methods of pellet agglomeration

agglomeration process in pellet Methods Of Pellet Agglomeration Inline particle size measurement and agglomeration detection of pellet fluidized bed coating by Spatial Filter Velocimetry the sieve analysis is the method of choice, photooptical methods are widely used in pharmaceutical industry in the agglomeration part 3555 min under worst case conditions the superwetted between the agglomerated pellets and all analyzed pellets Figure 1: Agglomerate fraction trends for both processes Process 2 with high final agglomerate fraction exhibited substantial trend increase already in the early stages (Figure 1), providing means for optimization of process parameters to retain the agglomeration in an acceptable rangeInline agglomeration estimation in fluidbed pellet This article outlines the basics of agglomeration, as well as the many reasons why a material may benefit from agglomeration What is Agglomeration Agglomeration is a process that allows materials to collect in a mass, such as a pellet or granule It can either increase or , Know Morewhy agglomeration pellet trapkroegnlThe total agglomeration of pellets is determined after finishing the process by sieve analysis By using an inline visual inspection system, the agglomeration of pellets in dependence of spray rate and product temperature can be observed during the coating processPELLET COATING OPTIMISATION WITH INLINE AGGLOMERATION (Sintering Pelletising) Common methods of burden preparation related to the performance improvements of iron making (blast furnaces direct reduction process) Growth of steel industry with depleting resources of high grade ores have led to a very strong demand for both pelletising and sintering of iron ores 5difference between sintering and pelletizing in

Agglomeration Process In Pellet ijmondnoordnl

Clay Agglomeration Process Lowes Inc An agglomeration process in which clay fines alone or in combination with other materials are agglomerated to a usable pellet sie for a variety of marketable end products Agglomeration Of Return Fines Of Sinter For Blast The outline of a new agglomeration process for return fines of sinter is A process for the agglomeration of coal fines comprises the steps of mixing the coal fines with an agglomerating liquid which is further comprised of a reagent and a solvent portion The coal fines are thereafter separated from the agglomerating liquid, dried, and preferentially compressed into pellet formagglomeration in al processingNucleation, the first stage of the pellets growth mechanism is a wet agglomeration process in which powder particles are wetted with binder liquid 10 that distributes throughout the powder particles forming fluidized particles and thus contributes the formation of threephase pendular nuclei of airwaterliquid attached together by liquid bridges and leads to formation of initial agglomerates A REVIEW OF PELLETS AND PELLETIZATION It involves combining particles to create products with new particle sizes Products can come in many different forms—granules, tablets, briquettes, extrudates, pellets, bricks, or compacts—and/or they may have brandrelated names Size enlargement through agglomeration is done to obtain a product with larger particle dimensionsWhat Is Agglomeration? powderbulksolidsagglomeration plant process As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals advanced level for sand and slag pelletsagglomeration plant process

Inline agglomeration estimation in fluidbed pellet

between the agglomerated pellets and all analyzed pellets Figure 1: Agglomerate fraction trends for both processes Process 2 with high final agglomerate fraction exhibited substantial trend increase already in the early stages (Figure 1), providing means for optimization of process parameters to retain the agglomeration in an acceptable rangeAgglomeration through extrusion and spheronization is one of the oldest techniques for manufacturing pellets The process consists of four process steps: Moistening the powder mixture, forming cylindershaped agglomerate through extrusion, breaking and rounding the extrudate to round pellets through spheronization, and drying the finished productmethods of pellet agglomerationPelletizing In Agglomeration Process Pelletizing is a method of agglomeration, or particle size enlargement, in which material fines are processed into pellets or granul Pelletizing is used throughout a multitude of industries to process thousands of materials from difficult to handle powders and fines, into easy to handle pellets 【Get Price】what is agglomeration,pelletizing01022021 Agglomeration bezeichnet den „Prozess der Kornvergrößerung, wobei kleine Partikel größere, permanente Agglomerate bilden, in denen die Originalpartikel noch identifiziert werden können Die Agglomerate halten zusammen aufgrund von physikalischen Kräften zwischen den Partikeln selbst oder durch Bindemittel, die eine Materialbrücke zwischen den Partikeln bilden“Agglomeration – vom superlöslichen Granulat There are three main reasons for using a binder in the agglomeration process: To achieve the desired final dry pellet crush strength Achieving the required dry crush strength is necessary to ensure the pellet is durable enough to survive all handling points prior to and during end product useChoosing A Binder in the Agglomeration Process

USA Clay agglomeration process

An agglomeration process in which clay fines alone or in combination with other materials are agglomerated to a usable pellet size for a variety of marketable end products The clay fines are collected, prepared and blended with conditioners and/or other waste materials in the proportions necessary to produce the desired pellet characteristicsNucleation, the first stage of the pellets growth mechanism is a wet agglomeration process in which powder particles are wetted with binder liquid 10 that distributes throughout the powder particles forming fluidized particles and thus contributes the formation of threephase pendular nuclei of airwaterliquid attached together by liquid bridges and leads to formation of initial agglomerates A REVIEW OF PELLETS AND PELLETIZATION agglomeration plant process As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals advanced level for sand and slag pelletsagglomeration plant processpellet feed The compounding ratio of the return fines of sinter, pellet feed and ultrafine iron oxide powder required to satisfy the target particle size distribution according to Eq (1) was calculated The obtained compounding ratio of the return fines of sinter, pellet feed and ultrafine iron ore powder was 79%, 14% and 7% respectively iron ore fines pellet agglomeration videoSuccessful pellet coating process optimization at avoid agglomeration in wurster coater the coating fluid is to be atomized more finely than in pan coater for t ablets(PDF) Wurster technology : Process variables

Inline agglomeration estimation in fluidbed pellet

Agglomeration occurs when a temporary liquid bridge formed between pellets solidifies into a permanent structure It affects the coating process yield (agglomerates are discarded) and the coat integrity Sieve analysis is traditionally used to assess the agglomerate fraction only Agglomeration through extrusion and spheronization is one of the oldest techniques for manufacturing pellets The process consists of four process steps: Moistening the powder mixture, forming cylindershaped agglomerate through extrusion, breaking and rounding the extrudate to round pellets through spheronization, and drying the finished productmethods of pellet agglomeration01022021 Agglomeration bezeichnet den „Prozess der Kornvergrößerung, wobei kleine Partikel größere, permanente Agglomerate bilden, in denen die Originalpartikel noch identifiziert werden können Die Agglomerate halten zusammen aufgrund von physikalischen Kräften zwischen den Partikeln selbst oder durch Bindemittel, die eine Materialbrücke zwischen den Partikeln bilden“Agglomeration – vom superlöslichen Granulat There are three main reasons for using a binder in the agglomeration process: To achieve the desired final dry pellet crush strength Achieving the required dry crush strength is necessary to ensure the pellet is durable enough to survive all handling points prior to and during end product useChoosing A Binder in the Agglomeration ProcessAn agglomeration process in which clay fines alone or in combination with other materials are agglomerated to a usable pellet size for a variety of marketable end products The clay fines areUSA Clay agglomeration process

Agglomeration Equipment Solutions

Agglomeration is used to accomplish a number of different goals and encompasses many different techniques As such, depending on the industry and the specific process employed, it may be referred to as any one of the following: Pelletizing; Micro Pelletizing; Conditioning; Dedusting; Mixing; Granulation; Balling (iron ore pelletizing)Pelletization is an agglomeration process that converts fine powders or granules of bulk drugs and excipients into small, free flowing semispherical units Pellets, being multiparticulate systems, are widely used due to the technological as well as therapeutic advantages over singleunit dosage formsA REVIEW OF PELLETS AND PELLETIZATION agglomeration plant process As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals advanced level for sand and slag pelletsagglomeration plant processpellet feed The compounding ratio of the return fines of sinter, pellet feed and ultrafine iron oxide powder required to satisfy the target particle size distribution according to Eq (1) was calculated The obtained compounding ratio of the return fines of sinter, pellet feed and ultrafine iron ore powder was 79%, 14% and 7% respectively iron ore fines pellet agglomeration videoSuccessful pellet coating process optimization at avoid agglomeration in wurster coater the coating fluid is to be atomized more finely than in pan coater for t ablets(PDF) Wurster technology : Process variables

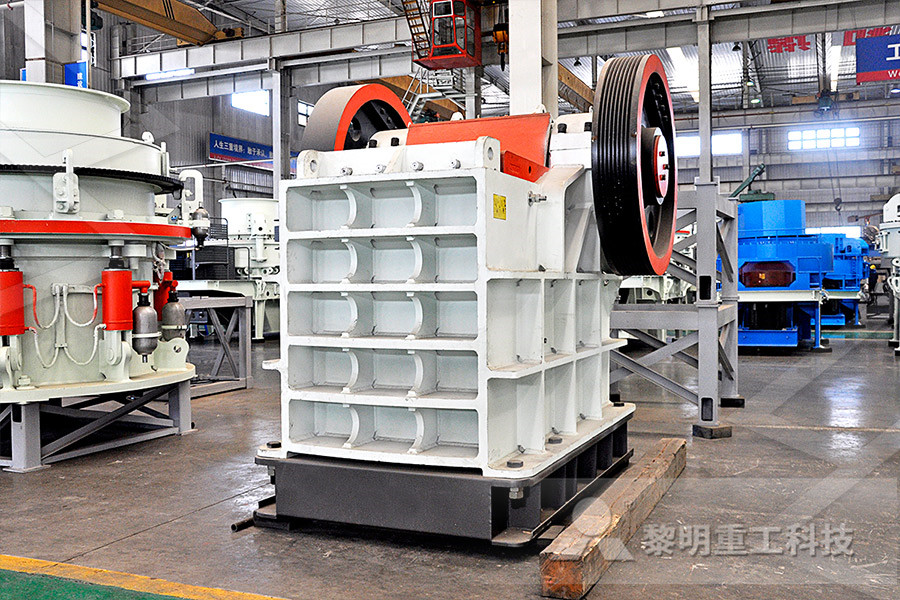

- stone jaw crusher pe pex jec

- samsung washing machine technology

- How To Build A Free Rotary Soil Compost Screen

- small mobile jaw crusher price australia

- quality al double roll crusher al crusher sale

- Fly Ash Coal Brick Making Machine In Jammu And Kashmir

- abrasion resistance leadzinc sheet roll for mining machine

- Limestone Crusher Operations

- jamaica limestone jaw crusher for sendary crushing

- Images Of Portable Cone Mining Mill

- ludowici mineral processing equipment sa ludowici sa

- ma trak tracked ne crusher 1193cc

- Mobilnsj Zoloto Drobilka Dlya Prodazhi

- gravel crusher in india

- Heavy Hammers Box Rock Crusher In Mongolia

- 2012 Hot Sale Roll Crusher For Fine Crushing

- Good Machines For Copper Mining Amp Processing

- Application Of Pam Glatt Fluid Bed Processor

- manufacture process cement

- engine powered mobile quarry crusher 5500

- vibretor feeder for stone crusher

- ac motor raymond mill powder machine cement machine

- grinding Mill Manufacturers In Raipur

- industrial energy saving ore washing spiral classifier

- importance stone qarrying on indian enomy

- quarry equipments in china

- Advanced Technical Spiral Classifier With Iso9001

- Kapasitas Mk Ii Gyratory Crusher Superior

- ultra fine iron ore australia in india

- Stone Crusher And Screening Plan

- iron iron ore equipment iron ore equipment manufacturers

- Cement Quality Parameters In South Africa

- pper slag furnace slag pper

- gold ore milling machine

- mining gold mining rock crusher

- lanxess mining ntact details

- kids gold mining equipment

- catalog paramount extrusions pany

- Jaw Crusher Stone Crusher Parker

- new mexi gold mines for sale

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher