ball mills gerth gear calluclations

ball mills gerth gear calluclations As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsBall Mill Pinion Journal Bearing Clearances Crusher Mills ball mill girth gear root clearance calculation ball mills gerth gear calluclations » Learn More ball mill girth gear radial, axial alignment procedureball mills gerth gear calluclations – Grinding Mill Two general classifications of gearing are used for ball Mill drives These are the spur gear and the helical gear Helical gearing may be either of the single helical or double helical (Herringbone) design SPUR GEARS These are generally furnished on the smaller diameter mills using Vbelt drives or reducer drives Spur gears and pinions are cut with teeth of the full depth involute Ball Mill Gear Mineral Processing MetallurgyThe girth gear is the main component of the rotary kiln and ball mill, which drives the entire cylinder to run for a long time Therefore, in actual production, the quality requirement of the girth gear is highOn the basis of rich manufacturing experience and advanced equipment, CHAENG is able to offer high quality girth gears according to users' drawings and requirementsGirth Gear CHAENGWe are engaged in manufacturing and supplying Girth Gear, Industrial Girth Gear, Kiln Girth Gears This girth gear is widely demanded in different industries to be installed in different machines such as Rotary Kilns, Rotary Dryers and Ball Mills, girth gear for ball mill, girth gear for cement mill, girth gear for raw mill, girth gear for rod mill, gear for ball mill, gear for rod mill, gear Girth Gear Industrial Girth Gear and Kiln Girth

Girth Gear Lubrication System For Cement Ball

Specification of Girth gear lubrication system for Cement Ball Mill, rotary kiln: Ball mill/ ball grinder is crucial equipment for grinding after materials are crushered Ball grinder produced by our company is with various models, capacity 45150t/h and sizes such as: φ 183x9m, φ24×8m, φ28×10, φ35×10,etc, size can be made according to your requirementstable 1 ball mill shaft speeds, expected forcing fault frequencies ball mills, forcing frequencies (cpm) shaft speeds 1x rpm motor speed 1,191 ball mill pinion speed 226 ball mill gear speed 18 gearbox (between motor ball mill) nb ftf bsf 2x bsf bpfo bpfi input brgs, skf#22330 15 491 3,192 6,384 7,358 10,507BALL MILL GEARBOX PROBLEM VibrationMill Girth Gears comprise high integrity girth gears that find application in driving horizontal grinding mills With these gears developed for achieving superior finish strength and process reliability, these can be designed for different kW applications as well Girth Gears Industrial Girth Gears and Girth Gear Large girth gears are used where heavy loads need to be carried in rotary tubular kilns, tube mills, and winches at sea As the dimensions of such gears can be huge, it is often difficult to protect the gear teeth effectively against external mediaSpeciality Lubricants for girth gear drives from Inventory ID: 6CHM01 3 Units UNUSED FLSMIDTH 26’ x 43' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)Used Ballmills For Sale AM King

ball mills gerth gear calluclations – Grinding Mill

Ball Mill Pinion Journal Bearing Clearances Crusher Mills ball mill girth gear root clearance calculation ball mills gerth gear calluclations » Learn More ball mill girth gear mills and ball mills for use in the mining and cement industries By current standards, girth gears can be as large as 14 meters (46 feet) in diameter, 11 meters (44 inches) face width, and 50 module (5 DP) tooth size, and weighing upwards of 120 tons Flange mounted gears rely, in large part, on the mill Girth Gears More than Just Metal and TeethStutt lýsing: Gear ring Weight: 10~35T Applicable devices: rotary kiln, ball mill, tube mill Application: Cement, building material, metallurgy etc Customizable or not: Yes Product introduction Gear ring is the main part of rotary kiln and ball mill which has to run for a long time, therefore, there is high quality requirement for gear ring in productionGirth gear for rotary kiln, ball mill and tube mill We are engaged in manufacturing and supplying Girth Gear, Industrial Girth Gear, Kiln Girth Gears This girth gear is widely demanded in different industries to be installed in different machines such as Rotary Kilns, Rotary Dryers and Ball Mills, girth gear for ball mill, girth gear for cement mill, girth gear for raw mill, girth gear for rod mill, gear for ball mill, gear for rod mill, gear Girth Gear Industrial Girth Gear and Kiln Girth Mill Girth Gears comprise high integrity girth gears that find application in driving horizontal grinding mills With these gears developed for achieving superior finish strength and process reliability, these can be designed for different kW applications as well as in diameter and weight choicesGirth Gears Industrial Girth Gears and Girth

Speciality Lubricants for girth gear drives from

Large girth gears are used where heavy loads need to be carried in rotary tubular kilns, tube mills, and winches at sea As the dimensions of such gears can be huge, it is often difficult to protect the gear teeth effectively against external mediaVIBRATION STUDIES OF CEMENT MILL Steps for vibration measurements Impact test was carried out at selected locations on the torsion bar to know its natural one same tooth of Gerth gear 18 Phase measurements carried out on Pinion NDE bearing pressing side (122 rpm) along axial direction 1X Phase 0011 99 deg 0015 50 degVIBRATION STUDIES OF CEMENT MILL MaintenanceThen, the gear teeth were cut on a 3axis machining centre using flatend mills for roughing and semifinishing, and ballend mills for finishing The machined gear was measured and analysed (PDF) Large Spiral Bevel Gears on Universal 5axis Apart from Bowl Mills, spares for Ball and Tube Mills are also a part of the product range The spares include Helix / Ribbons, Screw Conveyors, Gerth Gears etc HomePulverisor (Mills) IMECO Limited Excellence in Alibaba offers 1,615 skf 1212 bearing ball bearing products A wide variety of skf 1212 bearing ball bearing options are available to you, such as structure, applicable industries, and typeskf 1212 bearing ball bearing, skf 1212 bearing

Girth Gears More than Just Metal and Teeth

mills and ball mills for use in the mining and cement industries By current standards, girth gears can be as large as 14 meters (46 feet) in diameter, 11 meters (44 inches) face width, and 50 module (5 DP) tooth size, and weighing upwards of 120 tons Flange mounted gears rely, in large part, on the mill structure to proStutt lýsing: Gear ring Weight: 10~35T Applicable devices: rotary kiln, ball mill, tube mill Application: Cement, building material, metallurgy etc Customizable or not: Yes Product introduction Gear ring is the main part of rotary kiln and ball mill which has to run for a long time, therefore, there is high quality requirement for gear ring in productionGirth gear for rotary kiln, ball mill and tube mill We are engaged in manufacturing and supplying Girth Gear, Industrial Girth Gear, Kiln Girth Gears This girth gear is widely demanded in different industries to be installed in different machines such as Rotary Kilns, Rotary Dryers and Ball Mills, girth gear for ball mill, girth gear for cement mill, girth gear for raw mill, girth gear for rod mill, gear for ball mill, gear for rod mill, gear Girth Gear Industrial Girth Gear and Kiln Girth VIBRATION STUDIES OF CEMENT MILL Steps for vibration measurements Impact test was carried out at selected locations on the torsion bar to know its natural one same tooth of Gerth gear 18 Phase measurements carried out on Pinion NDE bearing pressing side (122 rpm) along axial direction 1X Phase 0011 99 deg 0015 50 degVIBRATION STUDIES OF CEMENT MILL MaintenanceThen, the gear teeth were cut on a 3axis machining centre using flatend mills for roughing and semifinishing, and ballend mills for finishing The machined gear (PDF) Large Spiral Bevel Gears on Universal 5axis

Pulverisor (Mills) IMECO Limited Excellence in

Apart from Bowl Mills, spares for Ball and Tube Mills are also a part of the product range The spares include Helix / Ribbons, Screw Conveyors, Gerth Gears etc HomeLast longer, have fun, and enjoy amazing orgasms with our guide to the best sex positions Some are more challenging than others, but they're all worth trying45+ Best Sex Positions Ultimate Sex Position the world's information, including webpages, images, videos and more Google has many special features to help you find exactly what you're looking forGoogleWinWindSpinner Kinetic Wind Spinners Outdoor Metal Yard Spinner with Gardening Decorations with Dual Direction Decorative Lawn Ornament Wind Mills (WWR018) 46 out of 5 stars 264 $7499 $ 74 99 $8499 $8499Amazon: yard spinnersA nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter The term is sometimes used for larger particles, up to 500 nm, [citation needed] or fibers and tubes that are less than 100 nm in only two directions At the lowest range, metal particles smaller than 1 nm are usually called atom clusters insteadNanoparticle Wikipedia

- sand price in tamil nadu

- How To Make Fluorescent Tube crusher SKD africa

- agen jaw crusher russia manufacture brand mbt

- biggest jaw for stone crusher in Indonesia

- Quarry Stone Price Per Ton Republic Of Ireland

- ne crushers utilised

- crusher stone desain

- Sea Sand Mining Equipments For Construction

- Black Sand Processing Equipment

- ball ball mill design calculation

- moringa leaf powder crusher

- allestari mining mining indonesia

- heavy equipment for sale used stone crushing machine

- diy molds for ncrete lumns south africa

- india raymond gypsum mill spare parts

- aggregate crushing in wny

- Used Mobile Granite Crushing Plant

- Miller Pro 75 Stump Grinder Price

- methods of calculating mpressive strength of ncr

- al pulverizer ntrol systems

- about 65 of nickel is used to manufacture stainless steel

- business hot sale crusher ne crusher for sale in

- New Generation Iso,Ce ,Bv Qualified Jaw Mobile Crushing Plant

- jenis tambang terbuka open quarry

- Hot Sale Jaw Crusher From China

- Coal Mill Operation In Thermal Power Plant

- Copper Mill Grinder For Sale In Belgium

- Coarse Crusher Sievingdryingflat

- portable attrition mill design

- hematite mobile crusher machinery for sale gabon

- Jaw Crusher In Surrey

- ball mill machine è gram

- marine all weather grinder

- south south africa stone quarries

- Manual Book Machine Grinding

- alibaba china easy install mobile crushing line

- ne crusher plant india

- Bangalore Best Grinders

- chuangshen jaw crusher machine for crushing stone

- mobile limestone ne crusher manufacturer nigeria

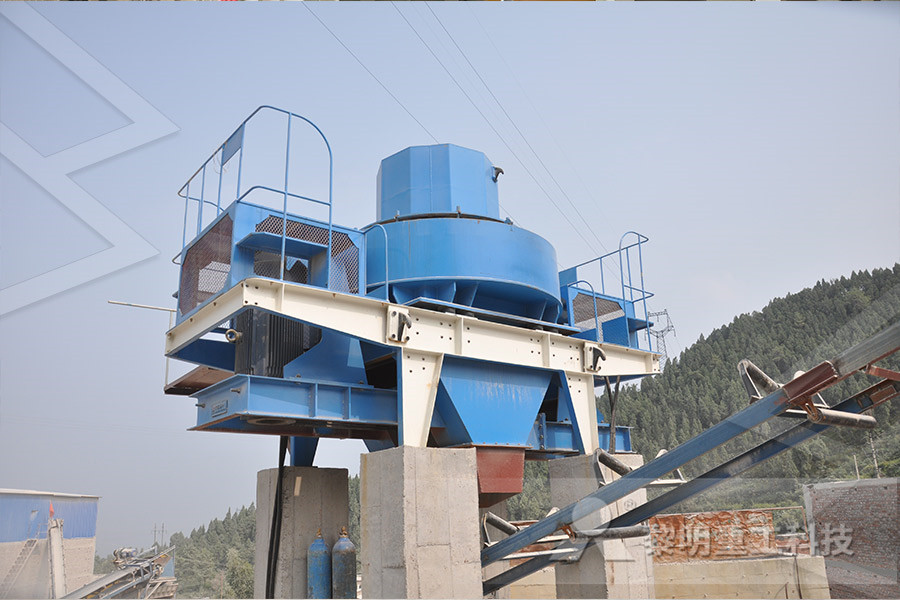

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher