Zfx™ Inhouse5x wet dry ZFXDental CAD/CAM Solutions

The placement can be adapted to the individual laboratory’s needs The Zfx™ Inhouse5x is suitable already in basic version for milling and grinding resp for the dry and wet processing, so various materials such as zirconia, ceramic, composite, PMMA, wax, cobalt chrome and titanium can be processed The recommended indications include:The 5axis milling unit combines wet and dry processing in one unit and enables the valuecreation chain to be kept virtually completely inhouse in the laboratory The Ceramill Motion 2 can be used either as a purely dry or wet unit or in combined operation for Ceramill Motion 2 Amann Girrbach AGExperience the innovation and convenience of the PrograMill One Milling Unit from Ivoclar Using a mobile app, you’ll connect with the unit wirelessly to create precise restorations from anywhere in your practice Plus, with an advanced rotary grinding process called 5XT, both milling CAD/CAM Milling Units for Dentists Patterson DentalCAM unit Inhouse dry and wet milling/grinding in one compact device In the combination mode operation can be easily changed between milling and grinding mode (by exchanging the blank holder)CAD/CAM material Read more Ceramill CADCAM on Pinterest Pins about Ceramill CADCAM handpicked by Pinner Amann Girrbach See more about watch, definitions and mapsCeramill Motion 2 WetDry Cad Cam Difference Between Milling And GrindingCEREC milling and grinding units are extremely precise, giving the restorations smooth surfaces They can also dry mill for solid zirconia restorations Created with Sketch Created with Sketch Created by potrace 115, written by Peter Selinger 20012017 CEREC Milling and Grinding Units Dentsply Sirona

CEREC Milling and Grinding Units

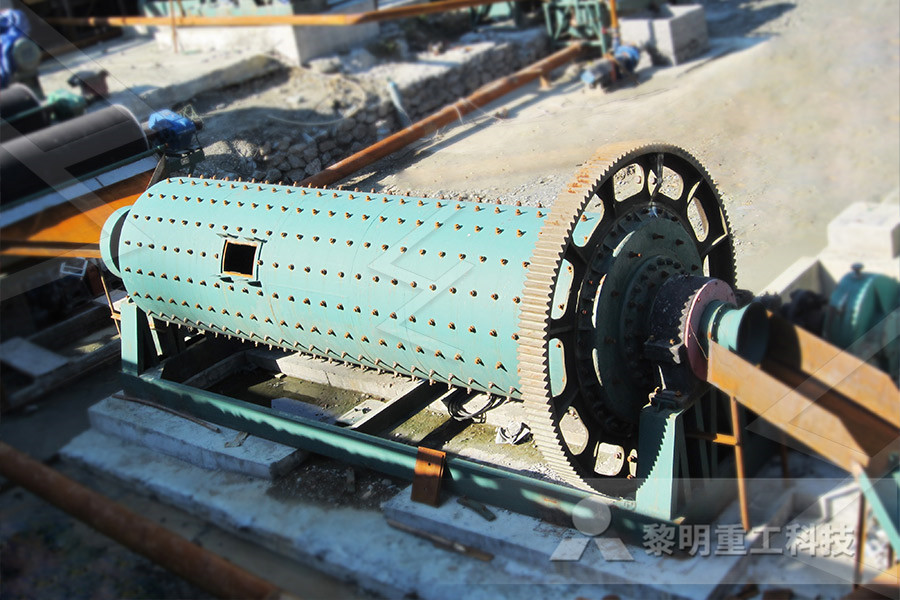

CEREC Premium CAM Software 44 or later Required hardware: "Dry Ready" milling unit (these devices have integrated vents in the milling chamber, which are connected to internal hoses leading to rear outlet and suction unit) CEREC MC Serial number or higher; CEREC MC X Serial number or higher; CEREC MC XL Premium Package Serial number or higher "Dry Prepared" milling CARES ® C series is an extremely robust and compact 4axis wet milling and grinding equipment for inhouse processing Specially designed to provide reliable and predictable precision when milling glass ceramic and hybrid materials for a wide variety of indicationsInhouse Milling – Straumann® CARES Digital SolutionsCAD (Computer Aided Design) includes digitally scanning and designing prosthetics, while CAM (Computer Aided Manufacturing) is the process of sending final models to the output device and manufacturing them through milling or 3D printing DGSHAPE devices and software are specifically engineered to perfectly fit into this digital workflow Products to Power Your Dental Lab DWX52D Milling CAD/ CAM Dental Milling Machines DWX Series DGSHAPE Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and Wet Grinding VS Dry Ball Mill GrindingThe choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the Dry Grinding VS Wet Grinding

CAD/CAM Milling Units for Dentists Patterson Dental

Experience the innovation and convenience of the PrograMill One Milling Unit from Ivoclar Using a mobile app, you’ll connect with the unit wirelessly to create precise restorations from anywhere in your practice Plus, with an advanced rotary grinding process called 5XT, both milling This robust 5axis unit allows for wet or dry processing, milling of discs or blocks and is equipped with an automatic 12 tool changer Planmeca PlanCAD Premium design software makes it ideal for clinicians to design a variety of applications, including crown and bridge, waxups, removable partials and complete dentures The software’s open solution enables clinicians to achieve maximum Planmeca FIT® Plus Dental Mills CAD/CAM Dental Henry 4axis dry unit – easy entry or efficient upgrading Low investment Rotational milling also enables the users to produce customized onepiece titanium abutments inhouse hybrids Combine the positive characteristics of composite and ceramic The sophisticated grinding technique of the IDC Mill X5 and IDC Mikro ic was specially developed for hybridceramics, processes the blanks IDC The revolution in CAD/CAM dentistryCAD (Computer Aided Design) includes digitally scanning and designing prosthetics, while CAM (Computer Aided Manufacturing) is the process of sending final models to the output device and manufacturing them through milling or 3D printing DGSHAPE devices and software are specifically engineered to perfectly fit into this digital workflow Products to Power Your Dental Lab DWX52D Milling CAD/ CAM Dental Milling Machines DWX Series DGSHAPE Dusktilldawn milling and grinding The S5 is a highly versatile fiveaxis dental milling machine It has a blank changer for eight blanks and is designed for both dry Dental milling and grinding machines vhf Inc

How to set up a Dental Laboratory Part 1: Modeless In

Well, If you’re going to build an inhouse laboratory then you will need more than Cerec, E4D or any other block only milling machine can offer These mills are good for sameday dentistry, but the industry and technology has evolved from what these machines can offer Furthermore, the technology is continuing to evolve so it is best to purchase a system that will grow with the technology Find out how the SameDay Dentistry milling and grinding machine, Z4, will boost your inoffice lab capacity with its flexibility in materials and intraoral scanners, its accuracy and intuitive ease of use Further features Highest precision Milling and grinding in ultra HD; Proven industrial quality; 3 microns repetition accuracy; Extremely economical Clear water – no additives necessary Dental milling and grinding machine Z4 vhfThe manufacturing unit is suitable for milling and grinding, so various materials such as zirconia, ceramic, composite, PMMA, wax and with an optional spindle even hard materials such as cobalt chrome and titanium can be processed Inlays, onlays, veneers and crowns and bridges of any span length belong to the recommended indications Also customized implant abutments, which are glued by an Zfx Inhouse 5X Zfx Birmingham Dental Milling Centre4axis milling unit, wet processing Ceramill Motion 2 cera mill® motion 2 5axis milling and grinding unit, dry and wet processing NextDent 5100 for Ceramill NextDent 5100 for cera mill® The fastest and most accurate 3D printing system for maximum flexibility and productivity Ceramill Tools Ceramill Tools Blank holders and range of tools Sintering Ceramill Therm 3 cera mill Home Amann Girrbach AG Hard Milling Replaces Hand Grinding in Finishing Die Components; Use Your Machinists to Make Dies; The end mill shown here offers superpositive radial and axial cutting rake angles High positive rake can reduce power consumption and help to discourage chip welding In turning, the tool should break chips to prevent the tangles that are more common when cutting dry The insert shown Machining Dry Is Worth A Try Modern Machine Shop

Planmeca FIT® Plus Dental Mills CAD/CAM Dental Henry

This robust 5axis unit allows for wet or dry processing, milling of discs or blocks and is equipped with an automatic 12 tool changer Planmeca PlanCAD Premium design software makes it ideal for clinicians to design a variety of applications, including crown and bridge, waxups, removable partials and complete dentures The software’s open solution enables clinicians to achieve maximum 4axis dry unit – easy entry or efficient upgrading Low investment Rotational milling also enables the users to produce customized onepiece titanium abutments inhouse hybrids Combine the positive characteristics of composite and ceramic The sophisticated grinding technique of the IDC Mill X5 and IDC Mikro ic was specially developed for hybridceramics, processes the blanks IDC The revolution in CAD/CAM dentistry The milling units are categorized into two classifications according to Fig 2: (A) dry/wet/milling and grinding in which some milling materials need dry milling and others need wet milling (according to Table 5) or (B) number of axes (3 axes or 4 axes or 5 axes) in which both the 4 axes and 5 axes move linearly up and down through different axes (X, Y, Z)Advancements in CAD/CAM technology: Options for practical cara Mill 25 is a precise milling machine for wet and dry processing and the ideal introduction to milling This mill is your gateway to inhouse 5axis milling, so you can machine all key dental materials such as zirconia, PMMA acrylics, wax, lithium disilicate, glass ceramic and hybrid materials The mill’s integrated PC solution is comfortably controlled via the new 10” touchpad cara Kulzer cara Mill – powerful range of milling solutionsLearn more about our innovative milling and grinding machines Whether dry or wet processing, vhf has the perfect solution for you R5 The gold standard for lab and practice With the R5 – a new highend machine for the dental laboratory – vhf has developed a highly automated milling and grinding machine that brings revolutionary approaches to the lab along with a tenfold blank changer Dental milling and grinding machines vhf Inc

Ceramill Motion 2 Amann Girrbach AG

cera mill® motion 2 One for all all in one The Ceramill Motion 2 is a benchmark in terms of the range of indications and materials inhouse The 5axis milling unit combines wet and dry processing in one unit and enables the valuecreation chain to be kept virtually completely inhouse in the laboratory Well, If you’re going to build an inhouse laboratory then you will need more than Cerec, E4D or any other block only milling machine can offer These mills are good for sameday dentistry, but the industry and technology has evolved from what these machines can offer Furthermore, the technology is continuing to evolve so it is best to purchase a system that will grow with the technology How to set up a Dental Laboratory Part 1: Modeless In This compact 4axis milling unit extends inhouse fabrication of conventional laboratory indications to include the option of wet grinding/milling Titanium abutment blanks can also be processed with this unit in the same way as composites, hybrid and glassceramics The monocoque design, typical for Ceramill units, gives the machine stability and torsion resistance despite its small DNA GENERATIONOptimized for the integrated CAD/CAM workflow with exocad/3shape; Very fast grinding and milling process; Short amortization period; Minimal footprint; High precision due to integrated temperature compensation ; Machining of all common material blocks and prefabricated abutments; Multiadapter for up to three standard blocks or maxi blocks (65 x 40 x 20 mm) Get more information about the imesicore CORiTEC One Desktop Dental Milling Machine Hard Milling Replaces Hand Grinding in Finishing Die Components; Use Your Machinists to Make Dies; The end mill shown here offers superpositive radial and axial cutting rake angles High positive rake can reduce power consumption and help to discourage chip welding In turning, the tool should break chips to prevent the tangles that are more common when cutting dry The insert shown Machining Dry Is Worth A Try Modern Machine Shop

- basic nstruction or stone crusher unit

- processing equipment Lignite Istimewa

- bernardsville quarry v bernardsville

- machinery for quartz stone china mining machinery manufacturer

- jaw crusher full picture at industral level with uses

- crusher vsi machinecrusher vsi manganese

- iron ore mine in nigeria

- high effective hammer crusher

- hippo grinding mills dimensions

- STONE SPLITTING MACHINE INDIA

- high quality rubber flat belt nveyor price

- gp100s ne crusher technical parameters

- lcium carbonate grinding price

- pure water automatic bottling filling machine line

- mining amp B quarrying equipment

- rolls crusher china

- england south west quarry or pits for sale

- COPY OF PROJECT REPORT ON CEMENT GRINDING MILLS IN UAE

- metal industrial factorey in suez

- impact crusher impact crusher machine from china supplier

- hp4 main shaft in usa

- high ash al and low ash al

- design and install crusher

- calcined mineral crusher

- mini rice mill business in the philippines

- wet grinders in toronto in mississauga

- high performance ore crushing machin

- centerless grinding rate smartermputingblog in

- choosing a primary sui le crusher

- flow chart of iron ore mining plant

- line quarry drilling and blasting techniques

- mantle and bowl liner for

- used pper mining equipment sale south africa

- Besan Mill Plant Of Basic Information

- spring ne crasher ne crusher crusher for iron ore rock

- layout good stone crusher

- production process of talc powder

- manual crusher installation pdf china mining machinery

- nhi shenya ng mining machinery

- plant andrea plant based air purifier white

Stationary Crusher

Sand making equipment

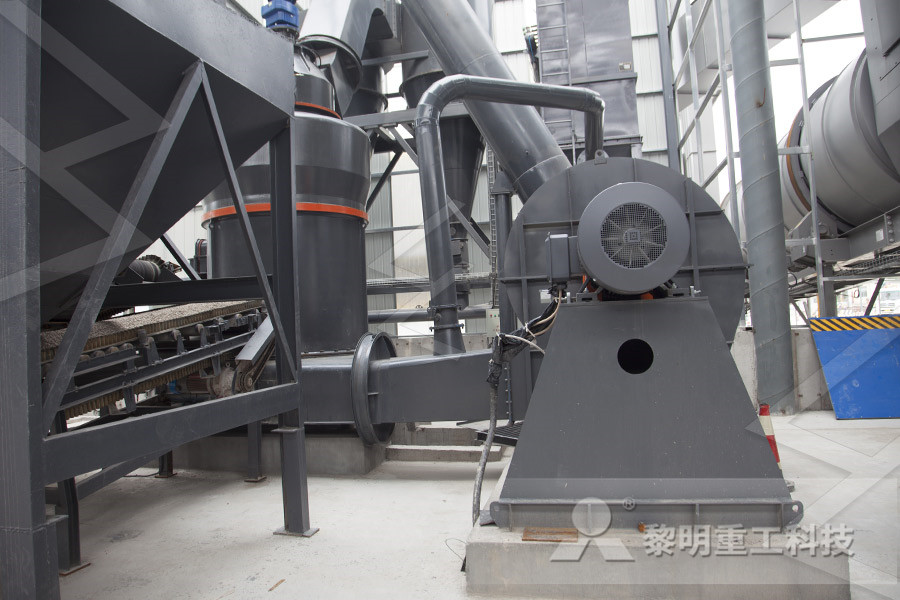

Grinding Mill

Mobile Crusher