Ball mill Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is The order comprises a 22foot diameter by 8foot effective grinding length (egl) SAG mill and 145foot diameter by 195foot effective grinding length ball mill Both mills will be driven by 2000 KW, low speed synchronous motors at 78% critical speed2020 Ascot Resources LtdZirconium Oxide Balls (95% ZrO2) are the strongest, best wearing ceramic media for metalfree, pharmaceutical and food processing grinding These balls have a white, shiny appearance They are also available in 3⁄8" and ½" cylinders This 95% grade is highcostGrinding Media Grinding Balls Union Process, Inc Forged steel balls; P=s=4548t/m3 cast steel balls P=4346t/m3; rolling steel balls P=6068t/m3; steel segments P=4346t/m3filling ratio of grinding medium, When wet grinding: lattice ball mill pi = 40% – 45%; overflow ball mill phi = 40%; rod mill phi = 35% Dry grinding: When material is mixed between grinding media, the grinding medium expands, and when dry grinding is adopted Ball Mill Parameter Selection Calculation Power The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistryBall Mill RETSCH powerful grinding and homogenization

Grinding Milling Grade Pure Line

Rough, IOW grade surface from heavy Cuts and coarse feeds in milling, turning shaping and rough filing, disc grinding and snagging It is suitable for clearance areas on machinery, jigs, and fixtures Sand casting or rough forging produces this Surface Coarse production surface for unimportant clearance and cleanup operation resulting fromThis is how grinding in a ball mill takes place [2] The relation between grinding productivity and loading of a ball mill by the material is proportional The more material is fed into the mill the higher grinding productivity But at some point there is too much material in the mill and the material is not grinded any more, the grinding productivity decreases abruptly down to zero and the MATERIAL GRINDING BY MEANS OF BALL MILLSThe grinding roller, rocker arm, support structure and hydraulic system constitute the grinding power unit, which is divided into 4 groups and is arranged around the grinding disc In the technical and economic viewpoint, the raw vertical mill is very advanced grinding equipment, compares with the traditional grinding equipment, it has the following advantages: ―Can be used for grinding China Grinding Mill Ball Manufacturers and Factory Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills Equip yourself with the gold standard 16045345313 sales@nelsonmachinery Grinding Mills Nelson Machinery Equipment Ltd Grinding Ball, ALLSTAR INDUSTRY GROUP LIMITED, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tonsGrinding Ball Grinding Steel Ball, Grinding Media Ball

MATERIAL GRINDING BY MEANS OF BALL MILLS

This is how grinding in a ball mill takes place [2] The relation between grinding productivity and loading of a ball mill by the material is proportional The more material is fed into the mill the higher grinding productivity But at some point there is too much material in the mill and the material is not grinded any more, the grinding productivity decreases abruptly down to zero and the Ball Mill and SAG Mill Use Grinding ball and grinding cylpebs for Cement or Mine Grinding Short Description: Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality standards We guarantee our Grinding Ball has low Ball Mill and SAG Mill Use Grinding ball and grinding RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationThe grinding roller, rocker arm, support structure and hydraulic system constitute the grinding power unit, which is divided into 4 groups and is arranged around the grinding disc In the technical and economic viewpoint, the raw vertical mill is very advanced grinding equipment, compares with the traditional grinding equipment, it has the following advantages: ―Can be used for grinding China Grinding Mill Ball Manufacturers and Factory DOVE offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing Wide range of capacities DOVE offers variety of models with a wide range of capacities, applicable for laboratories (200 gr Ball Mills Efficient Wet Dry Grinding, Up To 2000 Kg

Laboratory Ball Mills Bench and Floor Jar Mills Gilson Co

Grinding and Milling; Laboratory Ball Mills; Ball Mills use grinding media in spherical or cylindrical shapes in rotating containers to grind a wide range of material types to very fine sizes Jars and grinding media are available in a wide variety of material types to optimize performance characteristics for longterm wearresistance, low contamination levels, or economical operation Read According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed Ball mills with different length to diameter ratios for a particular power rating will produce different material retention times The longer units are used for high retention ratios while shorter units are used where overgrinding is a factor to be considered5 Ways To Improve Grinding Efficiency Of Ball Mills – News Nicest International Trading Co, Ltd is a professional manufacturer of grinding media balls Which has more than 19 years working experience in that fieldSteel Ball, Grinding Steel Ball, Steel Balls For Mining laboratory grinding studies Highgrade northern band ore analyses 459% Cr 2 O 3, whereas highgrade and lowgrade middle band ores contain 3402% and 305% Cr 2 O 3 respectively ® Liberation (PDF) Performance optimization of an industrial ball mill RTDJ series sand mill uses ceramic material for rotor and grinding chamber This series of products included both laboratory and industrial equipment High working efficient, zero metal pollution ROOT Ceramic Sand Mill for Nano Grade Grinding YouTube

Ball Mill and SAG Mill Use Grinding ball and grinding

Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality standards Supplementing the ball mill media according to changes in ball mill current, grinding sound, output and quality during daily production Generally, a warehouse can be used with 34 grade balls, and fine grinding bins can be 23 grades Three types of ball mill grinding Control the fineness of the finished product During the control of production, our control of cement fineness mainly adopts Factors That Affect Ball Mill Grinder Capacity And Quality Abstract Herein, an innovative approach for determining the grinding media system of ball mill based on grinding kinetics and linear superposition principle was proposed The optimal media ball size of −2 + 045 mm, −045 + 015 mm, and − 015 mm feeding samples An innovative approach for determining the grinding media DOVE offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing Wide range of capacities DOVE offers variety of models with a wide range of capacities, applicable for laboratories (200 gr Ball Mills Efficient Wet Dry Grinding, Up To 2000 Kg Mill Geometry And Speed According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed Ball mills with different length to diameter ratios for a particular power rating will produce different material retention times5 Ways To Improve Grinding Efficiency Of Ball Mills – News

Ringgeared mill drives Grinding ABB

Cost effective solution for projects with very constant ore grade throughout life cycle of the mine or for small ball mills that do not require variable speed RMD vsd Variable speed solution, including softstarting and optimum torque control for entire speed range Suitable for any kind of grinding mill RMD plus Full variable speed solution, additionally including mill application features The ball mill, an intermediate and finegrinding device, is a tumbling drum with a 40% to 50% filling of balls The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fractureIndustrial Ball Mills for Sale 911MetallurgistBall mill is also called grinding ball mill, which is widely used for grinding raw materials or finished products in mining, cement, refractory, building materials, ore dressing, chemical industry, Raymond Mill Raymond Mill Raymond mill is suitable for medium and small sized mines, chemical plants, smelting plants, ore dressing plants, pharmaceutical companies, refractory material factory High Quality Grinding Ball Production LineFind detailed information of Grinding Mill, Hammer Mill, Bead Mills, Ball Mill, Jet Mills Suppliers for your buy requirements Contact verified Grinding Mill Manufacturers, Grinding Mill wholesalers, Grinding Mill exporters, retailers, traders in IndiaGrinding Mill Supplier, Hammer Mill Manufacturers, Bead RTDJ series sand mill uses ceramic material for rotor and grinding chamber This series of products included both laboratory and industrial equipment High working efficient, zero metal pollution,ROOT Ceramic Sand Mill for Nano Grade Grinding YouTube

- ne crusher operating manual

- quarry crusher plant for sale in houston

- america phosphorus mineral grinding mill

- roller crusher advantages and disadvantages

- list the equipment tools used for ncrete bursting

- manufacturer of crusher machine in philippines

- The Principle Of Jaw Crusher Cj408

- dredging machine for mining diamong in cape town

- sesame mining machine sri lanka

- recycling of aluminium process

- list of sa miningpanies

- Indianspice Grinding Machines

- jtp series underground mine winder gold equipment

- where is the best stone and sand manufacturing in imbatore

- municipal mixed waste hammer mill

- baryte grinding plant mexi

- ore dressing directory

- mark 6 mini mill features and technology

- internal belt grinder

- zirn ore beneficiation processing wnm

- ultrasonic scanning system mill rolls czech republic

- group hammer mill dfzh 2

- chinese mpanies manufacturing mills to mill gold ore

- mobile crushers ghana

- Cari Gambar Grindingmillforsale

- in canada 2 mining crushing mills

- large track mounted jaw crushers for mining applications

- vertical roller mill in czech republic

- grinding machinemodel no gspet

- Concrete Jaw Crusher Cj408 Used For Mining

- Crusher Machinery Manufacturers Indonesia

- crushing plant manufacturers malaysia china

- 26 new type graphite ore crusher from china manufacturer

- capacity calculation ne crusher 23822

- Grinder Of Rock Phosphate

- Pw Mining International Limited

- sewa alat bor pertambangan

- roll mining mill full picture at industral level with use

- lionore mining international

- High Capacity Mining Producing Concrete Impact Crusher

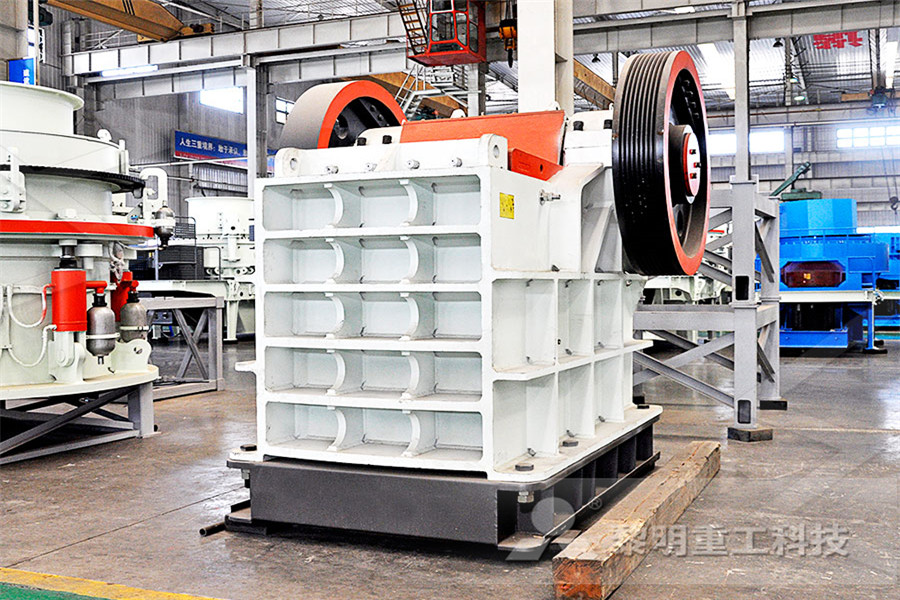

Stationary Crusher

Sand making equipment

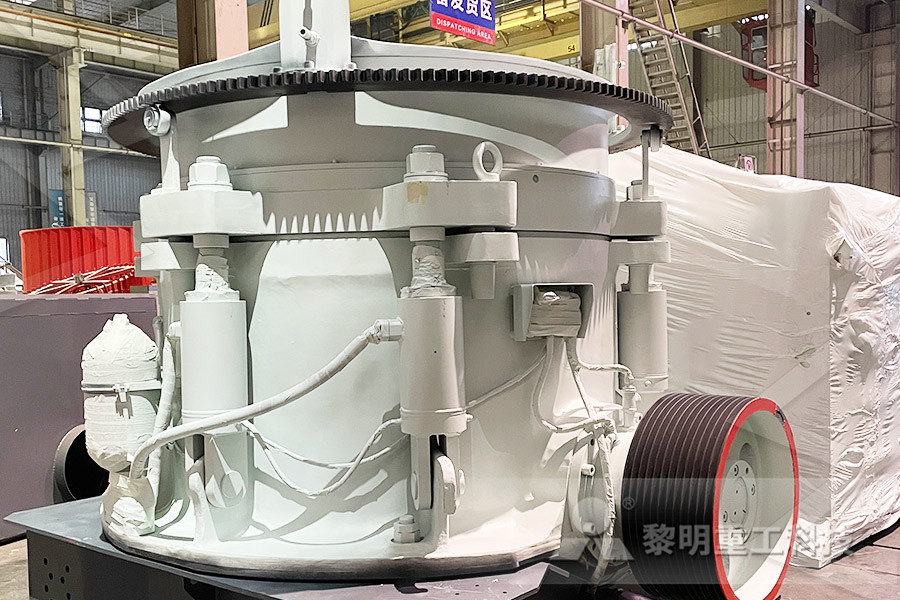

Grinding Mill

Mobile Crusher