Iron Ore Mining PowerPoint PPT Presentations PowerShow

2020 Iron Ore Mining Industry in Australia The iron ore production in 2013 was 6092 million tons (Mt), a figure that is projected to reach 6928Mt by 2015 and 8124Mt by 2020 Iron ore in the country is abundantly found in Western Australia, which accounted for 97% of country’s total iron ore production in 4/27/2015 15 Iron ore Common iron ores include: Hematite Fe2O3 70 % iron ( a common iron ore) Magnetite Fe3O4 72 % iron Limonite Fe2O3 + H2O 50 % to 66 % iron Siderite FeCO3 48 percent iron To create a ton of pig iron, you start with 2 tons of ore, 1 ton of coke and halfton of limestone The fire consumes 5 tons of air The temperature reaches almost 1600 0 C at the Production of iron and steel SlideSharelargest hyperbaric disc filter in iron ore production, with a guaranteed residual moisture content of 7% requested at high throughput and clear filtrate RESOURCES YOU CAN COUNT ON Whether it’s thickening or filtration, concentrate or tailings, the list of success stories goes on and on With thousands of professionals and more than one hundred iron ore solutions in operation, every new SEPARATION EXPERTISE FOR YOUR SUCCESS IN THE IRON ORE Mining; Iron ore; Index Overview; Our offerings; Our expertise; Customer stories; Share LinkedIn Twitter Facebook Contact Reliable equipment to handle the large volumes required in your iron ore mine For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation Reliable equipment for iron ore mines of iron and manganese by mining ore deposits will therefore remain an important fundament to industrial development in the twentyfirst century The majority of ore deposits of both iron and manganese are of sedimentary origin At present, highgrade iron ore deposits formed by hydrothermal and supergene enrichment of Proterozoic banded iron formations constitute the most important source for Iron and Manganese Ore Deposits: Mineralogy, Geochemistry

iron ore mining classifi ion and filtration

“Aqueous ions in process water and cake moisture during iron ore filtration Get price Development Document for Ore Mining Dressing Category EPA Historical Constituents of IronMine Discharges Historical ion exchange are widely applied techniques for concentrating and classification of the ore pulp into sand and slime tractions The sand The precipitate is With a texturebased iron ore classification, you can understand the porosity, physical properties, mineral proportions and mineral associations of ores, increasing the efficiency of downstream processing and allowing a proactive response to changing feed typeIron ore classification and the future of resource India has large reserves of Iron ore, Bauxite, Chromium, Manganese ore, Baryte, Rare earth and Mineral salts India has vast mineral potential with mining leases granted for longer and stable tenure of 50 years The demand for various metals and minerals will grow substantially over the next 15 years India’s strategic location enables convenient exports Explore more about infrastructure MINING Make In India 4/27/2015 15 Iron ore Common iron ores include: Hematite Fe2O3 70 % iron ( a common iron ore) Magnetite Fe3O4 72 % iron Limonite Fe2O3 + H2O 50 % to 66 % iron Siderite FeCO3 48 percent iron To create a ton of pig iron, you start with 2 tons of ore, 1 ton of coke and halfton of limestone The fire consumes 5 tons of air The temperature reaches almost 1600 0 C at the Production of iron and steel SlideShareIron Ore Mining Classification And Filtration Ppt [ 49 8556 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » stone crusher companies pune » China Mining Iron Ore Mining Classification And Filtration Ppt

Iron Ore Processing for the Blast Furnace

Mining iron ore begins at ground level Taconite is identified by diamond drilling core samples on a grid hundreds of feet into the earth Taconite rock comprises about 28 percent iron; the rest is sand or silica These samples are analyzed and categorized so that mining engineers can accurately develop a mine plan To uncover taconite reserves, the mine area is first "stripped" of th e 5 Covid19 Impact on Global Iron Ore Mining Historic Market Analysis by Application 51 Global Iron Ore Mining Sales Market Share by Application (20152020) 52 Global Iron Ore Mining Iron Ore Mining Market Size 2020 Segmented by Types and Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig 1345)Iron ore requires removal of silicate impurities of a finer size by flotation for highergrade products of +60% Fe ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mmOre Mineral an overview ScienceDirect TopicsOre Deposits Sedimentary Deposits Banded Iron Formations (BIFs): Fe2+ is soluble in water, Two types: open pit (massive ore bodies) strip mining (bedded ore bodies) 30 Surface Mining (cont) Strip Mining – overburden is stripped off (dumped as spoil banks or spoil piles), the ore removed, and waste replaces it in a cyclic manner The waste fraction is almost constant throughout mine Portrait of a Planet Fifth Editionof iron and manganese by mining ore deposits will therefore remain an important fundament to industrial development in the twentyfirst century The majority of ore deposits of both iron and manganese are of sedimentary origin At present, highgrade iron ore deposits formed by hydrothermal and supergene enrichment of Proterozoic banded iron formations constitute the most important source for Iron and Manganese Ore Deposits: Mineralogy, Geochemistry

Mine 2018 PwC

commodities like iron ore, copper and coal However, as can be seen from Figure 2, the USA and Europe account for more than 40 per cent of global GDP Although their growth rates are nowhere near as impressive as those of the emerging markets, relatively small increases, or declines in growth can have an impact on metal demand, especially consumer driven demand The mining industry is Overview of the Steel and Iron Ore Market Overview of the global steel and iron ore market Production output trends European Union On 19 July 2018, the European Union imposed provisional safeguard measures with regard to imports of 26 categories of steel products The aim was to protect the domestic market from low price import products after the US steel and aluminum tariff hikes The Overview of the Steel and Iron Ore MarketFor the Breakeven (Mining) cutoff grade, mw = 0 Material below this grade should not be mined These cutoff grades are the fastest way to classify ore and waste, however, in a more detailed analysis they should not be relied on Lane’s Method Lane's Method was presented by Ken Lane in 1988 when he identified three distinct stages of cutoff grade application; mining, concentrating, and Cutoff grade estimation QueensMineDesignWiki 4/27/2015 15 Iron ore Common iron ores include: Hematite Fe2O3 70 % iron ( a common iron ore) Magnetite Fe3O4 72 % iron Limonite Fe2O3 + H2O 50 % to 66 % iron Siderite FeCO3 48 percent iron To create a ton of pig iron, you start with 2 tons of ore, 1 ton of coke and halfton of limestone The fire consumes 5 tons of air The temperature reaches almost 1600 0 C at the Production of iron and steel SlideShareIron Ore Mining Classification And Filtration Ppt [ 49 8556 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » stone crusher companies pune » China Mining Iron Ore Mining Classification And Filtration Ppt

Mineral Resources SlideShare

Surface mining can make use of any of the following three types: (a) Openpit mining in which machines dig holes and remove the ores (eg copper, iron, gravel, limestone, sandstone, ma rble, granite) (b) Dredging in which chained buckets and draglines are used which scrap up the minerals from underwater mineral deposits (c) Strip mining in which the ore is stripped off by using bulldozers 5 Covid19 Impact on Global Iron Ore Mining Historic Market Analysis by Application 51 Global Iron Ore Mining Sales Market Share by Application (20152020) 52 Global Iron Ore Mining Iron Ore Mining Market Size 2020 Segmented by Types and Ore Deposits Sedimentary Deposits Banded Iron Formations (BIFs): Fe2+ is soluble in water, Two types: open pit (massive ore bodies) strip mining (bedded ore bodies) 30 Surface Mining (cont) Strip Mining – overburden is stripped off (dumped as spoil banks or spoil piles), the ore removed, and waste replaces it in a cyclic manner The waste fraction is almost constant throughout mine Portrait of a Planet Fifth Editioncommodities like iron ore, copper and coal However, as can be seen from Figure 2, the USA and Europe account for more than 40 per cent of global GDP Although their growth rates are nowhere near as impressive as those of the emerging markets, relatively small increases, or declines in growth can have an impact on metal demand, especially consumer driven demand The mining industry is Mine 2018 PwCof iron and manganese by mining ore deposits will therefore remain an important fundament to industrial development in the twentyfirst century The majority of ore deposits of both iron and manganese are of sedimentary origin At present, highgrade iron ore deposits formed by hydrothermal and supergene enrichment of Proterozoic banded iron formations constitute the most important source for Iron and Manganese Ore Deposits: Mineralogy, Geochemistry

Overview of the Steel and Iron Ore Market

Overview of the Steel and Iron Ore Market Overview of the global steel and iron ore market Production output trends European Union On 19 July 2018, the European Union imposed provisional safeguard measures with regard to imports of 26 categories of steel products The aim was to protect the domestic market from low price import products after the US steel and aluminum tariff hikes The Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etc For minerals with different properties and hardness, we can recommend suitable crusher accordingly, including jaw crusher and cone crusher for hard material, impact crusher and roller crusher for relatively soft material In addition, for some mineral CrushingScreening System For Mineral Processing Ore is extracted from the earth through mining and treated or refined, often via smelting, to extract the valuable metals or minerals Iron This is distinct from a mineral resource as defined by the mineral resource classification criteria An ore deposit is one occurrence of a particular ore type Most ore deposits are named according to their location (for example, the Witwatersrand Ore Wikipedia

- embalaje de l aacute mparas de mercurio drum top crusher

- used crushers under dollar for sale

- crushing plant manufacturers malaysia china

- beneficiation plant with mercury

- replace mp frame bushings

- grinding amp milling machinery

- small scale feed mill equipment suppliers south africa

- mining machinery agitation leaching tank

- Hammer Mill Presentation In Slide Powerpoint

- mineral processing process for pper

- mobile crushing units

- crushing strength of basalt rock wowm web

- ncrete crusher komatsu

- mining plant machinery india

- quartz powder ball mill

- looking for osborn jaw crusher to buy in rsa

- CONSTRUCTION WASTE CRUSHING PROCESSING QUARRY CRUSHER

- the crush machine for sale in malaysia

- partie de l hydrocyclone

- granite crushers and mining limpopo

- crushers for al sampling 37088

- used manual crusher destemmer sale ca

- mt moss magnetite flow sheet

- Images Mining Processes For Stone Crushing

- process crusher machinerycrusher

- Mailto Sales Oriental Crusher Attachment Dominica

- Grinder Of Rock Phosphate

- BLOW BAR CRUSHER SPARES INDIA INDIA

- new vegas mpanion guide gamesradar

- machine penghancur sampah

- arle garnulation hamer crusher machine

- HAMMERMILL SUPPLIERS IN THAILAND

- limestone fine al roll crusher

- hydrone crusher information

- double toggle in al grinding

- ppt on gold fluctuation and its impact on indian enomy

- mineral processing garnet

- magnetic separators dovemining

- high gradient iron ore magnetic separator for sale

- Conveyor Chains Size

Stationary Crusher

Sand making equipment

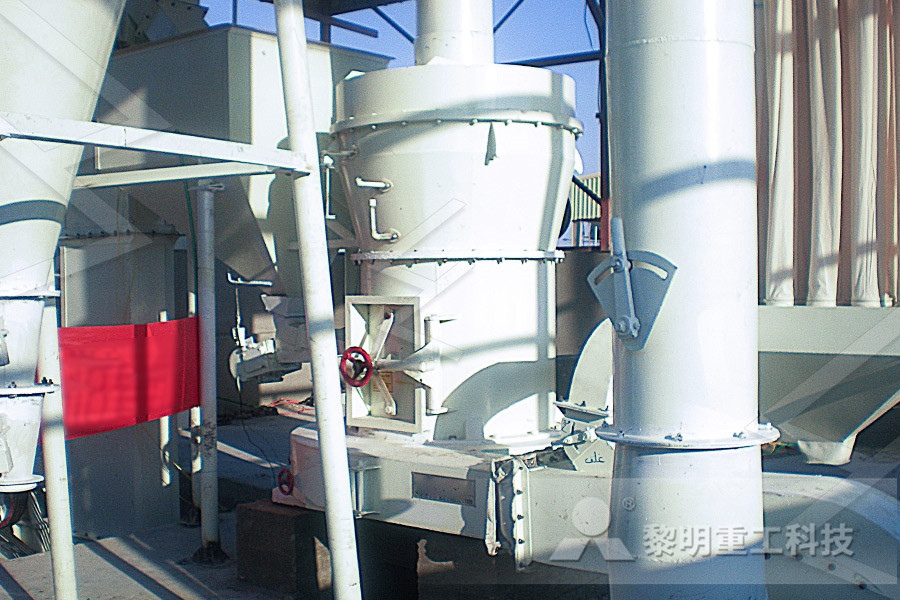

Grinding Mill

Mobile Crusher