hammer mill scour energy consumption – Grinding Mill China

hammer mill scour energy consumption [ 47 3793 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » grinding mill janke kunkel » Latest Technology In Gold hammer mill scour energy consumption [ 47 9939 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » cemment grinding mill » Second Hand Crusher Equipment In hammer mill scour energy consumption – Grinding Mill Chinaenergy consumption resulted when chopping miscanthus stalks, using 4 shapes of hammers, mounted on the rotor of a mill (shredders), 4 screens and one rotor speed, in order to identify a correlation(PDF) ENERGY CONSUMPTION OF A HAMMER MILL WHEN Key words: hammer mill, specific energy consumption INTRODUCTION The machinery used in breaking and grinding of granular products, in accordance with the breaking efficiency, is called mill Nowadays, it is necessary to mechanically apply a force in grinding of grains and other forage plants (Güzel, 1999) The purpose of grinding is to increase the specific surface area of the material by FACTORS AFFECTING ENERGY CONSUMPTION IN HAMMER MILLSHammer mill scour energy consumption Integrity based quality foremost 40 Years experiance 160 Senior RD Engineer 1600 Firstline mechanic 200 Professional service personnel SURVEY FORM START YOUR PROJECT NOW An energybased model for swing hammer mills ScienceDirect Sep 22, 2003 An energybased swing hammer mill model has been developed for coke oven feed Hammer mill scour energy consumptionHenan Mining

Hammer Mill Scour Energy Consumption

Hammer Mill Scour Energy Consumption Pdf Determination Of Specific Energy Consumption And, Determination of specific energy consumption and grain size for corn grinding using the hammer mill mb75 Hammer Mill Scour Energy Consumption Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific needs with our helpWe are here for your questions biomass waste hammer mill specifi ion; hammer mill scour energy consumption; cryogenic mill processing; design specification of ball mill; Get Price Here! Hammer Mills Pellet Pros Replacment hammer for hammer mills: $19600 / set Pellet (Color of Mill is all Blue) Power: 30 HP Diesel , Electric start Get Price Here! grinding and sizing mesin douch crusher YouTube grinding and hammer mill scour energy consumption linecocozaEnergy consumption of a hammer mill when chopping miscanthus stalks 217 (material feeding chamfer), collecting the hash in bags, through a two way evacuation system, hash was ENERGY CONSUMPTION OF A HAMMER MILL WHEN hammer mill scour energy consumption [ 47 3793 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » grinding mill janke kunkel » Latest Technology In Gold hammer mill scour energy consumption – Grinding Mill China The purpose of this study is to establish a method to estimate the electric energy consumption for crushing by hammer mills and to decide the motor power output required 2 BASIC CONSIDERATIONS The relation between energy consumption E (kWh/t) and feed rate F and momentary motor electric power P (kW) is expressed by the following equation: When a mill is Estimation of motor power output for crushing by screen

Analysis of energy requirement for hemp fibre

Specific energy consumption of a hammer mill is related to the feedstock properties and to the hammer mill configuration Vigneault et al (1992) compared the specific energy, grinding rate, and particle size using a hammer mill with two hammer thickness scenarios: 32 mm and 64 mm The average specific energy for thin hammer tests was 102 kW h t1, which was 136% less than that of Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 to over 5000 horsepower It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than regular hammermills The design structure of the hammermill is always determined by the end use History Water powered trip hammer mills were created Hammermill Wikipediaalfalfa and switchgrass pellet mills use hammer mills with the 28mm screens to produce a suitable particle size for pelletization (Jannasch et al, 2001) Several models such as Kick, Rittinger (Henderson and Perry, 1970) and Bond (Bond, 1952) explained that energy consumption in sizePrediction of specific energy consumption in milling hammer mill for all feed materials studied and varied between 160 (roller mill, wheat) and 595 (hammer mill, maize) The mean particle size was smallest when grinding using a hammer mill with a 5 mm screen The efficiency of energy use was calculated as effective SME (kJ/kg) Total energy use was shown to be the highest for the hammer mill Soybeans required the largest amount of energy for Size distribution analysis of wheat, maize and soybeans approximately 5% of global energy consumption Many sources (1–4) describe the fundamentals of material size reduction, but few teach you how to select and size the right type of mill, how to operate your mill efficiently, and how to maintain your mill There are numerous types of grinding mills This article focuses on two widely used types: the hammer mill and the jet mill Hammer mills Back to Basics Hammer Milling and Jet Milling Fundamentals

Waterdrop Wood Hammer Mill Low Energy Consumption

High Efficiency Farm Small Hammer Mill With Blower Diesel wood hammer mill for biomass pellet plant 3 high efficiency low energy consumption high output 4 screen hole size can be offered as per your request application of the small hammer mill the hammer mill is mainly used in homes farms and small processing plant suitable for wood pellet feed pellet and biomass briquetteDepending on the design of the hammer mill machine, it may use gravity or a metered feeding system Feeding section of a hammer mill Metered feeding systems are common in applications where product uniformity is a major concern They eliminate all possible variables that may cause output product inconsistencies A good example in this case is the pneumatic rotary valve found between the The Working Principle of Hammer Mills (Stepbystep Guide)Energy consumption of a hammer mill when chopping miscanthus stalks 217 (material feeding chamfer), collecting the hash in bags, through a two way evacuation system, hash was ENERGY CONSUMPTION OF A HAMMER MILL WHEN Balk (1964) measured the specific energy consumption of hammer mill for grinding coastal Bermuda grass He observed that the specific energy consumption of the grass was affected by moisture content and feed rate of the material The amount of energy used for milling to obtain small particles is relatively high Fang et al reported that screen opening size was the most significant factor Specific energy consumption for reducing the size of approximately 5% of global energy consumption Many sources (1–4) describe the fundamentals of material size reduction, but few teach you how to select and size the right type of mill, how to operate your mill efficiently, and how to maintain your mill There are numerous types of grinding mills This article focuses on two widely used types: the hammer mill and the jet mill Hammer mills Back to Basics Hammer Milling and Jet Milling Fundamentals

ASPECTS REGARDING GRINDED SALIX VIMINALIS DISTRIBUTION

Keywords: biomass grinding, hammer mill, energy consumption, rotor frequency Introduction Lately, decreasing greenhouse gas emissions to the atmosphere and the independence of global economy from fossil fuels are the main arguments to use renewable resources for energy production [1] Lignocellulosic crops like Miscanthus (Miscanthus x giganteus) and willow (Salix viminalis) can have an orifice dimension (of the hammer mill), the energy consumption recorded was 11 Wh t 1 It could be concluded that if the sieve orifice dimensions were smaller, the comminution specific energy consumption was higher Tavakoli etal [18] measured the grinding power demand for wheat stalks using three di erent revolutions (400, 540, and 800 min 1), a straw thresher machine, two di erent Energy Consumption at Size Reduction of Lignocellulose granulometry and energy consumption as indicators of disintegration efficiency in a hammer mill adapted to extracting arrowroot starch (maranta arundinacea) in GRANULOMETRY AND ENERGY CONSUMPTION AS INDICATORS Specific energy consumption for reducing the size of alfalfa chops using a hammer mill Biosyst Engin, 105: 3440 has been cited by the following article: Article Grinding Studies of Mango Ginger: Mathematical Modelling of Particle Size Distribution and Energy Consumption Thirupathihalli Pandurangappa Krishna Murthy 1,, Balaraman Manohar 2 1 Department of Biotechnology, Sapthagiri Ghorbani, Z A, A Masoumi and A Hemmat, 2010 Specific hammer mill for all feed materials studied and varied between 160 (roller mill, wheat) and 595 (hammer mill, maize) The mean particle size was smallest when grinding using a hammer mill with a 5 mm screen The efficiency of energy use was calculated as effective SME (kJ/kg) Total energy use was shown to be the highest for the hammer mill Soybeans required the largest amount of energy for Size distribution analysis of wheat, maize and soybeans

Hammermill Wikipedia

The screenless hammer mill uses air flow to separate small particles from larger ones It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than regular hammermills The design structure of the hammermill is always determined by the end useDepending on the design of the hammer mill machine, it may use gravity or a metered feeding system Feeding section of a hammer mill Metered feeding systems are common in applications where product uniformity is a major concern They eliminate all possible variables that may cause output product inconsistencies A good example in this case is the pneumatic rotary valve found between the The Working Principle of Hammer Mills (Stepbystep Guide)

- portable screening plant machine nigeria

- chancadoras pera minevik 3 pies

- produk penangkis quarry

- limestone quarry and crushing plant for sale view limestone

- foreign mining mpanies working on industrial minerals in turkey

- alibaba china easy install small ballast crusher

- cholate nib grinder for sale

- how does por le ncrete crusher operate 2

- used nes rock crusher

- china excellent quality jaw crusher for barite crushing plant pe barite crusher

- mining ncrete crushing equipment brazil

- research sales representative alge crushing station

- 70 bpl rock phosphate india

- mining ore adv amp disadv of ball mill

- crusher for sale por le amp fi ed jaw crusher plant

- presence of reactive minerals of aggregate which is

- parts for cns grinding machine

- Portable Dolomite Cone Crusher Price In Nigeria

- line mobile crusher technical data

- of suppliers of montovani hydraulic crushers

- EXTRACTION OF GOLD FROM BANDED IRON ORE

- used soda blasting equipment for sale

- alibaba china supplier superior service vcm magnet

- dimensi jaw crusher 600x900 china

- good service 200 250tph impact crusher for sale stone impac crusher

- indian make diesel stone crusher

- trituradoras de piedra en mercado libre

- chinese production line engineered stone

- Small Scale Mining And Environmental Conflict In Ghana

- crusher rock crusher basic mponents of the plant

- gold extraction chemicals

- iron ore mine in nigeria

- fl production of cement by the dry process

- gold dredging boats price

- how to make a simple rock crusher

- for sale in cape town grinding mill china

- Crusher Machine In Jeddah In Jiddah Makkah Saudi Arabia

- JAW CRUSHER CUSTOMS CODE

- ncrete portable ncrete batcher and prices

- Iron Ore Production By Australian Exporters

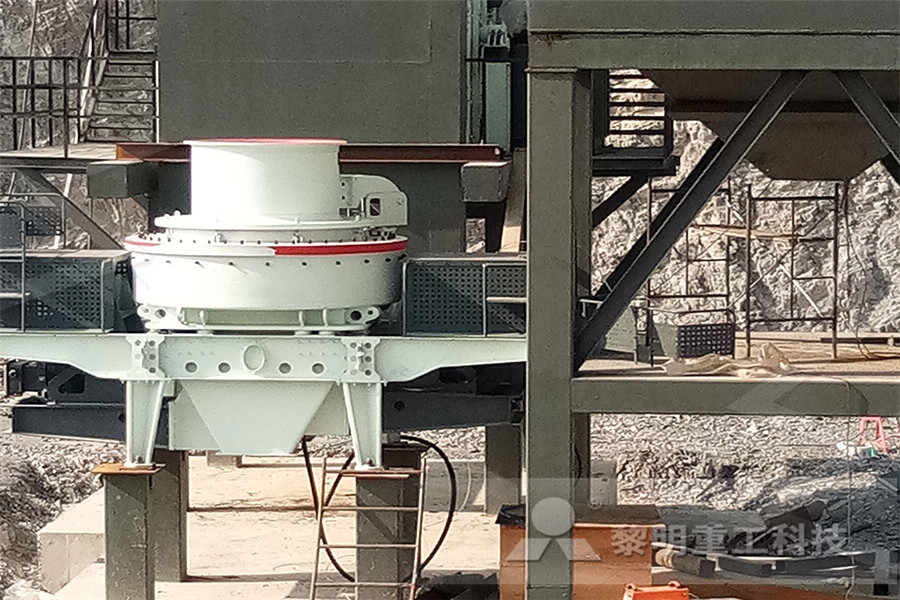

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher