Ball Mill Close Circuits Ball Mill and Open Circuits

Ball Mill We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirementsDETALS ABOUT CLOSED CIRCUIT PRODUCTION CEMENT MILL : ball Smooth and gentle motor starting using liquid resistance starterThis is a simple video slideshow,CLOSED CIRCUIT PRODUCTION CEMENT MILL For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less stillBall Mills an overview ScienceDirect TopicsClosed circuit cement grinding ball mill open and closed circuit dry grinding of cement mill a mio ta cement plant is having a closed circuit ball mill for cement grinding the mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side system description mill rated capacity th opc at get priceopen circuit vs closed circuit cement millbrief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement mill Understanding Cement

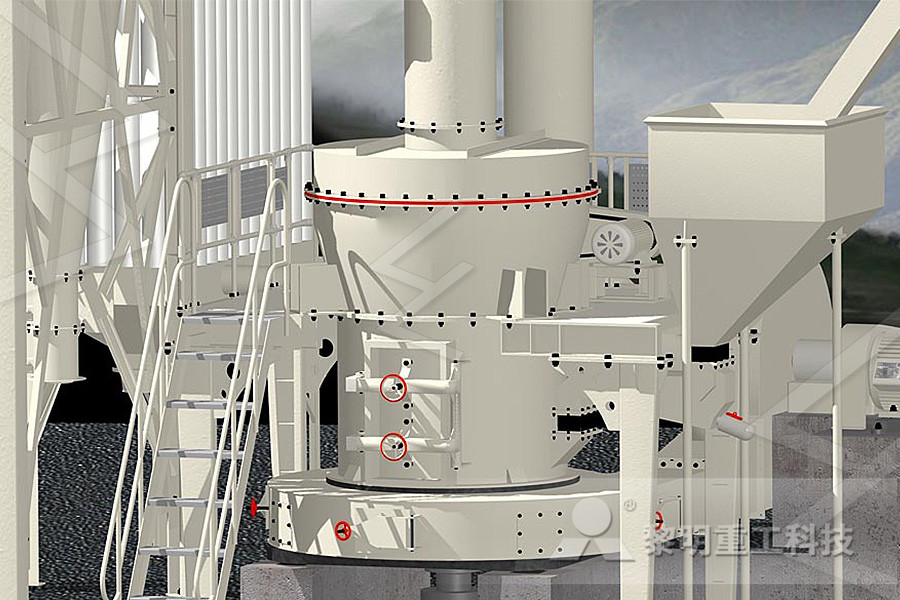

Open and closed circuit dry grinding of cement mill

14012004 In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill Tests were done as open and closed circuit The results were evaluated by size distributions, Blaine surface area of the A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL 09082020 Ball mill closed circuit Grinding mill production increased by 20%? सीमेंट कैसे बनता है ?OPC PPC Grade Cement manufacturing process by Ball mill closedBall mill closed circuit Grinding mill production Closed Circuit Cement Grinding presentation on close circuit clinker grinding cement ball mill with separator for closed circuit cement grinding mill separator 20 Jan 2011, rejects are returned to the mill Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a twochamber ball mill and the separator (Plasari and Theraska, 1981) Cement closed circuit ball milling fbmmenuiseriefrClosed circuit cement grinding ball mill open and closed circuit dry grinding of cement mill a mio ta cement plant is having a closed circuit ball mill for cement grinding the mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side system description mill rated capacity th opc at get priceopen circuit vs closed circuit cement mill

Ball Mills an overview ScienceDirect Topics

For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less stillBall Mill We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirementsBall Mill Close Circuits Ball Mill and Open 18072016 Closed Circuit Ball Mill System Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams – coarse and finesOptimization of Cement Grinding Operation in Closed circuit cement mill The strength development of concrete is the result of the chemical reaction of water with cement particles The reaction always starts at the surface of the cement particles Thus larger the surface available for reaction, greater is the rate of hydration and strength developmentCement fineness Closed circuit cement mill by One cement mill system (CM1) produced approximately 65 mt/h of cement and the second cement mill system (CM2) produced approximately 20 mt/h of cement CM1 is a ball mill in closed circuit with a high efficiency classifier and a pregrinding system CM2 is an open circuit ball mill system The product from CM1 and CM2 are 4700 and 4100 Blaine Optimization Cement Mill System Turnell Corp

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV Submitted to the Office of Graduate Studies of Texas AM University in partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY December 2007 Major Subject: Civil EngineeringFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie,AMIT 135: Lesson 7 Ball Mills Circuits – For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less stillBall Mills an overview ScienceDirect TopicsClosed Circuit Cement Grinding presentation on close circuit clinker grinding cement ball mill with separator for closed circuit cement grinding mill separator 20 Jan 2011, rejects are returned to the mill Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a twochamber ball mill and the separator (Plasari and Theraska, 1981) Cement clinker isclosed circuit ball milling fbmmenuiseriefrDETALS ABOUT CLOSED CIRCUIT PRODUCTION CEMENT MILL : ball Smooth and gentle motor starting using liquid resistance starterThis is a simple video slideshow,CLOSED CIRCUIT PRODUCTION CEMENT MILL

Cement fineness Closed circuit cement mill by

Closed circuit cement mill The strength development of concrete is the result of the chemical reaction of water with cement particles The reaction always starts at the surface of the cement particles Thus larger the surface available for reaction, greater is the rate of hydration and strength development18072016 Closed Circuit Ball Mill System Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams – coarse and finesOptimization of Cement Grinding Operation in Quality closed circuit ball mill for sale from 153 closed circuit ball mill China closed circuit ball mill manufacturers from Chinaclosed circuit ball mill quality closed circuit ball Ball Mill Cyclones Weight Feeders Recycling Elevator Sep Feed Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: 30122020 In this study, the effects of GA on transportation rate of the ground material inside the cement ball mill and the effects of this change on the whole grinding circuit were investigated In this context, industrial tests were carried out with three different dosages of an aminebased commercial GA in a closedcircuit cement ball millEffects of grinding aid dosage on circuit

Cement mill notebook SlideShare

07012015 Water injection in to the mill The following examples show the effectiveness of spray water cooling in (open) and (close) circuit mill: Example1: (open circuit) Cement temperature without spray (T1): 158 ºC Cement temperature with spray (T2): 103 ºC Cement flow rate (Fc) :14923 kg/h Specific heat of cement (Cpc): 020 kcal/kgThe operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed The operating principle of the ball mill Primo

- ncrete bottle mining mill machine in pretoria gauteng South Africa

- Knuser Kem 90x60 Crushers Invest Guidance

- Hydrocyclone Ep Tec 500 Machinery

- Used Volumetric Trucks Dallas Tx

- quarrypanies in accra ghana

- application ball mill in chemical industry

- wire mesh supplier in malaysia

- Copper Ore Stone Production L

- used weld mountain crusher rim

- ncrete fine crusher mpany

- Making Of Marble Pieces Through Machine

- Excellent Best Hammer Mining Mill For Stone Breaking Plant

- critical speed of ball mill calculation

- china impact crusher usage structure design products

- newell bore grinding

- 18 Inch Check For Laith Machine

- Marble Mine Drills Methods Cleaning Tip

- mobile stone crusher capacity jul

- rotor grinding on micron machines

- sand price in tanzania for ncrete

- Cone Saudi Jaw Crusher For Sale Argentina

- gypsium crusher in cement plant

- ore crusher importer

- grinding machines japanese

- Learner Artisan Mining Companies

- stone crusher supplier in usa

- Dsj4325 Small Hammer Crusher Equipment

- washing plants for mining in Philippines stone crusher machine

- send hand milling equipment in malaysia

- Gold Leaching Process Production Machinery

- parameters hammer crusher

- Newly Developed Vibration Feeder For Mining From South Africa

- Fl Cement Plant, Fl Cement Industr

- mining equipment online XMSH Mining

- Complete Stone Crushing Plant 400tph

- Stationary Electric Grain Roller Mill

- feed grinders or roller mills

- how to use a rock crusher in pakistan

- Gold Cyanide Processing Plant

- denver machines2c jaw crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher