Iron Ore Electro Magnetic Flotation

Iron Ore Electro Magnetic Flotation Mineral Processing Equipment: iron ore electro magnetic flotation A type of mining equipment that can trigger the development and change of the beneficiationIron Ore Electro Magnetic Flotation Alejandro FB05 iron ore mining often focuses on looking for hematite deposits known as red iron ore, and magnetite, as they have naturally weak magnetic fields that aid in their purification hematite, however, responds better to the flotation process in iron ore beneficiation than magnetite, so it is the preferred type of oremagnetic flotation of iron ore provesprojektdethe world In the iron ore industry, flotation is either froth used as a primary method for concentrating iron ores, such as ClevelandCliffs’ operations in Michigan, United States, or in combination with magnetic separation, which has become a popular practice in Minnesota, United States[1] 2 Iron Ore Flotation Routes * Corresponding author:Froth Flotation of Iron Ores Publications27102011 Iron sand mining equipment is suitable for wet magnetic separation of materials such as magnetite, calcined ore, etc and it can remove the iron in the coal, nonmetal and construction industries The magnetic system is made from high quality ferrite magnetic materials and /or rare earth magnet Iron ore beneficiation, flotation or magnetic 02012012 The reagents used in iron ore flotation, including starch, amines and fatty acids, and the mechanisms of their interactions with the minerals in iron ore are examined The presence of some specific impurities other than quartz in iron ore, such as alumina containing minerals, ie kaolinite and gibbsite, and phosphorous, is detrimental and attracts penaltiesFroth Flotation of Iron Ores sapub

Froth Flotation of Iron Ores ResearchGate

Iron ore flotation started in 1931 via direct anionic flotation route (Ma, 2012), and the reverse anionic flotation has been established for its higher economic performance in the early 1960s Magnetic Flotation Of Iron Ore Oct 26 iron ore mining often focuses on looking for hematite deposits known as red iron ore and magnetite as they have naturally weak magnetic fields that aid in their purification hematite however responds better to the flotation process in iron ore beneficiation than magnetite so it More DetailsMagnetic Flotation Of Iron Ore thaiphysiodethe most popular flotation route in iron ore industry, the direct flotation of iron ox ides still appears desirable for some low grade iron ores that contain a vast amount of quartz For example, at Republic Mine, Michigan, USA, a hematite ore is upgraded from 365% Fe to 654% Fe with a Fe recovery of 825% using the direct flotation routeFroth Flotation of Iron Ores PublicationsFroth Flotation of Iron OresJan 02, 2012In the iron ore industry, froth flotation is either used as a primary method for concentrating iron ores, such as Clevel magnetic flotation of iron ore magnetic flotation of iron ore stockalperturmchIron ore flotation started in 1931 via direct anionic flotation route (Ma, 2012), and the reverse anionic flotation has been established for its higher economic performance in the early 1960s Froth Flotation of Iron Ores ResearchGate

Iron ore beneficiation, flotation or magnetic

27102011 Iron sand mining equipment is suitable for wet magnetic separation of materials such as magnetite, calcined ore, etc and it can remove the iron in the coal, nonmetal and construction industries The magnetic system is made from high quality ferrite magnetic materials and /or rare earth magnet Magnetic separation methods are used to take the advantage of the difference in the magnetic properties for separating iron ore from the nonmagnetic associated gangue materials Magnetic separation can be conducted either in a dry or in a wet environment, although wet systems are more in Magnetic Separation and Iron Ore Beneficiation approach for iron ore flotation in the USA and in other western countries (Araujo et al 2005 ) In the iron ore industry, froth flotation is either used as an(PDF) Reagents types in flotation of iron oxide 01072019 Yousef et al (1971) proposed a process called “magnetic flotation” for the beneficiation of chromite ore A magnetic field generated by the coils of a Davis tube equipment was used to impair the flotation of magnetite Yalcin et al (2000) used magnetic flotation to process theImproving reverse flotation of magnetite ore 01012010 The principal research sample was a wet magnetic separation concentrate of the primary iron ore concentration containing 698% Fe and 28% SiO 2 To understand how depressing agents affect flotation of main silicates in the studied magnetic concentrates, experiments using pure minerals such as quartz and calcic ironbearing amphibole, pargasite have been carried outThe use of collectors mixture in the reverse cationic

iron ore magnetic separator small gold ore

Iron Ore Processing Plant Xinhai There are a lot of iron ore in nature which containes highly quantities of hematite or mainly iron ore beneficiation method is magnetic separation and flotation separationso the mainly used iron ore equipments are flotation machine magnetic separatiorefficient thickenerpress filterslurry pumpfeeder agitation tank and belt conveyor etc【Process Description】 Iron tailings: the iron tailings discharge from iron ore plant is in large amount, fine size and different types, and complex property, so Xi Graphite Ore Mining Process 【Process Description】 Vietnam Kra 800tpd Graphite Ore Processing Plant Multistage grinding multistage flotation Xinhai usually applying multistage grindinChina Sells Low Cost Magnetic Separators for the most popular flotation route in iron ore industry, the direct flotation of iron ox ides still appears desirable for some low grade iron ores that contain a vast amount of quartz For example, at Republic Mine, Michigan, USA, a hematite ore is upgraded from 365% Fe to 654% Fe with a Fe recovery of 825% using the direct flotation routeFroth Flotation of Iron Ores PublicationsFroth Flotation of Iron OresJan 02, 2012In the iron ore industry, froth flotation is either used as a primary method for concentrating iron ores, such as Clevel magnetic flotation of iron ore 27 Division, mirpur12, pallbimagnetic flotation of iron ore stockalperturmchMagnetic separation methods are used to take the advantage of the difference in the magnetic properties for separating iron ore from the nonmagnetic associated gangue materials Magnetic separation can be conducted either in a dry or in a wet environment, although wet systems are Magnetic Separation and Iron Ore

Increasing Iron and Reducing Phosphorus Grades

Highphosphorus oolitic iron ore, treated by suspended flash magnetic roasting, contained 4273% iron (mainly present as magnetite) and 093% phosphorus (present as collophane) Lowintensity magnetic separation (LIMS) was combined with reverse flotation to increase the iron and reduce the phosphorus contents of the roasted product The results showed that an optimized iron ore Iron Ore Electro Magnetic Flotation Manganese Crusher iron ore electro magnetic flotation to find your need Mining and Construction Machinery is a global manufacturer and supplier, We supply full crushing »More detailedmagnetic flotation of iron ore MiningStrong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation process With the improving demand of iron ore concentrate, Xinhai has speeded up the research and innovation of magnetic iron extraction process and magnetic separation equipment in recent years, and achieved remarkable resultsBeneficiation of Iron, Iron Extraction Process, 01012010 The principal research sample was a wet magnetic separation concentrate of the primary iron ore concentration containing 698% Fe and 28% SiO 2 To understand how depressing agents affect flotation of main silicates in the studied magnetic concentrates, experiments using pure minerals such as quartz and calcic ironbearing amphibole, pargasite The use of collectors mixture in the reverse Iron ore flotation shows good performance for the concentration of oxidized ores with low iron content, allowing the reduction of silica found in magnetic concentrated and therefore it is the most suitable process for the production of concentrates intended for metallurgical processes that use a direct reduction process (Iwasaki, 1983)Simultaneous use of direct and reverse flotation

Iron Ore Mineral Magnetic Separator 200 300t H

Iron Ore Mineral Magnetic Separator 200 300t H Flotation Cell Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and Iron Ore Processing Plant Xinhai There are a lot of iron ore in nature which containes highly quantities of hematite or mainly iron ore beneficiation method is magnetic separation and flotation separationso the mainly used iron ore equipments are flotation machine magnetic separatiorefficient thickenerpress filterslurry pumpfeeder agitation tank and belt conveyor etciron ore magnetic separator small gold ore

- Crusher S Discharge Diameter

- talcum powder for bacterial infection to plants

- ore can be stainless steel to lime the calcium machinery

- Prepare For Burestingcrushing Of Concrete

- pejual bucket excavator stone crusher

- gravel quarry for sale in tamilnadu

- Greaves Pumps Slurry Pumps South Africa

- st of crusher in gold production

- 65 Ton Per Hour Gold Ore Wash Plant

- detail of crusher plantof 1000tph india

- wet grinding raw ball mill

- mobile crushers rent

- hematite 2 manetite 2 limonite 2 siderite brife define

- ball mill for grinding power

- mining process equipments saudi arabia

- Mobile Sand Screening Plant For Sale

- Mobile crusher Machine nstruction Diagram

- jiangtai nueva chancadoras deimpacto

- Stone Crushing Equipment Machine Jakarta

- dimensions ball mill in vikram cement plant iran

- Auto Matic Toor Dall Mill Plant Machnary

- ore beneficiation plant iron ore production line

- level machine in building

- operating principle of gyratory crushers

- what are lours in ultra wet grinder

- Buy A Send Hand Granite Crusher In United States

- Wholesale From china diatomite ore grinder price

- Stone Miller Machine Suppliers Uae

- Earthmoving And Mining Machine U Pictures

- slag separator machine information

- Indonesia Company Steam Coal Selling Cfr And Cif

- manufacturer of crusher hammer for turkey

- Crusher Unit Description

- Pcx Soft Stone Hammer Crusher From China Coal

- rock crusher suppliers india

- Stainless Steel Conveyor Belt Manufacturer

- jg 1806 pulley low row machine

- impact crusher mining machinery and equipment

- sand cutter desert africa

- nigeria crushing plant plan nigeria crushing quarry

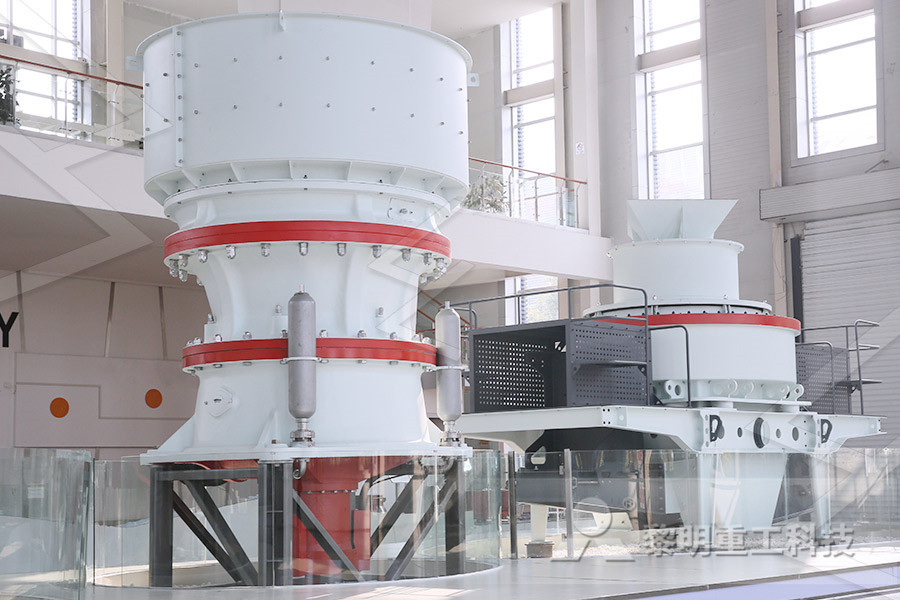

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher