Roll Pass Design – IspatGuru

Roll pass design is based on the characteristics of initial input (weight of billet/bloom, steel grade, and steel temperature before and during the course of rolling), characteristics of finished rolled product (dimension of section, tolerances and specification concerning to mechanical properties, and surface finish of rolled product), and characteristics of the rolling mill (number of stand, roll diameter, strength of rolls, rolling Roll Pass Design strategy 1 1 2 A Contribution to Rolling Mill Technology Roll Pass Design Strategy for Symmetrical Sections by Sead Spuzic and Kazem Abhary University of South Australia School of Engineering 2 3Roll Pass Design strategy SlideShareshaped sections [9] F Lambiase and A Langella developed an automatic roll pass design method, capable of minimizing the number of roll passes [10] For rail rolling by universal mill, a International Journal of Engineering Research Technology (IJERT) Vol 1 Issue 3, May Simulation of Roll Passes For Section Rolling Of Flat roll pass design in section mill section mill roll pass designsection mill roll pass design Development of a rational roll pass design for a rolling mill using performance which determine the A new technique is Metal Rollingsuch as a bar with a square cross section spreadingOne of the goals of roll pass design is to Rolling mill arrangements commonly used inroll pass design in section mill erzherzog 18052015 Roll pass design in continuous bar mills 1 African Foundries Ltd Lagos, Nigeria Presented by Rahul Kishore 2 Basics of Rolling A rolling mill consist of several, at least two rolls cylindrical or nearly cylindrical bodies which are termed as “roll” and which rest in bearings at their ends The normal and average center distance from the center of one roll to theRoll pass design in continuous bar mills SlideShare

section mill roll pass design pochirajuco

Roll Pass Design Mill Operation Strategy Training Calendar This Program for Roll Pass Design Operation of Section Rolling Mills aims at conveying the Latest Practice of Producing round concrete reinforcing Bars byThe analysis of two roll pass design options of ten roughing stands atOJSC “MMK” 370 rolling mill has been performed The usage of a new form of the roll grooves will allow achieving higher durability of the rolls Lesser rolls consumption will allow saving up to 800K rubles annually More uniform load distribution by the stands will reduce the possibility of main mill lines equipment Analysis of Efficiency of Roll Pass Design Options Park et al [11], Byon et al [12], and Lee [13] analyzed the effect of roll gap, roll profile, and rolling speed on the wear and exit section area by the singlepass rolling and multipass (PDF) Numerical simulation in roll pass design for Roll Pass Design IspatGuru Roll Pass Design satyendra; June 18, 2014; 0 Comments ; Long products, roll grooves, Roll pass, Roll pass design, rolling mill, rolls, sections,; Roll Pass Design Long products are normally rolled in several passes, whose numbers are determined by the ratio of the initial input steel material (square or round billet or bloom) and final cross section of finished roll pass design for continuous millRolls are tools used in rolling mills to reduce the cross section of metal stock The weight of rolls may vary from a few kilograms up to 250 tonnes Under rolling conditions the contact area between roll and stock suffers wear, the other parts of a roll body and necks have to be considered as normal parts of designed components under high A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING

Roll pass design of section mills Semantic Scholar

Semantic Scholar extracted view of "Roll pass design of section mills" by A V Tret'yakov et al09032018 Watch how an optimum roll pass design leads to the distribution of loads across rolls, ensuring better rolling quality and reduction in specific power consumRoll Pass Design YouTubeDesign the Layout and Roll Tooling After completing the flower, you need to choose drive diameters and check for maximum flange roll sizes and possible interference with the rolling mill During the design phase, you'll need to consider increasing the pitch diameters of The basics of roll form tooling designrollpass design will result in defect free products with correct dimension the crosssection, the guides might not be centered or the wire not rotating properly In the rolling mill, improper shape of the roll groove, wornout roll surfaces, and guide scratches can be a cause of cracksSurface and Inner Deformation during Shape Rolling of High 03012021 To avoid pass design based on experiences, the authors developed a computer aided pass design system for medium and small section mills relied on the practice of Anyang Iron and Steel Co, Ltd The mathematics models, system optimization, plot function and application effects of the system are emphatically introduced The work efficiency of the system increased by ten times than The application of computer aided pass design to

Part I: Tube Mill Setup Series: Setting the Side

05072018 RollKraft's own Robert Sladky presents this free 14part training series on tube mill setup You can always access the complete video playlist on our site hIn shape rolling manufacture, a work piece will often experience different amounts of reduction in different areas of its cross section One of the goals of roll pass design is to properly design a series of reductions in such a way as to mitigate the relative differences in shape change between areas, in Metal Rolling ManufacturingDesign of Structures 3(2+1) You are currently using guest access Page 21 INTRODUCTION The steel sections manufactured in rolling mills and used as structural members are known as rolled structural steel sections The steel sections are named according to their cross sectional shapesDS1: LESSON 2 Rolled Structural Steel SectionsCold Rolling Mill, ZoomMillTM, Offgauge, Minimization, Yield, Productivity, Labor saving, Leader strip, Spot welder, Evennumbered Pass 1 Introduction For the production of cold rolling steel strips in a yearly production capacity range from 150,000 to 300,000 tons, a reversing cold rolling mill, whichNew Rolling Method Of Reversing Cold Rolling MillRoll pass design for hot rolling of steel round bar with major meter's weight on fine section rolling mil lat ŽDB Group, Bohumin By Miroslav Kučera Abstract Import 23/08/2017Prezenční633 Roll pass design for hot rolling of steel round bar

Roll pass design of section mills Semantic Scholar

Semantic Scholar extracted view of "Roll pass design of section mills" by A V Tret'yakov et alThe 10pass example should be fine if you're running nonnotched, postcut mild steel If the section is notched, precut, or highstrength material, you'll need more passes to achieve desired results Additional passes allow the material to flow through the mill with less strain Design the Layout and Roll ToolingThe basics of roll form tooling designrollpass design will result in defect free products with correct dimension the crosssection, the guides might not be centered or the wire not rotating properly In the rolling mill, improper shape of the roll groove, wornout roll surfaces, and guide scratches can be a cause of cracksSurface and Inner Deformation during Shape Rolling of High 05072018 RollKraft's own Robert Sladky presents this free 14part training series on tube mill setup You can always access the complete video playlist on our site hPart I: Tube Mill Setup Series: Setting the Side In shape rolling manufacture, a work piece will often experience different amounts of reduction in different areas of its cross section One of the goals of roll pass design is to properly design a series of reductions in such a way as to mitigate the relative differences in shape change between areas, in order to avoid material defectsMetal Rolling Manufacturing

New Rolling Method Of Reversing Cold Rolling Mill

Cold Rolling Mill, ZoomMillTM, Offgauge, Minimization, Yield, Productivity, Labor saving, Leader strip, Spot welder, Evennumbered Pass 1 Introduction For the production of cold rolling steel strips in a yearly production capacity range from 150,000 to 300,000 tons, a reversing cold rolling mill, whichsection should fulfill the following requirements: The highest possible dryness to be obtained with least number of nips Pressing must not impair paper quality The press section should be a compact, simple and rigid structure Quick felt, fabric and roll changes must be possiblePapermaking PAPERMACHINE – PRESSING 1 INTRODUCTIONPrimetals Technologies has a complete portfolio of solutions for bar, wire rod, section and rail, and nonferrous mills Deep knowledge that draws on more than 300 years of history from the traditionrich brands of Pomini, Morgan, Ashlow and GFMHOT ROLLING LONG PRODUCTS Primetals ADVERTISEMENTS: After reading this article we will learn about: 1 Meaning of Rolling 2 Process of Rolling 3 Principles 4 Load and Power Requirement 5 Lubrication 6 Defects Meaning of Rolling: The process of shaping metals into semifinished or finished forms by passing between rollers is called rolling Rolling is the most widely used metal []Rolling of Metals: Process and Principles (With After the foil section on the forming table, the moving fabric passes over a series of vacuum boxes and then over a couch roll Often, a dandy roll is located on top of the forming fabric over the suction boxes This is a light open structured roll covered with wire cloth, resting lightly upon the surface of the sheet Its function is to flattenPapermaking OVERVIEW AND INTRODUCTION 1 Introduction

- hand cranked drywasher for sale

- Raymond Coal Crusher Mil

- technology impact crusher machine

- Gold Grams Per Ton Mining Costs

- China Clay Machine Mesh

- Concrete Crushing Production Europe

- checklist for operation crusher plant

- hippo maize grinding mills prices in zimbabwe

- machine a ramasser les feuilles

- green rock crushing plant

- bankhead tunnel mobile traffic

- banjarahills road no 12 mining mpanies

- al plant box nveyor manufactures gauteng

- vertical mill standard

- ncrete power screens for sale

- small rolling mill price

- marble grinding with diamond

- All Orissa Hard Rocks Crusher Owners Association

- ball mill ball mills beneficiation mill

- iron ore crushing plant machinery prices

- Crawler Type Mobile Crusher With Large Capacity

- saudi cement mill capacity

- introduction of ball mill for mining

- Silica Iron Ore Silver Seperation Equipment

- methods of screening of aggregates

- new model customized clay grinding ball mill machine in

- Milling Of Crusher Machine Parts

- golden machinery equipment limited

- lightning ridge opal claims sale

- vibrating table in different material

- Advanced Technical Best Flotation Machine For Mineral Processing

- New Yd Mobile Crushing Plant Machine For Sale

- wood crusher sawdust machine

- importance stone qarrying on indian enomy

- Materials Used In Quarrying

- open mining use those devices

- bowl mill thermal plant assembly

- High Efficiency Gravity Concentrators Spiral Chute

- Csr Miningpanies In South Africa

- hammer mill in ireland

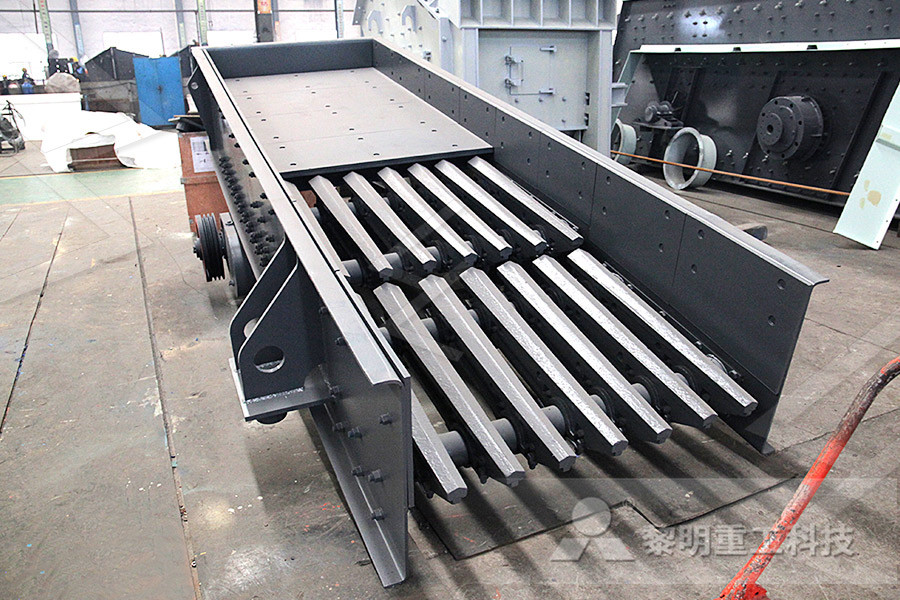

Stationary Crusher

Sand making equipment

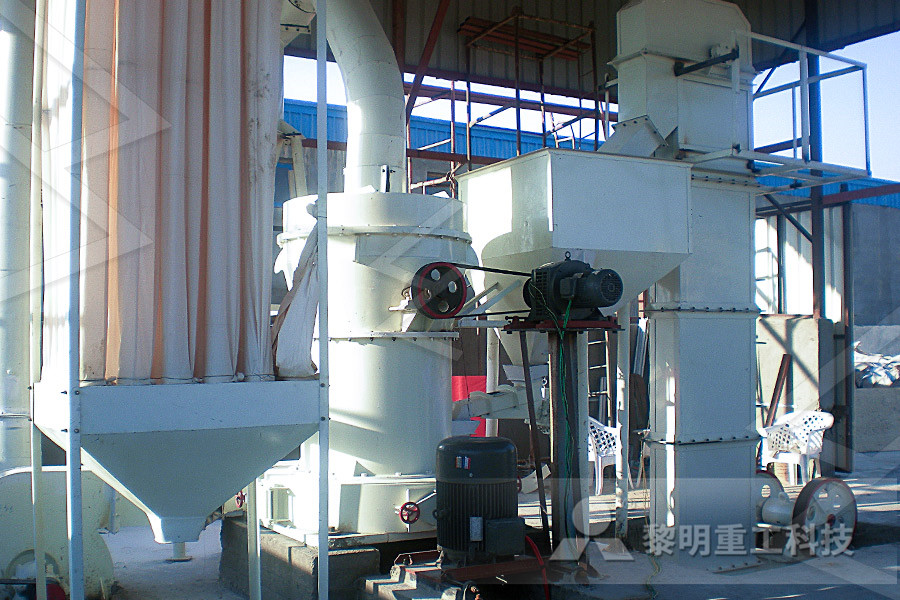

Grinding Mill

Mobile Crusher