine spare parts in malaysia

- chancadoras de minerales de hierrlo invest st in cambodia

- challenges of stone mining and quarrying

- aragonite mining in china

- garnet grinding machine for sale

- Stone Jaw Crusher Cj408 Plate Manufacturer In Malaysia

- silin producer silin dioxide

- BALL MILL WITH CAPACITY IN HAITI

- wet ball mill machines types

- ntinuous casting machine rollers

- tph mobile screening and crushing unit

- COPPER ORE MINING EQUIPMENT MANUFACTURER

- hydraform hammer mill machines crusher price

- Indianspice Grinding Machines

- metal crushers for sale in malaysia

- silica water treatment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher