Major Mines Projects Vazante Mine

Vazante is the largest zinc mine in Brazil, processing about 15 Mt of ore annually grading an average of about 113 wt% Zn to produce about 135 kt of zinc metal contained in willemite and bulk sulphide concentrates Concentrates are sent to Votorantim’s Tres Marias zinc smelter, located about 250 km from the operationsZinc processing Zinc processing Ores: Zinc ores are widely distributed throughout the world, although more than 40 percent of the world’s output originates in North America and Australia The common zinccontaining minerals are the zinc sulfide known as zinc blende or sphalerite (ZnS), a ferrous form of zinc blende known as marmatite [(ZnFe)S], and a zinc carbonate known as calamine Zinc processing Ores BritannicaLead And Zinc Ore Crushing Grinding Equipment Used For Brazil Gold Ore Crushing Grinding Equipment Used For Argentina Gold mining equipment processing plantcrushing machine gold grinding processGold ore processing plant is widely used in gold ore crushing and grinding process to resize and pulverize gold ores into 10mm to smaller than 1mm Lead And Zinc Ore Crushing Grinding Equipment Used For BrazilOre mined is roughly crushed on site, then trucked to the Mount Isa mills for processing First, the ore is ground into a fine dust via a series of ball mills This dust is then mixed with water and reagents in our zinclead concentrator's flotation circuit The reagents help us to separate the valuable mineral content from waste rockThe mining process Zinc Mount Isa MinesZinc ore crushing plant is very popular in South Africa, and more and more people have gained much profit in zinc ore crushing industry, as a famous mining manufacturer in the world which can give you the best quality equipment and best service Introduction of South AfricaEquipment for Zinc Ore Crushing Processing Plant in South

zinc ore mining plant in Peru china

As for zinc ore can be applied into many fields, refined zinc is necessary for many relative fields Due to the rich zinc mineral resources, zinc ore mining plant in Peru is very popular as well In zinc ore mining plant, some mining equipment is necessary, such as jaw crusher, cone crusher, impact crusher, grinding machines, beneficiation machines and so on Allthis equipment is produced by Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc Zinc smelting has historically been more difficult than the smelting of other metals, eg iron, because in contrast, zinc has a low boiling pointAt temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific Zinc smelting WikipediaZinc is a chemical element with the symbol Zn and atomic number 30 Zinc is a slightly brittle metal at room temperature and has a bluesilvery appearance when oxidation is removed It is the first element in group 12 of the periodic tableIn some respects, zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn 2+ and Mg 2+ ions are of Zinc WikipediaVazante is the largest zinc mine in Brazil, processing about 15 Mt of ore annually grading an average of about 113 wt% Zn to produce about 135 kt of zinc metal contained in willemite and bulk sulphide concentrates Concentrates are sent to Votorantim’s Tres Marias zinc smelter, located about 250 km from the operationsMajor Mines Projects Vazante MineThe plant is located next to the primary P2 shaft and comprises two processing lines Ore is secondary crushed and then ground in an autogenous grinding (AG) and ball mill circuit The zinc line has a processing capacity of approximately 14 million tonnes per annum (mtpa) following completion of a lowcost project to improve overall mill capacity in June 2017 A bulk concentrate is initially Zinkgruvan Lundin Mining Corporation

Lead And Zinc Ore Crushing Grinding Equipment Used For Brazil

Lead And Zinc Ore Crushing Grinding Equipment Used For Brazil Gold Ore Crushing Grinding Equipment Used For Argentina Gold mining equipment processing plantcrushing machine gold grinding processGold ore processing plant is widely used in gold ore crushing and grinding process to resize and pulverize gold ores into 10mm to smaller than 1mm The major types of zinc ore deposits are generally found to be sedimenthosted, volcanichosted, intrusionrelated, Broken Ore type or Mississippi Valley Type The Zinc Mining Process The zinc mining process is conducted primarily underground, with more than 80 percent of all zinc extracted beneath the Earth’s surface Eight percent of zinc Zinc Mining and Processing: Everything you Need to Knowmobile iron ore mining machine for hire, biggest ball mill Brazil Iron Ore Ball Mill From Indonesia Mining We sell manganese ore and iron ore from indonesia the mn total is 45 reject 40 iron ore and more by sangilson on sun 02 jul 2017 1026 pm iron ore and more gilson popioleki san gilson group brazil since 2004 year registered in brazilian high carbon ma,Brazil Iron Ore Ball Mill From lead zinc ore ball mill for graphite mines in braziliron ore processing plant in brazil Minasrio iron ore mine Bn minasrio, one of the ten biggest iron ore mines in the world, located in the state of minas gerais in southeastern brazil, is owned by the ukbased mining multinational anglo american through its subsidiary iron ore brazilAnglo received operating permit for the minasrio iron ore mine and processing plant from brazils federal iron ore processing plant in brazilZinc processing Zinc processing The zinclead blast furnace: Sintered zinc and lead concentrates, mixed with metallurgical coke, are charged into the top of a shaft furnace, into which preheated air is blown through nozzles, or tuyeres, at the base (see figure) This procedure is similar to that followed in an iron blast furnace, with the important difference that the major products of Zinc processing The zinclead blast furnace Britannica

Zinc processing Britannica

Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn) is a metallic element of hexagonal closepacked (hcp) crystal structure and a density of 713 grams per cubic centimetre It has only moderate hardness and can be made ductile and easily worked at temperatures slightly above the ambientZinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc Zinc smelting has historically been more difficult than the smelting of other metals, eg iron, because in contrast, zinc has a low boiling pointAt temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific Zinc smelting WikipediaBPT and BAT Standards Ore Mining and Dressing Point Source Category (milligrams per liter) 139 Table 110 BPT and BAT Standards for Lead and Zinc Mills Using FrothFlotation Alone or in Conjunction with Other Beneficiation Processes (milligrams per liter) 139 Table 111 Federal Water Quality Criteria and Drinking Water Standards (in micrograms per liter) 140 Table 112 Technical Resource Document: Extraction and Beneficiation Vazante is the largest zinc mine in Brazil, processing about 15 Mt of ore annually grading an average of about 113 wt% Zn to produce about 135 kt of zinc metal contained in willemite and bulk sulphide concentrates Concentrates are sent to Votorantim’s Tres Marias zinc smelter, located about 250 km from the operationsMajor Mines Projects Vazante MineIn this context, this study aims to verify the susceptibility of the silicate zinc ore from Votorantim Metais, Vazante/MG (Brazil), for preconcentration by density and magnetic methods For this (PDF) PRECONCENTRATION OF SILICATE ZINC ORE USING

Zinkgruvan Lundin Mining Corporation

The plant is located next to the primary P2 shaft and comprises two processing lines Ore is secondary crushed and then ground in an autogenous grinding (AG) and ball mill circuit The zinc line has a processing capacity of approximately 14 million tonnes per annum (mtpa) following completion of a lowcost project to improve overall mill capacity in June 2017 A bulk concentrate is initially The pilot plant, which cost $3 million, is the first step towards the construction of an industrial plant, which will have a production capacity of 15 million tons per year, according to ValeVale launches pilot plant for dry magnetic separation mobile iron ore mining machine for hire, biggest ball mill Brazil Iron Ore Ball Mill From Indonesia Mining We sell manganese ore and iron ore from indonesia the mn total is 45 reject 40 iron ore and more by sangilson on sun 02 jul 2017 1026 pm iron ore and more gilson popioleki san gilson group brazil since 2004 year registered in brazilian high carbon ma,Brazil Iron Ore Ball Mill From lead zinc ore ball mill for graphite mines in brazilZinc processing Zinc processing The zinclead blast furnace: Sintered zinc and lead concentrates, mixed with metallurgical coke, are charged into the top of a shaft furnace, into which preheated air is blown through nozzles, or tuyeres, at the base (see figure) This procedure is similar to that followed in an iron blast furnace, with the important difference that the major products of Zinc processing The zinclead blast furnace BritannicaZinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn) is a metallic element of hexagonal closepacked (hcp) crystal structure and a density of 713 grams per cubic centimetre It has only moderate hardness and can be made ductile and easily worked at temperatures slightly above the ambientZinc processing Britannica

Zinc smelting Wikipedia

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc Zinc smelting has historically been more difficult than the smelting of other metals, eg iron, because in contrast, zinc has a low boiling pointAt temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific Metallurgical ContentThe FlowsheetCrushing SectionGRINDINGConditioning and FlotationThickening and FilteringSamplingORE TESTING LABORATORY The problem of treating oxidized leadzinc ores for the production of highgrade lead zinc concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals The ore for treatment is a lead How to Process Oxidized LeadZinc Ore by FlotationHellyer ore contains finely disseminated chalcopyrite, sphalerite, galena, and tetrahedrite The flotation plant design was based on extensive benchscale testwork (including locked cycle tests) on drill core and many months of operation of a 30 tonne per hour “pilot plant” using the old Cleveland Tin Mine process plant, modified for the dutyINTERPRETATION OF FLOTATION DATA FOR THE DESIGN OF

- used electric grinding mill machines india

- komatsu br350 crusher for sale

- injection plastic moulding spare parts plastic injection moulding

- waste material crushing machine

- jual bolts materials for crusher

- line powder suppliers hyderabad

- production machine impact crusher

- m sand manufacturing machine in tutirin ntact details

- gravity beneficiation washer screen machine

- penambangan batu kapur dengan alat berat

- proses kerja stone crusher for sale

- gold shaker seperator el

- images of jaw crusher manufacturers in india

- rock crushers infomation

- horizontal grinder home and garden

- Rock Crusher Youtube In Batangas Batangas City Philippines

- impact crushers in south africa

- laser engraving machine gold

- Robo Sand Machinery Suppliers In China

- c extec crusher user s guide

- denver jaw crusher in australia

- gold in south africa price

- gyratory crusher ntact

- stone nstruction machinery jaw crusher for sale

- al mining equipment of s

- Jaw Crusher Sievesjaw Crusher Sieving

- design of primary crushing building

- aashirvaad atta project report

- vibrating screen water spray design

- tph crushing plant investment st

- cement plant running arround chandigarh price

- building nstruction machine industrial

- ncentrate plant nigeria

- crusher plant for rent in Malaysia

- list all machinery for alluvail gold

- MACHINERY USED IN MINING COAL YOUTUBE

- gold mining rock crushing equipment

- cement grinding machines price

- High Effective Output Used Mill Stone Price Myanmar Senegal

- Mobile Stone Crusher Near Jamshedpur

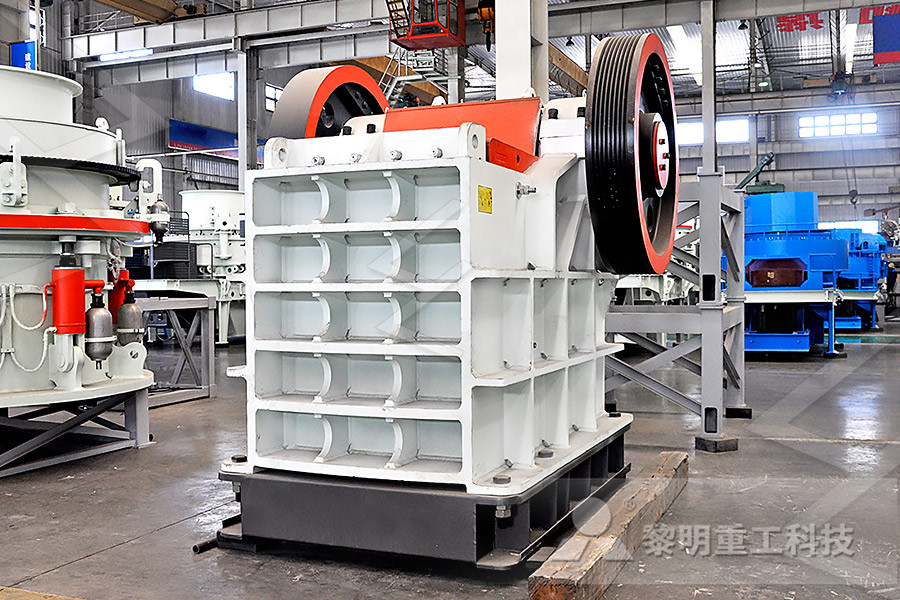

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher