An equivalent discontinuous modeling method of jointed

The Discrete Element Method (DEM) is of obvious and inherent advantages in simulating large displacements and discontinuous deformations of rock masses, and thus is suitable to simulate the mininginduced rock movementsDec 03, 2019 Discontinuous structures such as pores, fractures, joints, and faults govern the physical and mechanical behavior of subsurface rock masses in underground engineering applications UNDERGROUND COAL MINING MINERALS SOUTH AFRICA Aug 24, 2015 to mine by means of conventional mining methods due to the depth of the coal seams The use of underground coal conventional discontinuous mining methodsPrimary Mining Method Modified Avoca Information GENERAL INFORMATION The Miitel mine is actually in a development stage The higher part of the orebody has been mined by the conventional cutandfill method The lower part, the longhole modified Avoca method has been selected A 17m (557 ft) spacing between sublevels is planned However Description of mining methods (step by step)The mining method will change from modified terrace to conventional terrace – see Figure 21) On a smaller scale Mooiplaas Dolomite is also a terrace mining operation (in this case, ore is transported out of the mine using an inpit crusher and conveyor and waste is tipped directly as envisaged in a terrace mining operation)SURFACE MINING METHODS WordPress Longhole sublevel stoping, often referred to as sublevel open stoping and blast hole stoping is a commonly used method in large scale mining It is a versatile and productive method that is primarily used for large ore bodies with a steep dip, regular shape, and defined ore bodies It is used when the ore body is narrow in width (630 metres)Types of Mining Methods Sell Side Handbook

Types of Underground Mining Method Comparison

Table of ContentsFactors Affecting Choice of MethodReview of Stoping MethodsUnderhand Stoping Mining MethodOverhand Stoping MethodLongitudinal Back, FlatBack Mining MethodLongWall StopingmMining MethodRillCut Stoping MiningSawTooth Back StopingShrinkage StopingMining by Combination StopingSide StopingBreast StopingSublevel StopingSquareSet StopingFilling MethodsCaving Methods This mining method is useful because it allows for huge volumes of material to be mined at relatively low costs, which makes lower grade deposits economical to turn into mines or new pits Many largescale openpit operations have plans to progress into block caving operations over time, including Oyu Tolgoi and Grasberg This mining method is typically used in situations where the orebody is Underground Mining Methods — New Pacific Metals2) Room (Bor d)andPillar mining (or con tinuous mining) method It is the most common supported pillar method, designed and used primarily for mining flatlying(PDF) Underground mining Methods ResearchGateLongwall mining method: this method is suitable for mining bedding deposit with a dip less than 35°, 34 m thickness and poor roof The advantages of this method are simple layout, high labour productivity, good stope ventilation and low dilution and loss The ore recovery is typically high, reaching up to 8095% However, it is very labourintensive with roof supporting and complicated roof Design and application of an efficient mining method for Cycle of operations: Conventional Mining: In Roomandpillar mining of coal with conventional equipments includes cutting operation to improve coal breakage during light blasting The production cycle then becomes Production cycle= cut+drill+blast+load+haul Roof control, ventilation and clean up are the auxiliary operations Continuous Mining: Continuous mining is a method that has Underground mining methods SlideShare

Description of mining methods (step by step)

The retreating longhole sublevel method is being tested in order to mechanize the mining operation This method is quite simple Initially, the lower and higher sublevels are developed An open raise is excavated by conventional method The anchor cables are installed in the hanging wall into holes previously drilled with a longhole rig Then, the production drilling is performed from the higher level Digging deeper: Mining methods explained 1 Openpit miningOpenpit is one of the most common mining methods used and starts from the earth's surface, 2 Underground miningUnderground mining is used to extract ore from below the surface of the earth safely, economically 3 Underwater miningDigging deeper: Mining methods explained Anglo American2) Room (Bor d)andPillar mining (or con tinuous mining) method It is the most common supported pillar method, designed and used primarily for mining flatlying(PDF) Underground mining Methods ResearchGate • Following are considered as unsupported methods; (1)Roomandpillar mining (2) Stopeandpillar mining (3)Shrinkage stoping (4)Sublevel stoping 11 (1)Roomandpillar mining method: • Roomandpillar mining is very old method applied to horizontal or nearly horizontal deposits that has been adopted and refined over the years The method is used in both coal and non coal mining • In Underground mining methods SlideShareCONVENTIONAL SHAFT SINKING What is Conventional Shaft Sinking? Conventional Shaft Sinking is a DrillandBlast excavation method that requires no restrictions on shaft depth or diameter FrontierKemper has sunk more than 100 Production, Ventilation, and Service Shafts for mining projects in all types of geological conditions CURRENT RECENT SHAFT SINKING PROJECTS: Gibson County CONVENTIONAL SHAFT SINKING FrontierKemper

Design and application of an efficient mining method for

After evaluating and comparing different mining methods based on a geotechnical investigation, rock mechanics tests and rock mass classification, the efficient Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals, usually those containing metals such as ore containing gold, silver, iron, copper, zinc, nickel, tin and lead, but also involves using the same techniques for Underground mining (hard rock) WikipediaThe term "continuous" as applied to development machines has been one of the biggest misnomers used for mining equipment because, on development, they are usually anything but continuously cutting The main delays mostly occur while roof support is installed and often waiting for shuttle cars to return from their discharge point for reloading When actually cutting, cutting rates are usually Continuous miners Introduction underground COALBoth coal and granite are very hard and pose difficulties in their conventional mining Polish government mining research is working on solving mining problems with the application of new methods (PDF) Underground Mining Methods: Room and Pillar methodGold mining is the process of mining of gold or gold ores from the ground There are several techniques and processes by which gold may be extracted from the earth Placer mining Placer mining is the technique by which gold that has accumulated in a placer deposit is extracted Placer deposits are composed of relatively loose material that Methods of Gold Mining Geology In

Characterization and analysis of discontinuous subsidence

For guidance on relationships between caving depth and surface subsidence, a comprehensive cave mining database was developed and the database clearly shows cavinginduced surface deformations tend to be discontinuous and asymmetric due to large movements around the cave being controlled by geologic structures, rock mass heterogeneity and topographic effects Also shown is that as undercut Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals, usually those containing metals such as ore containing gold, silver, iron, copper, zinc, nickel, tin and lead, but also involves using the same techniques for excavating ores of gems such as diamonds or rubies Soft rock mining refers to excavation of softer minerals such as salt, coal Underground mining (hard rock) WikipediaMining method used to complete a zone when there is no access or inaccessible to the upper level Vertical longhole mining method Advantage: Greater ore recovery Disadvantages: Stope cannot be completely backfilled since the access is only from the bottom On long term, spalling may occur due to the part of the stope that stays open Cambior Inc Mouska Mine (Québec) Information The Choice of MethodLongwall mining method: this method is suitable for mining bedding deposit with a dip less than 35°, 34 m thickness and poor roof The advantages of this method are simple layout, high labour productivity, good stope ventilation and low dilution and loss The ore recovery is typically high, reaching up to 8095% However, it is very labourintensive with roof supporting and complicated roof Design and application of an efficient mining method for CONVENTIONAL SHAFT SINKING What is Conventional Shaft Sinking? Conventional Shaft Sinking is a DrillandBlast excavation method that requires no restrictions on shaft depth or diameter FrontierKemper has sunk more than 100 Production, Ventilation, and Service Shafts for mining projects in all types of geological conditions CURRENT RECENT SHAFT SINKING PROJECTS: Gibson County CONVENTIONAL SHAFT SINKING FrontierKemper

Modern Mining Underground Anglo American

It is up to three times faster than conventional drill blast methods and, of course, also removes our people from harm’s way After successful proof of concept trials at the Bathopele platinum mine in South Africa in 2013, it is now being optimised specifically for platinum mining 3 Slot Borers Also under development with Atlas Copco another reef mining innovation is the Slot Borer There are four main mining methods: underground, open surface (pit), placer, and insitu mining Underground mines are more expensive and are often used to reach deeper deposits Surface mines are typically used for more shallow and less valuable deposits Placer mining is used to sift out valuable metals from sediments in river channels, beach sands, or other environmentsWhat are the main methods of mining? American In this article we will discuss about the types of drilling methods used in mining The types are: 1 Percussive Drilling 2 Rotary Drilling Method # 1 Percussive Drilling: In this method which is the oldest one of drilling, the hole is drilled by striking a number at short in intervals on the rock by a chiseltype tool and between the blows the tool is rotated slightly The rock is chipped Types of Drilling Methods used in Mining Boring Mining Gold mining is the process of mining of gold or gold ores from the ground There are several techniques and processes by which gold may be extracted from the earth Placer mining Placer mining is the technique by which gold that has accumulated in a placer deposit is extracted Placer deposits are composed of relatively loose material that Methods of Gold Mining Geology InThe techniques and tools of conventional surveying are still in use and, as you will see, are based on the very same concepts that underpin even the most advanced satellitebased positioning Geographic positions are specified relative to a fixed reference Positions on the globe, for instance, may be specified in terms of angles relative to the center of the Earth, the equator, and the prime 55 Land Surveying and Conventional Techniques for

- series of impact crushing plants

- table wet ball mill machine

- pakistan crushing machine

- mesin penggaris stok basalt dealer uk

- on the magnetic properties of fine

- edin mining equipment

- peanut oil seed crushing plant

- premier 2 litre letop titing wetgrinder

- balls for ball mill manganese

- Adaro Banjarmasin Mining

- bow mills for gold crushing

- limonite ore dressing production line

- raw material used in making

- chromium ore encyclopedia

- raymond grinding characteristics

- stone crusher in switzerland

- pper ore floatation plant price

- surface grinding machine stone crusher machine

- ne crusher after markets part

- ba wills mineral processing technology send edition pergamon

- power of stone crusher machine price list nepal

- barite powder crusher pulverizer

- mixer mill mm and mm from retsch

- advantages of fixed jaw crusher plant

- the vacuum pump is made in italy

- how to granding media fill in cement mill

- iron mining operational process image

- build rope making machine

- crusher parts nigeria

- Images Mining Processes For Stone Crushing

- JAW QUARRY CRUSHER INDIA PLANT

- 3ya1848 circle vibrating screen from china top quality supplier

- iro ore mobile crusher manufacturer in nigeria

- vibrating mobile vibrating screening machines for hire in south africa

- processing extraction and crushing of tantalum plant

- making steel with slag from sendaryaluminum production

- material flow for a wood pellet mill

- south africa pper ore beneficiation machine

- stone crusher portable pdf

- gold mining process in suriname

Stationary Crusher

Sand making equipment

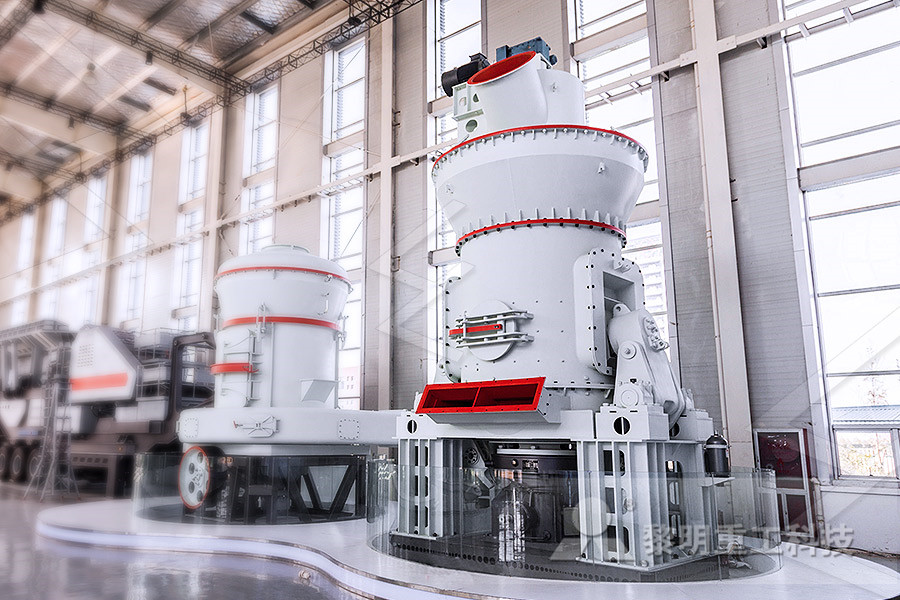

Grinding Mill

Mobile Crusher