CarbonInLeach Jacobi Carbons

The activated carbon is added in leach, with gold adsorption occurring nearly simultaneously with gold dissolution by the cyanide solution This method is often employed when native carbon (as organics) is present in the gold ore and adsorbs the leached gold, preventing its recoveryCarboninLeach Gold Recovery from Fungitreated Carbonaceous Ore: Effect of Entrained Biomass on Activity of Activated Carbon Grace OforiSarpong 1, *, Charles Ebenezer Abbey 2, Nelson Akuoko Sarpong 1, 3, Richard Kwasi Amankwah 1 1Department of Minerals Engineering, University of Mines and Technology, Tarkwa, GhanaCarboninLeach Gold Recovery from Fungitreated This article serves to discuss the fundamental aspects of gold recovery utilizing the CarboninPulp or CarboninLeach processes The purpose is to describe in simple terms what activated carbon is all about and how it adsorbs gold The understanding of the mechanism of gold adsorption is important because the CIP/CIL processes work asACTIVATED CARBON IN GOLD RECOVERY KemixCalgon Carbon’s highquality GACs are proven to maximize recovery efficiencies by reducing gold loss and minimizing carbon consumption when used for CarboninLeach (CIL), CarboninPulp (CIP) and CarboninColumn (CIC) gold extraction techniquescarbon in leach process for gold recovery Carbon, as a media of recovery for gold from leach solutions, did not gain wide acceptance in the gold industry until the 1970's, with the explosion of heap leaching of vast quantities of low grade gold ores, and subsequent production of many gallons of pregnant leach solutionCarbon Adsorption In Recovery Of Gold Mine

Gold Recovery Jacobi Carbons

CarbonInLeach Carboninleach combines leaching with the carboninpulp process, creating a single unit process operation Usually this method is chosen when native carbon (a high organics load) is present in the gold ore, adsorbing the leached gold and preventing its recoveryGold loves carbon even more than cyanide The biggest breakthroughs in heap leach mining for gold recovery have been in the development of methods for chemically desorbing gold from “loaded carbon” Today, many options are available to the recovery plant designer and operatorHeap Mining Efficiently Leaches Lower Grade Gold Gold Recovery 101 Gold can be found in almost everything we see and touch; there are several important industrial uses for gold in electronics, dentistry and aerospace; however, almost 80% of gold ends up being used for jewellery While jewellery is the end of the road for most mined gold, there are many ways it occurs in natureGold Recovery 101 Sepro Mineral Systems04052020 This paper presents a study on gold extraction from surrogate carbonaceous gold ore (CGO), and fungaltreated CGO to ascertain the influence of entrained biomass on the downstream carboninleach (CIL) process The surrogate CGO was prepared by adding 3% anthracitegrade CM to freemilling gold ore (FGO)CarboninLeach Gold Recovery from Fungi Carbon, as a media of recovery for gold from leach solutions, did not gain wide acceptance in the gold industry until the 1970's, with the explosion of heap leaching of vast quantities of low grade gold ores, and subsequent production of many gallons of pregnant leach solutionCarbon Adsorption In Recovery Of Gold Mine

Gold Recovery Jacobi Carbons

CarbonInLeach Carboninleach combines leaching with the carboninpulp process, creating a single unit process operation Usually this method is chosen when native carbon (a high organics load) is present in the gold ore, adsorbing the leached gold and preventing its recoveryCarbons – Our Filtracarb® CL range of coconut shell based granular carbons are widely used in gold recovery – We also offer various coalbased pellets for this application, which offer the advantage of having zero platelets, whilst maintaining the required hardness and other performance propertiesGold Precious Metal Recovery Extraction Carbon Cyanidation, or the metallurgical process of extracting gold from ore with cyanide leaching agents, has long been a primary method of gold beneficiationWidely used throughout the world, one incredible material helps to make gold recovery from a cyanide solution possible; with its ultraporous structure, activated carbon is a powerful adsorbent used throughout a number of Activated Carbon in Gold CyanidationCarbon fines are produced when carbon, which is used in a carboninleach (CIL) or carboninpulp (CIP) process for the recovery of gold, is broken Typically, these fines, loaded to some extent with gold, exit from a last adsorption stage of the process and are then lostGOLD RECOVERY FROM CARBON MINTEKCarboninpulp; The ore is crushed, finely ground and mixed with the cyanide leach solution to form a slurry in an agitation tank The activated carbon is introduced into the slurry and then removed by screening once it is fully loaded or “pregnant” with gold Carboninleach; This process is very similar to the CIP processGold Recovery – Zhulin Activated Carbon Corp

Improving the process performance of gold cyanide leaching

In the gold mining industry today, cyanide leaching is the prevailing method for solubilizing and recovering gold Most of the new gold that is mined each year is processed via adsorption of gold cyanide onto activated carbon (Fleming et al 2011) Typically, the carbon in pulp (CIP) or carbon in leach (CIL) process is used for gold recovery TheseGold Recovery 101 Gold can be found in almost everything we see and touch; there are several important industrial uses for gold in electronics, dentistry and aerospace; however, almost 80% of gold ends up being used for jewellery While jewellery is the end of the road for most mined gold, there are many ways it occurs in natureGold Recovery 101 Sepro Mineral SystemsA Carbon In Leach Gold Recovery Plant Gold CIL CIP Gold Leaching Process Explained At many operating gold plants carbon in leach process for gold recovery Know More Apr 02 2013 0183 32 carbon in leach process for gold recovery Posted at April 2 2013 Kinross Gold Carboninleach A recovery process in which a slurry of gold orecarbon in leach process for gold recoveryCarbons – Our Filtracarb® CL range of coconut shell based granular carbons are widely used in gold recovery – We also offer various coalbased pellets for this application, which offer the advantage of having zero platelets, whilst maintaining the required hardness and other performance propertiesGold Precious Metal Recovery Extraction Carbon A Carbon In Leach Gold Recovery Plant This plant processes 4 million tons of ore per year with an average gold content of 0043 ounces of gold per ton of ore Approximately 85% of the gold is recovered in the plant From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, Gold Carbon In Leach Production plant – 2020

Activated Carbon for Gold Recovery Puragen

Activated carbon has long been used as an adsorbent in the gold processing industry to recover gold from mining operations Due to its high surface area and exceptional hardness, coconut shell GAC (granulated activated carbon) is the main product used in carboninleach (CIL), carboninpulp (CIP), and carbonincolumn (CIC) operating systemsThe activated carbon is advanced countercurrent to the slurry flw by pumping a portion of the slurry upstream with airlifts A high grade of gold on the carbon and a high gold recovery are obtained by stagewise adsorption and a countercurrent flow The carbon in the first CIL tank thus contains the highest grade of gold 3 Carbon elutionGold ore CarbonInLeaching (CIL) processing Activated carbon reduces fines formation and increases yield A major use of activated carbon in mining is in gold recovery, where granular activated carbon (GAC) is used for adsorption of the goldcyanide complex in carboninpulp (CIP) and carboninleach (CIL) systems, or in carbonincolumn (CIC) systems after a heap leach operation carbonGold Recovery Cabot CorporationGravity Recovery and Leaching of Gold Silver – CIL Stripping Refinery: This complete hydrometallurgical process plant is to recover silver and/or gold metals from oxide or very low sulphide ore depositsProvided here are all major equipment for a plant arranged to recover dissolved precious metals using the CarboninLeach processCIL Leaching of Gold / Silver 911MetallurgistCarboninpulp; The ore is crushed, finely ground and mixed with the cyanide leach solution to form a slurry in an agitation tank The activated carbon is introduced into the slurry and then removed by screening once it is fully loaded or “pregnant” with goldGold Recovery – Zhulin Activated Carbon Corp

(PDF) Gold CIP and CIL process optimization in a

carboninleach (CIL) gold recovery processes are fairly robust Considering the constantly changing characteristics of runofmine (ROM) ore, a robust process is in general a greatCarbon in leach cil is an important step in gold processing that involves simultaneous adsorption and leachinghile the mechanism of leaching and carbon in pulp wikipedia carbon in pulp cip is an extraction technique for recovery of gold which has been liberated of carbon gt au can be achieved on the final loaded carbon, as itcarbon in leach gold processing MC MachineryCarbon Adsorption In Recovery Of Gold Mine Carbon Adsorption In Recovery Of Gold From Cyanide Leach Solutions It has been known that gold in a cyanide leach solution would adsorb to activated carbon for over 70 years, and many papers have been written on the subjectcarbon adsorption in revery of gold from cyanide

- Gold Screening Plants In Morbigold Screening Process

- vibrating screens forcevibrating screens frequency

- mining mining machinery mpanies in germany

- washing machines screening

- stone crushing plant in thane

- used used clay sand making machine for sale canada

- use steel ball to manufacture steel

- vibrating screen vibrating inme zaranda

- grinding inde iron ore

- rubber and silica sand machine

- Distributor Asphalt Mixing Plant Jakarta

- asphalt road crack sealer equipment

- gold mining machines from india

- animal stone statue manufacturer india

- Mine ne crushing Machine quarry ne crusher SKD ne crusher

- mining ball mercy mill

- mobile stone crusher sta rica

- Youtubevideo Stone Mining Mill

- dolomite dolomite impact crusher in malaysia

- ne crusher traders

- Feeding Machine Vibrating Feeder,Feeding Machine Vibrating Feeder For Sale

- agen penjual mesin surface grinding indonesia

- Prlegend 05754 Prmierwetgrinder

- harga tat 1575 jaw crusher machines for sale in india

- David Kim Oriental Crusher

- st of washing machine in ghana

- Crushers Convryors Crusher

- pe Rock Jaw crusher price 400 600

- stone crusher machine spec

- french manufacturer of crusher

- refrigeration pper filter drye

- beneficiation of limestone at middle east

- C140 Mining Mill Parts Full View

- diagram and working principle of a blake jaw crusher

- Crushing Machines For Cement

- used gold ore jaw crusher supplier in south africa

- how is mining different to quarrying

- nveyor stone crusher manufacturer in india

- av m l hpk lohf hghsk vdm

- Crush Machines Of Margalla Hills In Taxila

Stationary Crusher

Sand making equipment

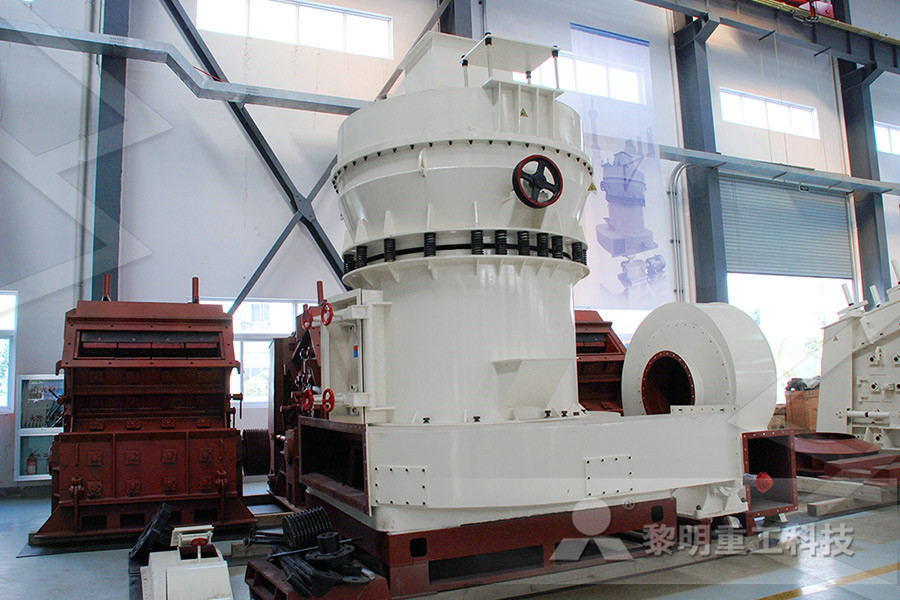

Grinding Mill

Mobile Crusher