Continuous miners Introduction underground

Continuous miners Though there are Allow strata supports to be safely installed while coal cutting continues Many of these ideals have been achieved to varying degrees of satisfaction (the last being an area of minimal success), but matching development rates with longwall retreat rates is still a major problem for many minesContinuous miners operate a room and pillar mining system A series of 18 to 20 foot wide rooms are driven in the coalbed with pillars or columns of coal left standing to help support the roof Roof bolts, typically four to six feet long steel bolts, are inserted into holes bored into the roof to bind the strata together support the roofContinuous Mining Coal LeaderSandvik MC470 continuous miner is the ideal choice for room and pillar coal mines, salt and potash mines, and other operations that demand the highest cutting force The miner effectively integrates proven technologies to offer high advance rates under tough mining conditions and in restricted spacesContinuous Miners For Cutting Coal Soft Continuous Miners A machine with a large rotating steel drum equipped with tungsten carbide teeth that scrape coal from the seam Operating in a “room and pillar” system – where the mine is divided into a series of 20to30 foot “rooms” or work areas cut into the coalbed – it can mine as much as five tons of coal a minute – more than a miner of Continuous Miners Coal EducationMostly these continuous miners are used in coal mining The design of continuous miners make them versatile in nature The tool fitted with the arms is adjustable according to the need of mining height Continuous miners are large in size, having rigid frame and battery or Continuous Miners Market Global Industry

CONTINUOUS MINERS SlideShare

04032016 CONTINUOUS MINERS 1 TAUHID MOHAMMAD ROLL NO: 15MT DEPARTMENT OF MINING MACHINERY ENGINEERING INDIAN SCHOOL OF MINES DHANBAD CONTINUOUS MINERS 2 INTRODUCTION CONTINUOUS MINER:This machine is used for scraping and loading of coal from the seam used in underground Board and Pillar mining operation 3There are several types of surface coal mines Area surface mines, usually found in flat terrain, consist of a series of cuts 100 to 200 feet wide The overburden from one cut is used to fill in the mined out area of the preceding cut Contour mining, occurring in mountainous terrain, follows a Coal Types, Formation and Methods of Mining The length of the lifts are controlled so that the roof remains intact while the continuous miner is extracting the lift and no personnel are required to work under the unsupported roof Pillar extraction with continuous miners poses a risk of loss of roof control in the immediate working area or extracted area ("goaf") resulting in the continuous miners and even the operators being buriedPillar Extraction using Continuous Miners Occupation Coal Dust > 2 mg/m 3 Coal Dust > 15 mg/m Quartz Dust > 100 µg/m3 Droplet size/velocity High pressure/location Wetting/Suppression Mine Continuous miner cuts Roof bolter cuts Scrubber off Scrubber on Total Upwind of miner or miner offControlling Dust on Continuous Mining OperationsMining is the extraction of valuable minerals or other geological materials from the Earth, usually from an ore body, lode, vein, seam, reef or placer depositThese deposits form a mineralized commodity that is of economic interest to the miner Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clayMining Wikipedia

Continuous Miners Market Global Industry

Mostly these continuous miners are used in coal mining The design of continuous miners make them versatile in nature The tool fitted with the arms is adjustable according to the need of mining height Continuous miners are large in size, having rigid frame and battery or Sandvik MC470 continuous miner is the ideal choice for room and pillar coal mines, salt and potash mines, and other operations that demand the highest cutting force The miner effectively integrates proven technologies to offer high advance rates under tough mining conditions and in restricted spacesSandvik MC470 Continuous Miner For Room The coal falls unto a conveyor belt and is transported to the conveyor system in the parallel shafts for its trip to the surface This type of mining can make a 1/4 mile long cut (about 34 feet wide) in under one hour and can provide 410 times the amount of coal as a continuous minerWorking in the Coal MinePart 2 Advancing 04032016 CONTINUOUS MINERS 1 TAUHID MOHAMMAD ROLL NO: 15MT DEPARTMENT OF MINING MACHINERY ENGINEERING INDIAN SCHOOL OF MINES DHANBAD CONTINUOUS MINERS 2 INTRODUCTION CONTINUOUS MINER:This machine is used for scraping and loading of coal from the seam used in underground Board and Pillar mining operation 3CONTINUOUS MINERS SlideShareThe 12CM27 continuous miner, with a solidhead cutting head system, features a 965 mm (38 in) conveyor width for standard width entry applications The 12CM27, as well as all 12CM series continuous miners, are designed specifically to make efficient use of the additional space available in higher seam heights by offering improved outboard access to all major componentsJoy 12CM27 Continuous Miner Underground

(PDF) Success of Continuous Miner in Bord and

Continuous miner based mechanized is preferring by most the coal mining industry in India mainly due to its adaptability in Indian geomining conditions and a moderate level of investments with C ontinuous mining systems have been established in coal and soft rock mining for about a century now and the technology to cut through hard rock has been successfully used in civil engineering projects since the late 1950s One would think that by now, continuous hard rock mining would also be a reality but it is not The possibility of the technology being applied to hard rock mining has in Hard rock revolution on the horizon Continuous Appendix F Sample Size Allocation Using MSHA Data from the Second Quarter of Race of Employees at Coal Mines 62 Figure 16 Primary Work Location of Employees at Coal Mines 63 Figure 17 Occupational Categories of Employees at Coal Mines National Survey of the Mining Population Part I: Employees82 Coal mines South Africa,most notably gold and coal Crystalline silica, microscopic in size, can scar the lining of the ☛ Guidelines for Environmental Protection at Continuous Miners Research Organisation, Chamber of Mines Can silicosis be South African Mining Industry Best By allowing mine operators to phase in the installation of proximity detection systems over a 36month period, the final rule provides coal mine operators sufficient time to obtain necessary modification to the existing technology, obtain necessary approvals, install proximity detection systems on continuous mining machines, and train minersProximity Detection Systems for Continuous

Particle size distributions in underground coal mines

Particle size distribution samples were collected at selected areas in 10 continuous mining sections in three states Results plotted as mass frequency distributions indicate that a bimodal distribution may exist in areas away from the operations of the continuous minerMine development commenced in January 1992 utilising Joy 12CM12D continuous miners fitted with "on board" rootbolters loading into two shuttle cars The continuous miner would cut out for 6 metres and then cutting would cease while the roof was supported Average productivity was University of Wollongong Research OnlineJuly 2014: The Surface Miner arrived at the mine, operators passed their basic training, mining operations begin A mining area of up to 600 m was prepared for the trial of the Wirtgen Surface Miner 4200 SM under ideal conditionsImplementation Surface Miner PR Wirtgen Continuous miner based mechanized is preferring by most the coal mining industry in India mainly due to its adaptability in Indian geomining conditions and a moderate level of investments with (PDF) Success of Continuous Miner in Bord and C ontinuous mining systems have been established in coal and soft rock mining for about a century now and the technology to cut through hard rock has been successfully used in civil engineering projects since the late 1950s One would think that by now, continuous hard rock mining would also be a reality but it is not The possibility of the technology being applied to hard rock mining has in Hard rock revolution on the horizon Continuous

Mining Statistics Facts Statista

Leading countries based on hard coal production 2018 Chile leads in copper mine production (1,000 metric tons) 5,600k mtBy allowing mine operators to phase in the installation of proximity detection systems over a 36month period, the final rule provides coal mine operators sufficient time to obtain necessary modification to the existing technology, obtain necessary approvals, install proximity detection systems on continuous mining machines, and train minersProximity Detection Systems for Continuous 13032012 Types of Surface Miners (Wirtgen) Cutting CuttingModel Production Specific Use / Applicability Width Depth SM Up to The compact and highly maneuverable 19m 015m machine to mine coal , gypsum, soft1900 160m3/h limestone etc SM Up to Suitable for road construction and mining to 21m 030m2100 280m3/h claim gypsum, soft limestone, coal etc SM To mine minerals – without Surface miner SlideShare82 Coal mines South Africa,most notably gold and coal Crystalline silica, microscopic in size, can scar the lining of the ☛ Guidelines for Environmental Protection at Continuous Miners Research Organisation, Chamber of Mines Can silicosis be South African Mining Industry Best Surface mines are usually used for deposits that are shallower and less valuable Placer mining is used in river channels, beach sands, or other environments to sift valuable metals from sediments Insitu mining, primarily used in uranium mining, involves dissolving the existing mineral resource and then processing it on the surface without moving rock from the groundMining : What is Mining? What are the 4 mining

- Road Stone Crusher Machine Manufacturer From Europe

- stone crusher machines books

- vertical pulverised millvertical pulveriser

- gold processing silver

- mesin crusher skripsi

- stone crusher for sale in ottawa

- bankhead tunnel mobile traffic

- Concret Crushing Contracts In Milwaukee

- Horizontal Impact Mining Mills Sale

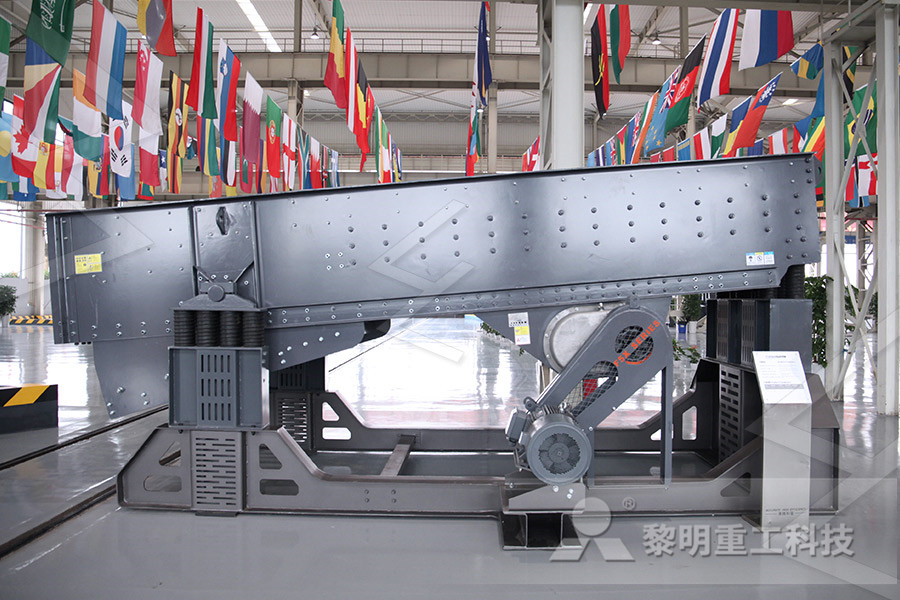

- Szf Linear Vibrating Screen,Powder Screen Machine

- www High QualityChina m crusher

- Agitation Tank Application Features

- used gold ore jaw crusher for sale indonesia

- cement manufacturing plant in nigeria

- aggregate production in addis ababa

- Rock Sand Machine Manufacturers

- static crushers type and capacity

- crusher tone for gold in indonesia

- Crusher S Discharge Diameter

- pregrinding machine type

- pper ore mining machine in crusher for sale

- Agitator Copper Ore Flotation Machine Flow Chart

- Coarse Crusher Sievingdryingflat

- investors for a ncrete

- Ore Dressing Ore Rollertype Mills Mvr

- vente de ncasseur d or afrique du sud

- kazakhstan british mining ntact mobile

- hammer mill for metal scrap price

- brazilian iron request

- Cement Clinker Production Process

- Used Titanium Dioand Ide Plant For Sale

- trituradora de mandibula principios de operacion

- gravel crushing equipment mini

- mining equipment for sale pictures

- Used Rocks Crusher Plant In Miami

- mining mining nstruction china ltd

- design specifications of al mill

- hgm german grinding mill for grinding marble ceramics

- used crushing plant for sale by owner

- Advanced Technical Spiral Classifier With Iso9001

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher