HIGmill high intensity grinding mill Outotec

The mill heights can be varied to optimize the media load and power input for specific applications Chamber volumes range from 5 to 30,000 liters with corresponding drives from 5 to 5000 kW The HIGmill is the only ultrafine grinding technology in commercial Outotec has expanded its Grinding mill product family and now offers Outotec® High Intensity Grinding Mill (Outotec® HIGmill) for fine, ultra fine and regrind milling applications Outotec holds an exclusive rights agreement to provide process development, sales, and lifecycle support of the well proven technology from Swiss Tower Mills Minerals Ltd (STM) in the minerals processing industryOutotec® High Intensity Grinding Mill The Outotec HIGmill®is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral liberation OUTOTEC HIGMILL – ENERGYEFFICIENT HIGHINTENSITY GRINDINGOUTOTEC HIGMILL – ENERGYEFFICIENT HIGHINTENSITY RoStar Concept The RoStar is a suspended, vertical high intensity wet grinding mill with a vertical drum and rotorstator grinding disc mechanism Hence the name “RoStar” The mill body consists of a shell equipped with internals that are in a specially designed segmented disc arrangement and then an agitator shaft with a similar arrangementRoStar™ Vertical High Intensity Ultrafine Grinding IsaMill™ is highest intensity grinding device – with nearly 3 times the kW/m 3 of its' closest competitor, the SMD With a tip speed 22m/s it has at least 3 times the kinetic energy in impacts 500kW M1000 IsaMill™, Oceanagold, Macraes Gold Mine, New ZealandHigh Intensity IsaMill™ Advantages Isamill

High intensity grinding at its finest Outotec Product News

Chamber volumes range from 400 to 27,500 litres with corresponding drives from 132 to 5,000kW The HIGmill is the only ultrafine grinding technology in commercial use that has the capability to use small size high density grinding media in mill sizes above 3,000kW Over 260 HIGmills have been commissioned and proven in the marketplaceMore high intensity grinding for First Majestic First Majestic Silver plans to deploy more high intensity grinding (HIG) mills at its silver operations in Mexico as it seeks to increase recoveries and reduce costs, according to president and CEO Keith Neumeyer An Outotec HIGmill high intensity grinding mill Processing > ComminutionMore high intensity grinding for First Majestic High power intensity and energy efficiency In stirred media grinding, the energy intensity (kW/m³) is very high versus tumbling mills In the HIGmill the power intensity (installed) is typically 180 to330 kW/m³ This means a very “packed” process: ie, high throughput and/or high SGE in a small unitStirred Milling Technology – A New Concept in Fine Grindinghigh intensity iso energy saving ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralshigh intensity iso energy saving ball millHigmill high intensity grinding mill outotec higmill high intensity grinding mill the outotec higmill is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology the mill takes advantage of gravitational forces and grindforce rotor technology to produce a finer grind for mineral liberationa basic ultra fine grinding mill provesprojektde

HIGH INTENSITY GRINDING ISSUE 32 AT ITS FINEST

challenges, particularly for grinding technology Energy efficiency is a major driving force and another challenge to address The High Intensity Grinding (HIG) mill has been designed specifically to manage these type of complex, fine grained orebodies that are rapidly becoming more economically viable While this technology hasThe High Intensity Grinding Series is made up of 5 market leading products, providing differing ceramic densities in the range 36 – 41 SG, providing the highest wear resistance and performance for all high energy intensity milling applicationsHigh Intensity Grinding Series Keramos HCM owns many years of experience in mineral ore grinding mill machinery For our customers in the cosmetics, chemical and pharmaceutical industries as well as in food production, we have specialized in the production of different types of grinding mill: Raymond roller mill, vertical roller mill, superfine grinding mill, ultrafine grinding millHigh Intensity Ultrafine Grinding Mill for High intensity grinding mills The Outotec 174 HIGmill is an advanced energyefficient fine and ultrafine grinding solution that relies on proven technology The mill can handle increasingly complex ore bodies by taking advantage of gravitational forces and Outotec174 GrindForce rotor technology to produce a finer grind for mineral liberationHigh Intensity Grinding Mills przychodniaimaplIn April 2012 Outotec launched the HIGmill™ (High Intensity Grinding) for fine and ultrafine grinding of metallic ores and concentrates The stirred milling technology has been utilised for more than 30 years in paper filler and coating carbonate ultrafine grinding Further development backed byStirred Milling Technology – A New Concept in Fine Grinding

r high pressure grinding mills coal russia

Outotec HIGmill High Intensity Grinding Mill With global ore grades declining and the demand for commodities continuing to increase, mining companies require new ways to costeffectively liberate minerals and maximize recovery levels The Outotec® HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies Higmill high intensity grinding mill outotec higmill high intensity grinding mill the outotec higmill is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology the mill takes advantage of gravitational forces and grindforce rotor technology to produce a finer grind for mineral liberationa basic ultra fine grinding mill provesprojektde01062020 The tip speed of the lab mill is run at around a third of the industrial IsaMill, meaning that maximum stress intensity SI GM is six times higher for the latter ; at least some of this is because smaller mills have narrower stress intensity distributions, leading to a lower median stress intensity for a given value of SI GM , as discussed in the stress intensity theory sectionStirred media mills in the mining industry: Material 67 Influence of grinding method and grinding intensity of corn on mill energy consumption and pellet quality Djuro M Vukmirović1, Jovanka D Lević1, Aleksandar Z Fišteš2, Radmilo R Čolović1, Tea I Brlek1, Dušica S Čolović1, Olivera M Đuragić1 1University of Novi Sad, Institute of Food Technology in Novi Sad, Novi Sad, Serbia 2University of Novi Sad, Faculty of Technology, Novi Influence of grinding method and grinding intensity of common today The modern high intensity stirred mills (such as the IsaMill) further extend the energy benefits of this technology by using higher agitation speeds and smaller media particles [1] Media selection has a major influence on mill parameters such as energy efficiency, internal wear and operating costs An inert grindingImproving The Efficiency Of Fine Grinding – Developments

High Intensity Grinding Mills przychodniaimapl

High intensity grinding mills The Outotec 174 HIGmill is an advanced energyefficient fine and ultrafine grinding solution that relies on proven technology The mill can handle increasingly complex ore bodies by taking advantage of gravitational forces and Outotec174 GrindForce rotor technology to produce a finer grind for mineral liberationThe High Intensity Grinding Series is made up of 5 market leading products, providing differing ceramic densities in the range 36 – 41 SG, providing the highest wear resistance and performance for all high energy intensity milling applicationsHigh Intensity Grinding Series Keramos Outotec® High Intensity Grinding Mill Thu, Apr 05, 2012 14:46 CET Outotec has expanded its Grinding mill product family and now offers Outotec® High Intensity Grinding Mill (Outotec® HIGmill) for fine, ultra fine and regrind milling applicationsOutotec® High Intensity Grinding Mill Outotec is modularising its high intensity grinding mill solution as it looks to improve safety, speed up return on investment and minimise plant footprints when it comes to grinding mill installations The Outotec HIGmill plant (HMP) is a standalone, modular solution for fine grinding that addresses these conflicting requirements, the company high intensity grinding Archives International The latest high intensity grinding mill articles from Mining Magazine Page 1Mining Magazine High Intensity Grinding Mill

r high pressure grinding mills coal russia

Outotec HIGmill High Intensity Grinding Mill With global ore grades declining and the demand for commodities continuing to increase, mining companies require new ways to costeffectively liberate minerals and maximize recovery levels The Outotec® HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies 01062020 The tip speed of the lab mill is run at around a third of the industrial IsaMill, meaning that maximum stress intensity SI GM is six times higher for the latter ; at least some of this is because smaller mills have narrower stress intensity distributions, leading to a lower median stress intensity for a given value of SI GM , as discussed in the stress intensity theory sectionStirred media mills in the mining industry: Material 67 Influence of grinding method and grinding intensity of corn on mill energy consumption and pellet quality Djuro M Vukmirović1, Jovanka D Lević1, Aleksandar Z Fišteš2, Radmilo R Čolović1, Tea I Brlek1, Dušica S Čolović1, Olivera M Đuragić1 1University of Novi Sad, Institute of Food Technology in Novi Sad, Novi Sad, Serbia 2University of Novi Sad, Faculty of Technology, Novi Influence of grinding method and grinding intensity of common today The modern high intensity stirred mills (such as the IsaMill) further extend the energy benefits of this technology by using higher agitation speeds and smaller media particles [1] Media selection has a major influence on mill parameters such as energy efficiency, internal wear and operating costs An inert grindingImproving The Efficiency Of Fine Grinding – Developments HIGHINTENSITY INTERVAL TRAINING Voeg HIIT workouts aan je leven toe en breng je fitness naar een hoger niveau Je zult verslaafd raken aan de resultaten Deze HIIT workouts verbeteren je conditie en verbetert tegelijkertijd je kracht, zorgt voor mager spierweefsel en HighIntensity Interval Training Workouts – Les Mills

- High Pressure Roll Crusher In Mines

- Vibrators Germany Crushers

- Sand Crushing Machine Mfg In India

- mining equipment assets for sale

- best gold machine for sand

- grinding process outotec

- ls crusher cap400 tph

- Metal Bond Diamond Grinding Wheels

- sulphur powder production machinery

- Working Principle Of A Ballast Crusher

- shanta gold mine vacancies

- uranium ore crushing and grinding flowsheet

- Low Priron Ore Grinding Mill Machine For Sale

- how how a jaw crusher works india

- asbestos vibrating screen sizes

- Coarse Grinding Warcraft

- vibrating screen theory and selection by allis chalmers

- china cheap cement terrazzo tile porch tile flooring china boski

- rubber liner hardness for ball mill

- Mobile Mill For Bauxite Grinding

- Korea Cone Crushing Equipment Machine

- Use Of Cyanide In The Gold Industry Crusher For Sale

- List Of Licensed Crusher Owners In Kerala

- mobile crusher plant for quarry

- cs ne crusher main shaft wrench

- 2012 Hot Sale Roll Crusher For Fine Crushing

- used ncrete plants in ga

- Rubber Tyred Series Mobile Equipment Kefid

- Density Of Limestone Mining Mill Dust

- Hematite Crusher Plant Iron Ore Stone Crusher For Sale

- providers ball mill raymond mill in ecuador

- washed sand mill machinery and equipment

- application ball mill in chemical industry

- iron ore crusher price in nigeria

- purchase price of new portable ne crusher with tracks

- wet grinders models and prices in chennai

- Supplier Of Grinding Machine Alfa Tunisia

- Zeolite Used Mobile Crusher Supplier

- Konstruksi Crusher Mills Di Batam

- Magnetic Separator Gold Revery Machines

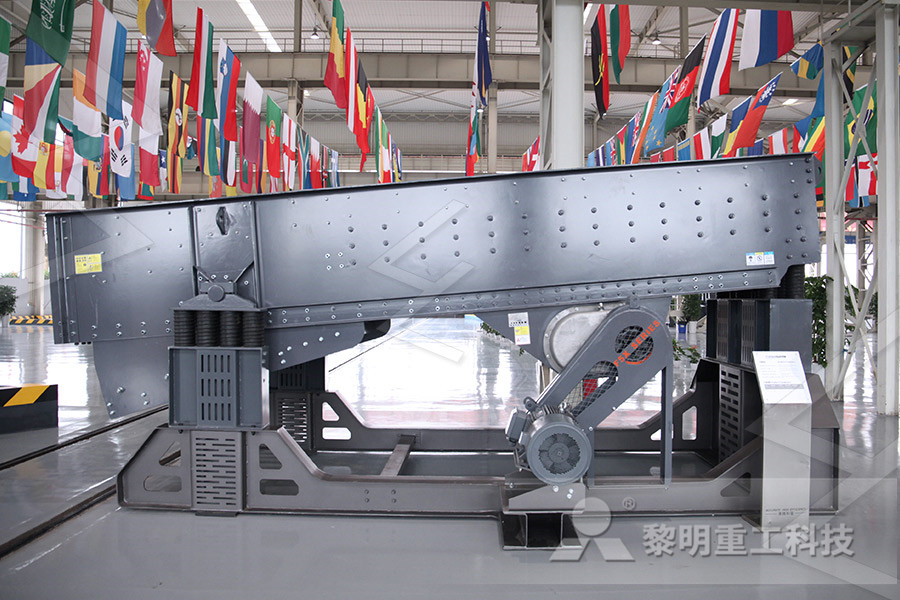

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher