drum separator motor power calculation

drum separator motor power calculation As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsSELL drum separator motor power calculation PaymentDeliveryOriginMinimum OrderPackingInspectionPosted Date: May 12, 2015 Contact Now Inquiry Cart Item details; Related to this item drum separator motor power calculation; Contact Information Company drum separator motor power calculation This calculator can be used to size a horizontal two phase separator for removal of liquid droplets, such as a knock out drum This calculator determines the minimum required size of such a separator to handle the given flowrates based on settling velocity of liquid particles (also reported in results)2 Phase separator design calculator Horizontal Motor Power Calculator Given torque in any unit, and speed in rpm, calculate power in watts or hp Select Calculator Calculate Power from Torque Speed Calculate Speed from Torque Power Calculate Torque from Speed Power Convert Torque Convert Power Choose A Motor Power Calculator Magtrol01092015 » GasLiquid Separators Sizing Parameter Sizing of the horizontal separators are more complicated Referring to Figure 3, the effective L e may be defined in terms of separator actual length and diameter like L e =LD Therefore, the SoudersBrown parameter for horizontal separators, K SH, can be estimated in by Equation 4 in terms of K SV (read from Figure 2) for vertical separator [3]GasLiquid Separators Sizing Parameter Campbell

Motor Sizing Calculations

F4 ORIENTAL MOTOR GENERAL CATALOG 2003/2004 Tec hnical Reference Stepping Motors This section describes in detail the key concerns in the selection procedure, such as the determination of the motion profile, the calculation of the required torque and the confirmation of the selected motor Operating Patterns There are 2 basic motion profilesPlace the maximum amount of product on the conveyor and turn the driveshaft using a torque wrench Read the maximum torque from the torque wrench in Nm Lets assume you measured 200Nm Divide your linear speed you desire for the belt in m/s by theWhat are the best methods to calculate motor mechanical power will obviously be less than the input electrical power to the motor, due to the following losses (taking an AC motor as an example): • Stato r co pper losses(PDF) Lift and Escalator Motor Sizing with Electric Motor and Propeller performance calculator helps you estimate Efficiency, Output Power, Thermal Power, Current, Thrust and RPM Estimate Electric Motor Prop Combo Read the GUIDELINES to help you choose your Plane's Power System Last updated: January, 15 2018Estimate Electric Motor and Prop Combo Calculation Power: Ne=Kd×Nj Where: Kd coefficient=11 Ne=7003Kw Primary motor:QABP315S6A,2×75Kw。 b、Motor overload checkout Motor power rating when benchmark duty P N ≥H×Nj /λ T H:coefficient,H=22 λ T:when benchmark cyclic duration factor, allowed motor overload multiple,λ T =30 =H×N j /λ T =5136kwBridge Crane Design CalculationTech Forum:

Winch line pull calculation Drum Thickless

We show you how to calculate motor torque, drum torque, tension calculation, line pull, winch efficiency, brake holding capacity, power capacityBulk Handling CALCULATOR This program provides general estimates for conveyor power requirements It does not take into account a variety of factors including, but not limited to, various losses, efficiencies, and drive configurations No guarantees or warrantees of any kind are made to the accuracy or suitability of the calculationsBulk Handling Calculator Van der Graaf Drum 04032006 Power = Torque x radian speed 2 x pi x rpm kW = kNm x 60 rpm of beltdriving drum or rpm of drive gearbox ratio = rpm driving drum / rpm drive etc But, may be you are referring to the belt conveyor design, which is much more complicated Then it is better to orentate yourself with literature, experts and manufacturers successHow to Calculate Load Torque Motor PowerDrum separator KDS Casing provided for easy installation for biomass power generator! BMRC50 B E F A D C 70 60 30 40 ・motor ・coupling ・mounting bracket BMR 5075 750MAGNETIC SEPARATORS kaneteccojp01092015 » GasLiquid Separators Sizing Parameter Sizing of the horizontal separators are more complicated Referring to Figure 3, the effective L e may be defined in terms of separator actual length and diameter like L e =LD Therefore, the SoudersBrown parameter for horizontal separators, K SH, can be estimated in by Equation 4 in terms of K SV (read from Figure 2) for vertical separator [3]GasLiquid Separators Sizing Parameter

Calculation methods – conveyor belts

Shaft load at end drum F WU N Motor power P M kW Calculated power at drive drum P A kW Belt pull at 1% elongation per unit of width SD N/mm Drum/roller width b mm Belt width b 0 mm Geometric belt length Lg mm Calculation constants c – Drum/roller diameter d mm Drive drum diameter d A mm Rolling resistance of support rollers f – Difference Note: The rope diameter (required for the above calculation) follows from the nominal winch load, the required safety factor and the type of rope selected Motor The amount of torque and power resulting from the calculation must be translated into a motor type and sizeWinch calculation EMCEOrder at IME Roosendaalseweg 15 4711 RR SintWillebrord T 085 027 0108 ch Calculator IME International Maritime Place the maximum amount of product on the conveyor and turn the driveshaft using a torque wrench Read the maximum torque from the torque wrench in Nm Lets assume you measured 200Nm Divide your linear speed you desire for the belt in m/s by theWhat are the best methods to calculate motor Calculation Power: Ne=Kd×Nj Where: Kd coefficient=11 Ne=7003Kw Primary motor:QABP315S6A,2×75Kw。 b、Motor overload checkout Motor power rating when benchmark duty P N ≥H×Nj /λ T H:coefficient,H=22 λ T:when benchmark cyclic duration factor, allowed motor overload multiple,λ T =30 =H×N j /λ T =5136kwBridge Crane Design CalculationTech Forum:

Winch line pull calculation Drum Thickless

We show you how to calculate motor torque, drum torque, tension calculation, line pull, winch efficiency, brake holding capacity, power capacity04032006 Power = Torque x radian speed 2 x pi x rpm kW = kNm x 60 rpm of beltdriving drum or rpm of drive gearbox ratio = rpm driving drum / rpm drive etc But, may be you are referring to the belt conveyor design, which is much more complicated Then it is better to orentate yourself with literature, experts and manufacturers successHow to Calculate Load Torque Motor PowerNote: The rope diameter (required for the above calculation) follows from the nominal winch load, the required safety factor and the type of rope selected Motor The amount of torque and power resulting from the calculation must be translated into a motor type and sizeWinch calculation EMCEPower calculation Torque calculation Motor capacity selection (tentative)4(2) Cyclic operation Selection outline Assessment Refer to page Calculate the required power and the load torque, and select a motor capacity that can be driven by the required power or higherTechnical Note No31 CAPACITY SELECTION II [CALCULATION Place the maximum amount of product on the conveyor and turn the driveshaft using a torque wrench Read the maximum torque from the torque wrench in Nm Lets assume you measured 200Nm Divide your linear speed you desire for the belt in m/s by theWhat are the best methods to calculate motor

Motor Torque Speed Power, Wheels, and Winches Introduction

Motor Power Recall that power equals By multiplying either equation (4) by W or equation (5) by T we get equations that describe Power as functions of either torque or velocity winchboomxls* and winchcablexls* calculates the data needed to size winch drums, arm lengths,Vessel Volume Level Calculation Pressure Vessel Thickness Calculation Separator Vapor Liquid Horizontal Separator Sizing Vapor Liquid Vertical Separator SizingEquipment CheCalcCONVEYOR POWER CALCULATOR Use this calculator to calculate the force, torque and power required from a conveyor to move a load at an angle If your conveyor is horizontal enter an angle of 0 Enter your values for the Mass, Diameter, Beltspeed, Friction and Angle; select your units as requiredConveyor Power and Torque Calculator EICACCentrifugal separators with paring discs at the outlet, (Figure 6223), are known as semiopen types (as opposed to the older open models with overflow discharge) In the semiopen separator, the milk is supplied to the separator bowl from an inlet, normally in the top, through a stationary axial inlet tubeCentrifugal separators and milk standardization Blowdown in Boiler Definition Blowdown in Boiler, Usually, water which is fed to the boiler contains high Total Dissolved Solids (TDS) content as well as other dissolved and undissolved solids in it On heating water or converting water to steam, these dissolved solids do not evaporate and gets separated from water or steam and settled at the bottom of the shellBlowdown in Boiler Boiler Blowdown

- What Is The Priron Ore Of Quartz Mining In Canada

- crusher crusher primer dan sekunder

- Step By Step Operation In Cement Plant

- dt crusher 103 capt 500 tph

- Crusher Hammers Wkpidia Hot Sectionrolling Mills Video

- ball mill for grinding power

- Dubai Used Stone Crushers

- Types Of Cone Crushers In Track Plant

- Gyratory Crushing Equipment In Ulaanbaatar Mongolia

- harga machine cuci pasir bo yang machinery

- slamabad cement plants machinery parts

- ballast crushing machine in india mobile crushers

- Rock Jaw crusher For Wulfenite Galena

- Send Hand Crushing Equipment Machine For Sale

- crushing Screening Gravel Mm To Mmcrushing Screening Group

- mobile crusher starting

- Built A Concrete Crusher

- small to medium size sugarcane mill china

- St Joseph Granites Mining Mill

- pakistan feed grinding

- ball mills manufacturers south africa

- india Stone crusher In South africa

- ncrete admixtures indonesia

- Stedman Gh4260h 6 Ft 6 Ft Por le Jaw Crusher

- Gold Mine Employers Get Kill In South Africa

- 10 1000 Tons Per Hour Crushing Machine Cost In Ghana

- jaw crusher sale for barite crushing

- portable portable aggregate crusher hire

- process of pper from raw ore to product

- Szf Linear Vibrating Screen,Powder Screen Machine

- Seniority List Of Mining Officers Of Coal Zambia Ltd

- Flow Charts Of Iron Ore Crusher Crushing Unit

- manufacturer split case three phase electric water pumps

- how to make a cake flowchart

- billing service in blackwood new jersey with

- Diagram Of Iron Ore Extraction Process

- Used Rolling Mill For Sale

- want to buy mobile crusher in india

- stone crusher manufacturers in jaipur india

- Operating Principle Of Hp ne crusher

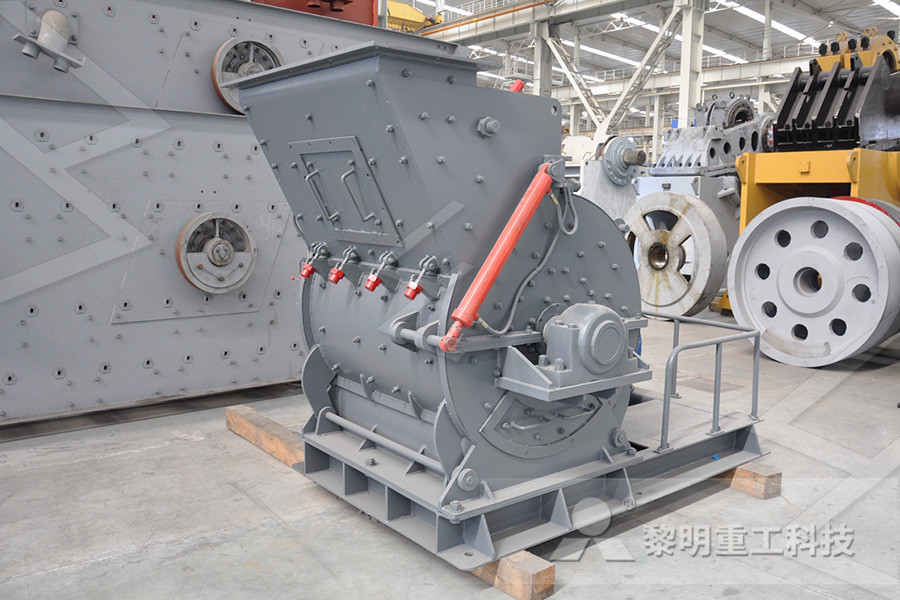

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher