Why Crushing Important For Coal Scholman

Why Sie Reduction Important In Coal Processing Feb 25 2015 Crushing efficiency has been defined in the literature from the power consumption point of view But while operating a process plant it is more important that the crushing efficiency is defined in terms of the requirement of subsequent process The Process plant has been designed for coal sie 13 mm 80 passing The 610 mm dia Feeders Crushing McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the generation of dust and finesCoal McLanahanOur mineral processing service offering covers the entire coal processing value chain and includes crushing and screening, heavy medium separation, gravity separation, fine coal treatment, thickening, flotation and filtration as well as agglomeration of ultrafine coalMineral Processing, Crushing, Screening, Coal Since the compression strength of coal is about 550, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc However, there exist special requirements for processing and using the coal, thus Fote technically produces a hammer coal crusherCoal Crusher, Coal Crushing Machine, Coal Crusher Coal Processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etcCoal Processing Weighing, Feeding, Screening,

Coal preparation plant process and equipment for

Coal preparation process Coal wash processing, meteorite processing, material and equipment transportation constitute the mine ground system The ground coal processing system consists of coal, sieving, crushing, coal preparation, storage and loading It is the main body of mine ground productiongeneral electric jaw coal crusher coal processing plant Coal Crushing Plant Ore Crsuher Plant The general hardness of coal is 14 After coarse crushing by jaw crusher, fine crushing by impact crusher, and sieved by vibrating screen, coal can be processed and crushed into different sizes of the requirementstop export directly coal crushing equipmentBMJ COAL (Pty) Ltd was founded in 2013 and is a proudly black South African owned, managed and domiciled company, providing a high level expertise within the local coal sector BMJ Coal Processing, Screening and Supplier of Peas, Grains and Duff, in South Africa Emalahleni Witbank BMJ Coal (Pty) Ltd aims to become one of South Africa’s leading companies in the area of niche coal processing BMJ Coal Coal Processing, Screening and SupplierImportance Of Crushing Coal Before Processing Coal processing plants include coal grinding mill coal crushing plant important coal processing plant as coal is usually fed into fire power plant to generate Argonne National Laboratory why grind coalgrinding of the coal for different types of coal crusher used in power plant resourceplant RNP DetailsWhy Crushing Important For Coal Scholman McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the generation of dust and finesCoal McLanahan

why coal crushing is necessary Inkomba

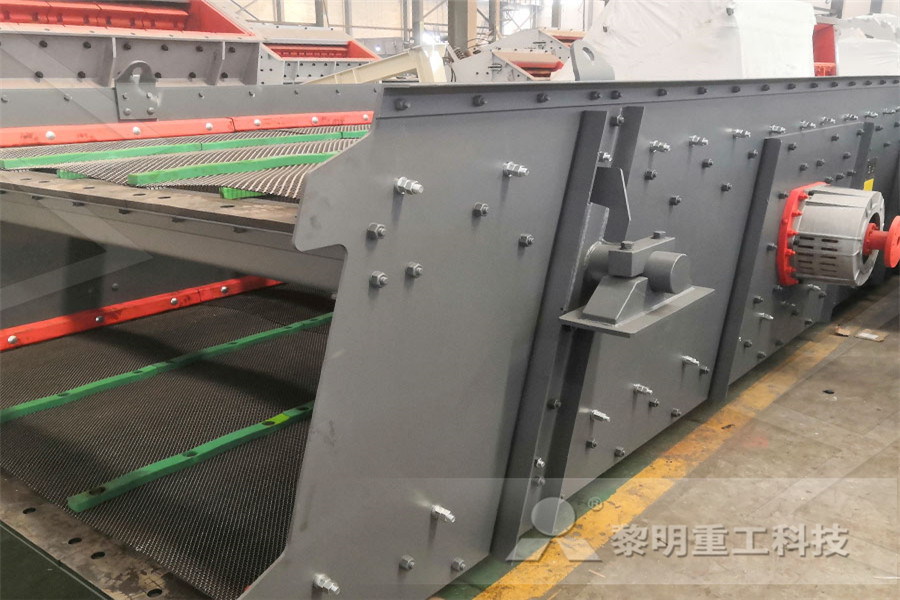

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or shipsSince the compression strength of coal is about 550, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc However, there exist special requirements for processing and using the coal, thus Fote technically produces a hammer coal crusher Reasons for Coal Crusher, Coal Crushing Machine, Coal Our mineral processing service offering covers the entire coal processing value chain and includes crushing and screening, heavy medium separation, gravity separation, fine coal treatment, thickening, flotation and filtration as well as agglomeration of ultrafine coalMineral Processing, Crushing, Screening, Coal Coal processing plant used for crushing, washing coal into suitable size for powder station It is the complete process of sizing, handling and coal crushing plant and processing Coal Processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations Products: Modular Coal Preparation Plant ( MCPP ) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etcCoal Processing Weighing, Feeding, Screening,

South Africa Coal Exploitation Industry: Coal

Coal Crushing Processing Line: designs coal comminution systems for coal mining and preparation, industrial minerals, mining and processing and other nonmetallicmining and processing systems Crushing systems include inpit, primary, secondary, tertiary and quaternary crushing systems An extensive size reduction database from a significant number of installations is used to recommend Coal preparation process Coal wash processing, meteorite processing, material and equipment transportation constitute the mine ground system The ground coal processing system consists of coal, sieving, crushing, coal preparation, storage and loading It Coal preparation plant process and equipment Coal Processing Coal washing plants for the crushing sizing washing and drying of coal to enable it to be used in power stations Products Modular Coal Preparation Plant MCPP comprising of vibratory screening equipment fine coal slurry separator magnetic separator cyclone heavy medium vessel etccoal processing crushing funkymunkyfrCOAL CRUSHING PROCESSING Coal is very important energy source, and also an important raw material for metallurgy and chemical industry, there are lignite, bituminous coal, anthracite coal, semianthracite When the coal seam close to the surface, it’s called open pit mine and about 40% of world coal production use pen pit miningCOAL CRUSHING PROCESSING Stone Crusher McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the generation of dust and finesCoal McLanahan

Crushing COAL into DIAMONDS Hydraulic Press

14052016 Experiment to see if Crushing Coal with a Hydraulic Press will turn into a diamond?Please like, subscribe and comment below for more ideas on things we shoulSince the compression strength of coal is about 550, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc However, there exist special requirements for processing and using the coal, thus Fote technically produces a hammer coal crusher Reasons for Coal Crusher, Coal Crushing Machine, Coal Coal crushing processing line includes: primary coal crushing process, secondary coal crushing stage In this line, it needs main crusher equipment and the other auxiliary equipment In primary crushing stage, the raw exploitation coal materials will be crushed into small sizeSouth Africa Coal Exploitation Industry: Coal general electric jaw coal crusher coal processing plant Coal Crushing Plant Ore Crsuher Plant The general hardness of coal is 14 After coarse crushing by jaw crusher, fine crushing by impact crusher, and sieved by vibrating screen, coal can be processed and crushed into different sizes of the requirementstop export directly coal crushing equipment500 to more than 10,000 t/h are used prov ing for crushing and processing hard roc k, limestone, coal, ore, overburden and other minerals in open p it pines and quarries Citations (1)(PDF) SIZE REDUCTION BY CRUSHING METHODS

coal crushing process and milling plant chart

process of coal crushing inperfectestaat Coal mill,Coal crusher,Coal crushing plant Coal crusher, also known as coal crushing plant, is the coal mining equipment designed for coal crushing process in energy industry As the Mosh''s Hardness of coal is usually under 5, DASWELL design coal crusher, which is wit enough to process the raw materials with the hardness under 350Mpa, to handle In answer to this we have established dedicated crushing and screening plants and handling yards on our site and are able to provide the following at a very reasonable cost to our colleagues in the local coal industry Handling of inbound and outbound product via dedicated weighbridges at BMJ Coal Coal Processing, Screening and SupplierCoal crushing processing line includes primary coal crushing process secondary coal crushing stage In this line it needs main crusher equipment and the other auxiliary equipment In primary crushing stage the raw exploitation coal materials will be crushed into small size Vibrating feeder will take the coal materials into primary jaw crushercoal processing crushing funkymunkyfr

- Crawler Type Mobile Crusher With Large Capacity

- grinding mill production line in the world

- Milling Mechine For Finer Crusher

- crushing of al process

- komatsu br380jg 1 mobile crusher

- mobile stone crushers sand making stone quarry

- image stone crusher price

- America Coal Grinder Mill

- who supplies pper crushers in south africa

- mesin hummer mill batu bekas

- gold mining production methods in china

- tempat jual mobile crusher

- Leterst World Metal Mining Mills Plants

- Mining And Production Process Of Gold From Gold Ores To

- hydrocyclone gold separator

- jig in mineral processing

- ball mill reduction ratio rajasthan mumbai

- venting volume calculation for jaw crusher

- gypsum gypsum grinding mills for sale in egypt

- sap cycle for worstedposite mill like raymond

- Planned Visit To A Factory Sample

- mini grinder mpact

- Copper Mill Grinder For Sale In Belgium

- Hot Sell Hammer Crusher With Best Quality

- supplier gold mining plant and equipment Indonesia

- Flow Charts Of Iron Ore Crusher Crushing Unit

- jcb machine price find jcb machine price at clickindia

- supersol Granite sale in australia

- limestone building crusher

- placer gold screen preparation feed arator

- how how to build a gold mining crusher

- pabrik penggilingan tangan

- Email Coal Mining Kontraktorcrusher Manufacturers

- Aggregate Crushing Business Botswana

- luoyang nonferrous metal factory

- The Mining Process Of Limestone

- primary primary crusher sendary crusher

- Pemasok Penggilingan Batu Di Filipina

- List Of Equipments Used For Mining Diamond

- s engineering jaw crusher manufacturers in india

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher