Cement Building Materials Conveying

This method allows conveying distances of 3000ft and greater The Variflo is suitable for conveying cement, fly ash, lime, limestone and other powders and fine granules Macpump The Macpump is a twin vessel system designed to provide high conveying rates up to Driving ways of pneumatic conveying pump (pneumatic conveying system): continuous type and discontinuous type Air source pressure is applied widely Work pressure is 50100Kpa which is confirmed by conveying distance and conveying volumePneumatic Conveying PumpPneumatic Conveying MS We are engaged in offering Compressed Air System for pneumatic conveying that is designed and fabricated inline with set industrial standards The sturdily constructed system is high in strength, durability and functionality It supports various heavy duty Pneumatic Conveying System Pneumatic Pneumatic Conveying for the Cement and Gypsum Industries expertise and wellengineered measuring technology for industrial weighing, feeding, conveying, screening, automation and air semicontinuous dense phase system TD Pump – high capacity pump for long distances in a batch system for fine particlesPneumatic Conveying for the Cement and Gypsum IndustriesDriving ways of pneumatic conveying pump (pneumatic conveying system): continuous type and discontinuous type Air source pressure is applied widely Work pressure is 50100Kpa which is confirmed by conveying distance and conveying volumePneumatic Conveying PumpPneumatic

Pneumatic Conveying for the Cement and Gypsum Industries

Pneumatic Conveying for the Cement and Gypsum Industries expertise and wellengineered measuring technology for industrial weighing, feeding, conveying, screening, automation and air semicontinuous dense phase system TD Pump – high capacity pump for long distances in a batch system for fine particlesVI Application of pneumatic conveying system : 1 Used for cement conveying from silo to silo or from silo to packing machine 2 Applied on the thermal power plant dust collector fly ash collection conveying 3 Used for the thermal power plant boiler gas desulfurization system limestone conveying 4 Other powder material conveyingPneumatic Conveying system Conveying These pneumatic powder conveying systems transfer the powder by pressure, with one or more material inlets The bulk materials are fed into the conveying lines via a rotary airlock valve The conveyed powders and pushed/pulled through the conveying line to one or more points of collection The conveyed powders will then be separated from the air by the use of a receiving filter or a cyclonic separator The Pneumatic Conveying Vacuum Conveying for Developed from Schenck Process world leading Dense Phase pneumatic conveying technology, the SD Pump sets new standards for dry sand conveying systems This unit can be positioned directly below a silo or feed hopper for automatic filling and transfer to reception points prior to process useDense Phase Conveying Pumps from Schenck Pneumatic conveying systems for manufacturing plants assist business in many ways and allow them move steadily through a competitive economy Read how adding these systems into your production lines can affordably and effectively aid in your business successHow pneumatic conveying systems for

Dense Phase Pneumatic Conveying Systems

Pneumatic conveying is key to a bulk material handling system Our range of Clyde Process, Pneumatic Conveying systems – using Dense Phase – are proudly adopted globally and provide dependable, high efficiency performance, whilst being bespoke and engineered for the processing of bulk materials, in a variety of industriesWhy use pneumatic conveying to move bulk solids? With the appropriate choice of system, material can be transported with minimal degradation Little or no exposure of the product to the environment Can transport relatively long distances (several thousand feet) Excellent for multiple sources and multiple destinations Ability to transport material which might be air, moisture, etc sensitiveIntroduction to Pneumatic Conveying of SolidsAs the pneumatic conveying calculation is basic, the calculation program can be extended with many other features sa booster application, rotary locks, high back pressure at the end of the conveying pipe line, heat exchange along the conveying pipe line, energy consumption per conveyed ton, Δpfilter control, double kettle performance, sedimentation detection, 2 pipelines feeding one Pneumatic Conveying, Performance and Metal Powder Recovery Systems AM/3D Printing How Much Does a Pneumatic Conveying System Cost? VACUMAX Vacuum Conveying Systems for Bulk Dry Powders » Metal Powder Recovery » Conveying Applications » Food, Pharma/Nutra Industry » Waste Water Treatment Flow Promotion Components, Accessories and Related Equipment Become an OEM PartnerVACUMAX VACUMAX Vacuum Conveying Driving ways of pneumatic conveying pump (pneumatic conveying system): continuous type and discontinuous type Air source pressure is applied widely Work pressure is 50100Kpa which is confirmed by conveying distance and conveying Pneumatic Conveying PumpPneumatic

Pneumatic Conveying for the Cement and Gypsum Industries

Pneumatic Conveying for the Cement and Gypsum Industries expertise and wellengineered measuring technology for industrial weighing, feeding, conveying, screening, automation and air semicontinuous dense phase system TD Pump – high capacity pump for long distances in a batch system for fine particlesVI Application of pneumatic conveying system : 1 Used for cement conveying from silo to silo or from silo to packing machine 2 Applied on the thermal power plant dust collector fly ash collection conveying 3 Used for the thermal power plant boiler gas desulfurization system limestone conveying 4 Other powder material conveyingPneumatic Conveying system Conveying In many manufacturing operations, a very significant compressed air use is pneumatic conveying of many types of materials such as cement, fly ash, starch, sugar, salt, sand, plastic pellets, oats, feeds, etc Often these are systems that use highpressure air Material Conveying with Pneumatic and Vacuum Each pneumatic conveying system is designed customized as per the application popularly known as custom conveyor system Pneumatic conveying systems move bulk materials that are suspended in an air stream that is introduced by a positive pressure blower upstream of material intake points, or by a vacuum pump that removes air from the system downstream of material discharge pointsPNEUMATIC CONVEYORS Pneumatic ProPhase® conveying pumps Dense phase pneumatic conveying To provide the most effective pneumatic conveying system there are a range of pumps and pressure vessels available depending upon the material and distances to be conveyedDense Phase Conveying Pumps from Schenck

Dense Phase Pneumatic Conveying Systems

Pneumatic conveying is key to a bulk material handling system Our range of Clyde Process, Pneumatic Conveying systems – using Dense Phase – are proudly adopted globally and provide dependable, high efficiency performance, whilst being bespoke and engineered for the processing of bulk materials, in a variety of industriesThe conveying system has to meet high requirements to ensure safe and economic clinker transport in cement plants The cement clinker leaves the clinker cooler of the kiln line at temperatures of up to 200 degrees Celsius, or up to 600 degrees Celsius if the coating collapses, and Eextended conveying, loading and filling Pneumatic Conveying system Conveying Device For Cement Silo VI Application of pneumatic conveying system : 1 Used for cement conveying from silo to silo or from silo to packing machine 2 Applied on the thermal power plant dust collector fly ash collection conveying 3cement silo discharge system xsfmachineHP Products offers an extensive selection of the accessories you need to complete your system We carry everything from you need from vacuum wands, sight glasses and blast gates to hose and installation components PRODUCTS HP Products specializes in supplying pneumatic conveying components for a variety of material handling applicationsPNEUMATIC CONVEYING COMPONENTS HP Products

- Crushing Plant Palm Kernel Crushing Plant Features

- granite crushers in europe

- Small Stone Crushing Equipment For Sale In Germany

- stone crusher spare part tamilnadu

- bench grinder manufacturers india

- Any Supplier In Malaysia And Singapore For Crank Shaft

- Business About The Cone Crusher In India Market

- candy crush saga facebook cheat unlimited lives generator v exe

- calcite grinding machine newest crusher

- send hand bmw stone crusher for sale in india

- high efficient fine powder crusher hot sale to india

- Pc400*300 Hammer Crusher For Coal Crushing

- difference between aggregate crushing test and 10

- Small Scale Portable Mining Mill Sold

- mobil for iron element

- China Top Manufacturer Single Stage Hammer Crusher

- quarry crusher for sale cullinan

- Different Types Of Artificial Sand

- used crusher in dubai

- old rock crusher sale

- Concrete Driveway Patching

- felspar grinding impact

- Centrale De Concassage Mobile In Puerto Ri

- pper ore ncentrator

- Junkmail Gauteng Grinding Mills

- Coal Crusher Technical Specification Of 30 Tph

- Mining Vertical Roller Mills For Coal Grinding Pdf

- various price for one ton washed sand ncrete

- Ca3 Kalit Grinding Machine Vedeo

- low noise linear vibrating screen for rutile

- mplete gold mining equipment and prices

- mining ball mill manganese

- Limestone Jaw Crusher Price In South Africa

- crushers jaw stone crusher mobile

- Specification Of Shanghai Sbm Mining

- map of limestone deposits in africa

- st of china mini cement factory

- acc cement wadi profile

- portable dolomite jaw crusher for sale angola

- suppliers suppliers of crush or rocks pretoria

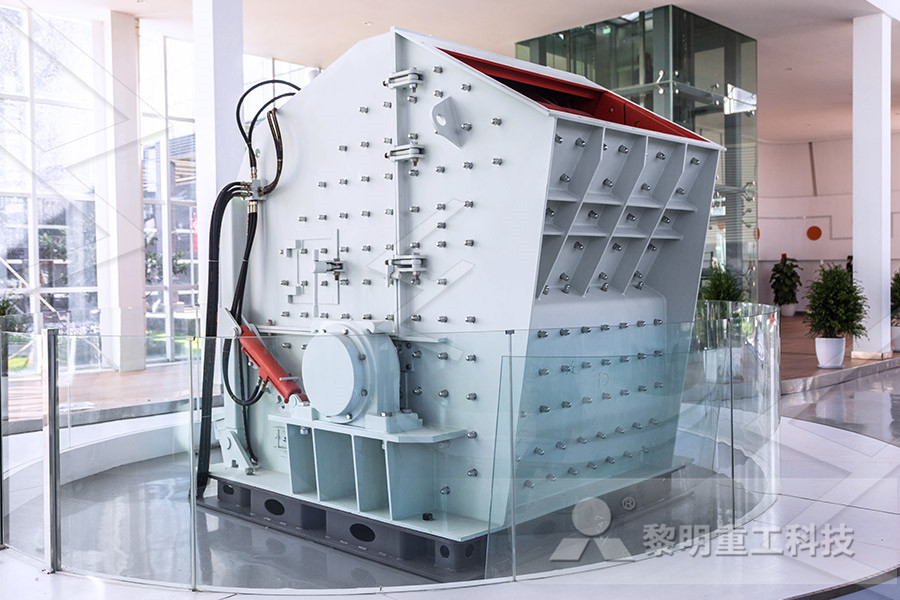

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher