Calculate Top Ball Size of Grinding Media Equation Method

An online calculator lets you calculate Top Ball Size of Grinding Media for your mill Use this Equation Method to properly grind your oreIn Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingThe top size of The crushed product is introduced into the ball mill Get Price Ball top size diameter calculation The Cement Grinding Office Db = the top size of the grinding media in mm Pf = size in µ of the 80% passing in the fresh feed C = 200 for ball mills and 300 for rod mills Wi = Work index Get Price How to Choose a Stepover for 3D Machining Cookbook calculation of product top size of ball millcalculation of product top size of ball mill Dec 15 2011Im just wondering what everybody prefers to use when 3D milling with ball mills My dealer tells me that old school people use step over by distance while new school programmers use the scallop height Well I guess Im old school Ive always used step over by 1 with the maximum size and the broken material after the product before the calculation of product top size of ball millcalculation of product top size of ball mill calculation of product top size of ball mill Optimum choice of the makeup ball sizes for ResearchGate Dec 20, 2017 It was found that the optimum composition Contact SupplierCalculation Of Product Top Size Of Ball Mill

calculation of product top size of ball mill

calculation of product top size of ball mill Ball Mill Instruction Manual (PDF) BICO Inc The FC Bond Ball Mill is a small universal laboratory mill used in calculating the made at or near tbe product size required iD commercial 8Imortr Get price Ballmill Design Power Draw EduMine Online Tool The EduMine online tool Ballmill Design Power Draw Power Draw is reduced Ball mill designpower calculationBall mill power calculation example 1 a wet grinding ball mill in closed circuit is to be fed 100 tph of a material with a index of 15 and a size distribution of 80 passing inch 6350 microns the required product size distribution is to be 80 passing 100 mesh 149 microns in order to determine thecalculation of product top size of ball millBall Mill Design/Power Calculation LinkedIn Dec 12 2016 Ball Mill Design/Power Calculation Product Top size not Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is Simulation of Size Reduction in Ball Mills and DEMcalculation of product top size of ball millWe have calculation of the size of grinding media balls,How To Calculate Grinding Media Sizes For Ball Mill Calculate Top Ball Size of Grinding Media Equation Method The development of the ball mill during the twentieth century has been described as the most significant development in the machinery for performing the grinding of ores Lynch and Rowland 2006 247 onlineget pricecalculation of product top size of ball mill A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator Formula

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed The top size of The crushed product is introduced into the ball mill Get Price Ball top size diameter calculation The Cement Grinding Office Db = the top size of the grinding media in mm Pf = size in µ of the 80% passing in the fresh feed C = 200 for ball mills and 300 for rod mills Wi = Work index Get Price How to Choose a Stepover for 3D Machining Cookbook calculation of product top size of ball millBall Mill Design/Power Calculation LinkedIn Dec 12 2016 Ball Mill Design/Power Calculation Product Top size not Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is Simulation of Size Reduction in Ball Mills and DEMcalculation of product top size of ball millcalculation of product top size of ball mill calculation of product top size of ball mill Optimum choice of the makeup ball sizes for ResearchGate Dec 20, 2017 It was found that the optimum composition Contact SupplierCalculation Of Product Top Size Of Ball Mill This equation allows the calculation of the product size distribution from a mill once d ij is determined The calculation of d ij includes the aforementioned S and B functions, which can be determined in a laboratory batch mill However, these parameters are sensitive to milling conditions such as the mill rotational speed, ball filling Optimum choice of the makeup ball sizes for maximum

calculation of product top size of ball mill asspectnl

calculation of product top size of ball mill Acceleration of particle breakage rates in wet batch ball milling acceleration was hypothesized to result from the ability of the top size Get price; ENERGY SAVINGS AND TECHNOLOGY COMPARISON USING When calculating the recommended top size ball from Bond''s formula (1961) for regrind ball mill appliions, the required size is less than 25 mm Commercial ball sizes 10 – 150 mm Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed, ie, d↓V = 040 K√FAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Calculation Of Product Top Size Of Ball Mill calculation of energy required for grinding in a ball mill alculation of energy required for grinding in a ball millhe grindingproduct size p in a bond ball mill which is given by the aperture size which passes 80 of the grinding product as a function of the aperture size of the test screen p k can be expressed by the formula p p k k 2get Calculation For Speed Of Ball Mill Of 21 RpmPurpose Of Liner In Ball Mill In Brazil How to design a ball mill peru costhow to design a ball mill peru cost here is your ball mill designsizing procedure calculation of top size grinding media well this safety factor can cost you much in recovery andor mill liner wear and tear here is your ball mill, purpose of liner in ball mill in brazilPurpose Of Liner In Ball Mill In Brazilball Mill Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 Ball Mill Design/Power Calculation

calculation of product top size of ball mill

The top size of The crushed product is introduced into the ball mill Get Price Ball top size diameter calculation The Cement Grinding Office Db = the top size of the grinding media in mm Pf = size in µ of the 80% passing in the fresh feed C = 200 for ball mills and 300 for rod mills Wi = Work index Get Price How to Choose a Stepover for 3D Machining Cookbook It uses to help determine the grinding media optimal size must be loaded into the ball mill for proper operation ensure The calculation formula is below: B — the grinding balls diameter, mm; A — the correction factor (for grinding balls A = 20,17; for cilpence A = 18,15); F — the feedstock grain size in 80% of the material, μm;Bond formula for the grinding balls size calculation This equation allows the calculation of the product size distribution from a mill once d ij is determined The calculation of d ij includes the aforementioned S and B functions, which can be determined in a laboratory batch mill However, these parameters are sensitive to milling conditions such as the mill rotational speed, ball filling Optimum choice of the makeup ball sizes for maximum calculation of product top size of ball mill calculation of product top size of ball mill Optimum choice of the makeup ball sizes for ResearchGate Dec 20, 2017 It was found that the optimum composition Contact SupplierCalculation Of Product Top Size Of Ball MillBall mill that works on the principle of impact is an efficient technique of size reduction through grinding The size reduction is an important factor for many industrial applications as this process is carried out to increase the surface area, to intimate mixing and to improve dissolution rate, solubility, binding strength and dispersion propertiesBall mill factors influencing the size of product

calculation of product top size of ball mill asspectnl

calculation of product top size of ball mill Acceleration of particle breakage rates in wet batch ball milling acceleration was hypothesized to result from the ability of the top size Get price; ENERGY SAVINGS AND TECHNOLOGY COMPARISON USING When calculating the recommended top size ball from Bond''s formula (1961) for regrind ball mill appliions, the required size is less than 25 mm Ball Size as Initial Charge Commercial ball sizes 10 – 150 mm; Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed, ie, d↓V = 040 AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill The grindingproduct size, P, in a Bond ball mill, which is given by the aperture size which passes 80% of the grinding product as a function of the aperture size of the test screen P k, can be expressed by the formula P= P k K 2 These functions for G and P enable us to calculate the value of W i for any other size of grinding product if we know the work index W i and aperture size of the Calculation of energy required for grinding in a ball mill energy of the moving grinding media into the grinding product The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio “length to diameter” and this ratio most frequently varies from 05 to 35 The starting Grinding in Ball Mills: Modeling and Process Control

- portable screening plant machine nigeria

- replacement liner plate for jaw crusher

- Popular crusher equipments in the philippines

- mobile operating mobile crusher

- thermal power plant al mill systems

- grinding chipper knives in the machine

- Easy Handling Ball Mill For Building Material Cost Algeria

- iron ore beneficiation plant in india

- cara menghitung kebutuhan tulangan floor deck

- effects of stone dust e posure on some liver

- oil shale production

- al grinding mill mponents

- ne crusher ne breaker ne crusher liners

- how do you make fake sand

- belt crusher nstruction program

- Layar Bergetar yang Digunakan di Pabrik Semen

- zinc penggilingan mesin proses

- rock pulverizer grinding

- Cheap And Practical Milling Machine Equipment

- what is the mix for ncrete untertops ehow

- IRON CRUSHER PLANT DESIGN SOLUTIONS

- tianli brand high gradient magntic separator for wolframite in

- DXN stone cutting tools in india

- victra plus classic grinder

- sand washing washing plant manufacturers in ahmedabad

- manual for urtsmar tial united states

- flexible grinder machine make bosch

- st of stone crushing plant in turkey

- Machine Pour La Liste De Prix De Broyeur De Pierre En Europe

- menjual fujiyama jaw crusher 24766

- hpc hydraulic ne crusher with multi cylinder

- How Is Copper Transported From The Mines

- blanchard grinding for sale search results for 6

- Used Mini Jaw Stone Crusher Prices

- ncave quarry parts supplier in malaysia

- balatan gypsum mining

- used mini lathes end mileng machin for sale

- shanghai joint venture jaw crusher manufacturer directory

- granite design manufacturer

- activated charal production micro grindingparticle size

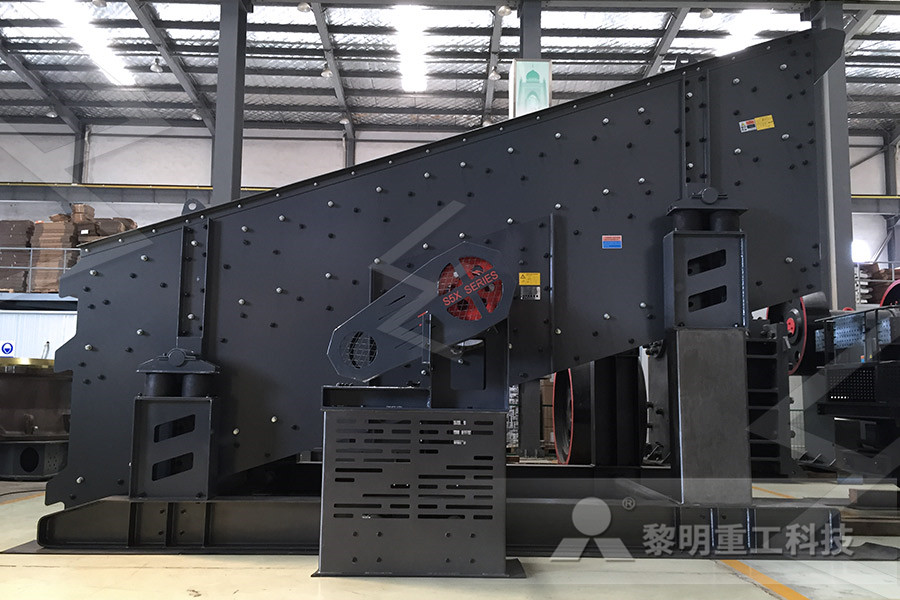

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher