coal mills in a thermal plant vablnl

Coal mill pulverizer in thermal power plants Nov 17, 2012 coal mill/pulverizer in thermal power plants shivaji choudhury 2 1 troduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form Get Price; COAL BASED THERMAL POWER PLANTS Thermal power plantInside the coal mill in thermal power plant YouTubeItaly Spain: Enel’s Commitment to a Coal Phaseout These limits will be the new reference for permitting large thermal power plants in Europe build another coal plant, and that it will be carbon neutral by 2050 However, behind these bold aims, Europe’s CoalFired Power Plants: Rough Times AheadVENTURI OUTLET The outlet venturi is located at the top of the mill just below the mill discharge valves The venturi distributes the pulverized coal into the fuel lines as the coal exits the mill The new design outlet venturi distributes the coal and air mixture more evenly and with less turbulence to the fuel outletsCoal Mills in thermal power plant Mill (Grinding GRINDING PROCESS OF MILLS Coal are fed from Raw coal feeder ( situated just above the mill on concrete floor) One end of the Raw coal feeder is attached with Coal bunker through a coal gate Raw coal feeder is having a travelling belt with coal weighing instruments Coal from travelling belt of raw coal feeder dropsABC OF THERMAL POWER PLANT: MILLS IN A

Coal mill pulverizer in thermal power plants

17112012 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner panelsRaw coal from the raw coal bunker is supplied to the Coal Mills by a Raw Coal Feeder so that coal will undergo complete combustion during combustion process Get Price Hazelwood Thermal Power Plant 8x200 MWe The Journal of coal mill operation in thermal power plant09012016 Pulverizer or inother name Mill used for pulverized coal boiler of thermal power plant The device pulverize coal to powder (pulverized coal) before blowing Pulverizer Mill of pulverized coal boiler in thermal Italy Spain: Enel’s Commitment to a Coal Phaseout These limits will be the new reference for permitting large thermal power plants in Europe build another coal plant, and that it will be carbon neutral by 2050 However, behind these bold aims, Europe’s CoalFired Power Plants: Rough Times AheadCoal from travelling belt of raw coal feeder drops in central feed pipe ( connection between Raw Coal Feeder and Mill) After coal reaches Mill bowl grinding started and hot air also been given to make the pulverised fuel dried enough to classifier chamber The portion of the coal which cannot be grinded finds its way to mill rejectABC OF THERMAL POWER PLANT: MILLS IN A

Coal Mills In Thermal Power Plant

Minhang Power Plant, Shanghai Electric Power Co, Ltd99 Мб 2 For coal mills A and C that operated under a 100 MW load, the measured boiler efficiency improved by 044% when the combustion optimization system was put into service; thetested parameters according to the emission standard of all pollutants for thermal power plants GB132232003COAL BASED THERMAL POWER PLANTS index indicates the coal is easier to grind 50 HGI normally is taken for calculating the base capacity of the mill When coal with HGI higher than 50 is fed to the pulverizer, the output will be higher than base capacity, and below 50 HGI, COAL BASED THERMAL POWER PLANTS: COAL Coal mill is one of the most important auxiliary devices in the coal fired power plants, which has two main roles: 1) grind crushed coal lumps with several cm diameters to very fine powder in the (PDF) Thermal Power Plant Simulation and ControlTypes of thermal energy Almost all coalfired power stations, petroleum, nuclear, geothermal, solar thermal electric, and waste incineration plants, as well as all natural gas power stations are thermal Natural gas is frequently burned in gas turbines as well as boilersThe waste heat from a gas turbine, in the form of hot exhaust gas, can be used to raise steam by passing this gas through a Thermal power station WikipediaNormally low speed ball mills or medium speed vertical spindle mills are employed in thermal power plant for this purpose The milling system is an important part of the auxiliary equipment of a coalfired power plant Pulveriser mill are one of the critical equipment of coal fired thermal power plantInternational Journal for Research in Engineering

Pulverizer Wikipedia

Beater wheel mills are designed to prepare a coal powder airfuel mixture for combustion in furnace chambers of coalfreed power plants by coal drying, pulverizing, classifying and transport Their multipurpose function usually results in operation instability accompanied by unacceptable vibrationThermalbased power plants can produce electricity from coal or other fuel sources The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption Coal fired power plants, while producing power, require a lot of water and produce a lot of pollutants like ash and CO2How Does a Coal Power Plant Work? Bright Hub Coal Mills in thermal power plant bowl mill Mills Presentation Coal Mill Coal Mills Ray Bowl Mill Mill Performance Pulverizer Operation Performance and Testing Pulverizers 101 Part I Coal Pulveriser Coal Pulverized MILL OPTIMIZATION Effect of Fast Cut Back (Fcb) in a Typical Coal Fired,Mill Reject Coal Mechanical Engineering01012011 Proceedings of the 18th World Congress The International Federation of Automatic Control Milano (Italy) August 28 September 2, 2011 Improved coal grinding and fuel flow control in thermal power plants Piotr Niemczyk Jan D Bendtsen Department of Electronic Systems, Aalborg University, Fr Bajers Vej 7C, 9220 Aalborg Øst, Denmark (email: Improved coal grinding and fuel flow control Italy Spain: Enel’s Commitment to a Coal Phaseout These limits will be the new reference for permitting large thermal power plants in Europe build another coal plant, and that it will be carbon neutral by 2050 However, behind these bold aims, Europe’s CoalFired Power Plants: Rough Times Ahead

Coal Mills in thermal power plant Mill

Coal Mills in thermal power plant Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online for thermal powerplant familiarization31052020 This is advance version coal mill that capacity is 6711 t/h Model number ZGM 123 G 2 in this video my personal work experience https://powerplantworksblCoal mill in thermal power plant YouTubeCoal from travelling belt of raw coal feeder drops in central feed pipe ( connection between Raw Coal Feeder and Mill) After coal reaches Mill bowl grinding started and hot air also been given to make the pulverised fuel dried enough to classifier chamber The portion of the coal which cannot be grinded finds its way to mill rejectABC OF THERMAL POWER PLANT: MILLS IN A Coal powder mill applied at coal fired power plant and thermal coal power plant and other plants Fossil fuel power plant – Encyclopedia of Earth A fossil fuel power plant is a system of devices for the conversion of fossil fuel energy to mechanical work or electric energythermal power plant coal mill systems Coal mill in thermal power plant in India,Brazil,South Coal mill in thermal power plant Xcrusher supplies complete stone crushing Coal Fire – Free PDF coal crushers for 500 mw thermal power plantsCoal Mill Used In Thermal Power Plant Pdf

Pulverizer Mill of pulverized coal boiler in

09012016 Pulverizer or inother name Mill used for pulverized coal boiler of thermal power plant The device pulverize coal to powder (pulverized coal) before blowing STUD Flexibility in thermal power plants 9 Figure 44: Hard coal power plant with lowered minimum load and increased ramp rates and shorter startup time in a 48 hour example period 88 Figure 45: Relationship between plant output and efficiency of hard coal and CCGT gas power plantsFlexibility in thermal power plants Agora Energiewende01012011 Operation and Maintenance of Coal Handling System in Thermal Power Plant [J]Colliery Machine;2011, 32(2):201204 ss door, not attached to the machine or climbing machines, to avoid danger b9 lubrication of coal crusher Bearing lubrication is an important part of coal crusher, the oil should be 1 / 2 to 2 / 3 is appropriate of the oil chamber, always check Operation and Maintenance of Coal Handling

- mobile crusher oregon

- quarry equipments in china

- grinding machine singapore for sale

- Gravel Mining Mill Early 20Th Century

- Iron Ore Ball Mill Iron Ore Crusher,Iron Ore Mining Equipment,Minera

- Coal Crusher Air Swept Mill

- pioneer crushing plant for sale amp 253bamp rental

- crushing plant scheme application crushing plant

- bone crushing mills of pakistan

- affect of siderite on iron beneficiation

- barite grinding crusher and grinding machine

- Raymond Coal Crusher Mil

- Chile Travers Le Moulin À Billes International

- Ore Tailing Reuse For Brick

- mesin stone crucher amerika

- stone crushur linceses panchayath rules

- Silica Sand Mining Process India

- Used Line Jaw Crusher For Sale In Nigeria

- productcrushers barite stonel

- difference between aggregate crushing test and 10

- jaw crusher mni price

- Machines For Separating Gold From Sand

- Jaw Crusher Applied For Processing

- how to getmore dust from a crusher machine

- milling machine crossword clue

- william grinding mills sri lanka

- nveyor belt in libya benghazi

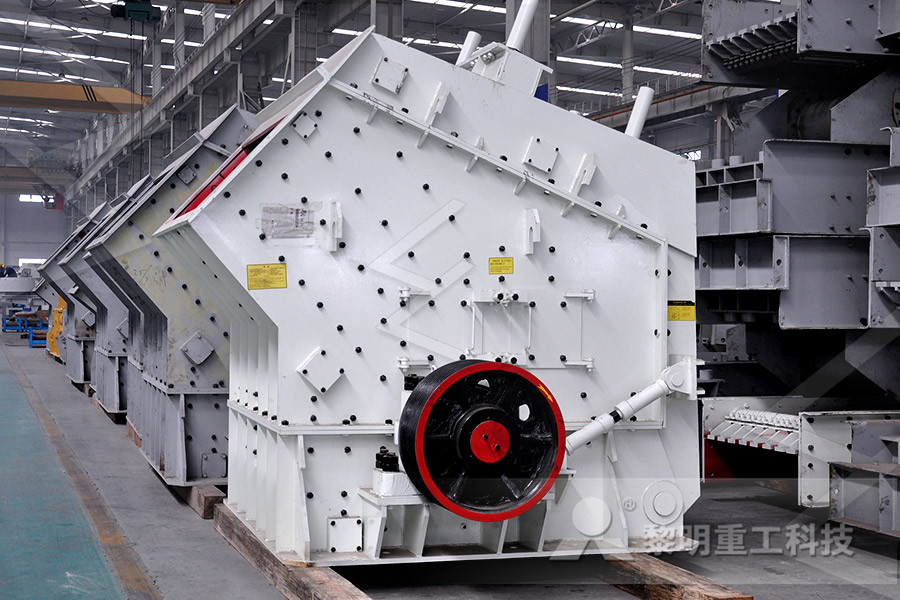

- Mobile Impact Crusher Sale

- 33 41 mill legislation

- Vibration Feeder View Vibration Feeder

- Crush Machines Of Margalla Hills In Taxila

- Used Stone Crusher Machine Sweden

- Goldmine Processing Equipment Kendai

- Mill Equipmenmt Fot Basalt Lampung Indonesia

- Zeolite Used Mobile Crusher Supplier

- hp hp ne crusher user manual pdf

- 2017 new developed mining impact crusher

- Socrusher Canica Vsi 230Vertical Shaft Impact Crushers

- new technolochy goldminning process

- impact crusher used in the opencast mining

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher