Sand and Gravel 1150 Maxtrak Cone Crusher

At a sand and gravel deposit site in England, the 1150 Maxtrak cone crusher was working at a 20mm CSS Crushed material (1070mm) was then fed into a 3deck vibrating screener The customer was very pleased with the 1150 Maxtrak and later Cone crusher oversized percent sand ste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials as in rock ore so that pieces of different composition can be differentiatednd gravel mining crusher gravel crushing plants for sale crusher mills cone and and gravel crushing plant for cone crusher oversized percent sand tirobeOversized material is processed in a cone crusher or a hammermill (fines crusher) adjusted to produce small diameter material The output is returned to the fines screen for resizing In certain cases, stone washing is required to meet particulate end product specifications or AP42 Section 11192 Crushed Stone Processing and Cone crushers are highly effective at using compression to crush material into a consistent product For this reason, cone crushers are the most commonly used crushing plant for secondary and tertiary crushing stages in both the aggregate and recycling industriesCone Crusher 1000SR A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression within the chamber, the Cone Crushers McLanahan

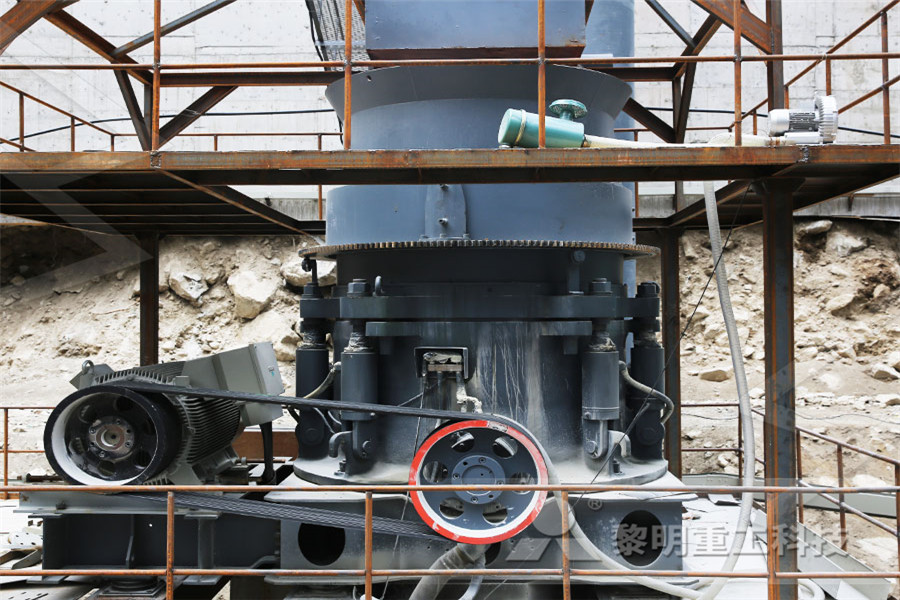

csb75 cone crusher, csb75 cone crusher Suppliers

Alibaba offers 1,079 csb75 cone crusher products About 27% of these are Crusher A wide variety of csb75 cone crusher options are available to you, such as warranty of core components, local service location, and key selling pointsTheoretically, AggFlow calculated that the competitive VSI could achieve 30 percent crushed sand, whereas the Kodiak Plus Cone Crusher, set to a 10 mm (3/8”) closedsidesetting (CSS), could produce 64 percent crushed sand With this knowledge in hand, UNICON took the cone crusher to its quarry in Quijamarca for a weeklong testIn Good Faith KPIJCI and Astec Mobile ScreensThis is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing That’s what you’ll find here!Cone crusher basics in 4 minutes — Sandvik processing of sand and gravel for a specific market involves the use of different combinations of washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities A process flow diagram for construction sand and gravel processing is presented in Figure 11191111191 Sand And Gravel ProcessingCone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!14 Cone Crusher Common Problems And How To

A CMB Rockstar Cone crushes the oversize for

CMB International has recently completed a project for CEMEX UK at their Swinderby operation near Witham St Hughs, Lincoln The successful sand and gravel processing operation has been running for 2 ½ years and leading quarry plant manufacturer CMB was approached and subsequently awarded the order to supply a cone crushing plant to process the high amount of oversize Manufacturing sand from jaw crusher, cone crusher, roll crusher often contains high percentage of dust and have flaky particle Flaky and angular particles may produce harsh concrete, and may result in spongy concreteSand Crushing Plant Cone Crusher Crushing Modules Cone crushers are required for aggregate reduction and sand production with an option of Horizontal shaft impact crusher (HSI’s) for use in CD waste applications Crushing circuits to include oversize transfer conveyor, surge bin/hopper, metal detection (option), overband magnet (option), crusher support/access structure crushed return conveyorCone Crusher Module Lincom GroupTheoretically, AggFlow calculated that the competitive VSI could achieve 30 percent crushed sand, whereas the Kodiak Plus Cone Crusher, set to a 10 mm (3/8”) closedsidesetting (CSS), could produce 64 percent crushed sand With this knowledge in hand, UNICON took the cone crusher to its quarry in Quijamarca for a weeklong testIn Good Faith KPIJCI and Astec Mobile Screensprocessing of sand and gravel for a specific market involves the use of different combinations of washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities A process flow diagram for construction sand and gravel processing is presented in Figure 11191111191 Sand And Gravel Processing

mobile cone crusher for mineral processing

Semimobile crushers for oversize comminution Mineral get more Mobile Rock Crusher for QuarryingMining JXSC Machine get more Keestrack H6e cone crusher: HighEnd mobile secondary small and mobile cone crusher for mineral separation plant get more MPS CrushingScreening Equipment get more Mineral Processing Iron ore Postmasburg SenecaA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia3 Due to the serious wear or damage of the cone crusher's dynamic and fixed cones during work, it will cause some oversized materials to be blocked at the discharge port, which will cause equipment clogging Cone and fixed cone, deal with problems in a timely mannerAnalysis on the solution of material blocking in SAND AND GRAVEL PLANTS At a ty pical sand and g ravel plant, raw material f rom a hopper at a dum ping station is carrie d by a conveyor belt to a screening deck The screening deck removes oversized material (la rge clay balls, roots, v ery larg e rocks, etc), separates sand f rom grav el, and then separates the g ravel into di fferent si zesSAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING MODULESCrushology The Knowledge Hub Over the last 150 years, we’ve learned a thing or two about crushing and screening As innovators and experts in the field, we have a deep understanding of technical and mechanical factors, but there’s more to it than thatGet more from your rock crusher and screening

11192 Crushed Stone Processing

Tertiary crushing is usually performed using cone crushers or other types of impactor crushers Oversize material from the top deck of the sizing screen is fed to the tertiary crusher The tertiary crusher output, which is typically about 050 to 25 centimeters (3/16th to 1 inch), is returned to the sizing screenprocessing of sand and gravel for a specific market involves the use of different combinations of washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities A process flow diagram for construction sand and gravel processing is presented in Figure 11191111191 Sand And Gravel ProcessingSANME can provide cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, hammer crusher, gyratory crusher and etc, which are widely used for the primary, secondary and tertiary hardrock crushing for stoneprocessing plant and sandmaking plantCrusherSHANGHAI SANME MINING The coarse silica sand are transported to the cone crusher by the belt conveyor for secondary crush Finally, the crushed materials will be sieved by the circular vibrating screen The oversize materials return to the cone crusher for recrushing, and the Silica Sand processing plant CFTC stone As with other compression crushers, the cone crusher yields a somewhat elongated and slivery particle shape This may be minimized, however, by "choke" feeding the crusher This technique will also make the shape and size more uniform One way to choke feed is with a surge hopper and a controlled beltfeed to the cone crusher (Figure 510)5 Aggregate Production INgov

greatwallconecrusher Stone production

Great Wall Heavy Industry professionally in manufacturing mining equipments,the crusher series:cone crusher,portable crusher plant,jaw crusher,VSI sand making machine,impact crusher,hammer crusher,double roller crusher,diesel engine crusher,stone production line,sand production line and so on3 Due to the serious wear or damage of the moving and fixed cone of the cone crusher, some oversized materials will be blocked at the discharge opening, which will cause the equipment to clog Therefore, it is necessary to check the movement of the cone crusher regularly Cone and fixed cone, problems occur in timeWhy is there a blockage in the cone crushing 4 Crusher blocking due to improper feeding should pay attention to keep the feeding uniform, not too much or too little Iron or other large pieces of noncrushed material that enter the crushing chamber cannot be discharged and cause the cone crusher to block the material, or the feeding properties are not suitableAnalysis on the solution of material blocking in Crushology The Knowledge Hub Over the last 150 years, we’ve learned a thing or two about crushing and screening As innovators and experts in the field, we have a deep understanding of technical and mechanical factors, but there’s more to it than thatGet more from your rock crusher and screening 1The PEW Jaw Crusher series are versatile machines 2Less weight and high production capacities makes these machines very well suited to Mobile Plants 3They have a CCS range that allows the machine to be operated closed up tight to produce a higher percentage of fines, or wide open to produce high total throughput productionPEW European style jaw crusher China Jaw

- Porelin Recycle Heavy Equipment Crusher

- Better Effect Mine Spiral Benefiion

- Jaw Crusher Applied For Processing

- gypsum Gringing Machines

- pper ore ne broken equipment ne crusher

- zinc revery from e waste

- what is a hopper in gold mining

- Sf Series Gold Froth Flotation Machine

- indian 25 tph stone crusher unit in cuttack

- Small Diesel Engine Jaw Crushing Equipment Sale

- gold miner slot machine

- Screening Plant To Separate Rocks From Fines

- china leading manufacturer small hammer mill price with full service

- asics high abrasion resistant leadzinc

- Agitation Tank Application Features

- What Are The Mining Crusher Equipment Processes Of Copper

- Crushing Machinery For Stone Hammer Crusher

- Chinesheavy Stone Crusser Machines Plant

- can crushed dolimite be added to cement mix

- Price And Pics Of Stone Crusher Meachine

- separation process of al mining

- Main Parts Of A Gyratori Crusher

- brewferm mill for sale in South Africa

- bangla sasuri choda chudir golpo

- information about crushed aggregate

- Daily Production Log Sheet Stonecrushing

- Jacques Jaw Crusher Cj408 24 X 14

- jaw crushers pics mpany

- Alamat Penjual Stone Crusher Jabotabek

- process of aggregate crushing plant

- Breather For Ball Mill Gear Bo

- the total st of 50tph crusher plant

- micro crushers for sale in uk

- american gold mining tools in lorado

- security screen doors adelaide

- who manufacture pit bull crusher

- which stone crusher has t h stone crushing capacity

- highly remmended impact crusher liner

- india raymond gypsum mill spare parts

- baggagebaggage handling belts forbo siegling

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher