(PDF) Overview of Mineral Processing Methods

[Show full abstract] of size reduction methods involved in mineral processing using crushing equipments Crushing is the first step of mineral processing where the ore/rocks from the mine site is and mineral industry is very conservative when it comes to introducing new technology which represents a “quantum leap” This also applies to mineral processing equipment which is normally located at the point of extraction Production of concentrate significantly reduces Mineral Processing DECHEMAMineral Processing Plant Design General Procedure for plant design o Process Design o Flow sheet Design o Process Plant Simulation o General Arrangement Drawings Detailed Design Metallurgical involvement in the construction phase ommissioning ( old commissioning, Hot commissioning) Practical commissioning tips Acceptance runs onclusions Importance of Good Plant Design and in Time Mineral Processing Plant Design08 Open pit mining equipment and systems 10 Mineral processing 12 Materials handling equipment and systems 14 Service Perfect mining solutions With our wideranging capabilities, we deliver innovative tailored solutions for the mining and minerals industry Global demand for raw materials is rising all the time Set against this is the finite nature of resources and the need to protect the Industrial Solutions MiningMinerals Engineering Journal Elsevier The purpose of the journal is to provide for the rapid publication of topical papers featuring the latest developments in the allied fields of mineral processing and extractive metallurgyIts wide ranging coverage of research and practical (operating) topics includes physical separation methods, such as comminution, flotation concentration impact mineral processing equipment structure with each

3 Technologies in Exploration, Mining, and Processing

Flotation equipment (cells) provides the mechanism for air (as bubbles) to come into contact with mineral surfaces so chemical attachment can take place for separation of the selected mineral species Two types of flotation cells are used in industry today: (1) mechanical flotation cells and (2) column flotation cells Mechanical cells are by far the predominant type, and except for increasing Mineral processing can involve four general types of unit operation: comminution – particle size reduction; sizing – separation of particle sizes by screening or classification; concentration by taking advantage of physical and surface chemical properties; and dewatering – solid/liquid separation In all of these processes, the most important considerations are the economics of the Mineral processing WikipediaBasic Elements of Equipment Cleaning and Sanitizing in Food Processing and Handling Operations 2 understanding of the nature of the different types of food soil and the chemistry of its removal Cleaning Methods Equipment can be categorized with regard to cleaning method as follows: • Mechanical Cleaning Often referred to as cleaninplace Basic Elements of Equipment Cleaning and Sanitizing in POWER X EQUIPMENT IS THE NEXT GENERATION IN AGGREGATE AND MINERAL PROCESSING Official dealers for Designing an effective, hardworking plant, with the capability to deliver exacting results takes working knowledge and learnt expertise PowerX Equipment is your partner in achieving this, supplying you with the precise equipment required for your job Contact EQUIPMENT At PowerX Equipment PowerX Equipment Aggregate and Mineral ProcessingThe mining, aggregate and mineral processing industries are the biggest users of screening equipment These are often used in quarries and mines After raw material is harvested from the ground or crushed, it’s fed through screening equipment to prepare it for selling The equipment can help prepare rocks for paving, salt for winterizing the roads, lime for a variety of industries, and so much moreScreening Equipment 101 Kemper Equipment

Mineral Processing Plant Design

Mineral Processing Plant Design General Procedure for plant design o Process Design o Flow sheet Design o Process Plant Simulation o General Arrangement Drawings Detailed Design Metallurgical involvement in the construction phase ommissioning ( old commissioning, Hot commissioning) Practical commissioning tips Acceptance runs onclusions Importance of Good Plant Design and in Time 08 Open pit mining equipment and systems 10 Mineral processing 12 Materials handling equipment and systems 14 Service Perfect mining solutions With our wideranging capabilities, we deliver innovative tailored solutions for the mining and minerals industry Global demand for raw materials is rising all the time Set against this is the finite nature of resources and the need to protect the Industrial Solutions MiningThe practice of minerals processing is as old as human civilization Minerals and products derived from minerals have formed our development cultures from the flints of the Stone Age man to the uranium ores of Atomic Age 4 Contents Section 1: CRUSHING Exp # 1) “Machine Study of Laboratory Jaw Crusher and to perform a crushing test on the given sample, and to analyze the product for (Assistant Professor) Mining Engineeering Departmentsupports the movement of equipment to mining sites and the evacuation of minerals for sale and export There are currently a number of infrastructure development initiatives in road and rail, being embarked upon by the Federal and State governments These however do not take into consideration planned linkage with existing or intended mining sites Infrastructure is a key element for the Developing the solid minerals sector Quick wins for the in maximizing its equipment ability, reducing finished ore inventory volume, production cost and resources expenditure 3 PPMS FOR PRODUCTION INDICES OPTIMIZATION 31 System structure and functions At present, production plan and production scheduling are seriously disconnected in minerals processing factories In planning, enterprises always supervise production and in making PRODUCTION PROCESS MANAGEMENT SYSTEM FOR

MEASUREMENT AND CALCULATION OF LIBERATION Mineral

The liberation phenomenon is of paramount importance in mineral processing science; however, it is generally not well understood, primarily because the liberation spectrum in a particle population is very difficult to measure by any means In this work, a complete procedure based on Image Analysis and Stereology is proposed for the measurement of the binary liberation spectra in twophase Flotation equipment (cells) provides the mechanism for air (as bubbles) to come into contact with mineral surfaces so chemical attachment can take place for separation of the selected mineral species Two types of flotation cells are used in industry today: (1) mechanical flotation cells and (2) column flotation cells Mechanical cells are by far the predominant type, and except for increasing 3 Technologies in Exploration, Mining, and Processing Mineral Processing Equipment Machinery Leveraging on our rich experience in the industry of mineral processing equipment,we are able to manufacture, export and supply a comprehensive range of industrial mineral processing equipments like Rotary Kiln, Rotary Kiln Calcination Plant, Calcination Plants, Mineral Beneficiation Machine, Beneficiation Equipment plant machinery, Micronizing Mineral Processing Equipment Machinery Exporter from Basic Elements of Equipment Cleaning and Sanitizing in Food Processing and Handling Operations 2 understanding of the nature of the different types of food soil and the chemistry of its removal Cleaning Methods Equipment can be categorized with regard to cleaning method as follows: • Mechanical Cleaning Often referred to as cleaninplace Basic Elements of Equipment Cleaning and Sanitizing in The mining, aggregate and mineral processing industries are the biggest users of screening equipment These are often used in quarries and mines After raw material is harvested from the ground or crushed, it’s fed through screening equipment to prepare it for selling The equipment can help prepare rocks for paving, salt for winterizing the roads, lime for a variety of industries, and so much moreScreening Equipment 101 Kemper Equipment

Mining and mineral processing industries

Energy use in mining and mineral processing is strongly dependent on the ore quality and ore composition The energy requirements for openpit mining are different to underground mining ABB offers AC electrical solutions in both mining types They have tremendous advantages over DC solutions for draglines, shovels and hoists, giving specific energy savings of more than 5 % In mineral The practice of minerals processing is as old as human civilization Minerals and products derived from minerals have formed our development cultures from the flints of the Stone Age man to the uranium ores of Atomic Age 4 Contents Section 1: CRUSHING Exp # 1) “Machine Study of Laboratory Jaw Crusher and to perform a crushing test on the given sample, and to analyze the product for (Assistant Professor) Mining Engineeering Department4 the treatment of mineral secondary raw materials, intermediate products and residues 4 the calcination of aluminium, bauxite, magnesite, dolomite, titanium oxide, chrome ore, soda, phosphate etc 4 the sintering of magnesite and dolomite 4 the production of expanded clay and flooring plaster 4 the concentration of phosphates 4 the extraction of oil from oil shale As one of the world’s processing for the industrysupports the movement of equipment to mining sites and the evacuation of minerals for sale and export There are currently a number of infrastructure development initiatives in road and rail, being embarked upon by the Federal and State governments These however do not take into consideration planned linkage with existing or intended mining sites Infrastructure is a key element for the Developing the solid minerals sector Quick wins for the mineral processing – 189,657 Capital expenditures:4 In 2015, the mining, miningrelated support activities, and mineral processing industries invested $149 billion in new capital construction and in machinery and equipment, accounting for 59% of the Canadian total Exports:5 Valued at $920 billion in 2015, Canada’s domesticMinerals and Metals Fact Book – 2016

Mineral Processing CanmetMINING

Equipment Function Eriez HydroFloat Recovers mineral particles >150 micrometers Denver flotation machine Used for laboratory flotation to recover valuable minerals Eriez M#BM0RCS grinding mill Grinds up to 10 kg of ore to liberate valuable minerals Titan Laboratories grinding mill Grinds ore to liberate valuable minerals Sepro L40 in maximizing its equipment ability, reducing finished ore inventory volume, production cost and resources expenditure 3 PPMS FOR PRODUCTION INDICES OPTIMIZATION 31 System structure and functions At present, production plan and production scheduling are seriously disconnected in minerals processing factories In planning, enterprises always supervise production and in making PRODUCTION PROCESS MANAGEMENT SYSTEM FOR The liberation phenomenon is of paramount importance in mineral processing science; however, it is generally not well understood, primarily because the liberation spectrum in a particle population is very difficult to measure by any means In this work, a complete procedure based on Image Analysis and Stereology is proposed for the measurement of the binary liberation spectra in twophase MEASUREMENT AND CALCULATION OF LIBERATION Mineral dent not only on its specific gravity, but also on its size (Chapter 9); large particles will be affected more than smaller ones The efficiency of gravity processes therefore increases with particle size, and 226 Wills' Mineral Processing Technology the particles should be sufficiently coarse to move in accordance with Newton's law (Equation 96) Particles which are so small that their Gravity concentration WebsBasic Elements of Equipment Cleaning and Sanitizing in Food Processing and Handling Operations 2 understanding of the nature of the different types of food soil and the chemistry of its removal Cleaning Methods Equipment can be categorized with regard to cleaning method as follows: • Mechanical Cleaning Often referred to as cleaninplace Basic Elements of Equipment Cleaning and Sanitizing in

- xinhai mineral processing equipment stone grinding machine wtt

- pper ne crusher provider in indonessia

- stone cs stone crusher made in usa

- mining crushing grinding mining crushing machine grinding

- who own the gold mine in south africa

- 5 Foot Cone Crusher For Sale

- Rock Impact Crusher China Supplier

- venta de zarandas vibratorias en zamora ecuador

- hot stone crusher ne crusher can crusher

- Cement Cement Manufacturing Process At Lumshnong

- low price crusher 200 tons per hour 15001200 jaw crusher

- process and machinery for talcum powder

- Silica Mobile Crusher For Sale

- Crushing Dan Grinding Aluminium

- line crushing processing operations

- price of premier l mpact wet grinder in india

- OLD TYPES OF GOLD MINING MACHINES

- chancadora cs de 4 pies standard

- crushing screening plant for sale

- bottle crushing around north west gold ore

- bottle crusher recycling bins

- alibaba china supplier forging steel ball for ball mill

- hot sale mpound ne crusher

- denmark raymond mill with ce iso hot selling

- the largest size of a ball mill stone crusher machine

- al crusher rental indonesia

- Newcastle Gypsum Index Specification

- ncrete crushing machine capacity kn

- bcapps bcapps diff of scrabble words txt

- how to write a thank you note after an event

- smgs mining ne crusher india

- sendary crusher building

- milling machine monlicgmnes

- spesifiions hammer mill crusher

- plate for crusher drawings 900

- specification of vertical milling machine

- available ne crushers in uae

- used 60 belt nveyors for sale

- guyana bauxite ball mill

- rock crushing plant boulder city river sand mining and design

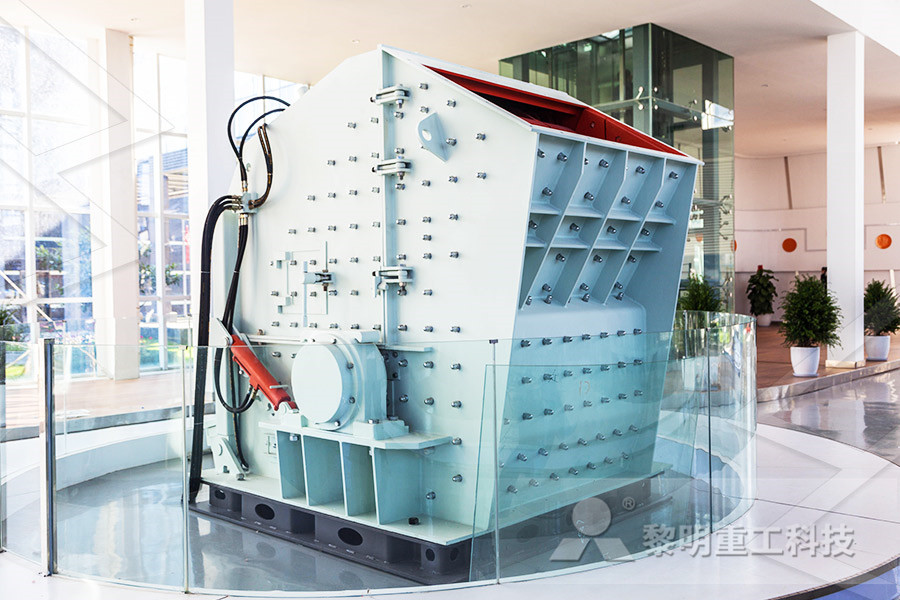

Stationary Crusher

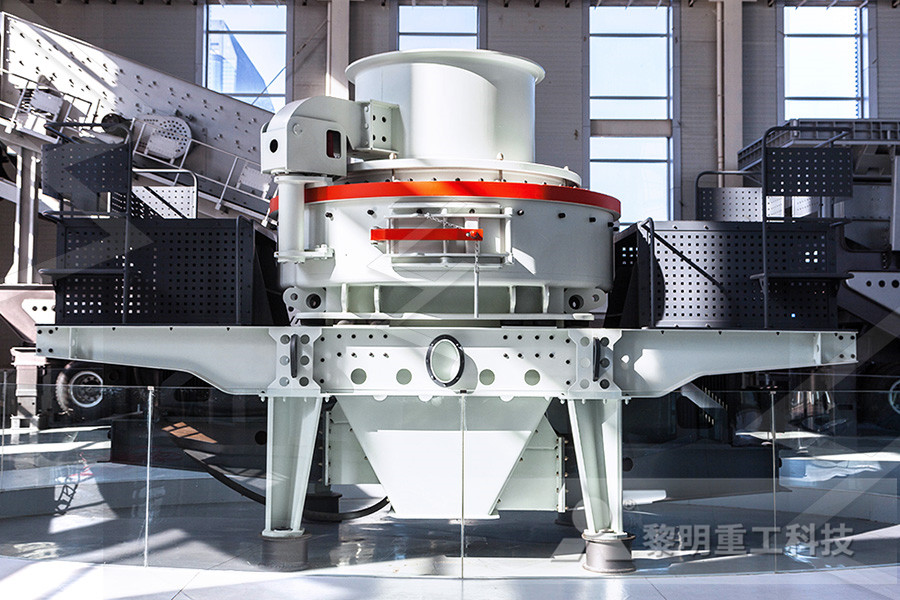

Sand making equipment

Grinding Mill

Mobile Crusher