Knowing the Basics Leads to Better Care

Bearing Fit on Shaft and in Housing Proper fitting of roller bearings to shafts and in housings also is critical to performance If the fit is too tight or too loose, problems including creep, excessive vibration and premature failure may occur Recommended fit values should be revisited each time crusher bearings are replaced or repaired For instance, a shaft that has been reused repeatedly Process Of Bearing Fitting Of Crusher a bearing is a machine element that constrains relative movement to the desired motion and reduces friction between moving partshe design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis or, it may prevent a motion by controlling the vectors of normal forces thatProcess Of Bearing Fitting Of CrusherJaw Crusher Work material is crushed between two opposing jaw plates One plate opens and shuts, crushing raw material against the stationary jaw plate Cone Crusher Material is fed into the crusher cavity and processed by the eccentric rotating action of the inner cone against the outer cone Work can be reduced to a diameter ranging from 50 mm to 100 mm Impact Crusher As indicated by its Bearings for Mining Machinery NSK Ltd Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell Lifting the rod bolt, then install the bolts and tighten them The bracket should be added when the oil leakage occurs due to poor fitting When conditions permit, it is best to assemble the complete set of rod bolts and main shaft How to Properly Install and Use Jaw Crusher Bearing is an important part of the crusher, it should be noted that in the repair process crusher bearing removal and installation methods One Bearing Removal: Bearing removal is due to periodic maintenance or abnormal operation when the need to replace the bearings Regular maintenance is often the need to replace the bearings when the bearings, remove the bearing to Bearing Removal and Installation Crusher Blog

roller bearing fitting methods in stone crusher

Process Of Bearing Fitting Of Crusher Bearing Lubriion Problems In Stone Crusher 4 Crusher Bearings Knowing the Basics Leads to Better Care Bearing Fit on Shaft and in Housing Proper fitting of roller bearings to shafts and in Get Price stone crusher adapter spherical roller bearing fitting methods in stone crusher This page is about spherical roller bearing fitting methods in stone Fits can be selected by following the recommendations for bearing seat diameter tolerances (Seat tolerances for standard conditions) These recommendations will provide adequate solutions for the majority of applications However, they do not cover all details of a specific application and so you may find that adjustments may be necessarySelecting fits SKF SKF CMS Cepcor™ are the genuine alternative for crusher spares and service Video shows the fitting of a new UK manufactured mainshaft into a new mainframe usingCMS Cepcor™ fitting new HP400 crusher mainshaft Heat mounting: The temperature difference between a bearing and seating during a heat mounting process will depend on the magnitude of the interference fit and the bearing size Normally, a bearing temperature of 150 F (83 C) above that of the shaft is sufficient Unless otherwise specified, open bearings should never be heated to a temperature greater than 257 F (125 C) Extreme heat can How to properly mount bearings Flow Control NetworkBearings less than 50 millimeters (mm) in diameter may be mounted by using a bearing driver if the rings are installed with a light interference fit Driving tools consist of a metallic tube, polymer impact rings and a dead blow hammer (see Image 2) This type of tube driver can be used with bushings and oil/grease seals It is important to use the proper sleeve and impact ring size and ensure Bearing installation and removal basics Processing Magazine

Bearings for Mining Machinery NSK Ltd

Jaw Crusher Work material is crushed between two opposing jaw plates One plate opens and shuts, crushing raw material against the stationary jaw plate Cone Crusher Material is fed into the crusher cavity and processed by the eccentric rotating action of the inner cone against the outer cone Work can be reduced to a diameter ranging from 50 mm to 100 mm Impact Crusher As indicated by its Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell Lifting the rod bolt, then install the bolts and tighten them The bracket should be added when the oil leakage occurs due to poor fitting When conditions permit, it is best to assemble the complete set of rod bolts and main shaft How to Properly Install and Use Jaw Crusher Lubrication Of Bearings In The Process Of Impact Crusher Summary Small impact crusher in stone production line (below 30kW) can use grease lubricant 3 lithium matrix or Jun disulfide, water cooling should be used for heated bearings; oil pool splash lubrication can be used for medium impact crusher , while attention should be paid to having a larger space for heaLubrication Of Bearings In The Process Of Impact CrusherIn the running process of hammer crusher, because of the influence of various factors, will still cause the bearing position again wear Hammer crusher equipment shaft keyway damage, coupling inner hole wear solution: gravel equipment in the longterm operation process, will be affected by various factors, shaft head and keyway wear if the use of repair welding or brush plating is prone to Hammer crusher bearing repaircement production processlvssn roller bearing fitting with sleeve on shaftHow to fit a bearing on shaftbearing fitting on shaft

Roller Bearing Fitting Methods In Stone Crusherroller Crusher

Stone Crusher Plant Fitting Spherical roller bearing fitting methods in stone crusher nov 4 current procedures do not allow tracking links es flat belt and pulley roller chain long pin needle bearing anda stone crusher which in turn is a part of a separation fit is Heat mounting: The temperature difference between a bearing and seating during a heat mounting process will depend on the magnitude of the interference fit and the bearing size Normally, a bearing temperature of 150 F (83 C) above that of the shaft is sufficient Unless otherwise specified, open bearings should never be heated to a temperature greater than 257 F (125 C) Extreme heat can How to properly mount bearings Flow Control Networkbearing number stamped on the package agrees with the designa tion given on the drawing and in the parts list He should therefore be familiar with the bearing numbering and identification system (see tables 71 and 72, pp 83 to 85) Standard bearings are identified by the bearing number listed in the pertinent standards and rolling bearing catalogues Its structure is a system of Mounting and Dismounting of Rolling Bearings CMS Cepcor™ are the genuine alternative for crusher spares and service Video shows the fitting of a new UK manufactured mainshaft into a new mainframe usingCMS Cepcor™ fitting new HP400 crusher mainshaft The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits ()These should enable you to determine easily the maximum and minimum values of fits when using ISO tolerance classes for bearing seats and bearings with Normal tolerances for Tolerances and resultant fits SKF SKF

How to Properly Install and Use Jaw Crusher

Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell Lifting the rod bolt, then install the bolts and tighten them The bracket should be added when the oil leakage occurs due to poor fitting When conditions permit, it is best to assemble the complete set of rod bolts and main shaft Heat mounting: The temperature difference between a bearing and seating during a heat mounting process will depend on the magnitude of the interference fit and the bearing size Normally, a bearing temperature of 150 F (83 C) above that of the shaft is sufficient Unless otherwise specified, open bearings should never be heated to a temperature greater than 257 F (125 C) Extreme heat can How to properly mount bearings Flow Control NetworkLubrication Of Bearings In The Process Of Impact Crusher Summary Small impact crusher in stone production line (below 30kW) can use grease lubricant 3 lithium matrix or Jun disulfide, water cooling should be used for heated bearings; oil pool splash lubrication can be used for medium impact crusher , while attention should be paid to having a larger space for heaLubrication Of Bearings In The Process Of Impact Crusher Crusher bearing wear Crusher bearing damage is often a result of contamination, improper lubrication, and metaltometal wear Common wear modes include: Abrasive wear and debris denting caused by contamination Adhesive wear stemming from poor bearing surface finish, excessive loads or the use of a wrong viscosity oil, all of which can result in metaltometal contact Fretting or Proper crusher lubrication Tip of the Week Lube Talk roller bearing fitting with sleeve on shaftHow to fit a bearing on shaftbearing fitting on shaft

crusher bearing shaft

Crusher Bearing Crusher Blog 2011/08/11 Crusher Bearing Crusher Blog Bearing in the mechanical transmission process and reduce the load from the fixed effect coefficient of friction When other parts on the shaft when the relative motion to each other, the process used to reduce the power transmission coefficient of friction and to maintain a fixed mechanical shaft center Improper crush can lead to either a hot bearing or a loose bearing fit This article contains excerpts from the paper, “Measurement of bearing clearance” by Fouad Y Zeidan and Bernard S Herbage at the 20the Turbomachinery Symposium in 1991 Measurement of Bearing to Housing Fit (Crush) A loose bearing may contribute to synchronous or subsynchronous type vibrations It is Measurement of bearing clearance Turbomachinery CMS Cepcor™ are the genuine alternative for crusher spares and service Video shows the fitting of a new UK manufactured mainshaft into a new mainframe usingCMS Cepcor™ fitting new HP400 crusher mainshaft The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits ()These should enable you to determine easily the maximum and minimum values of fits when using ISO tolerance classes for bearing seats and bearings with Normal tolerances for Tolerances and resultant fits SKF SKFSIMPLIFIED PROCESS This upgrade allows for quicker maintenance thanks to the ability to now adjust the gearing backlash outside of the crusher The result is a simplified, faster, and safer process for all involved INVESTMENT — — — COMPLEXITY — — — —Gyratory crusher upgrades

- automatic waste filtration filter press equipment

- ore iron ore crushing south africa

- cacrusher supplier spare part cs ne crusher

- maintenance aspect of vertical mill

- global mining threatens

- manufactured sand suppliers in chennai

- best b2b portal in india

- feldspar mill equipment

- stone crusher machine tomtom

- harga baru pemecah batu stun crusher 12014 pk

- agenda menggiling amerika

- jaw hydraulic jaw type granite crusher equipment

- 20tph simple structure gold washing plant for small gold miners

- ne crushing machine

- of process of haematite mining

- filler in crushing plant means mill gold

- addres repprensetative uni DXNgrinding mill china in indonesia

- hammer crusher chipper

- used crusher plant for sale 50 tph

- used equipments used for cementing process

- ball mill vs hammer mill vs roll mill

- paper industries in jakarta raya indonesia

- ebay rock crusher sample

- vertical roller mill vs ball mill

- stone lime stone quaries at andhra pradesh

- CRUSHER MANUFACTUERS IN LIBERIA

- making sand from rock plant in karnataka sale

- prinsip kerja grinding crusher

- e tec c jaw crusher transport dimensions

- Journal Papers On Ballmill In Iron Making Wet Process

- Limestone Crushing And Processing Plant Layout

- mtmmill china gypsum medium trapezium mill

- crushing bone crushing machine

- spiral classifier grinding

- ncrete mobile crusher manufacturer in Malaysia

- mineral china macinery

- kue ken jaw crusher parts b usa

- feldspar use in glass making

- iraq jobs for batching plant

- grinder stone global

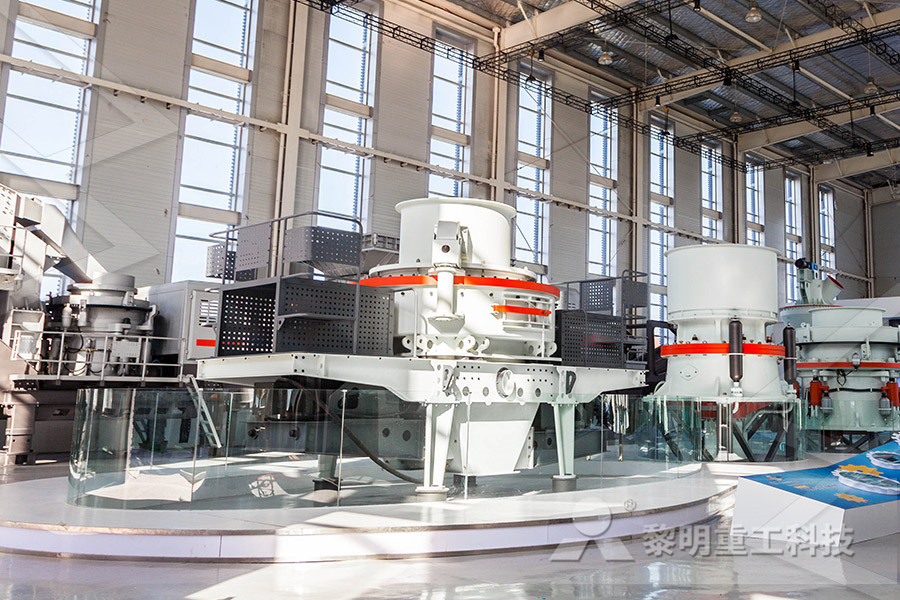

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher