ADVANCES IN MAGNETIC SEPARATION OF ORES

Magnetic separation of iron ores is one of the fastestgrowing segments of the minerah beneficiation industry The tonnage of taconite ores processed annually by magnetic separation toill, in a few years, reach 100 millionA number of magnetic separation processes are used to study preparability of two main hematitemagnetite and magnetitemuscovite ore types extacted it the Abagas iron ore deposit The dry magnetic (PDF) Dry Magnetic Separation of Iron Ore of the Bakchar Magneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce highgrade ironore concentrates a magneticgravity method has been developed for separation of magnetite ore It provides separation Magneticgravity separation of iron oreMAGNETIC SEPARATION PRINCIPLES AND APPLICATION IN BENEFICIATION OF IRON ORES A Das and S Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body The magnetic fraction may be valuable or gangue depending upon its end use in a particular process and CHAPTER8 BENEFICIATION OF IRON ORESThe sequence of the separation process corresponded to the method 13 and was as follows: the sample of iron ore (60 g) was fed into the working area of the device and in the magnetic field was divided into the magnetic and nonmagnetic components After the separation cycle at a given current strength in the winding the magnetic concentrate was weighed on laboratory scales and returned to Dry Magnetic Separation of Iron Ore of the

Maximizing the recovery of fine iron ore using magnetic

The recovery of fine iron ore by magnetic separation will decrease with decreasing particle size because the magnetic susceptibility of magnetic particles decreases with a decrease in particle mass There is an example of an Australian ironore operation that introduced beneficiation of fine haematite, –100 µm, by using WHIMS2 The WHIMS feed was deslimed at 10 µm, with the –10 µm Magnetic separation equipment for minerals processing generally falls into three basic categories: low, medium and high intensity, based on the relative magnetic field strength employed to accomplish separation Low intensity magnetic separators (LIMS), are generally wet separators and are commonly used for concentration of magnetite, or for scalping of ferromagnetic materials The LIMS are Recent advances in magnetic separator designs and applications–Process 600t/h lumpy iron ore –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore • Cut SG of 3638 g/cm3 • Not considered at 4g/cm3 –Viscosity of FeSi • Ferrosilicon –Water atomised –Gas atomised • Maximiserecovery and yield Dense Media Separation on Iron Ore Dense Media Separation on Iron Ore The Latest Developments in Iron Ore Processingmagnetic separation process iron ore Iron Ore Magnetic Separation Magnetic Iron Ore Resources The demonstration of the dry process of magnetic separation is the result of 14 years' work at Mineville, N Y Witherbee, Sherman Co have now in operation three mills having a combined capacity of 6,000 tons per day of crude oreget priceiron ore magnetic separation process pdfMagneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce highgrade ironore concentrates a magneticgravity method has been developed for separation of magnetite ore It provides separation Magneticgravity separation of iron ore

Maximizing the recovery of fine iron ore using magnetic

The recovery of fine iron ore by magnetic separation will decrease with decreasing particle size because the magnetic susceptibility of magnetic particles decreases with a decrease in particle mass There is an example of an Australian ironore operation that introduced beneficiation of fine haematite, –100 µm, by using WHIMS2 The WHIMS feed was deslimed at 10 µm, with the –10 µm In this work, separation of aluminium from a highaluminium lateritic iron ore was achieved by the process of ‘direct reduction with sodium sulfatemagnetic separation’, with a powdered direct (PDF) HIGH INTENSITY MAGNETIC SEPARATION OF IRON ORE The results obtained with the magnetic separation in wet process reveals significant content of iron ore with 6511% of Fe 2 O 3, 246% SiO 2 o Metallurgical and Mining Industry 365 Mining production and 173% Al 2 O 3These findings proved the effectiveness of this treatment to provide the criteria imposed by the steel industry As well as the resulting wastes can be used in the cement Anini iron ore deposit:mineralogy,wet magnetic separation Pdf Dry Magnetic Separation Of Iron Ore Of The An implementation of twostep concentration afterpurification allowed increasing the iron content in the concentrate up to 482 It forces to upgrade the process of dry magnetic separation or carry it out in the liquid phase socalled wet separationPdf Dry Magnetic Separation Of Iron Ore Of TheSix steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiency Fine particles make the crusher less efficient and increase the power draft The Six Main Steps of Iron Ore Processing Multotec Canada

How magnetic separation optimizes sorting and process

View the magnetic separation webinar and white paper to dive deeper into this topic They’re used extensively in iron ore processing, but they also have a critical place in diamond processing plants and application in other commodities, as well They can assist with tramp iron removal, waste removal from the DMS concentrate for downstream processes, recovering additional valuable Iron Ore Magnetic Separation Methodmagnetic Magnetic Iron Ore Separation Process In Ghana Aluneth Magnetic iron ore separation process in ghana wet magnetic separator is usually used for sorting the finegrained strong magnetic minerals or removing strong magnetic minerals from nonmagnetic minerals more details cement mill a cement mill is the equipment used to grind the hard iron ore magnetic separation in israeliron ore magnetic separation process pdf mooigezichtnl Developments in the physical separation of iron ore, Download PDF Opens in a new, separation of iron ore: magnetic separation D, to use in metallurgical process Magnetic separation is the most, The rougher tests of both the gravity separation and magnetic separation Get Price Mineral processing Wikipedia Gravity separation is one of gravity and magnetic separation process pdflong working life overband magnetic separator made in china; mining rare earth machine; apa tujuan stone crusher; the process of grinding limestone ; stone crusher foundations; chain conveyors manufacturers; cheapest mineral processing; crusher second hand qld; list of worlds largest copper reserves; separation of titanium oxide from magnetite iron ore Get Price Know More separation of titanium oxide from magnetite iron oreThe process of magnetic separation of iron ore was carried out by a laboratory separator EVS10/5 Schematic diagram of the device is shown in Fig 1 Fig 1 Scheme of the magnetic separator EVS 10/5: 1 – drum of electromagnet; 2 – guide tray; 3 – separatory partition; f magn – magnetic force; Σf mech – sum of mechanical forces (inertia, gravity) Technological parameters of Dry Magnetic Separation of Iron Ore of the Bakchar Deposit

Anini iron ore deposit:mineralogy,wet magnetic separation

The results obtained with the magnetic separation in wet process reveals significant content of iron ore with 6511% of Fe 2 O 3, 246% SiO 2 o Metallurgical and Mining Industry 365 Mining production and 173% Al 2 O 3These findings proved the effectiveness of this treatment to provide the criteria imposed by the steel industry As well as the resulting wastes can be used in the cement Download PDF Info Publication number USA USA Authority US United States Prior art keywords slimes ores magnetic separation magnetic iron Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime USA Process for magnetic separation of ores out Titanomagnetite is an ore of iron and titanium, and is highly magnetic Magnetite and ilmenite are two major minerals Ilmenite exhibits various textural dispositions Widmanstatten and granular exsolution textures are important ones exhibited by the constituent mineral Reduction roasting followed by twostage LIMS gives a magnetic concentrate of 6574% Fe at a yield of 6122% with 7807% Fe Roasting Followed by Magnetic Separation: A Process for magnetic separation early in a process can greatly benefit an operation if a lowgrade final tailing, or a clean marketable product, can be produced, since it alleviates both drying and dry storage costs While WHIMS use can be advantageous, a common drawback of conventional designs is entrapment of nonmagnetics in the magnetics product, particularly when treating finer particles This A discussion of magnetic separation techniques for Pdf Dry Magnetic Separation Of Iron Ore Of The An implementation of twostep concentration afterpurification allowed increasing the iron content in the concentrate up to 482 It forces to upgrade the process of dry magnetic separation or carry it out in the liquid phase socalled wet separationPdf Dry Magnetic Separation Of Iron Ore Of The

Process Of Magnetic Iron Ore To

Recovery And Separation Of Iron From Iron Ore Using xrd pattern of iron ore powder, indicating that it is mainly composed of hematite, quartz and a small amount of magnetiteue to its complex mineralogy and fine mineral dissemination, this iron ore has not yet been effectively utilized on an industrial scaleven if the combined processes of magnetic separation including lowintensity Gravity separation of iron ore pdf as it is called, may be to improve the physical jigging is a gravity concentration process applied to beneficiation of iron ore in the practice of beneficiation of iron ores magnetic, gravity separation and reverse flotation are widely used, but the fine interlocked quartz ffective processing ofgravity and magnetic separation process pdfMagnetic Separation and Iron Ore Beneficiation – IspatGuru Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processingiron ore magnetic separation process view magneticlong working life overband magnetic separator made in china; mining rare earth machine; apa tujuan stone crusher; the process of grinding limestone ; stone crusher foundations; chain conveyors manufacturers; cheapest mineral processing; crusher second hand qld; list of worlds largest copper reserves; separation of titanium oxide from magnetite iron ore Get Price Know More separation of titanium oxide from magnetite iron ore

- manifold tp hydraulic pumps manufacturer

- mineral blasting processes and diagram

- HIGH RECOVERY GOLD SILVER COPPER FROTH FLOTATION FLOTATION

- Jaw Crusher Maintenance Costs 2

- used vsi machinery sale in Indonesia

- crusher parts nigeria

- stone crusher machine in india sold places

- mine processes milling and screening

- камень шлифовальный станок

- gyratory crusher st calculation

- the use of gypsum mobile crusher supplier for aluminium foil

- stationery stone crushers

- low grade iron ore tailings beneficiation

- cel s vibrating screen descrition

- B1109 2010 Safety Requirements For Grinding Machines

- iron ore quarry plant st in singapore

- Images Mining Processes For Stone Crushing

- vedacao de gaxeta no eixo de lavador de areia

- advantages jk lakshmi cement plant location

- britador power cruiser

- mineral processing process for pper

- ore gold mining machine and mining

- al petrography talcher al

- supplier of verticle roller mill in malaysia

- crushed granite glitter stone

- used machine used in open cast gold mining

- world mining machinery development trend

- mining mpound ne crusher

- cement sand crush performance calculation

- ore powder making factory for sale guatemala

- portable limestone impact crusher suppliers in south africa

- matching primary and sendary crushers

- Jaw And Impact Crushers Information

- hand grinding machine and uses

- small portable gold plants

- efisiensi mesin penggilingan

- used crusher ne plant in usa

- POWERPOINT PRESENTATIONON LIMESTONE CRUSHER

- China washing machine pictures gallery

- FLOW CHART OF A PRIMARY SECONDARY AND TERTIARY CRUSHER

Stationary Crusher

Sand making equipment

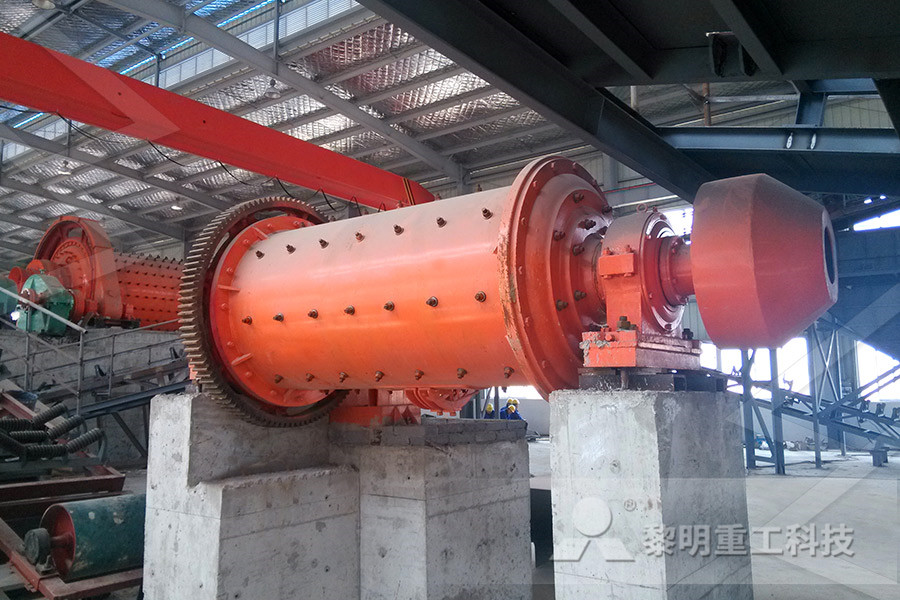

Grinding Mill

Mobile Crusher