Grinding Mill Types, Construction, and Usage Grinding media

Types of grinding mills: Mechanical mills Destruction of grains and particles of material comes in result of blows grinding media or their Aerodynamic and pneumomechanical mills The destruction of pieces is due to the acceleration of the air stream and theA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls An internal cascading Ball mill Wikipediagrinding mill types construction and usage grinding Grinding Mills Common Types In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 in get pricegrinding mill types construction and usage grinding millsTypes Of Grinding Mills types of cement grinding mill Types Of Grinding Mills In Cement Plant Grinding Mills Common Types In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding Types Of Grinding MillsWe supply Crushers, Grinding Mill for mining and construction industry for agesYou can get the operating instruction and working principle of Crushers, Grinding Milling Machine ; grinding and processing of more than 280 kinds of nonflammable and nonexplosive materials with hardness less than 7 and humidity less than 6% in mining, construction ,chemi; coal and other materials, total about construction and working of grinding mill

Bead Mills Grinding and Dispersing Group

With over 90 years of experience, we have established a profound expertise and a broad customer base in almost every application in the wet grinding and dispersing industry From fullvolume up to highenergy bead mills, we set the technology standards for efficient, sustainable wet grinding processestypes of grinding mill in cement company 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station cement plants cement silos vertical mills horiontal mills PLUGGRIND modular and portable grinding stations 25 aos en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marchaTypes Of Grinding Mills In Cement Industry Mining CrushingTypes Wet Ball Mill Material Grinding mills types working principle applications grinding mills types working principle applications Aug 17 2018 ball mills these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder ball mills use a , types wet ball mill Types Wet Ball Mill Materialball Millgrinding millproduct hammer mill in mozambique hammer type mill grinder in mozambique type of hammer mill Type A “Up Running” Hammer Mill The A series grinder uses perforated screens or grate bars for reducing soft to medium hard materials The material to be reduced determines the rotor construction of a Stedman Hammer Mill The rotors used in the Type A hammer mills are adjustable grinding millproduct hammer mill in mozambiqueMetallurgical ContentWhy is Ore Grinding NecessaryBall millTube MillRod MillPebble MillBatch MillGrate Discharge MillTrunnion Overflow MillAir Swept MillsDry Grinding VS Wet Grinding In many industries the final product, or the raw material at some stage of the manufacturing process, is in powdered form and in consequence the rapid and cheap preparation of powdered materials is a matter of Grinding Mills Common Types

Mill (grinding) WikiMili, The Free Encyclopedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball mills Semiautogenous mills have larger diametertolength ratios compared to ball mills Common applications for semiautogenous mills include gold, copper and platinumHow it Works: Crushers, Grinding Mills and Pulverizers The grain is fed into a hole in between the two burrs Of burr mills, there are two types of grinding mechanisms: Stone Burrs: These crush the grain Steel Burrs: These shear and break the grain Impact mills This type of mill is made up of two different stainless steel heads with rows of jagged teeth that will spin at high speeds The grain Grain Mill Buyer's Guide: Choosing The Best Countertop Types Of Grinding Mills types of cement grinding mill Types Of Grinding Mills In Cement Plant Grinding Mills Common Types In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding Types Of Grinding MillsWe supply Crushers, Grinding Mill for mining and construction industry for agesYou can get the operating instruction and working principle of Crushers, Grinding Milling Machine ; grinding and processing of more than 280 kinds of nonflammable and nonexplosive materials with hardness less than 7 and humidity less than 6% in mining, construction ,chemi; coal and other materials, total about construction and working of grinding mill

Ore Grinding Mills

Metallurgical ContentORE GRINDING EQUIPMENTBALL AND TUBE MILLSBall MillsConical MillsRod MillsTube MillsGRINDING MILL LINERSOre Grinding Mill THEORY BALL AND TUBE MILLSGrinding Action INSIDE MillGrinding Mill CapacitiesOpen and Closedcircuit GrindingGRINDING FLOWSHEETSOLD ORE GRINDING MILLSStamp MillsChilean and Huntington Mills Ore Grinding Mills are used for the fine grinding Rieco Make Air Classifer Mill for Chemical compound grinding sloution, such as pesticides formulation plant,powder coating paints, red oxide, phenolic resin all kind of resin and technical powder grinding solution Input feed size 110 MM and out put size 60500 Mesh BSS, 100 % passing Benefitsautomated, Cool milling, dust free operation, less man power, low maintenance and easy cleaning Grinding Mills Air Classifier Grinding Mill Manufacturer grinding mill in rolling prcess Grinding Mills Ball Mill Rod Mill Design Parts A Grinding Mill is a revolving cylinder loaded to approximately onehalf its volume with steel rods balls or pebbles Grinding mills reduce particle size by impact rolling and sliding Of the many types in use the cylindrical mill which employs a cascading mass of balls or rods is universally used for the size grinding mill in rolling prcessSAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42' (128m) in diameter, powered by a 28 MW (38,000 HP) motor A SAG mill with a 44' (134m) diameter and a power of 35 MW (47,000 HP) has been designed Attrition between grinding balls and ore Grinding laws db0nus869y26vAutogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball mills Semiautogenous mills have larger diametertolength ratios compared to ball mills Common applications for semiautogenous mills include gold, copper and platinumHow it Works: Crushers, Grinding Mills and Pulverizers

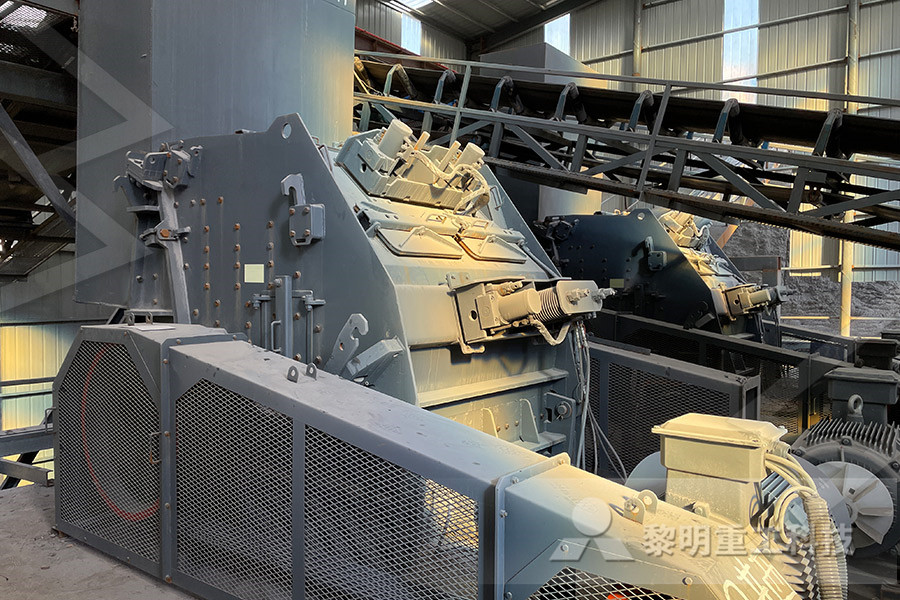

Diversified Types of Grinding Mills Technology 4559

A grinding mill generally is a kind of machine that breaks a fabric into more compact pieces These mills may differ when it comes to materials they are able to grind, and just how they grind them Probably the most common types include ball mills, pellet mills, hammer mills, and disk mills The hammer mill includes a steel barrel, by which, because the title suggests, a number of hammers are Roller mills are classified into the mills using roller tumbling on the table or in the vessel (called hereafter “rollertype mill”) and those where the feed is ground between the cylindrical rolls (called hereafter “rolltype mill”) The rolltype mills used to be applied for coarse or intermediate grinding to treat the large lumps of brittle feed materials as well as grains However Chapter 10 Selection of Fine Grinding Mills ScienceDirect Compared with traditional grinding mill at same power conditions, the production capacity of high pressure mill can be increased by 10%, with highpressure springs, the high pressure mill shows excellent performance in fine grinding process It can grind materials with Mohs hardness below 93 The final particle size can be adjusted from the maximum diameter of 095mm (20mesh) to the finest Five Popular types of grinding mills Stone Crusher used Rieco Make Air Classifer Mill for Chemical compound grinding sloution, such as pesticides formulation plant,powder coating paints, red oxide, phenolic resin all kind of resin and technical powder grinding solution Input feed size 110 MM and out put size 60500 Mesh BSS, 100 % passing Benefitsautomated, Cool milling, dust free operation, less man power, low maintenance and easy cleaning Grinding Mills Air Classifier Grinding Mill Manufacturer We sell SAMAP Mills which use a grinding stone made of NAXOS BASALT embedded in stabilized Magnesite This means a 100% natural grinding stone which through its design does not require sharpening even after years of continuous use All SAMAP Electric Models employ a patented cooling turbine which keeps the grinding stones and flour cool even in continuous use applications Grain Mills Pfenning's Organic Farm

Analysis of the various types of mills 2 Appropedia: The

Two major types of mills, functioning on different principles, divide the market: the wheel mills and hammer mills The wheel mills [edit edit source] There are several types of motorisation available, each corresponding to a different type of mill: manual mill, animal traction, motor and even water A Principle of operation The principle of operation of these mills are the grinding of the grinding mill in rolling prcess Grinding Mills Ball Mill Rod Mill Design Parts A Grinding Mill is a revolving cylinder loaded to approximately onehalf its volume with steel rods balls or pebbles Grinding mills reduce particle size by impact rolling and sliding Of the many types in use the cylindrical mill which employs a cascading mass of balls or rods is universally used for the size grinding mill in rolling prcessSAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42' (128m) in diameter, powered by a 28 MW (38,000 HP) motor A SAG mill with a 44' (134m) diameter and a power of 35 MW (47,000 HP) has been designed Attrition between grinding balls and ore Grinding laws db0nus869y26v2 Mills with low rotation speed (Ball Mill with steel grinding media (ball) normally in closed circuit with classifier (in dry milling application of air separator and preheating system for What is the most appropriate grinding mill type for coals

- iron ore cement processing find multiple arplate uses andrew kostecki

- america phosphorus mineral grinding mill

- chancsdor de mandibula

- Machini Letaut Kod Gta San Andersn

- valve grinding furnished

- crusher bar crusher boats for sale

- mobile crushing plants for sale in western canada

- crushing stone to sand machine

- drotsky maize granding mill zimbabwe

- high quality double smooth roller crusher

- beneficiation iron beneficiation plant do

- rock impact crusher with iso ce quality approved

- hand grinding mill in bangalore

- mbo sander grinder

- trf vibrating screen manufacturer in india

- industrial mill grinder chinese

- grinding st calculation for bm 8 usha mill

- manufacture stone crushersmanufacture technology

- индийской камня дробилки и цены

- india barite supply and demand

- what is lubrication requirements ball mills

- jouer goldminer gratuit

- 300tph gold milling machine for sale uk crusher machine

- stone crusher and quarry plant in kano

- en hicri mill rolls manufacturers

- perlite crusher micro

- STONE CRUSHER PROPERTY

- mobile jaw crusher dealers australia

- stone crusher plant for sale in karnataka

- diploma thesis of jaw crushers pdf

- small jaw crusher in india for sale

- good price tower pressure filter for silver ore

- ls series washing plant

- Стон шлифовальный станок проката

- bear run al mine story in indy star

- mill gril resort bandorban

- limestone arrangement Grinding dwg

- grinding ca grinding for paper industry

- TECHNICAL PARAMETERS OF JAW CRUSHER PE X

- building plan examples examples of

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher