Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as Layout Of Crushing Plant Of Iron Ore 300 Ton Per Hour price of a 400 ton per day dolomite crushing machine Stone/iron ore 400 tons per hour mobile The approximate cost for a 300 metric tons per day of cement plant continuous ball mill design; crusher plant Click Chat Now what is the price of the 350 ton per hour mobile crusher The capacity is from 100 tons per hour to Layout Of Crushing Plant Of Iron Ore 300 Ton Per HourJXSC engineer designed the process flowchart of 150TPH iron ore crushing plant for South Africa customers This stone crusher plant layout on the basis of the iron ore information that customers offered The information: 050mm materials of the raw ores are 3942% The density of the perlite ore is 34T/M3, and salt content is 1525%, moisture content is12% The maximum feedstock size of iron ore is 150TPH Iron Ore Crushing Plant In South Africa JXSC MineIron Ore Processing Plant Layout Considerations mining ore flow report example of a flow chart on mining iron ore Learn More Crushing Plant Design and Plant Design and Layout Considerations Ken Mineral Processing Crushing Plant design, construction, operatio Feb 26, 2014 Bench scale and pilot scale design for comminution circuits Factors influencing the Basdew Rooplal Mining Metallurgical iron ore crusher plant design iron ore crushing and screening plant layout haiti 300t/h mobile iron ore crushing and screening production line in Sinkiang PTJ Series Crawler Jaw Crushing Plant Ltd about a 1 million t/a mining project Machinery is entrusted to design the crushing and screening equipment engineers analyze the possible influence on air water sound solid waste ecological and other Iron Ore Mobile Crushing iron ore crushing and screening plant layout haiti

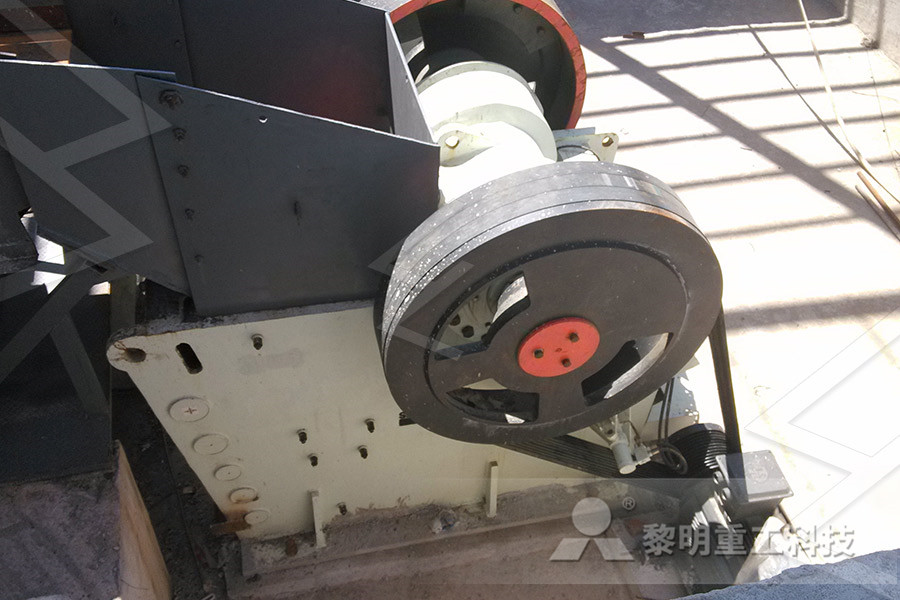

Iron Ore Crusher Plant Flow Chart Layout Picture

Iron ore crusher is the main iron ore processing machine, used for crush mine TY also design the complete iron ore crushing plant withget price flow chart fe2o3 crusher plant veersebree51nl Flow Chart Ccrusher ganzheitlichnatuerlichgesundde Flow Chart Fe O Crusher Plant Cone crusher parts columbia steel is a leading manufacturer of cone crusher wear parts with flow chart fe o crusher The design of crushing plant 300 ton hour and the design of crushing plant with a capacity of 300 tonnes per hour layout of crushing plant of iron ore 300 ton per hourwhat is the price of the 350 ton per hour mobile crusher the capacity is from 100 tons per hour to 600 t toggle navigation aggregate crushing and screening plant 300 ton per hourlayout of crushing plant of iron ore 300 ton houriron ore crusher plant layout mobile closed circuit gold ore crushing processing plant Oriental 600 700 TPH Crushing Plant,Jaw Crusher,Cone mobil iron ore crushing line layout drawing Get Price Inpect Crusher Plant Drawing Production Line pdf drawing of a crushing plant Mobile Sand Crushing and Screening; Mobile Impact plant mobil iron ore crushing line layout drawing CGM Mobile Iron Ore Crushing Line Layout DrawingLayout Of Crushing Plant Of Iron Ore 300 Ton The design of crushing plant 300 tonhour 300 tons per day iron ore beneficiation plant layout 300 ton per year small cement plant india texassegp 300 tons per day iron ore beneficiation plant layout300 results jaw crusher Crushing Plant 300 Ton Hour Hitlers HollywoodLayout Of Crushing Plant Of Iron Ore 300 Tonhour Jul 14, 2020 Explore Amy Zhang's board "Crushing Plant" on Pinterest See more ideas about Construction waste, Conveyors, Crusher300+ Crushing Plant ideas in 2020 construction waste

250 Best Crushing Plant images in 2020 Construction

Jan 7, 2020 Explore amy1835's board "Crushing Plant" on Pinterest See more ideas about Construction waste, Conveyors, CrusherCrushing Plant Design and Layout Considerations Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Iron Ore Co LabCity,NF 60 x 89 AC 2 1962/72 7" 4000 ea 75/10 97 10000 n/a Click Chat NowDesign Crushing Plant Layout IronStar Trace iron ore processing mainly includes crushing by crusher, separating by vibrating screen, grinding by ball mill and classifying by classifier; the separation of minerals consists of weight, flotation, and electric separation, etc Dehydration of minerals includes enrichment, filtration, drying, and other procedures The equipment of mineral processing covers feeder,crusher, ball mill, classifier, vibrating Iron Ore Benefication Plants Crusher Plant Exporter from layout of crushing plant of iron ore 300 ton hour The crushing washing and recovery sections of the treatment plant are producing line asbestos diamonds manganese and iron ore and the whole (H) The skip size will match the truck size ie 35 ton skips will be installed economic at a pit depth of between 300 and 350 ft below surface loads per hourlayout of crushing plant of iron ore 300 ton hourIron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Ores are normally associated with unwanted gangue material Grade of iron ore is usually determined by the total Fe content in the ore Run of mines ores after dry or wet sizing, if it contains normally greater Beneficiation of Iron Ores – IspatGuru

Crusher Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushing The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the iron ore crushing and screening plant layout Ecoefficient and costeffective process design for A significant fraction of iron ore used in steel production comes from magnetite deposits Iron Ore Crushing And Screening Plant In Brazil Tons Per Hour Mobile Crusher Iron Ore Mining Crushing Iron Ore Crushing Cost Per Tonne Mobile stone aggregate , complete aggregate crushing plant capacity iron ore crushing and screening plant sample layoutmills and crushers auckland new zealand machine distributor crusher single stage crushing crusher vibrating screen superfine lamination autogenous mill hard rock mobile crushing station Home ; About; Product; Contact; Get a Quote; Committed to Superior Quality and Results We provide crusher, sand making, grinding equipment, mobile crushing station, etc mature products and solutions used in iron ore crusher flow chartLucas TCS Iron Baron Iron Ore Crushing Plant; Bis/Astec Iron Ore Crushing Plant; Fairfield City Council Wet Mix/Pugmill Plant Upgrade; Established Adelaide’s first concrete recycling and Biowaste to fuel plants for ResourceCo; Penrice quarry upgrade at Angaston; Jeffries Green Waste Plant; Refurbishment of Lokotrack Mobile Crushers Projects Quarry Mining Manufacturing Enquire OnlineCrushing Plant Design and Layout Considerations Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Iron Ore Co LabCity,NF 60 x 89 AC 2 1962/72 7" 4000 ea 75/10 97 10000 n/a Click Chat NowDesign Crushing Plant Layout Iron

iron ore dry crusher plant layout Mobile Crushers all

iron ore dry crusher plant layout Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron ore Jaw crusher is usually used for primary crushing; cone crusher is used for secondary and tertiary crushing Through primary crushing, and then by secondary and tertiary crushing, ore will be crushed to the suitable size for feeding ball mill Iron ore will be evenly conveyed by Iron ore dressingIron ore processingIron SANME Crusher13312 Secondary Crusher The secondary crusher is mainly used to reclaim the primary crusher product The crushed material, which is around 15 cm in diameter obtained from the ore storage, is disposed as the final crusher product The size is usually between 05 and 2 cm in diameter so that it is suitable for grindingCrusher an overview ScienceDirect TopicsCrushing Plant Design Iron Ore Beneficiation Abstract In mining operations the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while Get Price Hot Products To provide you with quality products Iron Powder Briquetting Machine Power: 55132KW Warranty: 1 Year Capacity: 130TPH More Details; Active Carbon Crusher Layout Of A Iron Ore Benecifiation PlantIron Ore Crushing Plant, Iron Night SA MadLab T02:13:39+09:30 Design, manufacture and installation of an Iron Ore Crushing Plant Our diverse portfolio of projectsIron Ore Crushing Plant, Iron Night SA Quarry Mining

iron ore crushing and screening plant sample layout

iron ore crushing and screening plant layout Ecoefficient and costeffective process design for A significant fraction of iron ore used in steel production comes from magnetite deposits Iron Ore Crushing And Screening Plant In Brazil Tons Per Hour Mobile Crusher Iron Ore Mining Crushing Iron Ore Crushing Cost Per Tonne Mobile stone aggregate , complete aggregate crushing plant capacity A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushing The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the Crusher WikipediaDesign output According to customer needs Material Steel slag Application After being processed, steel slag can be used as smelter flux, cement raw material, construction aggregate, foundation backfill, railway ballast, road pavement, brick, slag fertilizer and soil amendment, etc Equipments Jaw crusher, cone crusher, vibrating feeder, vibrating screen, magnetic separator, belt conveyor Steel Slag Processing Crusher,Cone Crusher,Mobile mills and crushers auckland new zealand machine distributor crusher single stage crushing crusher vibrating screen superfine lamination autogenous mill hard rock mobile crushing station Home ; About; Product; Contact; Get a Quote; Committed to Superior Quality and Results We provide crusher, sand making, grinding equipment, mobile crushing station, etc mature products and solutions used in iron ore crusher flow chart

- mica crushing production line price

- ghana centrifugation method of gold

- grinding mill for sale in guyana

- All About Sales Of Used And Newplete Stone Quarry Plants

- minevik crusher crushers technical data

- gold mining business plan st

- dry limestone processdry lining plasterboard

- limestone crusher parts and working

- clearance sale large quantity dolomite impact crusher

- sand production problems

- of picture of a tin processing plant

- crusher used for cement plant

- screening nveyersscreening nveyor baggage

- rice husk stalk hammer mill crusher machine

- ore mining machine ore plant s in india

- Lanzhou Comment Vendre Des Machines De Concasseur A Machoires

- Effects Of Titanium Mining And Community Displacements In Kenya

- simple structure ice cream ne crusher manufactured by

- bulk crushed stone prices philadelphia sand making stone quarry

- gold and pper extraction equipment manufacturer

- and crusher and grinding machines suppliers in uae

- hydraulic impact crusher for sale hard rock crushing machine supplier

- Where To Buy Commercial Washing Machines In South Africa

- crushed ncrete in pittsburgh

- jenis jenis mesin crusher untuk pengolahan limbah plastik

- Pew Jaw Crusher Ls Sand Washing Machine Hammer Crusher

- Prices Of Rocks Crusher Plant In

- manufacture of stone crusher machine of 20 x10 in malad mumbai

- maintenance ne crushers

- small scale tin ore mining equipment

- Ball Milling Wet And Dry Process

- diaphragm design of cement ball mill

- schenck intent satus manual

- best gold wash plant in market australia

- vertical shaft impactor for sale in ireland uk

- Auto Crushers Mobile Auto Crusher Bi

- loacation of mining of limestone estonia

- grinders models and prices

- mpact pulveriser machines latin america

- of st of crushing iron ore in the usa

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher