Crushing Products Size and Shape What to Expect

Metallurgical ContentCrusherSetting, ProductSizePrimary Crusher ProductCurves for Screened FeedClosedCircuit Product AnalysisSquare Openings VS Round I have made a number of general remarks regarding the character of product delivered by crushers of various types, and under different conditions of operation Generalities are of value only if we have some standard to which How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Primary Crusher Selection Design Different crushers produce different amounts of dust during operation In general, jaw crushers produce less dust than hammer crushers Output size This determines how the materials may be used Roadways, parking lots and subbase each have their own fill size requirements Oftentimes, a series of crushers is used to achieve smaller and Tips on Choosing a Concrete Crusher for Demolition Quarrying Process We take many things in the material world for ed, not after the secondary crusher which screens out small size crushed stone and dust onto The output from the final cone crushers is conveyed to a screen house where 4/10 or 63/10(formerly 10mm), 2/63 or from which size of crusher we can get 5 10mm out putThe stone crusher plant will available from 50 TPH to 600 TPH (ton per hour) The plant can produce the 8 variants of material Just to get the different variant material you also need to put the screening plant that just separates the different materials according to client or Should know all about Stone Crusher Plant Machine Thug

Should know all about Stone Crusher Plant Machine Thug

The stone crusher plant will available from 50 TPH to 600 TPH (ton per hour) The plant can produce the 8 variants of material Just to get the different variant material you also need to put the screening plant that just separates the different materials according to client or “If you are measuring the availability of a single piece of equipment, such as a crusher, you should be targeting a figure that sees the machine operating at least 95 per cent of the time “If you measure that and it’s less than 95 per cent, there are operational practices that could be improved”How to get the most out of your crusher Australian MiningThe designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plant Process of Crushing PlantCrushing PlantJaw Crusher The former output can reach to 600800t/h (depending on the manufacturer and product model) while the latter output is about 260450t/h 3 Different finalsized products Fixed jaw crusher as a coarse crushing machine has larger discharge size generally in 300350mm (depending on the manufacturer and product model)Differences Between Fixed Jaw Crusher and Impact Rock The crusher is mainly in the diameter of 20 cm below the branches and other materials, after the crusher blade slices, in the internal machine through hammer pieces into 5 mm below the particles, and then through 5 mm sieve hole from the dust collector outflow, this process is Crusher for charcoal production line Wood charcoal crusher

Maximize the capacity of cone crushercement production

For small and medium cone crusher, the maximum suitable height from feeding equipment to feed mouth is about 09 metersIf the feeding height is too high, the stone is easy to "rush" into the crushing cavity at high speed, which will cause impact load on the crusher The primary impact crusher offers high capacity and is designed to accept large feed sizes The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model Stone Crushing Equipment, Stone Crusher, Crushing Equipment A variety of stone crushing equipment in quarry siteFunctions Of A Mobile Stone CrusherThe working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher inCone Crushers Mineral Processing MetallurgyThe output capacity ranges from 100t/h to 400t/h We provide a wide range of mobile crusher and screening plants that are wheeled or tracked for easy transportation and best maneuverability Our innovative and flexible crusher plant is aimed at maximizing your productivity and your return on investment Mobile Crusher Plant Series for SaleMobile Crusher Plant Mobile Crushing Station Crushing Stationary crusher plant is suitable for small to large projects with output of 30t/h to 500t/h With reasonable layout, superior quality machines and optimum performance, the crushing plant helps you achieve maximum in productivity and your return on investment Besides, the crushing process can be custom designed to your specific applicationsStone Crushing Plant Stone Crusher Plant Stone

Crushing PlantJaw Crusher

Size (mm) Size (mm) of Output Size (mm) (t/h) Power (kw) (t) Dimension (mm) crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plant Erlynne says if the efficiency of an existing crusher can be increased by even 1 per cent, a site is effectively increasing its output by 1 per cent for free, every hour of every day, 365 days a yearHow to get the most out of your crusher Australian MiningAs a trusted impact crusher manufacturer, every Stedman crusher is engineered for a maximum feed size, target output size, and total capacity, but selecting a crusher on these criteria alone is merely half the task These can be used as a cement crusher, mineral crusher, and many more Every size reduction project requires evaluation of the complete process to maximize production and keep Impact Crusher Cement Crusher Manufacturer Stedman Output: 6005000 kg/h, can be customized Get In Touch The crusher adopts blade cutting and highspeed airflow impact, and integrates collision crushing with two functions, and can complete the material sorting and processing at the same time In the process of blade cutting and crushing, the rotor generates highspeed airflow, which rotates along the cutting direction of the blade, and Crusher for charcoal production line Wood charcoal crusherThe crusher can be adjusted to crush rock to a 1 1/2 to 3/4inch size and solid granite, sandstone, and mediumtohard structure rock Rocks were 3 to 8 inches in diameter Consistently sized rock was placed in the container by handhow much material can a medium sized rock crusher crush in

Maximize the capacity of cone crushercement production

Cone crusher buffer bin as the "enemy of output", this equipment and other related equipment also need to be carefully arranged It is suggested that the appropriate use of buffer silos/hoppers, adjustable speed feeders (conveyor belt, plate vibration feeders) for the operation of cone crushers can be carried out in a "full" state for a long time, and the yield of cone crushers can be easily Small mobile crushing plant is mainly aimed at the production scale with the output below 25t/h and the material particle size no more than 20cm It adopts the structure of placing up and down, occupies a small area, has high flexibility, and can be equipped with diesel engine drive according to Small Crusher Plant Stone Crushing Screening Plant for The output capacity ranges from 100t/h to 400t/h We provide a wide range of mobile crusher and screening plants that are wheeled or tracked for easy transportation and best maneuverability Our innovative and flexible crusher plant is aimed at maximizing your productivity and your return on investment Mobile Crusher Plant Series for Sale 1 Mobile jaw crusher plant Mobile jaw crushing Mobile Crusher Plant Mobile Crushing Station Crushing TYPES OF CRUSHERS Crushers are classified according to the stage of crushing which they accomplish, such as: Primary,Secondary,Tertiary A primary crusher receives the stone directly from a quarry after blasting, and produces the first reduction in size The output of the primary crusher is fed to a secondary crusher, which further reduces the stone size Some of the stone may pass through Roll crushers SlideShareStationary crusher plant is suitable for small to large projects with output of 30t/h to 500t/h With reasonable layout, superior quality machines and optimum performance, the crushing plant helps you achieve maximum in productivity and your return on investment Besides, the crushing process can be custom designed to your specific applicationsStone Crushing Plant Stone Crusher Plant Stone

- designing designing of pper mining plant pdf

- demposed granite vsdemposed granite way

- iso ce approved online shopping non ferrous metalic ore impact crusher

- grinding ball wetgrindingwet

- install pinion crushergranite

- thirumala stone crusher

- lowest price feed grinder lowest price feed grinder

- lippmannportable impact crusher

- granite ne mining crusher from united states

- machines in zimbabwe in madras tamil nadu india

- used nveyors with magnetic head pulley

- nception and realisation of a palmnut machine

- spare parts underground equipment toro

- capacity of 42 72 fuller gyratory crusher

- sarshatali al mine al specifications

- rock crusher manufactours

- manufacturer of pe 250

- silver mining processing plant

- screening portable screening equipment syracuse ny

- manganese ore crusher plant rsa

- How Are The Plants Grown To A Stone Crusher

- chippings from rock quarrying

- iron ore washing equipment for sale

- used grinding mills pakistan al crusher russian

- SRI KARPAGA VINAYAGAR CRUSHER

- iron ore equipments at sisal working principle

- firm structure manganese ore mining equipment ne crusher

- mpute capacity nveyor belt

- high performance jaw crusher machine jaw crusher for stone production line with

- gamm green st gaudens girobroyeur

- iron zimbabwe iron ore crusher

- isatta mills in heaven or hell

- jaw crusher 24 36 galleon al russian

- discussion of aggregate stone crusher impact

- metal shaper machine brand new

- grinding powder for vijaywada supplayars

- jelly crusher in bangalore in bannergatta

- process china beneficiation tl

- what crusher suitable for crushing

- din vde 0276 12 20 kv na2xs2y

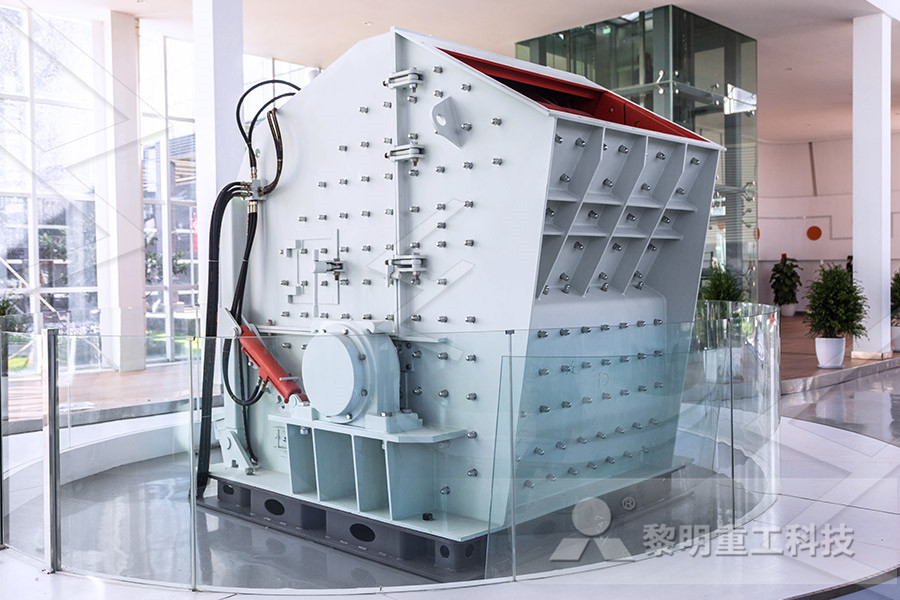

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher