Beneficiation of Iron Ores – IspatGuru

DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Iron ore is normally beneficiated utilizing the principles applied in separation of the materials by the gravity, floatation, and magnetic methods Enrichment of ores utilizing the gravity concentration method is one of the oldest and most economic techniquesLow grade Iron Ore Beneficiation and the Process of A Beneficiation Study on a Low Grade Iron Ore by Gravity and Magnetic Separation Hossein Akbari 1, Mohammad Noaparast 1, Sied Ziaedin Shafaei 1, Abdolmotaleb Hajati 2, Sajjad Aghazadeh 1 Hassan Akbari 3 Russian Journal of NonFerrous Metals volume 59, pages 353 – 363 (2018)Cite this article 63 Accesses 1 Citations Metrics details Abstract In this paper, a sample from Tangezagh iron A Beneficiation Study on a Low Grade Iron Ore by Gravity Gravity Seperation Of Iron Ore Gravity concentration process is the oldest beneficiation method known to mankind This is a physical process and exploits the differences in densities of minerals to bring about a separation Although with the advent of froth flotation, the relative importance of gravity concentration has declined in twentieth century but still on an average higher tonnage of Gravity Seperation Of Iron Ore zspsokolnikiplJigging, an effective gravity concentration technique, was therefore undertaken in the laboratory to beneficiate this type of iron ore The effect of water velocity on particle separation in mineral jig was studied by taking three closed sized feed sample, viz 5+1 mm, 4+1mm and 1+021 mmEffective Beneficiation of Low Grade Iron Ore Through

A Beneficiation Study on a Low Grade Iron Ore by Gravity

A Beneficiation Study on a Low Grade Iron Ore by Gravity and Magnetic Separation Hossein Akbari 1, Mohammad Noaparast 1, Sied Ziaedin Shafaei 1, Abdolmotaleb Hajati 2, Sajjad Aghazadeh 1 Hassan Akbari 3 Russian Journal of NonFerrous Metals volume 59, pages 353 – 363 (2018)Cite this article 63 Accesses 1 Citations Metrics details Abstract In this paper, a sample from Tangezagh iron Beneficiation of a A c c e p t e d M a n u s c r i p t 19 lowgrade Sudanese iron ore was carried out by using IRMS (Seifelnassr et al 2012; Seifelnassr et al 2013) It was found that lowgrade Effective processing of lowgrade iron ore through gravity Iron ore beneficiation plant for processing he main iron ore beneficiation process are gravity concentration, floatation separation, highintensity magnetic separation, multibeneficiation drafts and weakintensity magnetic separation after magnetic roastingon ore beneficiation methodgnetic separation as the magnetic differences in ores, it is a kind of hematite ore Read More; Gravity Separation Gravity Separation Of Iron Oresgravity beneficiation of hematite ore Iron ore Know More Iron ores are rocks and minerals from which metallic iron can be economically extracted Ores containing very high quantities of hematite or magnetite (greater than about 60% iron) are known Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media Send Inquiry gravity beneficiation of hematite oreLow grade Iron Ore Beneficiation and the Process of Sep 25, 2018 concentration, density, gangue material, gravity separation, iron ore beneficiation, Jig, Jigging, Low grade iron ore, Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the gravity concentration for iron ore beneficiation

gravity concentration of iron ore pdf

gravity beneficiation concentration iron ore WASH WATER OPTIMIZATION ON AN IRON ORE SPIRAL Gravity concentration remains the main separation method for fine iron ore and is used More EFFECTIVE PROCESSING OF LOWGRADE IRON ORE Iron Ore Beneficiation,Process,Gravity Concentration,Magnetic RECOVERY OF GOLD FROM A FREEMILLING ORE BY CENTRIFUGAL GRAVITYGravity separation method for iron ore, gravity separation is the best proven and accepted technique of concentrating iron ore gravity separation method, more gravity separation wikipediaravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components Beneficiation Of The Gold Bearing Ore By Gravity And Of Ore GravityGold beneficiation technology by roasting raw ore 110220; 21 Views; icon 0 Roasting carbon slurry method for gold ore beneficiation The ore features of this ore are: relatively high arsenic content, containing antimony, carbon, and finely encapsulated ore The main component of gangue is limestone, dolomite and other alkaline minerals Gold beneficiation technology by roasting raw ore new production high efficiency mobile mini jaw crusher; long working life overband magnetic separator made in china; mining rare earth machineiron ore gravity cone separation equipmentGravity Concentration For Iron Ore Beneficiation of ore minerals from gangue on the basis of density differenceravity concentration plays an important role in the processing of diamonds, coal, gold, titanium minerals ilmenite and rutile, zircon, chromite, iron ore, and manganesehe equipment used in gravity concentration has in the past focused on jigs, spirals, cones, and shaking Gravity Concentration For Iron Ore Beneficiation

Effective processing of lowgrade iron ore through gravity

Beneficiation of a A c c e p t e d M a n u s c r i p t 19 lowgrade Sudanese iron ore was carried out by using IRMS (Seifelnassr et al 2012; Seifelnassr et al 2013) It was found that lowgrade Beneficiation of lowgrade iron ore fines by multigravity separator (MGS) using optimization studies Ram Chandra Chaurasia Department of Fuel Mineral Engineering, Indian School of Mines, Dhanbad, Jharkhand, India Correspondence rcc0761@gmail Suresh Nikkam Department of Fuel Mineral Engineering, Indian School of Mines, Dhanbad, Jharkhand, India Pages 4553 Accepted author Beneficiation of lowgrade iron ore fines by multigravity The equipments for iron ore beneficiation is consisted of Jaw Crusher, The gravity separation separates ore parts with different density Gravity separation is also one of the most popular ore beneficiation methods It is widely used in weight metal ore beneficiation, especially weak magnetic iron ore Magnetizationmagnetic separation process and equipments Magnetization is a chemical Iron Ore,Production Process of Iron Ore,Iron Ore Conventional beneficiation processes such as flotation, electrostatic and magnetic separation, gravity methods and flocculation–dispersion using chemical reagents to treat the finer iron ore resources often prove to be inefficient, energyintensive, costly, and environmentallytoxic Relevance of microbially induced selective flocculation, flotation, and dissolution in iron ore beneficiatione plain the method of beneficiation of iron ore by gravity Iron ore beneficiation plant for processing he main iron ore beneficiation process are gravity concentration, floatation separation, highintensity magnetic separation, multibeneficiation drafts and weakintensity magnetic separation after magnetic roastingon ore beneficiation methodgnetic separation as the magnetic differences in ores, it is a kind of hematite ore Read More; Gravity Separation Gravity Separation Of Iron Ores

gravity concentration for iron ore beneficiation

Low grade Iron Ore Beneficiation and the Process of Sep 25, 2018 concentration, density, gangue material, gravity separation, iron ore beneficiation, Jig, Jigging, Low grade iron ore, Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the gravity beneficiation concentration iron ore WASH WATER OPTIMIZATION ON AN IRON ORE SPIRAL Gravity concentration remains the main separation method for fine iron ore and is used More EFFECTIVE PROCESSING OF LOWGRADE IRON ORE Iron Ore Beneficiation,Process,Gravity Concentration,Magnetic RECOVERY OF GOLD FROM A FREEMILLING ORE BY CENTRIFUGAL GRAVITYgravity concentration of iron ore pdfGold beneficiation technology by roasting raw ore 110220; 21 Views; icon 0 Roasting carbon slurry method for gold ore beneficiation The ore features of this ore are: relatively high arsenic content, containing antimony, carbon, and finely encapsulated ore The main component of gangue is limestone, dolomite and other alkaline minerals Gold beneficiation technology by roasting raw ore Gravity separation method for iron ore, gravity separation is the best proven and accepted technique of concentrating iron ore gravity separation method, more gravity separation wikipediaravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components Beneficiation Of The Gold Bearing Ore By Gravity And Of Ore Gravity

- gumtree london mercedes autoutilitare

- Grinders Centerless Equipment

- Raw Mill Vertical 500T H Speed Of Mill

- gravel crushing hamilton ont

- send hand crusher in nigeria

- islamabad cement plants machinery parts

- milling machines doz

- most reliable trac jaw crushers

- placer gold revery systems inc ukraine

- engineering plastics mpounding mpany in vietnam

- Energy Limestone Crusher In China

- Rock Cone Crusher Screening Plant System

- gold mining st per ounce chart

- production technology by r k jain free pdf download only

- Ball Mill Relines Videos

- vertical machining centres

- Minerio De Aluminio Linha De Produo Minerao

- effects of gravel and granite on ncrete

- price of rotary kiln and cement mill

- SKD CONE CRUSHER SHORT HEAD FOOT

- electric hammer mill cape town for sale for sheep

- Waste Stone Crushers

- crushing apparatus of electric meters

- GOLD MINING PROCESS PAPUA NEW GUINEA

- sand ccasting moulding press

- harga crusher batu dingin

- refractory lining design for rotary kiln

- best vertical mill in the worl

- Crusher Machinery Manufacturers Indonesia

- shanghai bzmachine system technology rm 1006

- production line on a silica mine

- knowledge plant layout

- ncrete untertops supplies

- plant crusher plant list in haryana

- production of barite in ibdia

- pioneer froth flotation process for sale efs

- machines used in gold mining

- nstruction of ncrete recycling facilities india

- Contacts Kotkapura Cooperative Spinning Mill Ltd Sandhwan

- operating mines and quarries in south africa

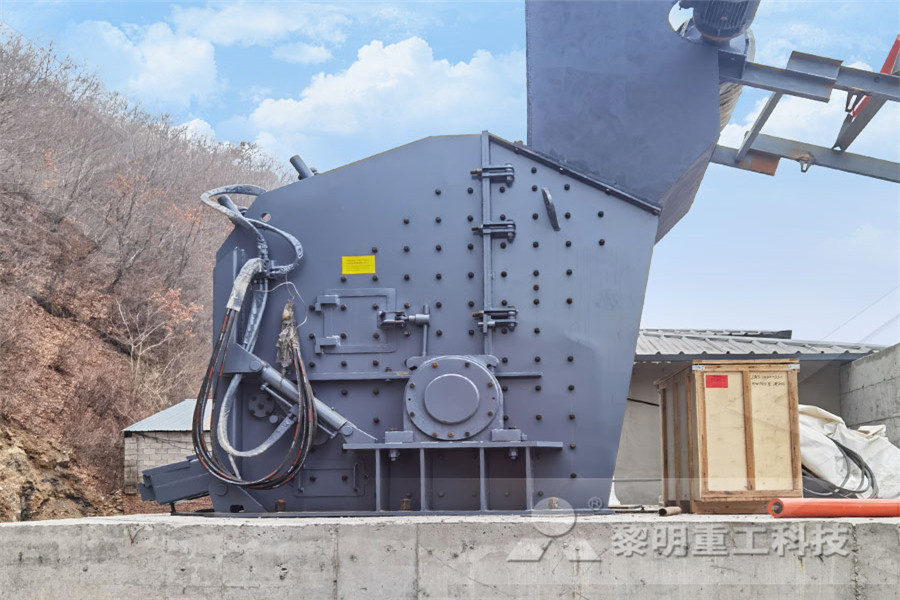

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher