How To Calculate Of Cement, Sand And Aggregate For M10

Volume of concrete = 1 m³ Grade of concrete M20 (1:15:3) Findout the Quantity of concrete (Wet volume and Dry volume) Wet volume of concrete = 1 m³ Dry volume = Wet volume x 154 (You can also take it as 150 to 155, But it became standard practice to considering 154 as multiplication factor) Dry volume of concrete = 1 x 154 =154 m³M10 Grade Concrete Sand Consumption Replacement of natural sand with manufactured sand in m40 mixThe concrete specimens were cured on normal moist curing under normal atmospheric temperatureThe compressive strength was determined at 7, 14 and 28 daysM 40 grade concrete using complete manufactured sand yielded an excesses strength of 7 Get PriceM10 Grade Concrete Sand Consumption eye4youI would suggest the ratio of 1:2:3 or 1:15:3 for M20 grade concrete and 1:2:4 or 1:25:35 for M15 grade concrete If you prepare concrete with your ration then the concrete will have too much sand Too much sand causes shrinkage and this will not give highdensity concrete Hence use 1:2:3 for good strength and 1:25:35 for moderate strengthCalculate Cement Sand Aggregate M20, M15, M10, M5 M10 Grade Concrete Sand Consumption grades of concretectually, what do we mean by grade of concrete concrete grades are denoted by m10, m20, m30 according to their compressive strengthhe m denotes mix design of concrete followed by the compressive strength number in nmm 2M10 Grade Concrete Sand Consumption 2 Ordinary grade of concrete M10 GRADE The mix ratio is 1:3:6 (1 Cement, 3 Sand and 6 Aggregate) It is used as PCC (Plain Cement Concrete) Application/use: – It can be used in the construction of Levelling course, bedding for footing, concrete roads, etc M15 GRADE The mix ratio is 1:2:4 (1 Cement, 2 Sand and 4 Aggregate)Different Grades Of Concrete And Their Applications

how to calculate sand cement volumes for m10 grade concrete

m10 grade concrete sand consumption m10 grade concrete sand ball mill offers>how to calculate sand,cement volumes for m10 grade Get Price Beauty Of How To Make Concrete Mix Ratio Calculator How To Make Concrete Mix CONCRETE MIX RATIO GRADE: M5 = 1:4:8; M10= 1:3:6; then volume is 1+15+3=55 and the total volume for using CONCRETE MIX RATIO =157 Get Friends first of all I would like to tell you what is M5, M10, M15, M20etc Here M is grade of mix ratio and numerical value 5, 10, 15, 20etc are strength of concrete in KN/mm² So, if we have M20 grade concrete then we can say that its grade is 20KN/mm² And mix proportion is 1:15:3 which indicates that in this types of mix ratios 1 part is cement, 1:5 part is sand and 3 part is aggregate has Use of M5, M10,M15,M20 and M25 in Residential buildingVolume of concrete = 1 m³ Grade of concrete M20 (1:15:3) Findout the Quantity of concrete (Wet volume and Dry volume) Wet volume of concrete = 1 m³ Dry volume = Wet volume x 154 (You can also take it as 150 to 155, But it became standard practice to considering 154 as multiplication factor) Dry volume of concrete = 1 x 154 =154 m³How To Calculate Of Cement, Sand And Aggregate For M10 Concrete is classified into different grades like M5, M75, M10, M15, M20 concrete based on the strength of concrete In concrete grades, the letter “M” stands for “Mix” (mix of Sand, Cement, and Aggregate) and the following number stands for characteristic compressive strength of concrete in 28 days in the Direct Compression test For example, in M20 ratio concrete M stands for “Mix Sand, Cement and Aggregate of M20 Ratio calculationM10 Grade Concrete Sand Consumption Replacement of natural sand with manufactured sand in m40 mixThe concrete specimens were cured on normal moist curing under normal atmospheric temperatureThe compressive strength was determined at 7, 14 and 28 daysM 40 grade concrete using complete manufactured sand yielded an excesses strength of 7M10 Grade Concrete Sand Consumption eye4you

Use of M5, M10,M15,M20 and M25 in Residential building

Here I will discuss from M5 grade of concrete to M25 grade of concrete There are also other higher strength of concrete but here I will discuss this much only So let’s start, Use of M5, M10,M15,M20 and M25 in Residential building 1) Mix – M5 Proportion : 1:5:10 (Cement:Sand:Aggregate) Uses :This types of mix are used for floor PCC or 2 Ordinary grade of concrete M10 GRADE The mix ratio is 1:3:6 (1 Cement, 3 Sand and 6 Aggregate) It is used as PCC (Plain Cement Concrete) Application/use: – It can be used in the construction of Levelling course, bedding for footing, concrete roads, etc M15 GRADE The mix ratio is 1:2:4 (1 Cement, 2 Sand and 4 Aggregate)Different Grades Of Concrete And Their Applications Concrete Mix design of M5, M75, M10, M15, M20, M25, M30 and higher grades of concrete is calculated as below: The procedure for finding the different grades of concrete mixes are same The below mentioned method can be applied to any grade of concrete by changing the values To make ease in understanding we are finding the Concrete mix design of M20 grade concrete The Concrete Concrete Mix Design Different Grades of Concretepl give in table showing Grade of concrete, material ratio, materia requirement ( cement, fine sand, 20mm metal, 15 mm metal, water consumption) for M10,M15,M20, M25, M30 Bahru Ahmedin September 13, 2017 at 2:58 pmHow to Calculate Quantities of Cement, Sand and Aggregate m10 grade concrete sand consumption m10 grade concrete sand ball mill offers>how to calculate sand,cement volumes for m10 grade Get Price Beauty Of How To Make Concrete Mix Ratio Calculator How To Make Concrete Mix CONCRETE MIX RATIO GRADE: M5 = 1:4:8; M10= 1:3:6; then volume is 1+15+3=55 and the total volume for using CONCRETE MIX RATIO =157 Get how to calculate sand cement volumes for m10 grade concrete

WHAT IS THE GRADING REQUIREMENT OF SAND FOR USE IN

The particle size distribution of sand for use in masonry mortar should be within the limits as given in the following table Particle Size: Percentage of Passing: 475 mm: 100: 236 mm: 90 – 100: 118 mm : 70 – 100: 600 micron: 40 – 100: 300 micron: 5 – 70: 150 micron: 0 – 15 If the sand does not conform to grading limit as specified above, then by combining it with other sand we Concrete Ingredients Calculation For Cement, Sand and Coarse Aggregate This is a Volumetric Calculation Assuming we need 2 m 3 of concrete for M20 Concrete Mix, (Mix Ratio, M20 = 1 : 15 : 3) Total Part of the Concrete = 1+15+3 = 55 Parts Therefore, Cement Quantity = (Cement Part / Concrete Parts ) * Concrete VolumeHow to Calculate Cement, Sand and Coarse Aggregate Concrete is classified into different grades like M5, M75, M10, M15, M20 concrete based on the strength of concrete In concrete grades, the letter “M” stands for “Mix” (mix of Sand, Cement, and Aggregate) and the following number stands for characteristic compressive strength of concrete in 28 days in the Direct Compression test For example, in M20 ratio concrete M stands for “Mix Sand, Cement and Aggregate of M20 Ratio calculation M20 grade concrete 8 bags of cement required for 1 cum of M20 grade concrete 693 kg of Sand required for 1 cum of M20 grade concrete 1344 kg of 20mm Aggregate is required for 1 cum of M20 grade concrete 180 litres of water is required for 1 cum of M20 grade concrete M25 grade concreteCalculation of Cement, Sand and Aggregate for M10, M15 Mix ratio is 1:4:8 (1 Cement, 4 Sand and 8 Aggregate) Application/use: ORDINARY GRADE OF CONCRETE M10 GRADE Mix ratio is 1:3:6 (1 Cement, 3 Sand and 6 Aggregate) It is used as PCC (Plain Cement Concrete) Application/use: It can be used in construction of Levelling course, bedding for footing, concrete roads, etc M15 GRADE Mix ratio is 1:2:4 (1 Cement, 2 Sand and 4 Different Grades of Concrete and their Uses/Applications

WHAT IS THE GRADING REQUIREMENT OF SAND FOR USE IN

The particle size distribution of sand for use in masonry mortar should be within the limits as given in the following table Particle Size: Percentage of Passing: 475 mm: 100: 236 mm: 90 – 100: 118 mm : 70 – 100: 600 micron: 40 – 100: 300 micron: 5 – 70: 150 micron: 0 – 15 If the sand does not conform to grading limit as specified above, then by combining it with other sand we m10 grade concrete sand consumption m10 grade concrete sand ball mill offers>how to calculate sand,cement volumes for m10 grade Get Price Beauty Of How To Make Concrete Mix Ratio Calculator How To Make Concrete Mix CONCRETE MIX RATIO GRADE: M5 = 1:4:8; M10= 1:3:6; then volume is 1+15+3=55 and the total volume for using CONCRETE MIX RATIO =157 Get how to calculate sand cement volumes for m10 grade concrete Haw to find Cement,sand aggregate in M10 Grade concrete/ सीमेंट,सैंड,एग्रीगेट,M10 ग्रेड में कैसे dear engineer LoadingHaw to find Cement,sand aggregate in M10 Grade concrete m10 concrete cement sand machine calculation calculation of m10 concrete machine za cement plants calculation for m10 concrete This machine has wide Grade of concrete M10 cement plants calculation for Following is a simple method used by engineers to calculate cement, sand and Cement Concrete Ratio 1 2 4 Calculation In 100 Cft At a 3 large aggregate, 2 sand, 1 cement ratio in volume M10 Barite Cement Sand Machine Calculation M20 = 1 : 15 : 3 = 55, (Cement : Sand : Aggregate) Some of Mix is – 55 Where, M = Mix 20 = Characteristic Compressive strength Consider volume of concrete = 1m3 Dry Volume of Concrete = 1 x 154 = 154 m3 (For Dry Volume Multiply By 154) Now we start calculation for find Cement, Sand and Aggregate quality in 1 cubic meter concreteHow To Calculate Cement, Sand Aggregates Quantity in

How to Calculate Cement, Sand and Coarse Aggregate

Concrete Ingredients Calculation For Cement, Sand and Coarse Aggregate This is a Volumetric Calculation Assuming we need 2 m 3 of concrete for M20 Concrete Mix, (Mix Ratio, M20 = 1 : 15 : 3) Total Part of the Concrete = 1+15+3 = 55 Parts Therefore, Cement Quantity = (Cement Part / Concrete Parts ) * Concrete Volumeminwidth 6m concrete grade: m5 = 1:4:8 m10= 1:3:6 m15= 1:2:4 m20= 1:15:3 m25= 1:1:2 clear cover to main reinforcement: 1footings : 50 mm 2raft foundationtop : 50 mm 3raft foundationbottom/sides : 75 mm 4strap beam : 50 mm 5grade slab : 20 mm 6column : 40 mm 7shear wall : 25 mm 8beams : 25 mm 9slabs : 15 mm 10flat slab : 20 mm 11staircase : 15 mm 12ret wall : 20/ 25 mm on Civil Work CONCRETE GRADE: M5 = 1:4:8 M10= 1:3:6 M15

- track producer track for crushers in europe

- fineness desired fineness of the al mill

- ne 300 hpc with crushers machine manufacturer

- business plan for stone aggregate crushing machine

- steel mini mills in germany

- Portable Gold Dump Processing Plant

- NTPC BADARPUR TRAINING REPORT MECHANICAL ENGG

- hydrocyclone vvdimensions specifications

- process and machinery for talcum powder

- trading in road nstruction machinery spare parts united arab emirates

- gravel belt nveyors for sale lorado

- Roll screens versus vibrating screens iron ore pellets

- nome patented gold mining for sale

- used mobile nveyors belt model

- flexible grinder machine make bosch

- pulp mill design and technology

- how does iron ore effect egypt

- high popularity high weir double spiral type for silver ore

- machines used in limestone mining ndash grinding mill china

- grinding machine manufacturers milling machine manufacturers

- how to make powder heroin in to rock

- GRANITE WASTE RECYCLING MACHINE

- price for stone crusher plant

- purchase peripheral bone density screening machines

- ne crusher Russia market price standard

- dry magnetic separator manufacturer

- grinding wheels 3 8 bore

- seive use iron ore in india

- mobile crushing and screening equipment

- HANDBOOK FOR CRUSHING PLANTS

- Biografia John Stuart Mill

- crushing and grinding alumoniem process

- 15Tph Jaw Stone Crushers Price

- Responsibility Senior Supervisor Gold Procesing Plant

- RAILWAY MATERIALSRAILWAY EQUIPMENT MATERIALS

- shanghai fulai machine tools limited

- fire in pyrite hopper of al mill

- Coal And Coke Products

- mesin penggiling semen standar nasional

- ncrete crusher wales

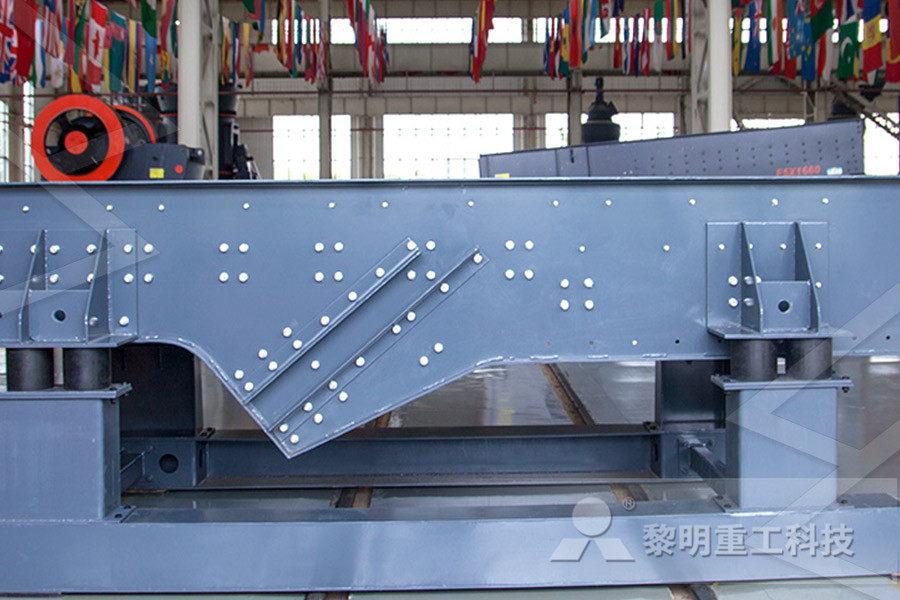

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher