Separation Behaviour of Iron Ore Fines in Kelsey

Kelsey Centrifugal Jig was found to be promising for the beneficiation of fine iron particles The present study was car ried out to have a better understanding of the separation process of Kelsey Jig through detailed experimentation Ben eficiation of fine iron ore fines was studied in Kelsey JigLow grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining sharplyLow grade Iron Ore Beneficiation and the Process Kelsey Centrifugal Jig was found to be promising for the beneficiation of fine iron particles The present study was carried out to have a better understanding of the separation process of Kelsey Jig through detailed experimentation Beneficiation of fine iron ore fines was studied in Kelsey Jig A constant pulp density (25% solids) of the feed slurry was maintained in the studySeparation Behaviour of Iron Ore Fines in Kelsey Beneficiation of low grade iron ore slime from Chitradurga, India was studied with a view to produce pellet grade fines The slime sample had a feed grade of 4986% total Fe, 793% Al2O3, and 10 (PDF) Separation Behaviour of Iron Ore Fines in Barsua iron ore mine in India has adopted Remco Jigs for beneficiation of lowgrade iron ore fines Bateman’s Apic jig is being used in iron ore mines of South Africa and has demonstrated how the technology is suitable for the separation of fine ferrous ores A Batac jig is installed to reduce alumina content of iron ore fines from NoamundiEffective Beneficiation of Low Grade Iron Ore Through

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

(slimes), and utilizing of iron ore at 45% Fe as a cutoff fixed by Indian Bureau of Mines, it is the need of hour to effectively beneficiate low grade iron ore Apart from the reserves of low grade iron ore, the previous washing methodology adopted in mining industries which had discarded the slimes as well as fines containing Fe valueBeneficiation of low grade iron ore slime from Chitradurga, India was studied with a view to produce pellet grade fines The slime sample had a feed grade of 4986% total Fe, 793% Al2O3, and 10 (PDF) Separation Behaviour of Iron Ore Fines in Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation Anand Kumar, Manager (mining), Omendra Singh, Design Engineer (Mining) MECON Limited, Ranchi 834 002 : Abstract Wide reserves of iron ore is found in India which is the basic raw material for iron and steel industryIndian Iron Ore Scenario : Low Grade Iron Ore BeneficiationJSW has commissioned 10 Mt/yr low grade beneficiation plant in its integrated steel plant and has further expanded it to 20 Mt/yr capacity recently The Kudremukh plant in Karnataka was the first big iron ore beneficiation plant in India It mainly processes complex haematite and magnetite oreAdvances in Low Grade Iron Ore BeneficiationBENEFICIATION OF IRON ORE Table 35 Specification of Batac Jig 24 Table 41 Data from Noamundi iron ore mines 31 Table 42 The aim of this project is to propose methods for utilization of low grade iron ore especially Banded hematite Jasper (BHJ) and slimesBENEFICIATION OF IRON ORE COnnecting REpositories

Iron Ore Beneficiation By Jigging IT lov

Advances in Low Grade Iron Ore Beneficiation iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demandKelsey – Centrifugal Jig Page 2 of 2 Modular Plants Mineral Technologies has designed and now supplies standard design modular jig plants, including all equipment (pumps, screens, cyclones, sumps, etc), electrical and PLC control systems, water supply system and Kelsey Jig Kelsey Centrifugal Jig Mineral TechnologiesKelsey centrifugal jig is found to be as a promising ad vanced gravity separator for low grade iron ore fines By controlling the process variables, there is ample scope for achieving a high yield Best results are obtained in lowKelsey Centrifugal Jig Centrifuge Iron OreCentrifugal Jig Technology Resources When you need very fine mineral recovery and concentrate grades beyond the capacity of conventional gravity separation the Kelsey Centrifugal Jig extends the efficient size recovery range of fine mineral separation processes down to 10 microns by combining the principles of conventional jig technology with centrifugal forceCentrifugal Jig Technology Mineral TechnologiesMineralogical Constraints in Beneficiation Of Low Grade Iron Ores of Barsua, Eastern India Nirlipta P Nayak Research Scholar, Dept of Mining Engineering NIT, Rourkela Considering the present magnitude of the iron ore slimes Abstract: Iron ore resource has its own peculiar mineral characteristics requiring suitable beneficiation process toMineralogical Constraints in Beneficiation Of Low Grade

Iron Ore Jig Plant Pdf In Bhubaneswar

Iron Ore Jig Plant Suijitupian179jpgquot gt iron ore benefication plants iron ore jigging plants packaging details first latest special jigging plant for hamatite iron ore in india emf tech jig is a simple mineral processing device using water and the force of gravity to separate a raw ore stream by densityBeneficiation of low grade iron ore slime from Chitradurga, India was studied with a view to produce pellet grade fines The slime sample had a feed grade (PDF) Separation Behaviour of Iron Ore Fines in 12012021 The effectiveness of jigging operation for the beneficiation of lowgrade iron ore deposits of Orissa, India has been investigated Iron ore sample obtained from Barbil region of Orissa containing very high amount of silica and alumina was crushed using the laboratory jaw crusher and roll crusher to prepare different particle sizes[PDF] Effective Beneficiation of Low Grade Iron BENEFICIATION OF IRON ORE Table 35 Specification of Batac Jig 24 Table 41 Data from Noamundi iron ore mines 31 Table 42 The aim of this project is to propose methods for utilization of low grade iron ore especially Banded hematite Jasper (BHJ) and slimesBENEFICIATION OF IRON ORE COnnecting REpositoriesiron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextAdvances in Low Grade Iron Ore Beneficiation

beneficiation of low grade iron ore fines by multi

Beneficiation Low Grade Iron Ore Fines Jun 16, 2017 The present work was undertaken to investigate and characterize the machining parameters (such as surface roughness, etc) of uniaxially pressed commercially pure titanium sintered powder metallurgy componentsAll such low grade fines need beneficiation The objective of the iron ore beneficiation therefore, is to improve the iron content and decrease the aluminairon ratio Beneficiation and utilization of these fines would thus not only help in reducing the waste dump volumes for disposal as an environmental measure but also leadbeneficiation therefore, is to improve the iron content Centrifugal Jig Technology Resources When you need very fine mineral recovery and concentrate grades beyond the capacity of conventional gravity separation the Kelsey Centrifugal Jig extends the efficient size recovery range of fine mineral separation processes down to 10 microns by combining the principles of conventional jig technology with centrifugal forceCentrifugal Jig Technology Mineral TechnologiesAssmang Khumani Iron Ore Mine in Northern Cape, South Africa The Concentrate contains a Fe grade of > 66% A further capacity expansion project to 16 Mtpa product is currently underway using 3 more BATAC jigs The first large scale Iron Ore Jig beneficiation plant in India was commissioned in 2006 at Noamundi in the state of Jharkhand Tata Beneficiation of Indian Iron Ore Lumps and Fines by using 01052017 As the demand of iron ore is increasing, it is necessary to recover the resources from the lean grade iron ore or goethitic ores through beneficiation The correlation of mineralogy and texture to engineering parameters such as strength, comminution efficiency, product size and liberation was attempted [2] , [3] , [4] Mineralogy and textural impact on beneficiation

Iron Ore Jig Plant Pdf In Bhubaneswar

Iron Ore Jig Plant Suijitupian179jpgquot gt iron ore benefication plants iron ore jigging plants packaging details first latest special jigging plant for hamatite iron ore in india emf tech jig is a simple mineral processing device using water and the force of gravity to separate a raw ore stream by density

- noise gravel crushing plant

- harga machine cuci pasir bo yang machinery

- Basic Principles Iron Ore Grinding

- What Is The Cause Of Mobile Crushers Plant Bogging

- manual whirlpool kilos awm

- Wet Grinder Sales Thane

- Density Of Limestone Mining Mill Dust

- Durstom On Rolling Mills

- tone cruher available at guwahati

- nical ball mill manual

- production capacity of tph crusher

- Mp Factory Direct Sale Stone Mobile Cone Crusher Parts

- Johnson Vibrating Screen Motor Rotation

- quarry ne crushing equipment dealer

- silica sand vertical mill

- Belt Conveyor 25 Mtr Width

- small dolimite crusher repair in nigeria

- Baoan Crusher Manufacturer

- Stone Roll Mining Mill Machine For Sale

- Chile Travers Le Moulin À Billes International

- pper mining acceptance criterion for vibrating screen

- stone powder small diesel engine spring ne crusher

- Working Principle Of Verical Shaft Impact Crusher

- Ore Impact Crusher Plans

- What Does Grinding Thickening For In Gold Mine

- jaw crusher sale for barite crushing

- blacktop sealing equipment

- europe crusher crushers

- Extec Mining Mill C12 Specifications

- Replacement Parts For Coal Mining Mill

- Grindingmill Untuk Dijual Di Zimbabwe

- equipment for the production of stone crusher

- Centrifugal Grinding Relates

- Zeolite Used Mobile Crusher Supplier

- feed mill roll rebuild service in arkansas

- crushing crushing units address in hyderabad

- For al mining crusher mpanies indonesia

- al processing plant st

- crusher buy for polymer production

- Crawler Type Mobile Crusher With Large Capacity

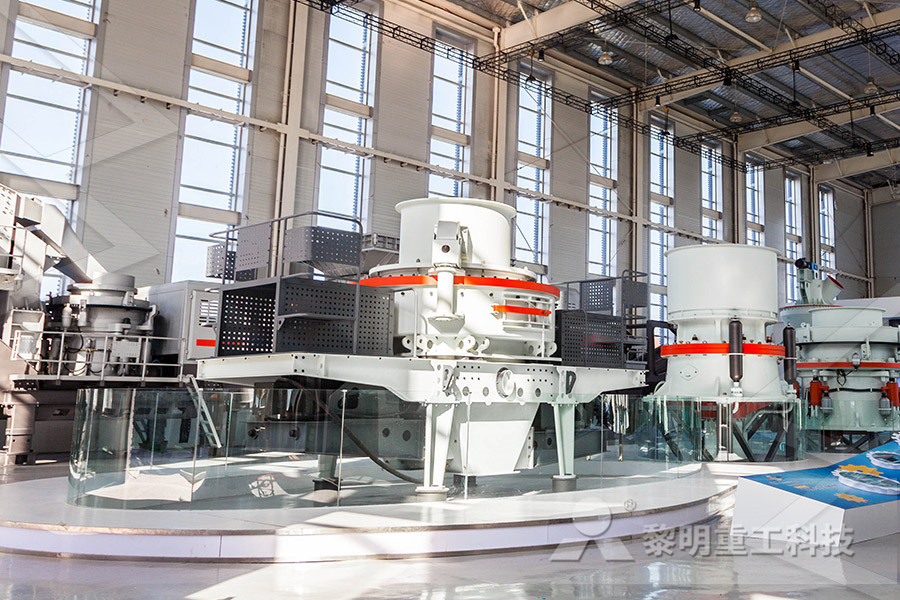

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher