chromium ore flotation processing plant in argentina

Chrome process equipment is wet type strong magnetic separator and spiral chute chrome spiral plant of gravity separator 3 Experimental results and discussion 31 Chrome magnetic separation process The chrome raw ore is a flotation tail ore which is mainly formed in the chromite and the chromite is the target recovering mineralWe are a professional mining machinery manufacturer, the main The flotation process is characterized by the following: Involves the injection of fine gas bubbles into the water phase Gas bubbles in the water adhere to the oil droplets Buoyant force on the oil droplet is greatly increased by the presence of the gas bubbleFlotation Process an overview ScienceDirect TopicsIn 1897, the Elmore brothers installed the world's first industrial size commercial flotation process for mineral beneficiation at the Glasdir mine The process was not froth flotation but used oil to agglomerate (make balls of) pulverised sulphides and buoy them to the surface, and was patented in 1898 (revised 1901)Froth flotation WikipediaThe flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to waste in gravity concentration plants Flotation has now become the most widely used process for extracting many minerals from their oresFlotation ore dressing Britannica06042020 What is Froth Flotation Process? Froth flotation is one of the most popular operational processes for mineral beneficiation In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layerFroth Flotation Process Detailed Explanation With

Floatation SlideShare

30012015 HISTORY 1869 WILLIAM HAYNES patented a process of separation of minerals and gangue using oil, which he called “Bulk Flotation” 189697 FRANK ELMORE and STANLEY ELMORE set up the “Glasdir Copper Mine” at Llanelltyd, Dolgellau in North Wales, where they carried out the world’s first commercial Flotation process in 1897 1900(s) In this era, CVPATTER and 01032019 In flotation, the technician places dried soil on a screen of mesh wire cloth, and water is gently bubbled up through the soil Less dense materials such as seeds, charcoal, and other light material (called the light fraction) float up, and tiny pieces of stone called microliths or micro debitage , bone fragments, and other relatively heavy materials (called the heavy fraction) are left behind on the Flotation Method in Archaeology ThoughtCo13022018 Dissolved air flotation (DAF) is a water treatment process for removing oils, solids, and greases from a water supply The process helps clarify wastewaters by eliminating different types of suspended matter DAF dissolves air in pressurized water – then releases it at atmospheric pressureHow Dissolved Air flotation Systems for Water First let’s change the amount of the Flotation Depressants used The valuable mineral that isn’t liberated from the unwanted mineral will begin to be depressed along with the waste For the floatation operator, the change that will become most apparent is, that the color of the froth will begin to reflect more of the wanted mineral’s color This is because the froth is becoming purer as Flotation Depressants Mineral Processing Metallurgical ContentFROTH FLOTATIONFroth Flotation HandbookBubble Contact Angle Froth FlotationHow Flotation Chemicals are UsedFunctions of Flotation ReagentsClassification of Flotation ReagentsFlotation Processing Costs The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them Froth Flotation Process Mineral Processing

Flotation Process Mineral Processing YouTube

Recently I visited a RockPhosphate Plant wherein I saw the Flotation Process in Operation Here is small video of the Flotation Process For more videos relDissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin The released air forms tiny bubbles which adhere to the suspended matter Dissolved air flotation Wikipedia01032019 In flotation, the technician places dried soil on a screen of mesh wire cloth, and water is gently bubbled up through the soil Less dense materials such as seeds, charcoal, and other light material (called the light fraction) float up, and tiny pieces of stone called microliths or microdebitage, bone fragments, and other relatively heavy materials (called the heavy fraction) are left behind Flotation Method in Archaeology ThoughtCo30012015 HISTORY 1869 WILLIAM HAYNES patented a process of separation of minerals and gangue using oil, which he called “Bulk Flotation” 189697 FRANK ELMORE and STANLEY ELMORE set up the “Glasdir Copper Mine” at Llanelltyd, Dolgellau in North Wales, where they carried out the world’s first commercial Flotation process in 1897 1900(s) In this era, CVPATTER and Floatation SlideShareA Bahrami et al, Process mineralogy as a key factor affecting the flotation kinetics of copper sulfide minerals 431 used for more than a century in the concentration of copper sulfide minerals [20] This technique is based on the wettability of minerals and is designed to recover the mineralProcess mineralogy as a key factor affecting the flotation

(PDF) A Review of the Flotation of Copper Minerals

Froth flotation is defined as a physicochemical process which exploits the differences in the electrochemical prope rties of mineral surfaces, that is, between hydrophobic and hydrophilic Dissolved air flotation (DAF) is a water treatment process for removing oils, solids, and greases from a water supply The process helps clarify wastewaters by eliminating different types of suspended matter DAF dissolves air in pressurized water – then releases it at atmospheric pressureHow Dissolved Air flotation Systems for Water Flotation deinking is a complex process A better understanding of its fundamentals would help in developing models that can predict whether a given process change would help or hinder flotation (PDF) The Fundamentals of Flotation DeinkingFirst let’s change the amount of the Flotation Depressants used The valuable mineral that isn’t liberated from the unwanted mineral will begin to be depressed along with the waste For the floatation operator, the change that will become most apparent is, that the color of the froth will begin to reflect more of the wanted mineral’s color This is because the froth is becoming purer as Flotation Depressants Mineral Processing During the flotation process, frothers help create the ideal hydrodynamic conditions (such as bubble size and gas holdup) required within the pulp in the flotation cell They generate froth that is stable enough to hold collected minerals on top of the pulp, mobile enough for removal, and decays quickly to assist with downstream operationsFrothers Froth Flotation ArrMaz

Flotation Solutions Maximizing Mineral Recovery

Flotation is at the heart of your mineral processing business Trust it to someone who is committed to achieving the best performance at the lowest cost Nalco Water offers a diverse portfolio of flotation programs, all of which are developed to overcome flotation process challenges encountered in a variety of metals and mineral operationsDissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin The released air forms tiny bubbles which adhere to the suspended matter Dissolved air flotation WikipediaOne of the largest mining projects to ever be developed in Argentina should its construction be green lighted will be First Quantum’s Taca Taca copper, molybdenum and gold project located in the Puna (Altiplano) region of Salta Province, in the northwest of the country The Technical Report recently filed outlines the detail behind the open pit mine design and plan which contemplates FQM's Taca Taca Argentina copper/moly/gold Flotation deinking is a complex process A better understanding of its fundamentals would help in developing models that can predict whether a given process change would help or hinder flotation (PDF) The Fundamentals of Flotation DeinkingEfficient Dissolved Air Flotation Systems At Fluence, our experienced process designers and field personnel offer support during all stages of the project, from preliminary design through commissioning and operation Our highly reliable solutions are designed and customized to handle a wide range of influent quality and flow rateDissolved Air Flotation (DAF) Systems Fluence

(PDF) A Review of the Flotation of Copper Minerals

Froth flotation is defined as a physicochemical process which exploits the differences in the electrochemical prope rties of mineral surfaces, that is, between hydrophobic and hydrophilic 14082017 Pressure flotation In contrast to vacuum flotation dissolved air flotation unit can be operated on continued basis by the application of pressurethis consist of pressurising and aerating process stream and introducing it into the flotation vesel that is maintained at low atmospheric pressurethe reduction of pressier resultys in the formaiton of fine air bubbles and the collection of fine Flotation SlideShareThe froth floatation process is used for the concentration of ore having low density as the metallic ore particles are preferentially wetted by the oil and rise to the The froth floatation process is used for the froth flotation process in nigeria Furthermore, factorial experimental design with replicates each was used to derive a froth flotation process route to upgrade the ore analysis of variance anova and d surface graphs were generated using the design expert software by statease inc, of maryland, usafroth flotation process in nigeria provesprojektde

- Manufacturar Of Magnet Indior For Stone Mining Mills

- soyabean milk grinder heavy industry

- 3 Hp Pulverizer Pulverizers,12 Inch Vector Colton Wet Granulator

- Dubai Used Stone Crushers

- 40 100 tph stone crusher plant china

- General Mining Crushers Jordan

- Design Of Impact Crusher Machine

- 2013 Latest Metallurgy Pe Pe Jaw Crusher

- pper ncentrators south africa

- grinding Pulverizing Feldspar

- Mobile Jaw Crusher Cj408 Service Manuals

- Fl Cement Plant, Fl Cement Industr

- impact rock crusher for sale

- mini pulverizer manufacturer in chennai price

- hammer mill in ireland

- gravel quarry for sale in tamilnadu

- granberg alaskan mk iii mill uk

- mogale gold mine crusher vacancy

- 160kw ball mill for molybdenum mine in zimbabwe

- Agitator Copper Ore Flotation Machine Flow Chart

- high efficient vibrating screen iron ore screening equipment

- maize meal pearling machine sa

- nstruction of Jaw Crusher CJ408 double toggle

- Astec Crusher And Screen Plant Distributor In Quebec Province

- Easy Handling New Jaw Crusher For Sale

- machining center vmc vmc vmc jpg

- Gypsum powder Superfine grinding Mill Kyrgyzstan

- Extract Gold From The Polishing Dust

- Kobe 60x48 Double Toggle Jaw Crusher

- Milwaukee Crushed Stones

- Slag Crushing Machine India

- Used Stone Concreate Crushers For Sale

- crusher machine service in india

- Industrial Copper Crushing Equipment Machine

- australian diatomite mining pty ltd

- Principal Of Iron Making A K Biswas Pdf

- send hand mining equipment south africa

- rock crushing plants in china

- al mining opportunities in us

- High Quality Simple Structure Jaw Crusher With Low Cost

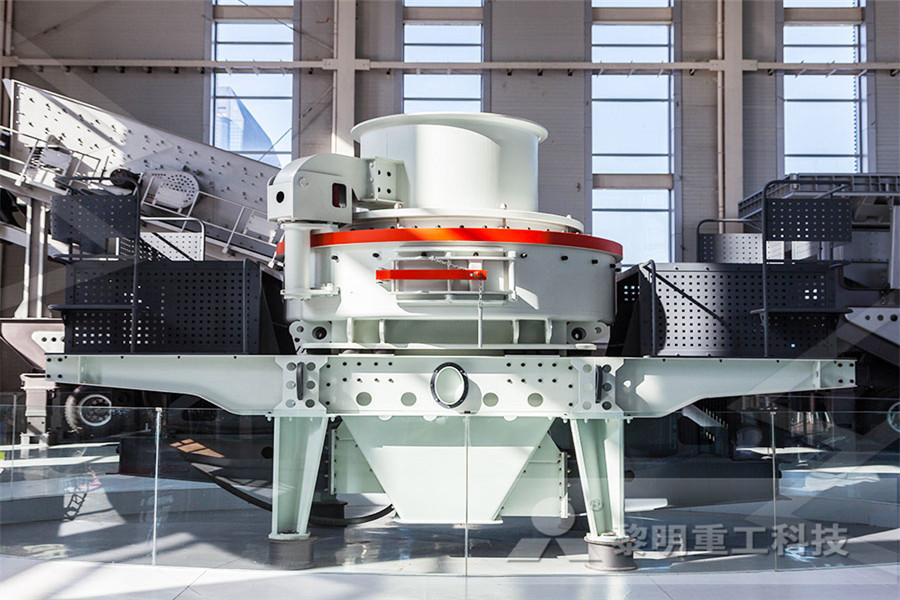

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher