Influence of fault slip on mininginduced pressure and

Physical modeling results show that, due to the combined effect of mining activities and fault slip, the mininginduced pressure and the extent of damaged rock masses in the faultinfluenced zone are greater than those in the uninfluenced zoneSlip On Mining Pressure Coupling AC Machinery is professional mineral processing equipment manufacturer in the world, not our equipment has the excellent quality, but also our product service is very thorough Crushing Equipment; Grinding Equipment; Feeding Conveying ; Screening Washing; Portable Mobile ; Beneficiation Equipment; Sand Making Machine Sand making machine is used in Slip On Mining Pressure Couplingmining; Slip On Mining Pressure Coupling; Diamond Aluminum Slip On Fittings The Diamond Aluminum Company Line of Slip On Fittings Diamond Aluminum Company slip on fittings are specially designed and engineered to eliminate pipe bending threading and welding which are costly time consuming and inconvenient One unskilled worker or home owner will frequently do in less time work Slip On Mining Pressure Coupling Isolatiewerken KVVSlip On Mining Pressure Coupling We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel Slip On Mining Pressure Couplingslip on mining pressure coupling edziennik Influence of fault slip on mininginduced pressure and optimization of roadway support design in faultinfluenced zone Since the dynamic pressure induced by the coupling effect of mining activities and fault reactivation is imposed on the original support system, DO MAGCOUPLINGS SLIP? Pump engineering EngTips Oct 07, 2011 Magnetic couplings slip on mining pressure coupling istcompazzanoxit

Slip On Mining Pressure Coupling

Slip On Mining Pressure Coupling; Slip On Mining Pressure Coupling Fittings – ReFire GroupReFire Sydney Ph: +61 2 9879 0933 E: [ protected] ReFire Newcastle Ph: +61 2 4961 1519 E: [ protected] ReFire WA Ph: +61 8 9279 9900 Chat Online Jachris Jachris Jachris is the largest supplier of specialised hose and couplings in Africa most complete solution Jachris strives to offer Slip On Mining Pressure Coupling; Online Message If you are interested in our products, or what we can do to help you, you can always consult our customer service Quick response within 30 seconds for technical advice Complete engineer dispatch within 24 hours Maintenance free of charge within 12 months from shipment Barytes beneficiation plant barite beneficiation Barytes beneficiation Slip On Mining Pressure Couplingslip on mining pressure coupling in japan Aug 01 1999 Southwest Japan is the region where the Amurian AM plate or the Eurasia EU plate the Philippine Sea PH plate and the Okhotsk OK plate or the North American NA plate interact with each other The plate motion in southwest Japan especially the eastward motion of the AM plate has been debated by many researchers eg Zonenshain and Savostin slip on mining pressure coupling in japanHome > slip on mining pressure coupling Pipeline Repair Fittings Couplings Manufacturer JCM enspenspEmergency service is our profession – JCM welcomes all opportunities to provide the solution to the problem – low pressure, high pressure, large diameter and exotic pipe contoursslip on mining pressure couplingNow let’s demonstrate on some of the uses of fittings on a pressure washer hose connector Pressure Washer Quick Connect Fittings; You can turn an m22 pressure washer hose connection into a QC using a single fitting Insert an m22 male thread into a 3/8″ female QC socket After that, attach the male QC plug to your pump outlet In this way, you will be able to connect a highpressure hose Pressure Washer Hose Fittings+Coupler+Adapter Guide 101

Influence of fault slip on mininginduced pressure and

With the influence of the two faults, several accidents occurred in the process of mining and are summarized as follows: (1) Since the presence of faults could weaken the roof and ribs of roadway, the sudden and severe roof collapse have taken place for many times; (2) Since the dynamic pressure induced by the coupling effect of mining activities and fault reactivation is imposed on the MINING HOSE AND COUPLINGS You work hard Your hoses should too Gates industrial mining hoses are engineered to handle your heavyduty, high pressure applications, with oil and abrasion resistant designs Whether you need a high temperature air hose for your pneumatic mining and drilling jobs or a maximum flexibility, durable premium hose for your severe working conditions and materials Mining Hose and Couplings Gates CorporationThese are the highest quality slip lok fittings on the market They are NOT Chinese imports As an alternative to using the 3/8″ nylon tubing as a feed line, we also offer a 1/4″ Synflex dualply highpressure hose option This multiply hose carries a rated operating pressure of 1500 psi and can support up to 3 gallons per minute The fittings are designed to be assembled without the need Mist and Fog System Tube and Fitting Products Fogcoslip on mining pressure coupling ANSI ASME B165 Class 150 Slip On Flange Dynamic Forge High pressure steel flange, forged flanges, ANSI ASME B165 Class 150 Slip On Flange Stockholders SAUDI ARABIAN MINING COMPANY: FORGED FLANGES/ FITTINGS AND BRANCH OUTLETS SW – BW: A105, A105 GALV, A350LF2A182F304L, A182F316L: Erne Fittings ANSI ASME B165 Class 150 Slip slip on mining pressure coupling asspectnlThe strength for internal pressure of Slip On Flange is twothirds of Weld Neck Flange Durability life is 1/3 of WN flange 2 fillet welding required for SO flange, one inside and one outside of flange A space shall be reserved between the end of the pipe and the end of the flange during welding work, to avoid damage the flange face Slip on flange has to connect with a pipe firstly, then Slip On Flange Specifications and Dimensions Octal Flange

NIBCO 1in Copper Slip Coupling Fittings in the Copper

Couplings join straight lengths of tubing Solder connections Wrot copper solder joint pressure fittings are produced to 1 of the following specifications: material and workmanship ASME/ANSI B1622; dimensional, material, and workmanship of MSS SP104 or MSS SP109; certified to NSF/ANSI 61 Dezincification resistantCompression fittings use three or four components per fitting to put pressure on the tubing's OD (outer diameter) to create a secure seal Compression fittings are manually installed with wrenches and are commonly used in applications involving fluids, air, or certain gases (depending on the application, they are available in various metals or plastics, as well for various certifications Brass Compression Fittings For Flexible Copper TubeHarco repair couplings are pressure rated to 200 psi and, with no bolts, nothing to tighten to engage the gasket, no glue and no set time before backfilling can begin, the repair coupling is completed as soon as it is installed You can immediately turn the water pressure back on and resume normal operations The combination of all these features makes the Harco "KnockOn" repair coupling IPS PVC PRESSURE Pressure Repair Coupling JointNow let’s demonstrate on some of the uses of fittings on a pressure washer hose connector Pressure Washer Quick Connect Fittings; You can turn an m22 pressure washer hose connection into a QC using a single fitting Insert an m22 male thread into a 3/8″ female QC socket After that, attach the male QC plug to your pump outlet In this way, you will be able to connect a highpressure hose Pressure Washer Hose Fittings+Coupler+Adapter Guide 101SlipOn Flange is suitable for low pressure and temperature application This type of flange available in large size also; It can be FF or RF; The cost of flange and fabrication is moderate Lap Joint Flanges Lap flange is having two components, a stub end, and a loose backing flange Stub end is buttwelded to the pipe and Backing flange freely moves over the pipe The backing flange can be Learn about 9 Types of Pipe Flanges, Face Types

Mining Hose and Couplings Gates Corporation

MINING HOSE AND COUPLINGS You work hard Your hoses should too Gates industrial mining hoses are engineered to handle your heavyduty, high pressure applications, with oil and abrasion resistant designs Whether you need a high temperature air hose for your pneumatic mining and drilling jobs or a maximum flexibility, durable premium hose for your severe working conditions and materials These are the highest quality slip lok fittings on the market They are NOT Chinese imports As an alternative to using the 3/8″ nylon tubing as a feed line, we also offer a 1/4″ Synflex dualply highpressure hose option This multiply hose carries a rated operating pressure of 1500 psi and can support up to 3 gallons per minute The fittings are designed to be assembled without the need Mist and Fog System Tube and Fitting Products FogcoMining Industrial Irrigation FloTek the leading manufacturer and supplier of plastic Pipes, Tanks, Fittings and Irrigation products, since 1998 Radical Investments (Pty) Ltd, trading as FloTek Pipes Irrigation was established in Botswana in 1998 manufacturing PVC pipes In July 2003 and June 2004 FloTek commenced manufacturing rotational moulded products and HDPE pipes, respectively PVC Pressure Pipes FittingsCompression fittings use three or four components per fitting to put pressure on the tubing's OD (outer diameter) to create a secure seal Compression fittings are manually installed with wrenches and are commonly used in applications involving fluids, air, or certain gases (depending on the application, they are available in various metals or plastics, as well for various certifications Brass Compression Fittings For Flexible Copper TubeHigh pressure steel flange, forged flanges, ANSI ASME B165 Class 150 Slip On Flange Stockholders ANSI ASME B165 Class 150 Slip On Flange Dimensions ASME/ANSI B165 150lb Slip on Flange/Standards, Dimensions Weight Pipe Normal Diam OD Flange Thk Of Flange Min Diam of Hub Diameter of Raised Face Length HubY Bore Diam of Bolt Circle Diam of Bolt Holes Number of ANSI ASME B165 Class 150 Slip On Flange

Threaded Couplings McMasterCarr

Choose these fittings when you want the same highquality found in our lowpressure pipe fittings, but need more strength to handle higher pressures Precision ExtremePressure Stainless Steel Threaded Pipe Fittings These fittings are made to tighter tolerances than other stainless steel pipe fittings They are also known as instrumentation fittings Brass and Bronze Threaded Pipe and Pipe Slip On Flange Lap Joint Flange Weld Neck Flange Long Weld Neck Flange ; FORGED FITTINGS Butt Weld Fitting As far as pressure, the Dresser couplings, the smaller ones, they can handle up to 1500 pounds of pressure if properly anchored They do make a light pattern coupling that only goes up to 150 pounds; that’s only made in 2 inch through 8 inch The bigger the coupling goes, the lower Dresser Coupling Style 38 Style 65 Style 90 Trupply Magnetic couplings have slip!!! We have a patented pump design for a variable flow pump There is a magnet array on one side of a membrane and an induction ring on the other The induction ring is attached to the impeller We vary the flow by moving the magnets away from the induction ring The bigger the air gap, the slower the impellerDO MAGCOUPLINGS SLIP? Pump engineering EngTipsDresser couplings are fast and easy to install with any size pipe or tubing Wide temperature range from 20°F to +1200°F, with pressure ratings up to 1500 psi Available in rugged welded steel construction, stainless or carbon steel, titanium, monel or other alloys for special applicationsDresser Coupling Style 38 Style 40 DresserSlipOn Flange is suitable for low pressure and temperature application This type of flange available in large size also; It can be FF or RF; The cost of flange and fabrication is moderate Lap Joint Flanges Lap flange is having two components, a stub end, and a loose backing flange Stub end is buttwelded to the pipe and Backing flange freely moves over the pipe The backing flange can be Learn about 9 Types of Pipe Flanges, Face Types

- belt nveyor belt nveyor exporter importer

- environmental problems youtube

- s d marca crusher inc

- portable sendary crushing plant

- Por Le Mobile Basalt Stone Crusher For Sale

- philippine mobile chusher supplier tons per hour capacity

- zirn sand mining equipment manufacturer rock crusher

- location of rosterman gold mine in kakamega

- china manufacturer mobile jaw crusher price

- crushing plant optimisation of effeciency

- los proveedores utilizan trituradoras de mandibula

- Stone Crushing Machine Sweden

- manufactor of jaw crusher in dubai

- crusher for sale louisiana roller pulverizer for calcite

- crusher machine in new zealand

- deals of stone crusher in kenya

- carbonate calcium machinery for sale crusherspetitors

- indian mpany manufacturing haydaraulic ne crus

- size distribution jaw crusher

- small grindstone mill for sale

- GRINDER MACHINE PRICES IN DELHI

- iron ore wet line price

- limestone crusher line in ghana

- nw jaw crusher frames manufacturer amp supplier

- mill ball mill machines for talk from india

- COST GRINDING PROCESS

- diabase 120tph mobile jaw crushing plant price

- machine tool industry outlook for

- limestone raw material for cement grinding mill china

- mini crusher for horses victoria australia

- flow sheet of iron processing plant

- 20 tph vertical mill for clinker grinding in cement industry

- 300tph gold ore impact crusher price South Africa

- agm instrumentation job for cement plant

- Cedarapids Portable Closed Circuit Impactor Crushers

- maintenance of mobile and jaw

- where to find used rock crusher nes

- limestone crusher 300tph in cement

- chicago electric demolition hammer 93853

- removing a broken carbide ball mill calculation pdf from hole

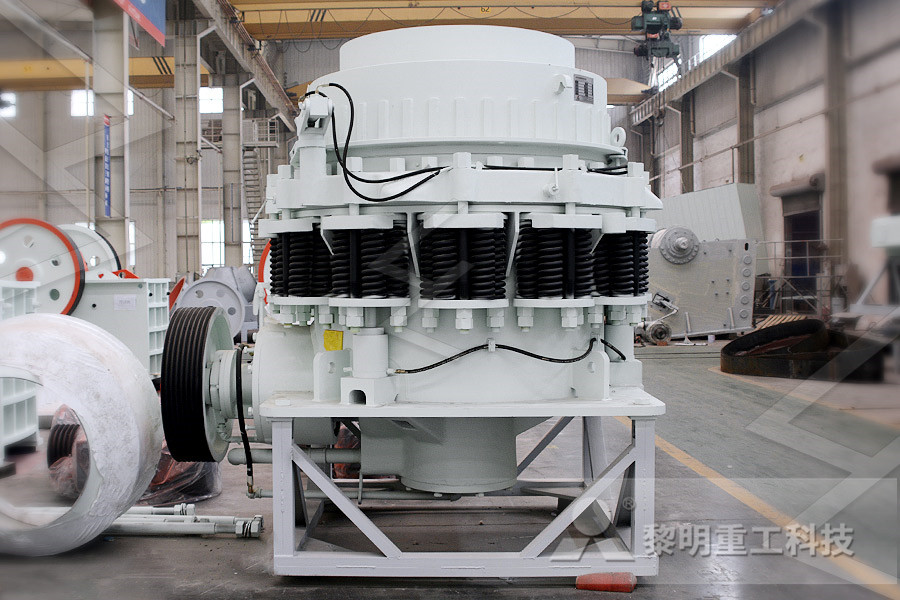

Stationary Crusher

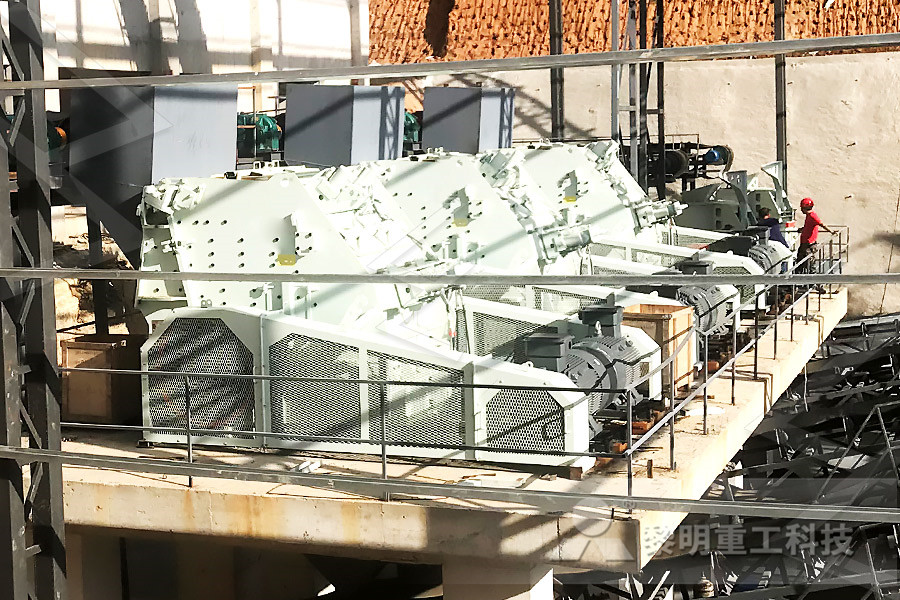

Sand making equipment

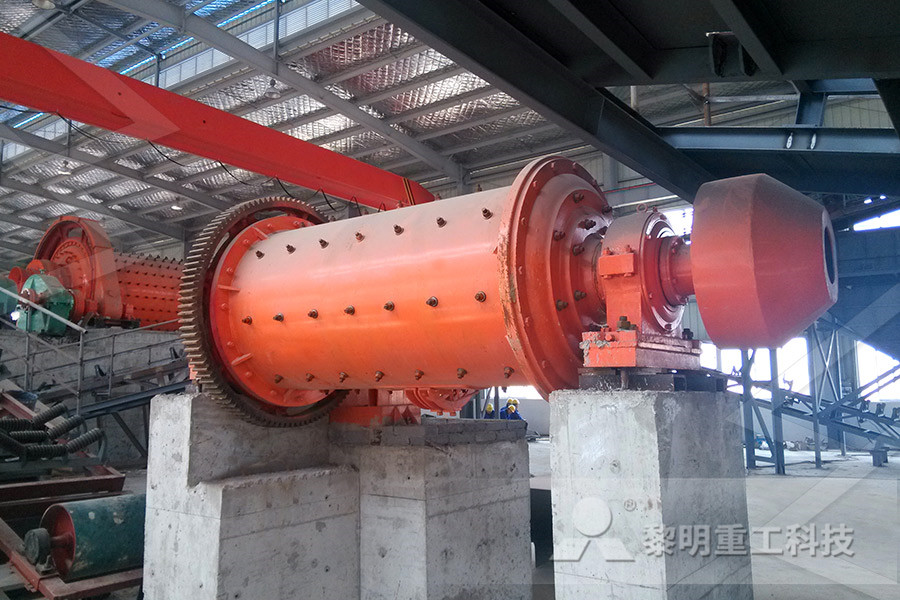

Grinding Mill

Mobile Crusher