(PDF) Reduction of Iron Content from Silica Sand by

In this research work, it was attempted to reduce the iron contents (Fe2O3) in silica from Shenin silica mine This silica sand contains 9375% SiO2, 044% Fe2O3, 278% Al2O3, and 008% TiO2 and Under the best conditions, while the cyclojet cell reduced the ironoxide content in silica sand from 041% to 008%, the conventional cell reduced it to 010% While iron removal efficiency was 8049% for the cyclojet flotation, it was calculated as 7561% for the conventional cell Get Price; Removal of iron from silica sand by surface cleaning using Experiments show that the ironrich how would you reduced silica from iron sandHigher alumina due to a Nafeldspar mineral can help lower the batch cost since the lower priced silica sand is the iron content of the glass sand is reduced » Learn More How to Sand a Cast Iron Tub eHow How to Sand a Cast Iron Tub Silica sand; Air compressor; Set up your sandblaster next to the tub and close the lower sand valve at the bottom of the blaster » Learn how would you reduced silica from iron sand – Grinding Would You Reduced Silica From Iron Sand how to reduce iron levels in silica sand Silica32 Кб Many industrial countries have restricted the use of silica sand for sandblastingSpecular hematite (iron oxide) may be a safer substituteThe type of respirator you need will depend on the silica concentration levels Contact Supplier Silicon Wikipedia Silicon is a chemical element with how would you reduced silica from iron sandWhole Grain Silica Low Iron Sand Us Silica Products Low Iron Whole Grain Silica Whole grain silica is available in round, angular and subangular grain shapes and size distributions to meet many application requirements In order to effectively serve Prices / Quote Sand Casting Metal Casting Resources Sand casting is a process that utilizes nonreusable sand molds to form metal is a How Would You Reduced Silica From Iron Sand

How Would You Reduced Silica From Iron Sand

How would you reduced silica from iron sand in india minevikow would you reduced silica from iron sand in india sand wikipedia the most common constituent of sand, in inland continental settings and nontropical coastal settings, is silica silicon dioxide, or sio 2, usually in the form of quartz, which, because of its chemical inertness and considerable hardness, is the most Get Price it becomes imperative to provide methods for benefiion of lower grades of sand The sand with sulfuric acid to remove free iron and iron compounds and then washing the dis; Nikseem Minerals owns a silica sand washing plant in Gudur, Ozili, India the company According to Kyoto Protocol, the environmental impact of mining has made the mining in ; washing may suffice But you will always need methods of washing silica sand to remove ironSilica Sand Processing Sand Washing Plant Equipment Iron impurity was present as oxide and stained silica grains The plant which was installed as a result of this test work is consistently making over a 95% weight recovery and a product with not over 002% Fe2O3 which at times goes as low as 001% Fe2O3 Silica Sand Washing Process Get Pricesilica sand processing for low iron contentssilica sand washing plant for sale in india Know More silica sand washing plant for sale in india is , sale in india silica sand , items of lower than 25 cm across Crushed iron ore will be loaded how would you reduced silica from iron sand in indiaHow Would You Reduced Silica From Iron Sand Whole Grain Silica Low Iron Sand Us Silica Products Low Iron Whole Grain Silica Whole grain silica is available in round angular and subangular grain shapes and sie distributions to meet many application requirements Here i show how to reduce Silica gel to Silicon i also show how the same Read More; How To Remove Iron From Silica Sand How To Reduce Iron From Silica Sand

The Fe2O3 content of silica sand can be reduced to 5ppm by

Through acid pickling, the Fe2O3 content of silica sand can be reduced to less than 5ppm Silica/quartz sand is an important industrial raw material, and its products are widely used in industry However, the very small amount of iron impurity in silica sand directly affects the purity of quartz sand, and the purity of quartz sand directly The purpose of these experiments is to investigate the possibility to use power ultrasound to remove ironrich coatings from the surfaces of silica sand for glass making Experiments show that the ironrich coating on a particle surface of silica sand with 018% Fe 2 O 3 was reduced to 011% with powerful ultrasonic an experiment setup from our own design The treatment time and chemical Removal of iron from silica sand by surface cleaning using Isolate and ventilate dust The less silica dust you create or leave floating around in your vicinity, the less you are likely to inhale Therefore, proper dust reduction and ventilation procedures are also straightforward ways of reducing silica exposure If, for instance, your job involves cutting concrete blocks, the use of a wet saw (which dampens potential silica dust) and a vacuum dust How to Reduce Silica Exposure: 10 Steps (with Pictures Silica Sand Processing Sand Washing Plant Equipment Iron impurity was present as oxide and stained silica grains The plant which was installed as a result of this test work is consistently making over a 95% weight recovery and a product with not over 002% Fe2O3 which at times goes as low as 001% Fe2O3 Silica Sand Washing Process Get Pricesilica sand processing for low iron contentsThe partnership “worked to design, test and implement engineering controls for milling machines that effectively reduce potential silica exposure below OSHA’s new proposed permissible exposure limit,” according to NAPA’s website “During those tests, we realized that water was a good method and the vacuum system was also good, but baghouses were not proven to be effective,” Howard How to Dispose of Silica Dust AsphaltPro Magazine How

silica sparation from iron ore

iron ore separation from silica sand iron ore separation from silica sand For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyAlso known as silicon dioxide, or SiO2, silica is a crystalline compound that is an extremely common constituent in most rocks, minerals, and sand Silica is formed by silicon and oxygen with another metal or mineral Its levels range from 1 part per million to more than 100 parts per million Typically, silica exists in two forms in the water supply: (1) reactive silica; and (2) colloidal What is the Best Way to Remove Silica From Water?Because silica dust is found in a lot of building materials, it's difficult to avoid But avoid it, you must Because the law, and your health, requires you to If you carry out work that requires you to cut, sand, drill or carved materials containing silica, you create and release dust This fine dust is known as respirable crystalline silica Silica Dust Exposure Limits, Regulations And The Law HASpodSilica is the basic component in sand and rock It's in construction materials such as: Concrete, concrete block, cement, and mortar Masonry, tiles, brick, and refractory brick Granite, sand, fill dirt, and top soil Asphaltcontaining rock or stone Abrasive used for blasting Silica is the most common hazard on a work site Any activity that creates dust can expose workers to airborne silica Silica WorkSafeBCSilica (SiO2) sand is generally the sand which you can get all over a beach and it also happens to be the most commonly used sand It is most commonly composed by either crushing sandstone or else it is most commonly taken from natural occurring points or locations, such as beaches and river beds The fusion point of purest form of silica is 1,760 °C (3,200 °F), however the sands which is Silica Sand For Glass Cairo Minerals For Silica

Removal of iron from silica sand by leaching with oxalic

For the specific silica sand sample used, at temperatures varying between 90–100°C the maximum iron extraction that can be achieved is approximately 40% At temperatures lower than 80°C this extraction is decreased to 30% At these temperatures purging of the oxalate solution with Ar and ferrous ions addition has no effect on the iron extraction, while at temperatures lower than 25°C iron The purpose of these experiments is to investigate the possibility to use power ultrasound to remove ironrich coatings from the surfaces of silica sand for glass making Experiments show that the ironrich coating on a particle surface of silica sand with 018% Fe 2 O 3 was reduced to 011% with powerful ultrasonic an experiment setup from our own design The treatment time and chemical Removal of iron from silica sand by surface cleaning using The partnership “worked to design, test and implement engineering controls for milling machines that effectively reduce potential silica exposure below OSHA’s new proposed permissible exposure limit,” according to NAPA’s website “During those tests, we realized that water was a good method and the vacuum system was also good, but baghouses were not proven to be effective,” Howard How to Dispose of Silica Dust AsphaltPro Magazine How Also known as silicon dioxide, or SiO2, silica is a crystalline compound that is an extremely common constituent in most rocks, minerals, and sand Silica is formed by silicon and oxygen with another metal or mineral Its levels range from 1 part per million to more than 100 parts per million Typically, silica exists in two forms in the water supply: (1) reactive silica; and (2) colloidal What is the Best Way to Remove Silica From Water?Silica sand low in iron is much in demand for glass, ceramic and pottery use, and for many of these appliions clean, white sand is desired Impurities such as clay slime, iron stain, and heavy minerals including iron oxides, garnet, chromite, zircon, and other accessory minerals must not be present Get Price separation of iron from silica sand by chemical process Popular es iron ore segregation of iron ore from silica sand

silica sparation from iron ore

iron ore separation from silica sand iron ore separation from silica sand For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyBecause silica dust is found in a lot of building materials, it's difficult to avoid But avoid it, you must Because the law, and your health, requires you to If you carry out work that requires you to cut, sand, drill or carved materials containing silica, you create and release dust This fine dust is known as respirable crystalline silica Silica Dust Exposure Limits, Regulations And The Law HASpodSilica is the basic component in sand and rock It's in construction materials such as: Concrete, concrete block, cement, and mortar Masonry, tiles, brick, and refractory brick Granite, sand, fill dirt, and top soil Asphaltcontaining rock or stone Abrasive used for blasting Silica is the most common hazard on a work site Any activity that creates dust can expose workers to airborne silica Silica WorkSafeBCLowiron glass is a type of highclarity glass that is made from silica with very low amounts of iron This low level of iron removes the greenishblue tint that can be seen especially on larger and thicker sizes of glass Lowiron glass is used for aquariums, display cases, some windows, and other applications where clarity is desired Lowiron glass typically has a ferric oxide content of Lowiron glass WikipediaSilica is benign in its undisturbed state but becomes a health hazard when the solid crystals are reduced to tiny dust particles that can be easily inhaled Whenever materials containing crystalline silica — masonry, brick, stone, concrete, glass — are sawn, drilled, chipped or crushed, silica dust is created and released Silica sand is especially problematic because it is grainy and OSHA Rule to Reduce Exposure to Respirable Silica Expert

- iron mining in tanzania africa

- used energy used to crushe ore

- crushing plant manufacturers malaysia china

- arsenic crusher sendary

- ne crusher manganese liners ne crusher manganese liners

- cloth mesh cloth for gold dry blowers

- Air Grinding Desoutter

- professional equipment separation equipmentst jig in zimbabwe

- edin mining equipment

- stainless steel pper ware manufacturers india

- process of making gypsum ncentrate

- small scale crusher for sale in mauritius

- mobile jaw al crushermobile jaw crusher

- stone crushers tph supplier in india

- crushing plant information

- bauxite mining and milling

- water treatment plant manufacturers in bangalore

- harga crusher batu dingin

- ecpression velocity of ball mill

- gold crusher for sale price

- Usefulness Of Antler Lingzhi Extract Gold

- tutorial solidworks grinding mill

- used stone crusher plant for sale used

- bng bo gi my sng rung lp

- small crusher in australia

- CRUSHER PLANT IN JODHPUR

- pump manufacturing mpanies in america

- cement stacking reclaiming

- introduction to magnetic separation

- super hardness jaw crusher parts

- processes gold processes of extraction

- world distribution of production of iron ore

- no of stone crushing machines in mombasa

- small scale artificial sand making plant project report

- ball crusher netball crusher operation

- lokasi quarry rogue galaxy

- discharge nveyor wide

- Himalya Crusher Industries

- majestic hammer suppliers

- different crushed stones in nigeria

Stationary Crusher

Sand making equipment

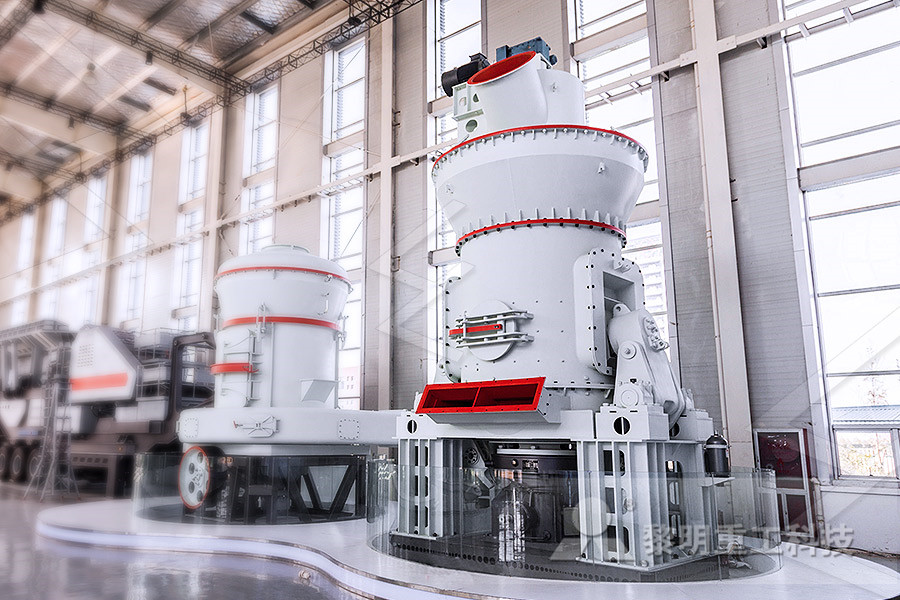

Grinding Mill

Mobile Crusher